Patents

Literature

50results about How to "Reduce production and labor costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

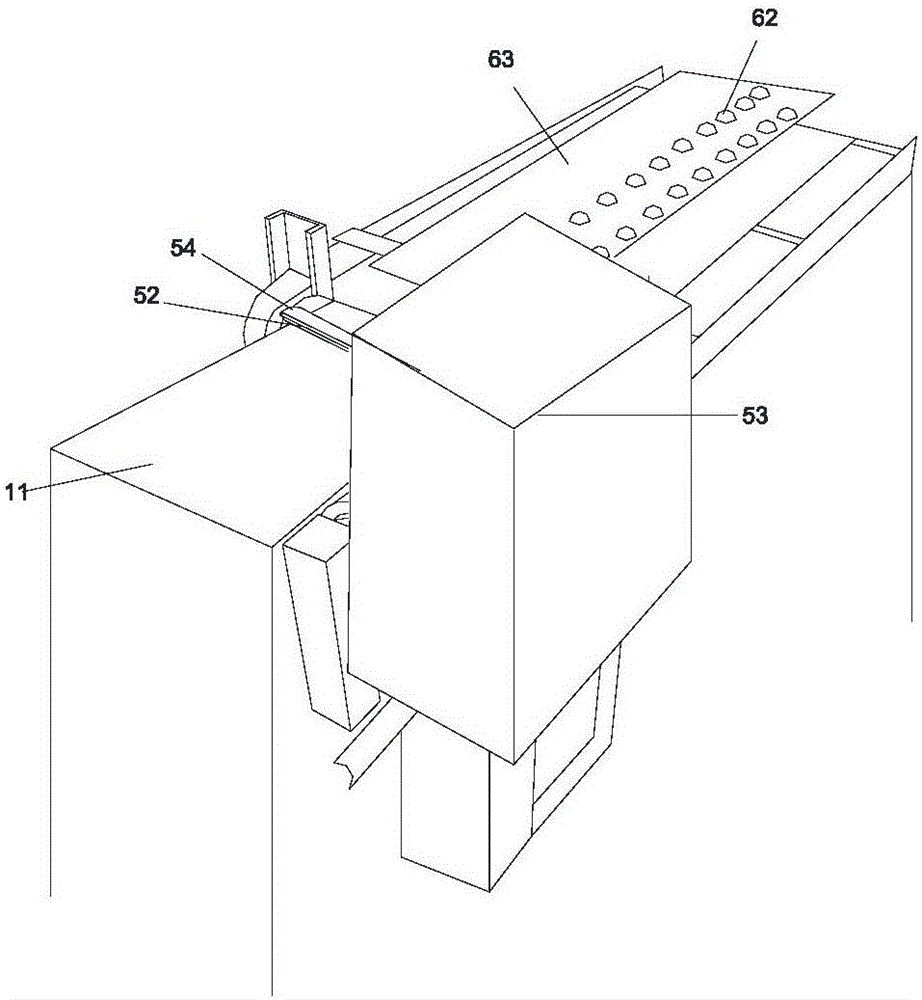

