Dry ash sealing and telescopic bulk device

A bulk device, dry ash technology, applied in transportation and packaging, loading/unloading, dispersed particle filtration, etc., can solve the problems of dry ash reducing work efficiency, secondary waste, low filling efficiency, and large amount of dry ash escaping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

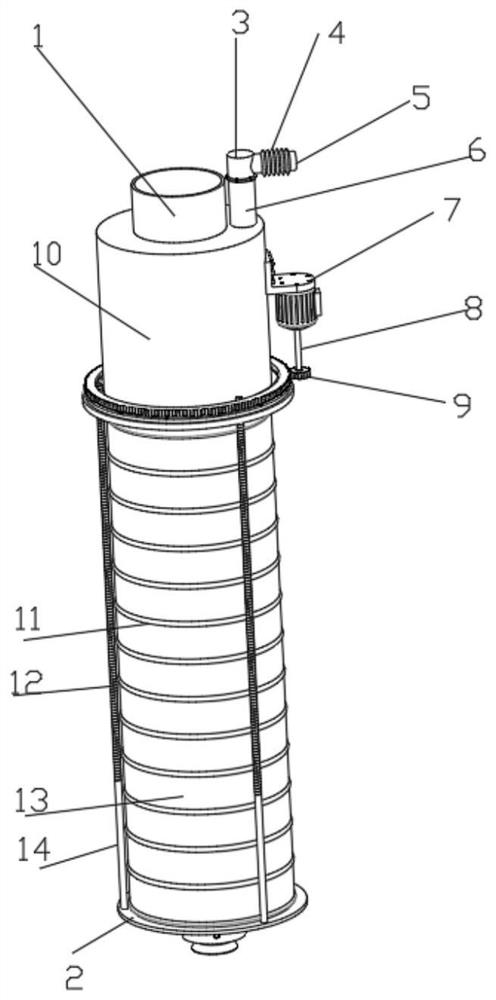

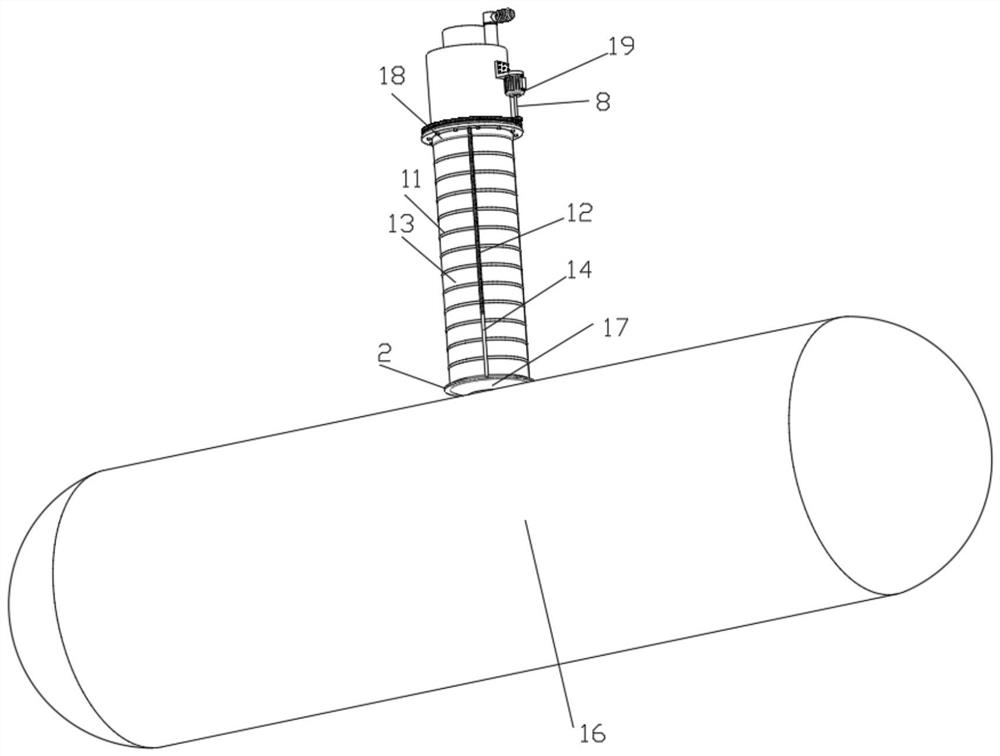

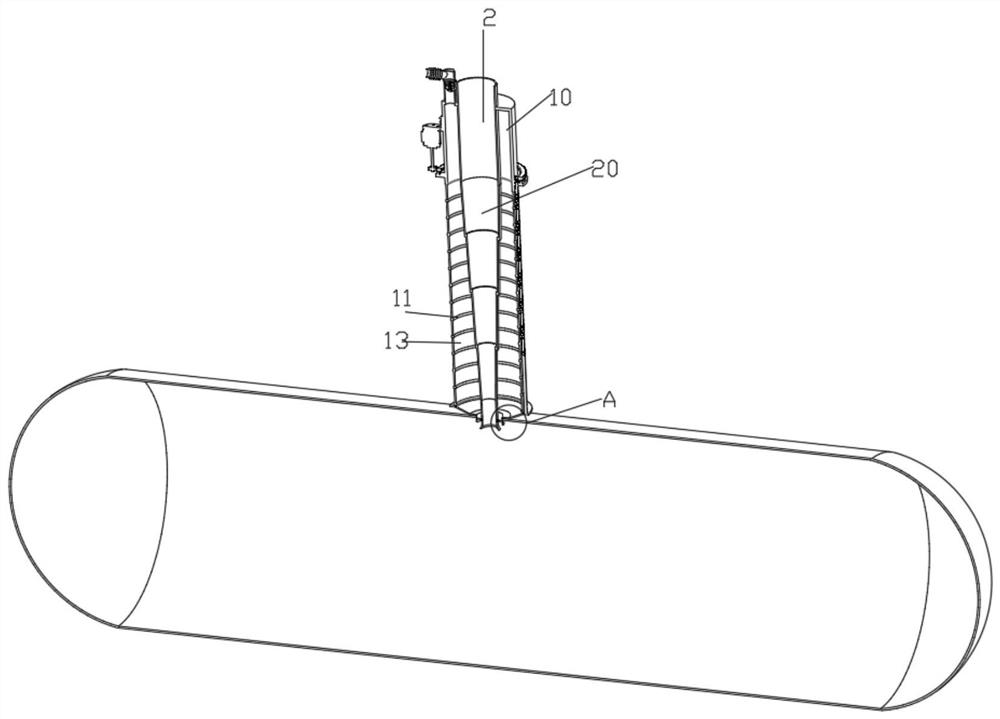

[0034] Such as figure 1 , 2, shown in 3, 4, 5, 9, a kind of dry ash sealing shrinkage bulk device, comprises feeding pipe 1 and tank car 16, and the top middle end of tank car 16 is provided with feeding hole 161, and the bottom of feeding pipe 1 is provided with There are shrink sleeves 20, and there are six groups of shrink sleeves 20, the bottom of the inner wall of the upper set of shrink sleeves 20 is in contact with the top outer wall of the next set of shrink sleeves 20, and the uppermost shrink sleeve 20 The top is fixedly connected with the top of the feeding pipe 1, and the shrink sleeve 20 is inclined inwardly by 2° in the vertical direction, and the bottom of the lowermost shrink sleeve 20 is fixedly connected with a blanking inner ring 28, and the feeding pipe The outer wall of the upper end of 1 is fixedly connected with a dust suction sleeve 10, and the top of the dust suction sleeve 10 is fixedly connected with a straight pipe 6, and the straight pipe 6 is con...

Embodiment 2

[0037] Embodiment 2 is a further improvement to Embodiment 1.

