Method for recovering neodymium iron boron alloy powder from neodymium iron boron oil sludge wastes by shot flow and preparation method of regenerated sintered magnet

A technology for recycling NdFeB and sintered magnets, applied in the direction of improving process efficiency, etc., can solve the problems of long process flow and environmental pollution, achieve the effects of shortening the process, reducing production costs, and realizing recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

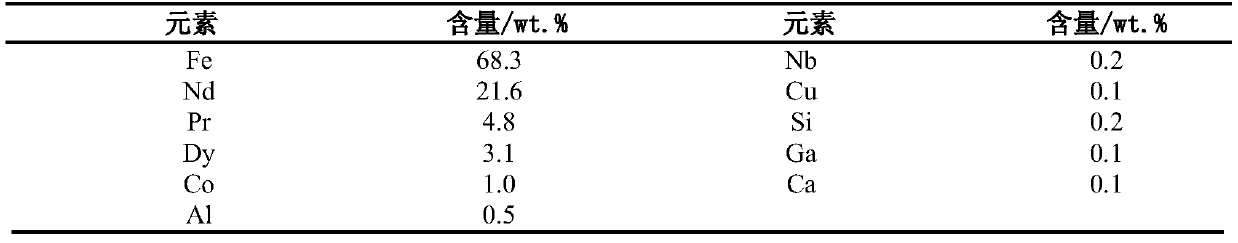

[0037] Weigh 50g of NdFeB sludge waste into a crucible, heat at 350°C for 5 hours, and dry to obtain 46.1g of sludge powder; test XRF, the results are shown in Table 1. According to the contents of rare earth elements and iron elements in Table 1, add 0.4g of neodymium hydride powder, 0.1g of FeB powder, and 5.9g of calcium particles to the sludge powder, mix the reactants evenly, cover them with molybdenum sheets, and put them into a tube furnace , first carry out hydrogen reduction in hydrogen at 350°C for 90 minutes, and then carry out calcium reduction and diffusion reaction under the protection of inert gas. Ultrasonic water washing under 0.5kOe magnetic field, washing 6 times, 10min each time, and finally washing once with acetone, time 20min; drying under vacuum condition, temperature 400 ℃, time 90min, to obtain 23.3g NdFeB alloy powder, particle size is About 8μm, the recovery rate of NdFeB is 50.5%.

[0038] Add 20wt% neodymium hydride powder (particle size less tha...

Embodiment 2

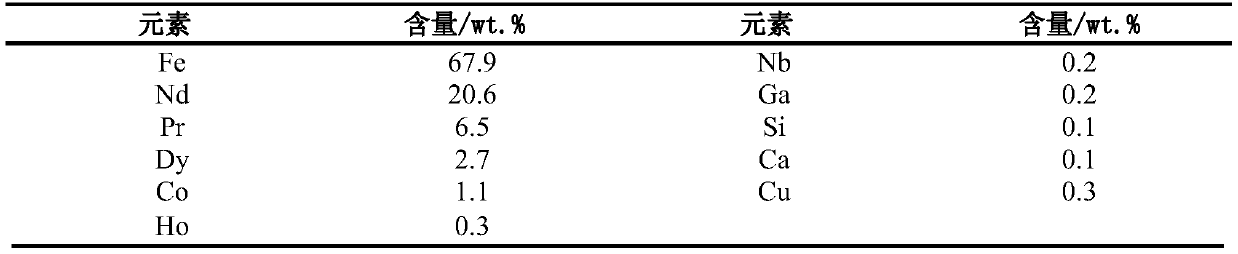

[0042] Weigh 50g of NdFeB sludge waste into a crucible, heat at 200°C for 8 hours, and dry to obtain 45.8g of sludge powder; test XRF, the results are shown in Table 2. According to the content of each element in Table 2, add 0.3g of neodymium hydride powder, 0.1g of FeB powder, and 6.7g of calcium particles to the oil sludge powder, mix the reactants evenly, cover them with molybdenum sheets, put them into the tube furnace, and Carry out hydrogen reduction at 400°C for 30 minutes in hydrogen, and then carry out calcium reduction and diffusion reaction under the protection of inert gas. Ultrasonic water washing, washing 3 times, each time 20min, and finally washing once with acetone, time 10min; drying under vacuum conditions, temperature 400 ℃, time 150min, to obtain 23.1g of NdFeB alloy powder, the particle size is about 8μm, neodymium The recovery rate of iron and boron is 50.4%.

[0043] Add 10wt.% neodymium hydride powder (particle size less than 5 microns) and ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com