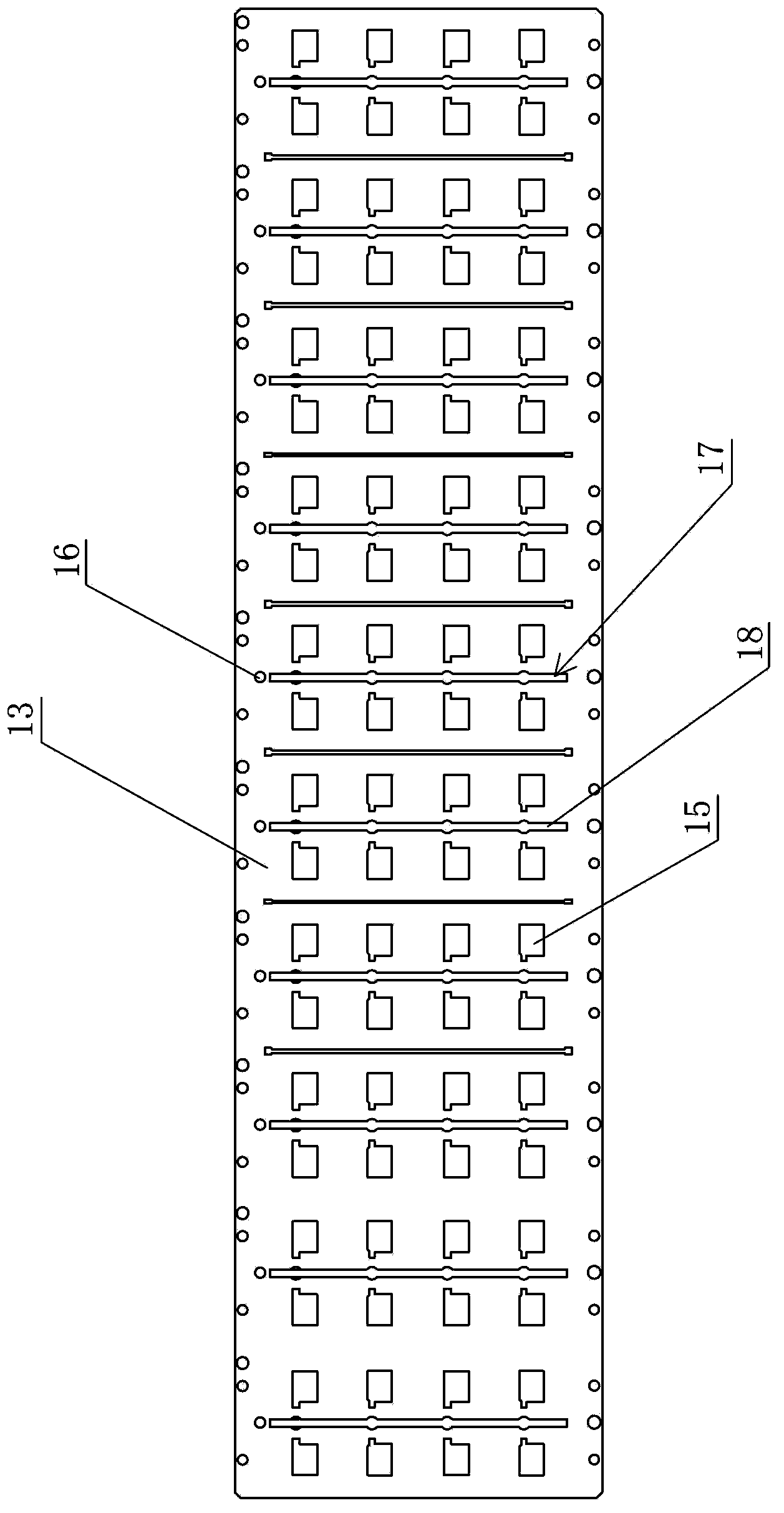

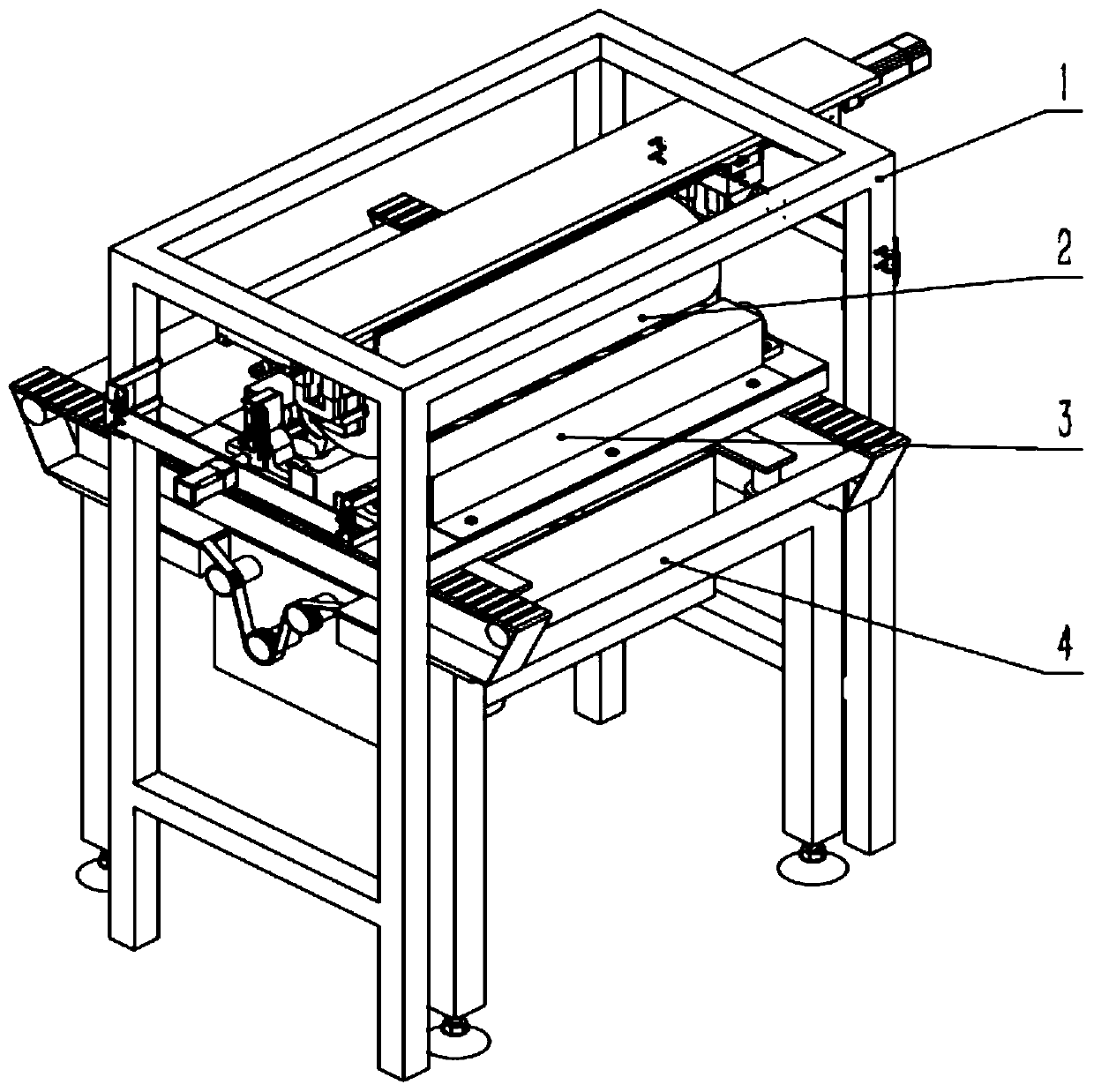

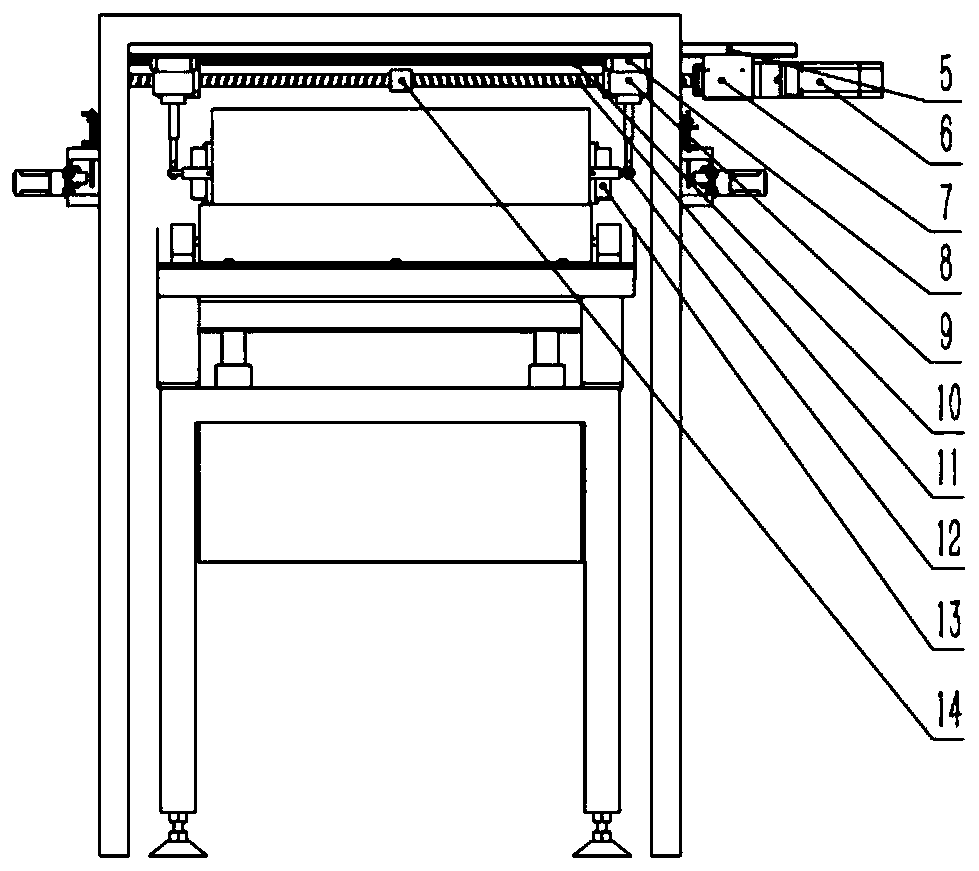

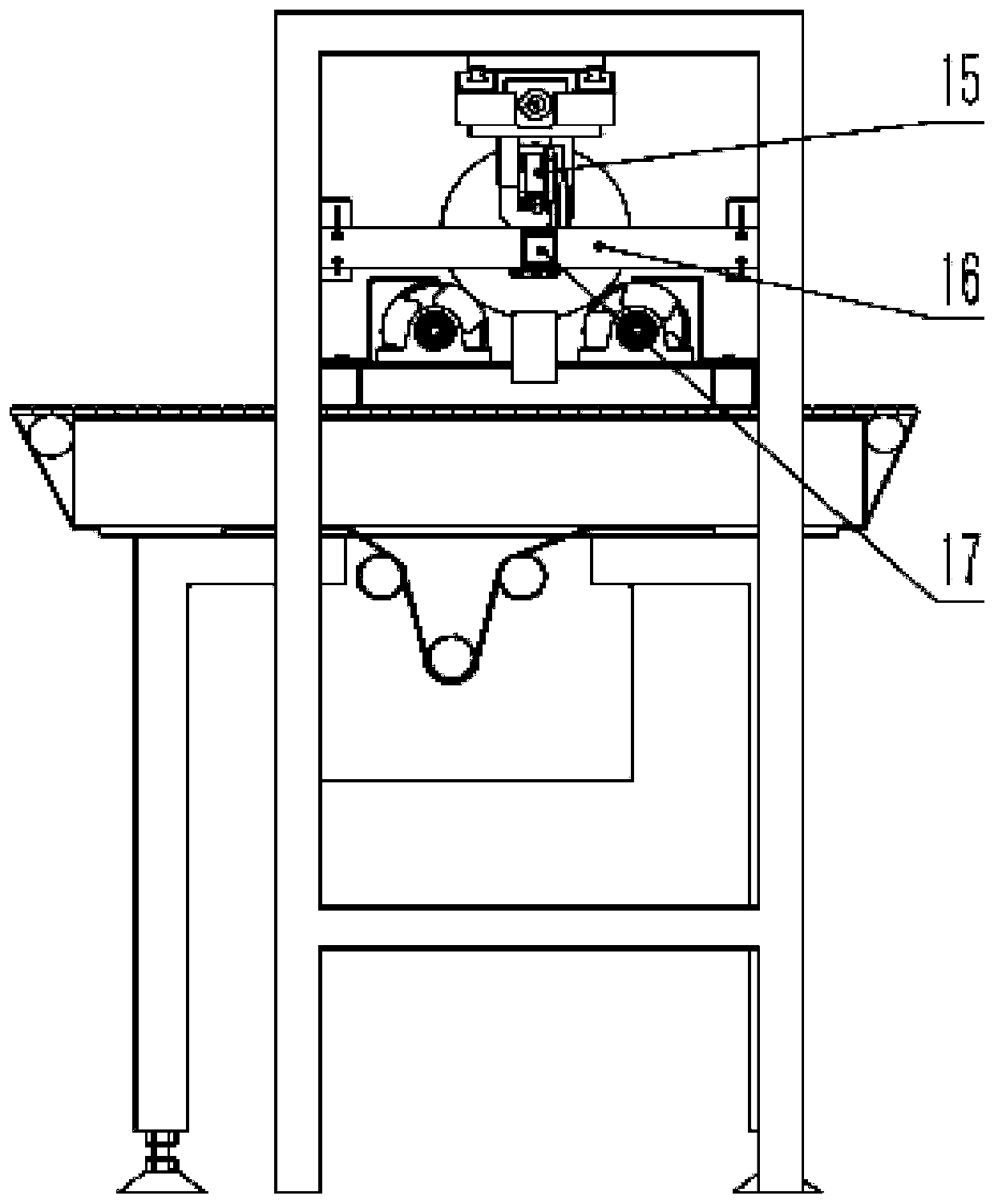

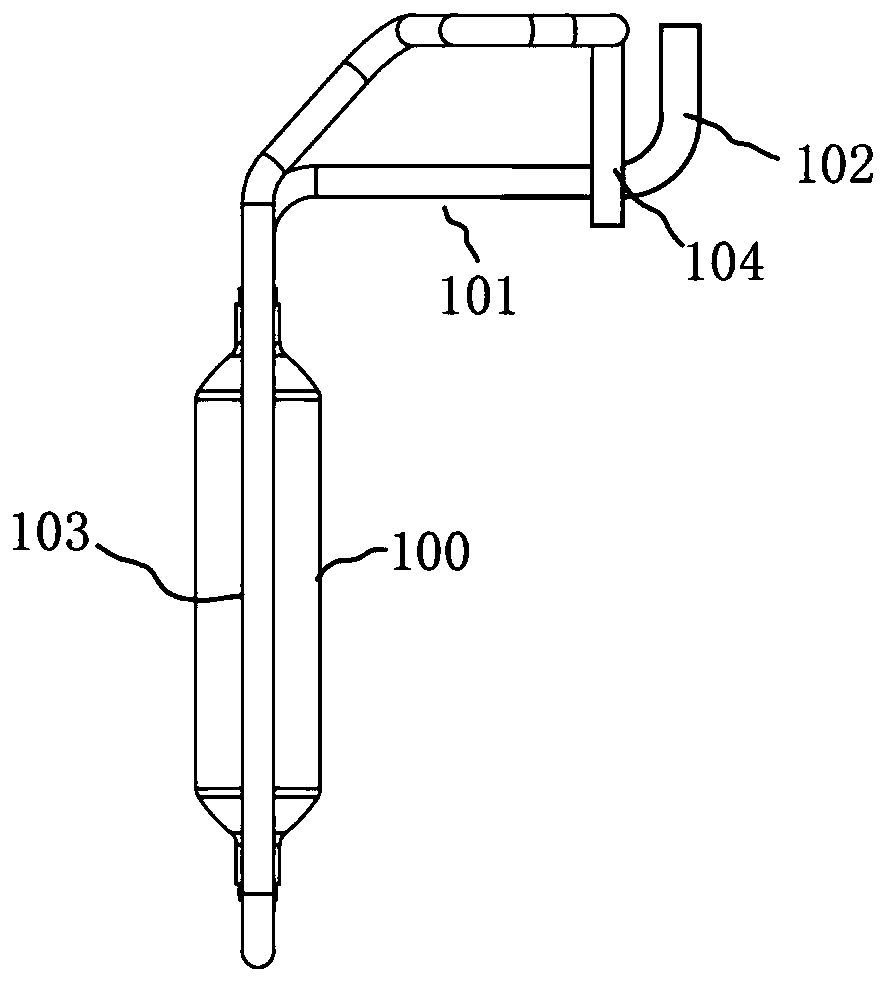