[0038] Such as figure 1 , 2 , 3, 4, 5, 7, and 8, the height adjustment structure includes a support ring 2, a first rotating shaft 8, a ring gear 9, a connecting pipe 11, a thread groove 12, a dustproof canvas 13, a straight rod 14, Connecting sleeve 18, drive motor 19, lower flange 21, first threaded sleeve 22, first bearing 23, upper flange 29, gear block 30 and support ring 31, upper flange 29 is fixedly installed on the bottom of dust suction casing 10 The bottom of the outer wall, the top of the connecting sleeve 18 is fixedly connected with the lower flange 21, the upper flange 29 and the lower flange 21 are connected by bolts, the top of the first threaded sleeve 22 is fixedly connected with the first bearing 23, and the inner part of the first bearing 23 The top of the ring is fixedly connected with a support ring 31, the top of the support ring 31 is fixedly connected with a first threaded sleeve 22, th...

Embodiment 3

[0040] Embodiment 3 is a further improvement to Embodiment 1.

[0041] Such as Figure 6 As shown, the connection structure includes a second threaded sleeve 24, a bolt 25 and a groove 26. The second threaded sleeve 24 is evenly fixed and installed on the outer wall of the blanking inner ring 28 along the circumferential direction, and the groove 26 is evenly opened on the lower wall along the circumferential direction. The outer wall of the outer ring 27 of the feed port, the outer ring 27 of the feed port is rotatably connected with a groove 26, and the inner end of the groove 26 is threadedly connected with the second threaded sleeve 24, and the second threaded sleeve 24 and the bolt 25 of the connecting structure Used together, the inner ring 28 of the blanking is limited in the outer ring 27 of the blanking port, which ensures the normal ventilation of the outer ring 27 of the blanking port and the inner ring 28 of the blanking port, and prevents the inner ring 28 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com