One-piece and two-piece Chinese-style armored door and manufacture and installation process thereof

An armored door, Chinese-style technology, applied in the field of production and installation of new environmentally friendly armored doors, can solve the problems of low installation and construction efficiency, difficult to dismantle, difficult to ensure quality details, etc., to simplify installation and construction procedures, reduce production labor costs, and have Conducive to the effect of finished product protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

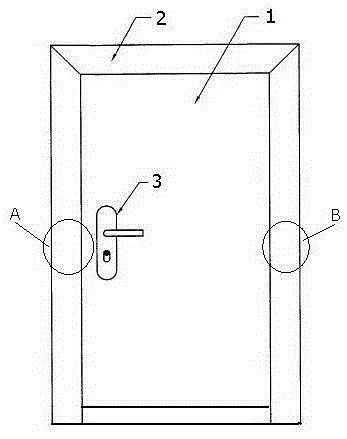

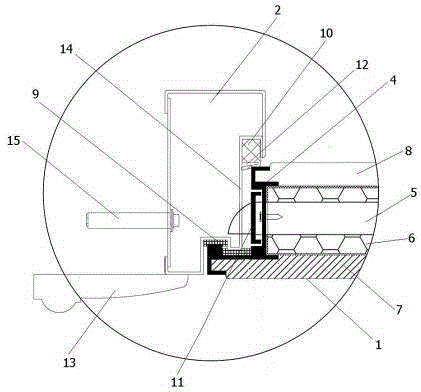

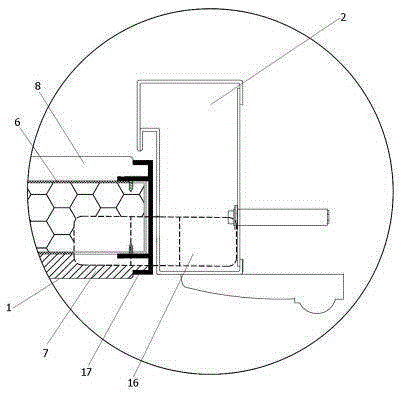

[0047] like Figure 1-4 As shown, a single-leaf steel-wood door includes a door leaf 1, a door frame 2, a door lock 3 and a hinge 16, the door leaf 1 is hinged on the door frame 2 through the hinge 16, and the door lock 3 connects the door leaf 1 and the door frame 2, and the door leaf 1 is connected to the door frame 2. The door leaf 1 is composed of a door core 6 and front and rear decorative panels 7 and 8 fixed on the door core 6. The periphery of the front and rear decorative panels 7 and 8 is provided with plugs, and the door lock side edge 4 is integrally formed. The door lock side hemming 4 is composed of a fastening part 18 and front and rear hemming parts 19, 20 connected to the fastening part. The left side of the fastening part 18 is provided with a groove 21, and the groove 21 is provided with a screw. hole, the cover plate 11 is fastened in the groove 21 of the fastening part 18, the fastening part 18 of the door lock side edge 4 is clamped and screwed to the sid...

Embodiment 2

[0049] like Figure 5-9 Shown, a kind of mother-in-law double-opening Chinese style armored door comprises a door frame 1', a child door leaf 2', a mother door leaf 3', a door lock 4' and a hinge 6', and the child and mother door leaves 2' and 3' are hinged on the hinge 6' On the door frame 1', the hinge 6' is an open hinge or a concealed hinge. According to needs, the child door leaf 2' is on the left and the mother door leaf 3' is on the right or the child door leaf 2' is on the right and the mother door leaf 3' is on the left. The door lock 4' locks the child and mother door leaves 2' and 3', and a small door lock is provided below the child door leaf 2', and the small door lock locks the child door leaf 2' on the door frame 1'. Mother door leaf 2 ', 3 ' is made of sub-mother door core 22 ', 32 ' and sub-mother front trim panel 20 ', 30 ' and sub-mother rear trim panel 21 ', 31', the child and female front panels 20', 30' and the child and female rear panels 21', 31' are p...

Embodiment 3

[0051] like Figure 1-4 As shown, a single-opening Chinese-style armored door manufacturing and installation process includes the following steps:

[0052] A. To make the door frame 2, first fold the steel plate 90 degrees to form a U-shaped first frame or integrally form it, then fold the steel plate into a 2-shaped second frame or form it at one time, and the third frame is a straight steel plate; The front end of the 2-shaped second frame is provided with a first flange and the end is provided with a second flange, and the front end of the U-shaped first frame is parallel to the first flange of the front end of the 2-shaped second frame Welding or screwing, the said one-shaped third frame is welded or screwed in parallel with the second flanging of the end of the U-shaped first frame and the end of the 2-shaped second frame, or the door frame 2 is integrally formed;

[0053] B makes the door core 5, folds and welds the steel plate to form a cuboid door core, and fills the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com