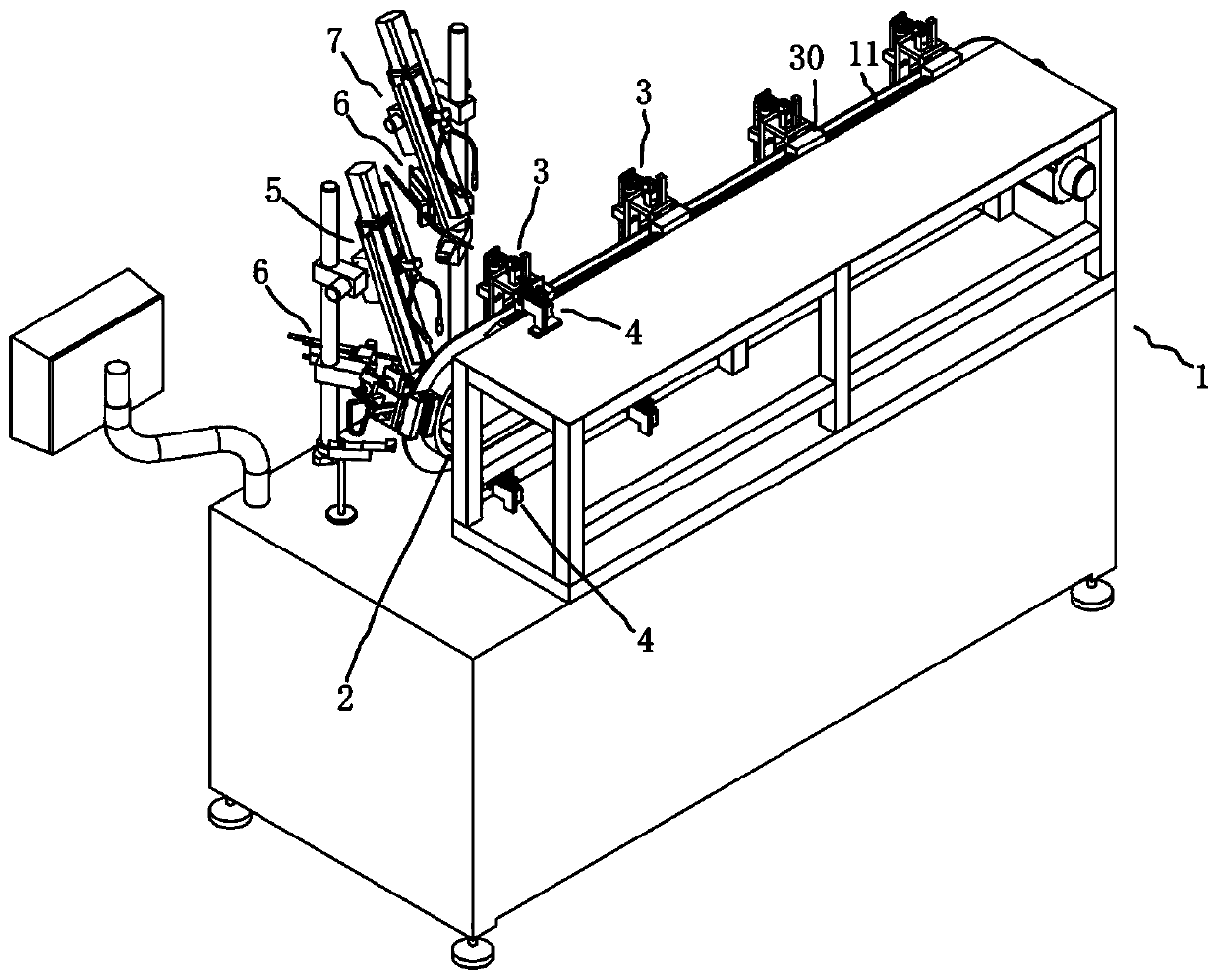

Valve sack processing device

ActiveCN107433735AReduce production and labor costsLow costBag making operationsPaper-makingLarge sizeBiomedical engineering

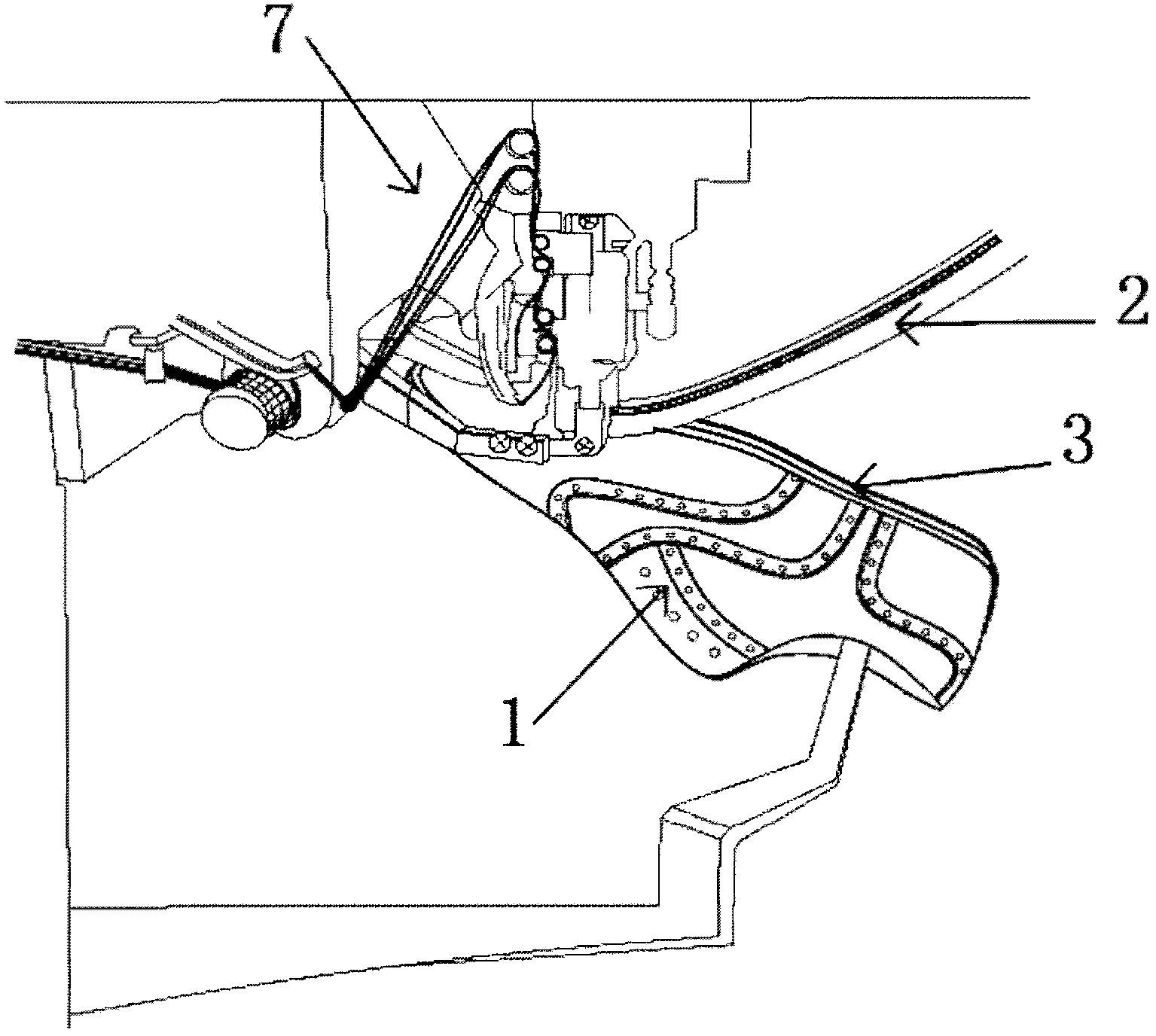

The invention provides a valve sack processing device, relates to the technical field of paper sack processing devices and solves the technical problems of complicated structure and large size of an existing device. The valve sack processing device comprises a worktable, a first gluing device, a finished product collecting device, a first flanging device, a cutting device, a cut-off device, a second flanging device, a second gluing device, a third flanging device and a compacting device, the first gluing device is arranged at an inlet end of the worktable, the finished product collecting device is arranged at an outlet end of the worktable, and the first flanging device, the cutting device, the cut-off device, the second flanging device, the second gluing device, the third flanging device and the compacting device are sequentially arranged on the worktable. The valve sack processing device is used for producing a valve sack with two open ends, can be used for producing a liner with a film or the valve sack without the liner, and has the advantages that the device is simple in structure, convenient to operate and low in production cost, all processing links are automatic production links, and manpower is saved.

Owner:北京正达利业工贸有限公司

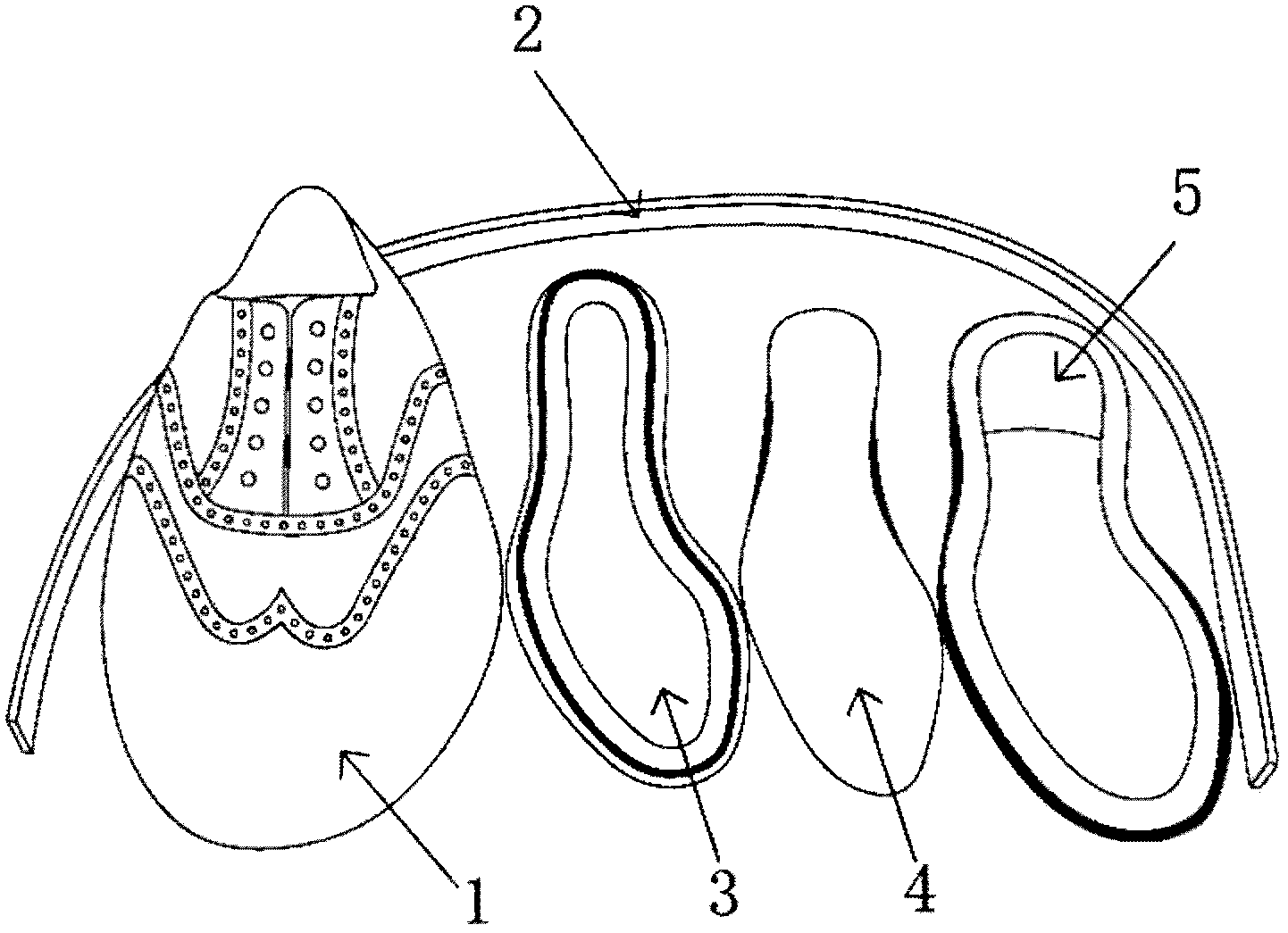

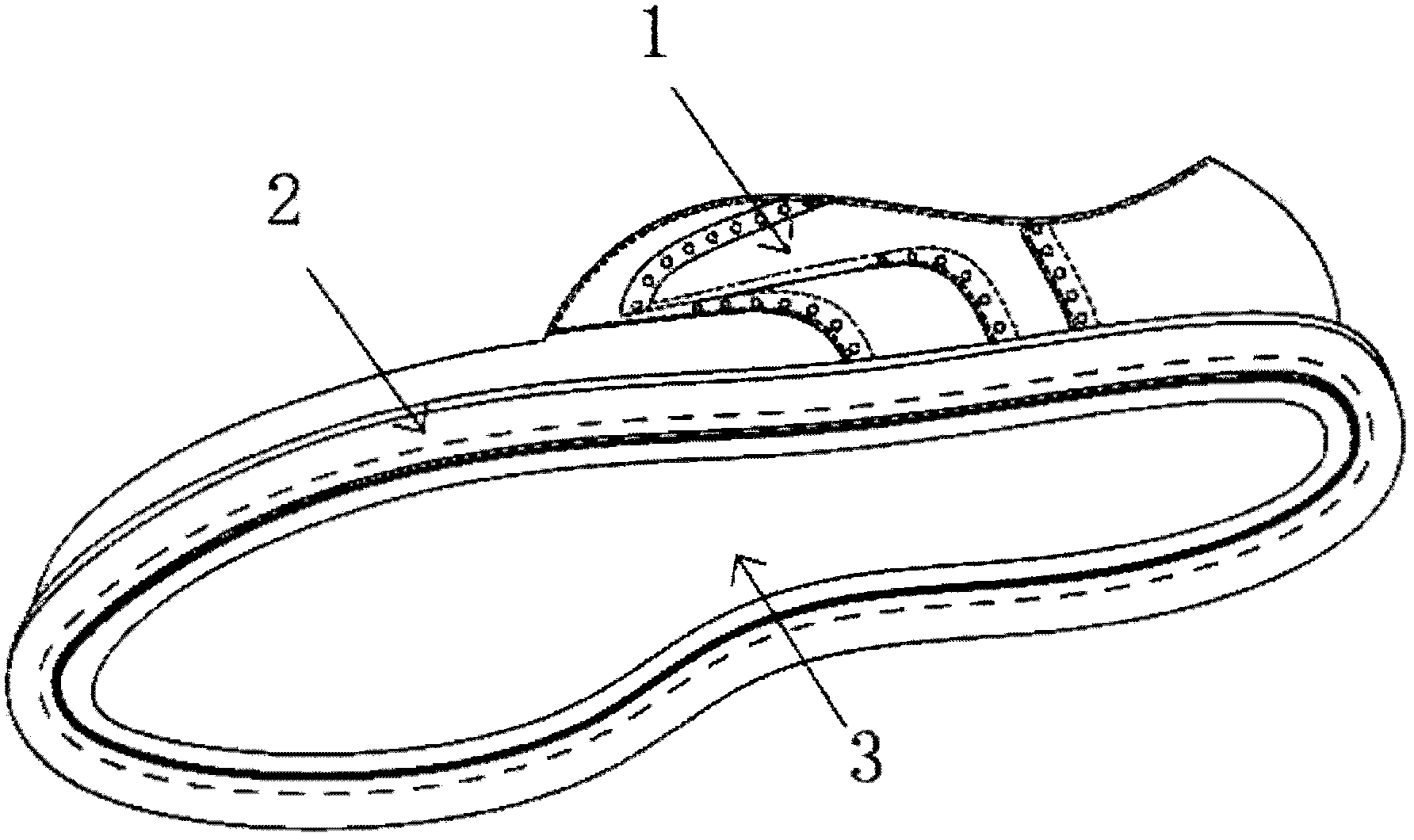

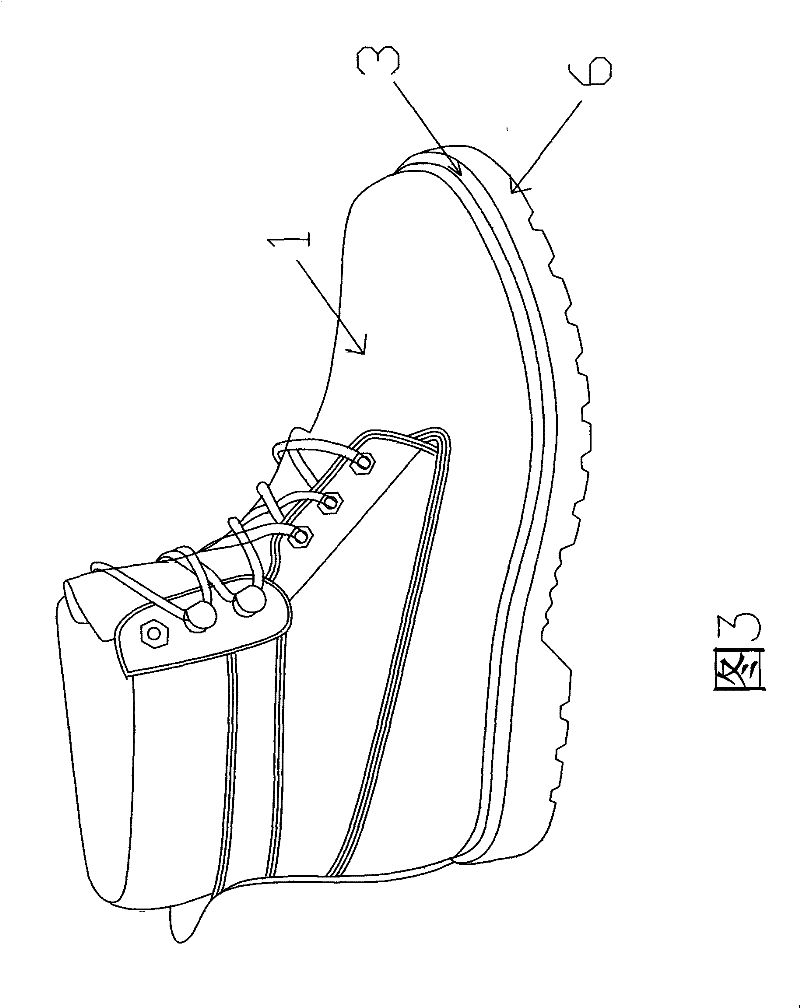

Lean making method for Goodyear seam shoes

The invention discloses a lean making method for Goodyear seam shoes. The method comprises the steps that all components of a shoe body are divided into standard components, namely a vamp, a welt, an insole, a packing layer and an outsole; the vamp, the welt and the insole are sewn into a whole; the packing layer and the outsole are mounted, and then a Goodyear seam shoe is made through a heat setting process and a cold setting process. According to the lean making method, five processes including upper clamping, nail pulling, upper foot cutting, grinding and upper bottom bonding in the traditional art are omitted, production cost is lowered, investment of personnel is reduced, the making process is simplified, and more consumers can put on the novel Goodyear seam shoes which are firm and durable; besides, a whole plastic piece is used as the packing layer of the insole, and the insole is more comfortable than a traditional insole filled with cork; moreover, bonding through mucilage glue is not needed, so that time and labor are saved, and environmental friendliness is achieved.

Owner:KANGNAI GROUP

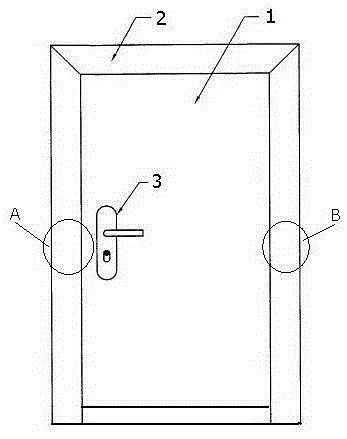

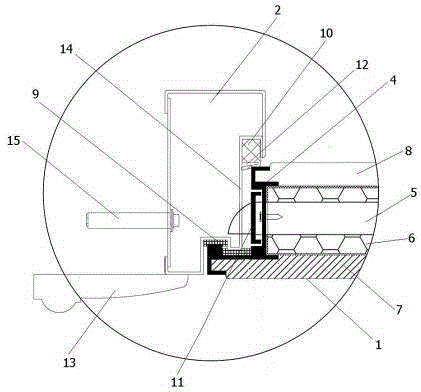

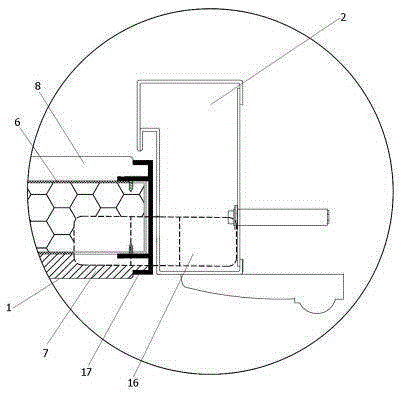

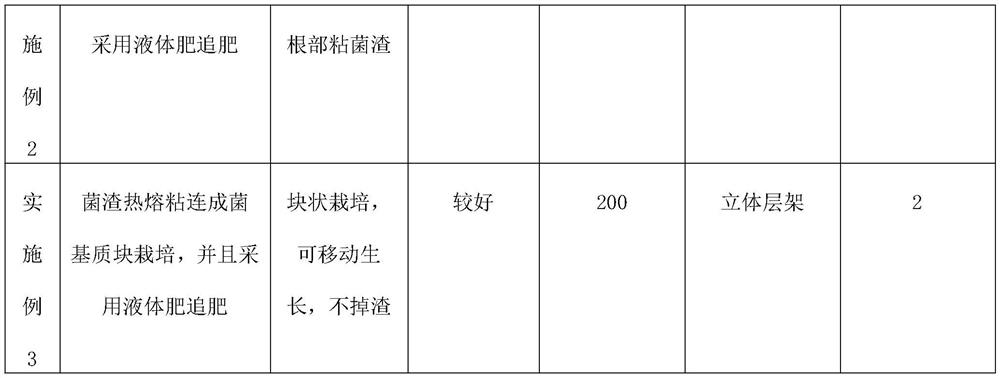

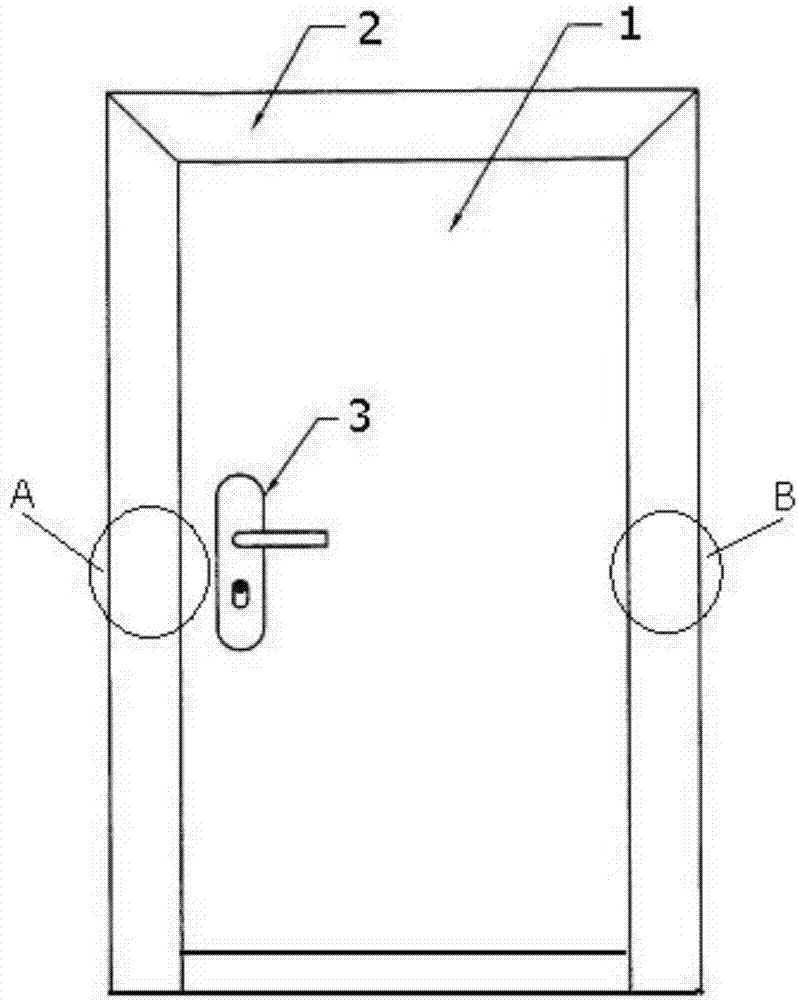

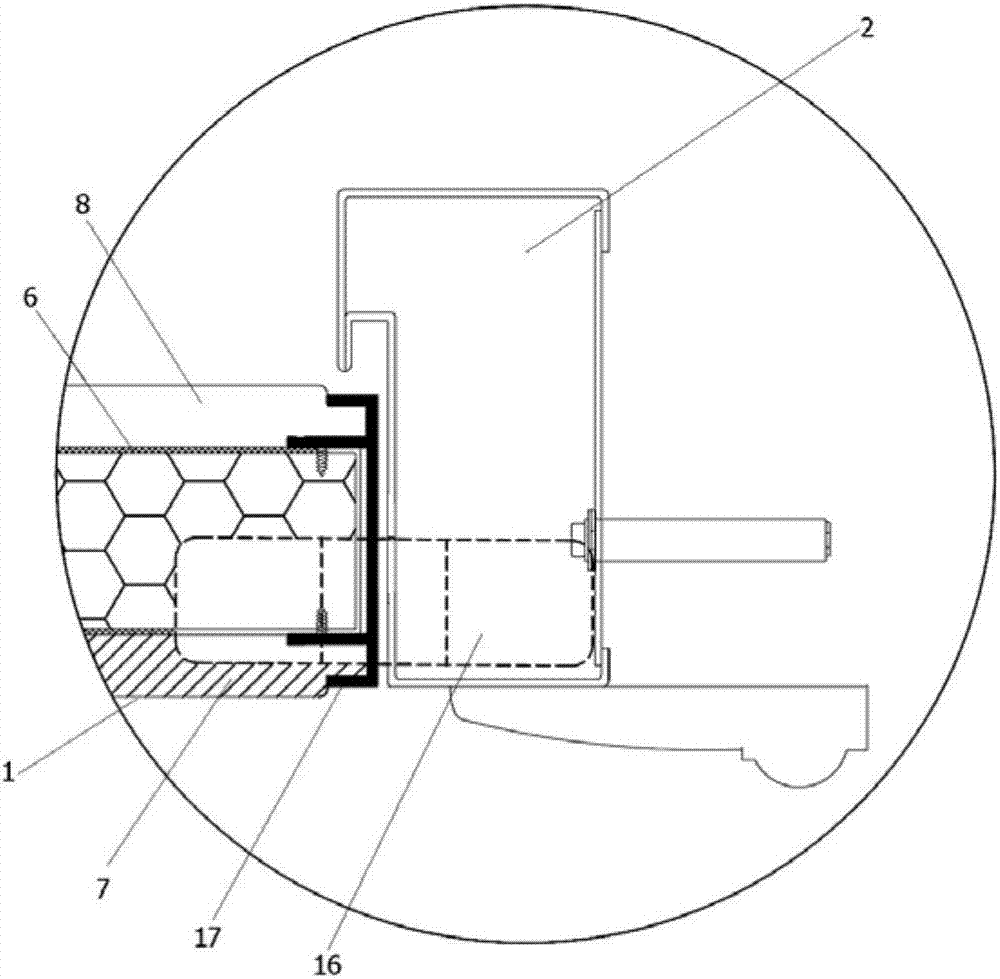

One-piece and two-piece Chinese-style armored door and manufacture and installation process thereof

ActiveCN105298335AAvoid damage phenomenonSolving the Wasted White Space ConundrumFrame fasteningWindow/door framesEngineeringMechanical engineering

The invention discloses a one-piece Chinese-style armored door which is composed of a door frame, a door leaf, a door lock side covering edge, a hinge side covering edge, a door lock, a hinge and a door core. A two-piece Chinese-style armored door which is composed of a door frame, a child door leaf, a mother door leaf, a door lock side covering edge, a hinge side covering edge, a door lock, a hinge, a child door core and a mother door core. A manufacture and installation process of the one-piece Chinese-style armored door comprises the steps of manufacturing the door frame, manufacturing the door core, manufacturing the covering edges and a cover plate, assembling the door frame and the door core, manufacturing a veneer and assembling the veneer. A manufacture and installation process of the two-piece Chinese-style armored door comprises the steps of manufacturing the door frame, manufacturing the child door core and the mother door core, manufacturing the covering edges and a cover plate, assembling the door frame and the door core, manufacturing a child veneer and a mother veneer and assembling the veneers. By the adoption of the one-piece Chinese-style armored door or the two-piece Chinese-style armored door, the problem that door sheets are damaged in the cross construction process is solved; secondary waste caused by replacement and maintenance of a damaged door set is avoided, and environmental protection is facilitated; production and construction procedures are simplified, labor cost is reduced by 40%, and leakproofness, the sound insulation effect and the heat insulation effect are good.

Owner:上海璞玉门业有限公司

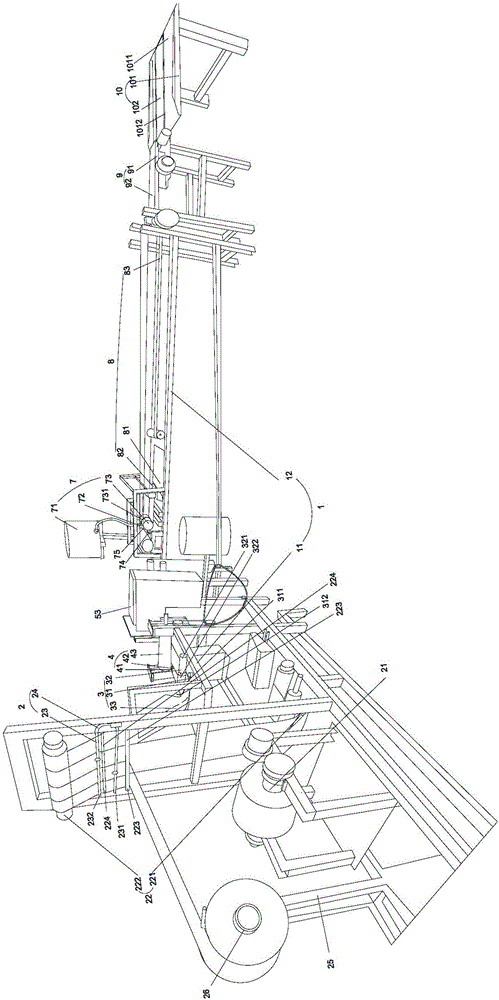

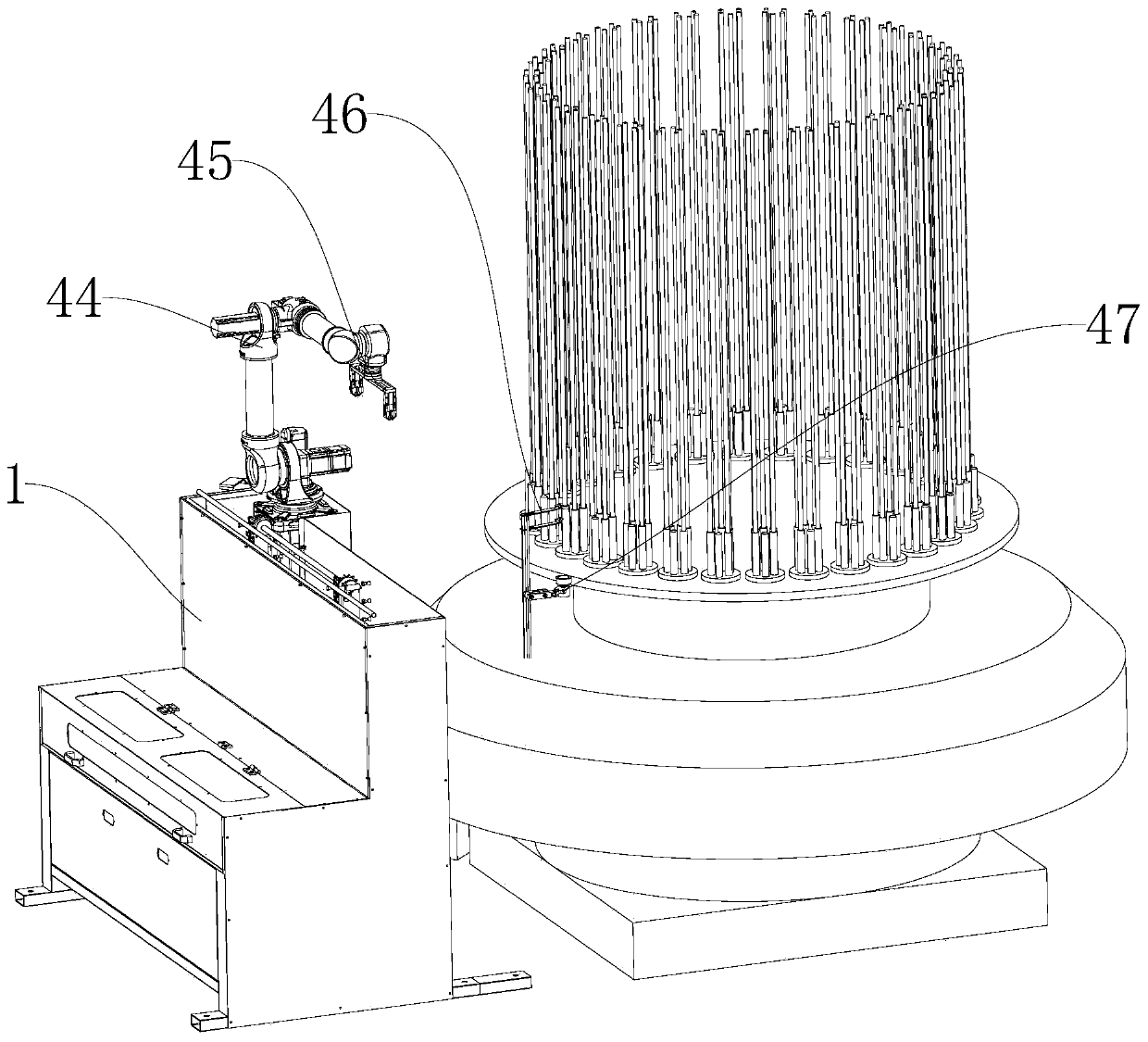

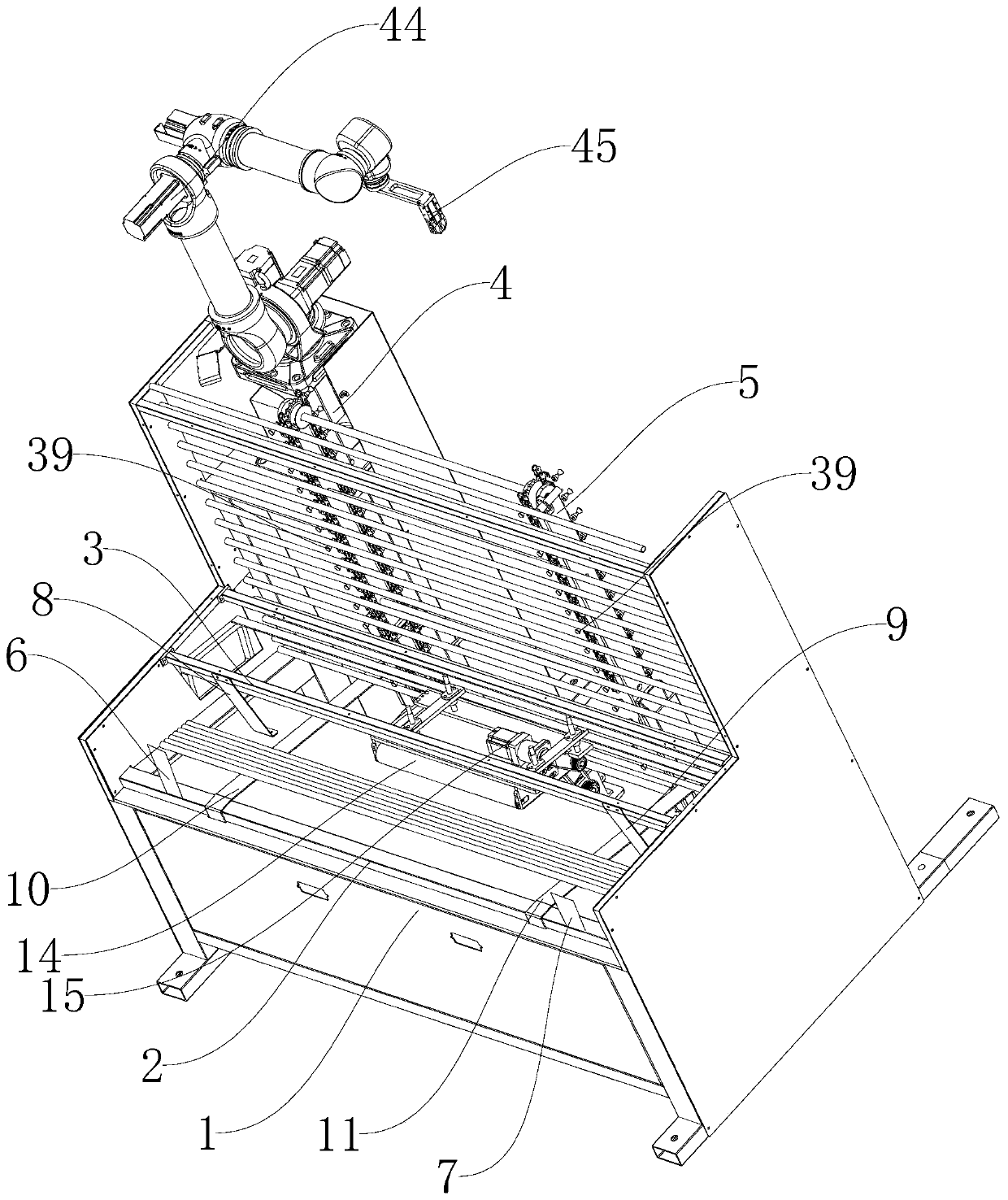

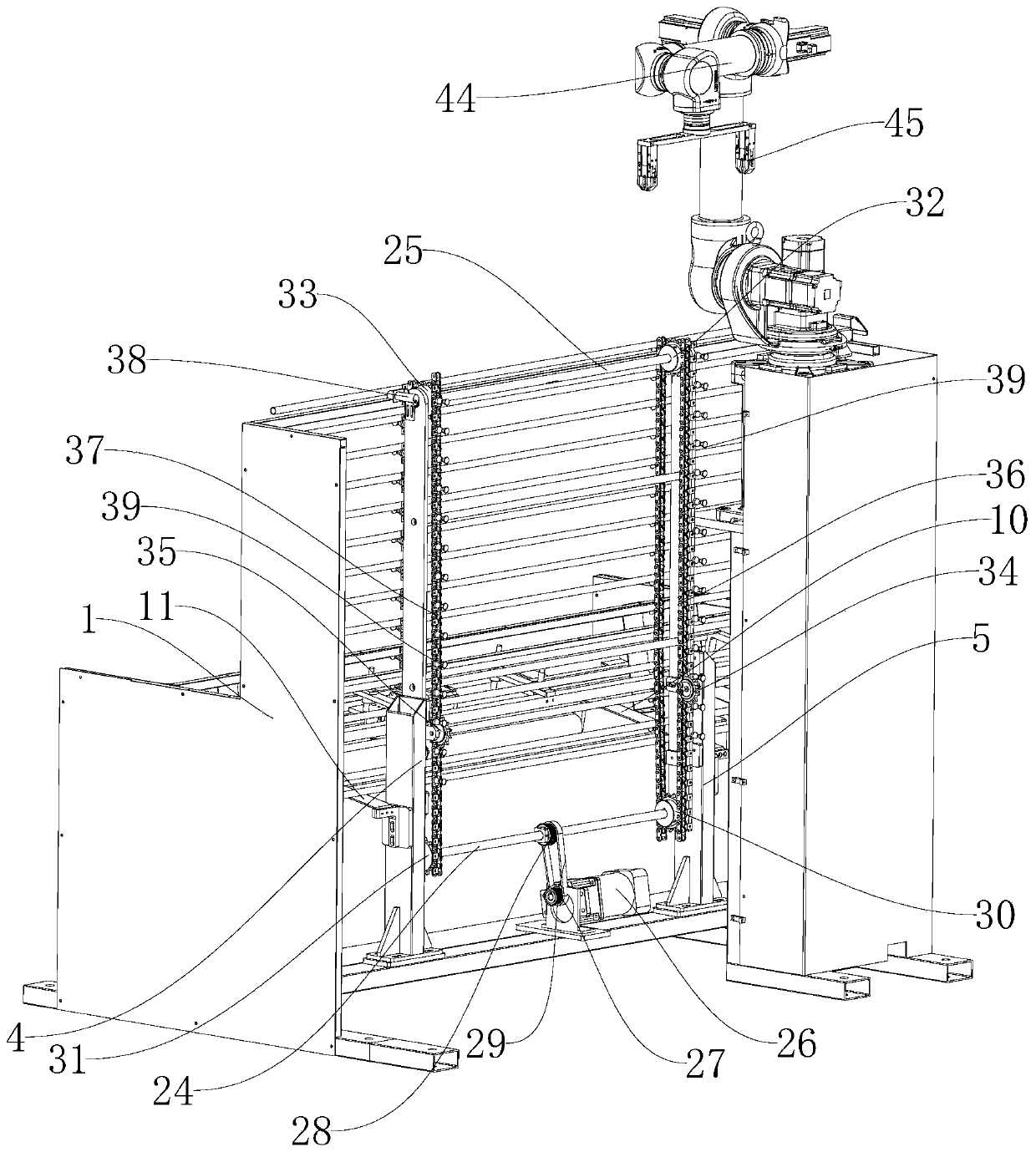

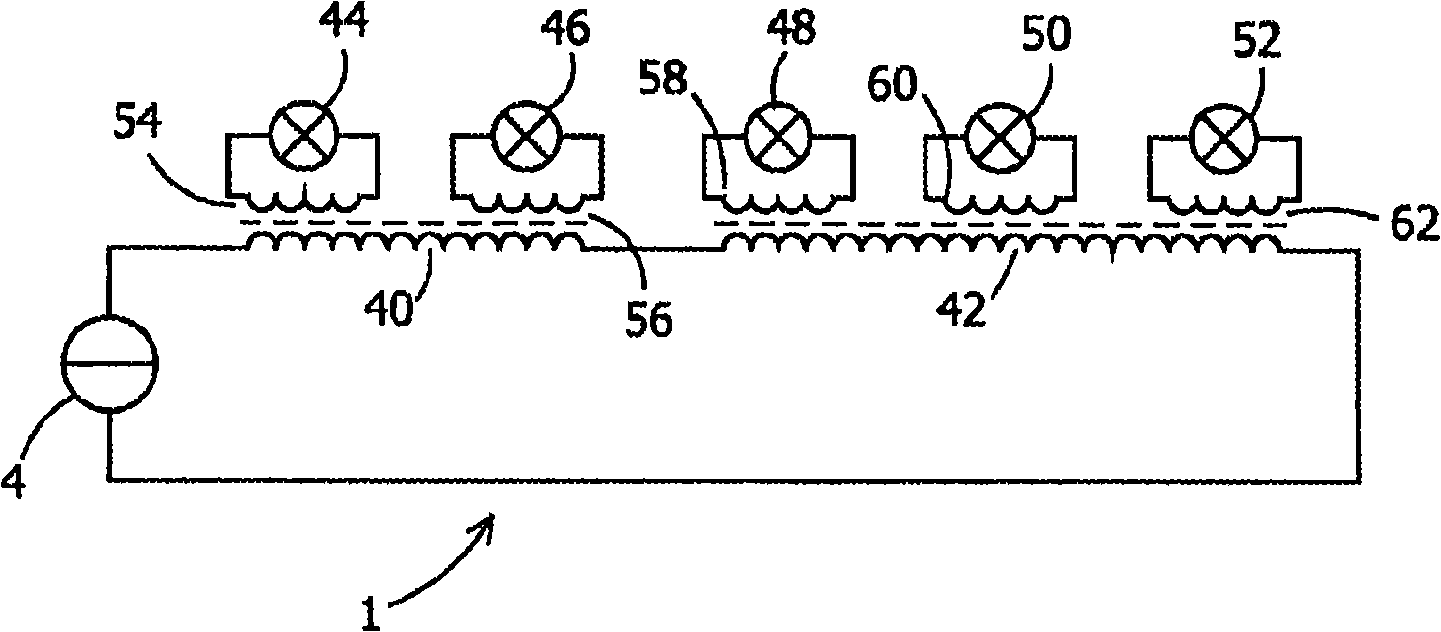

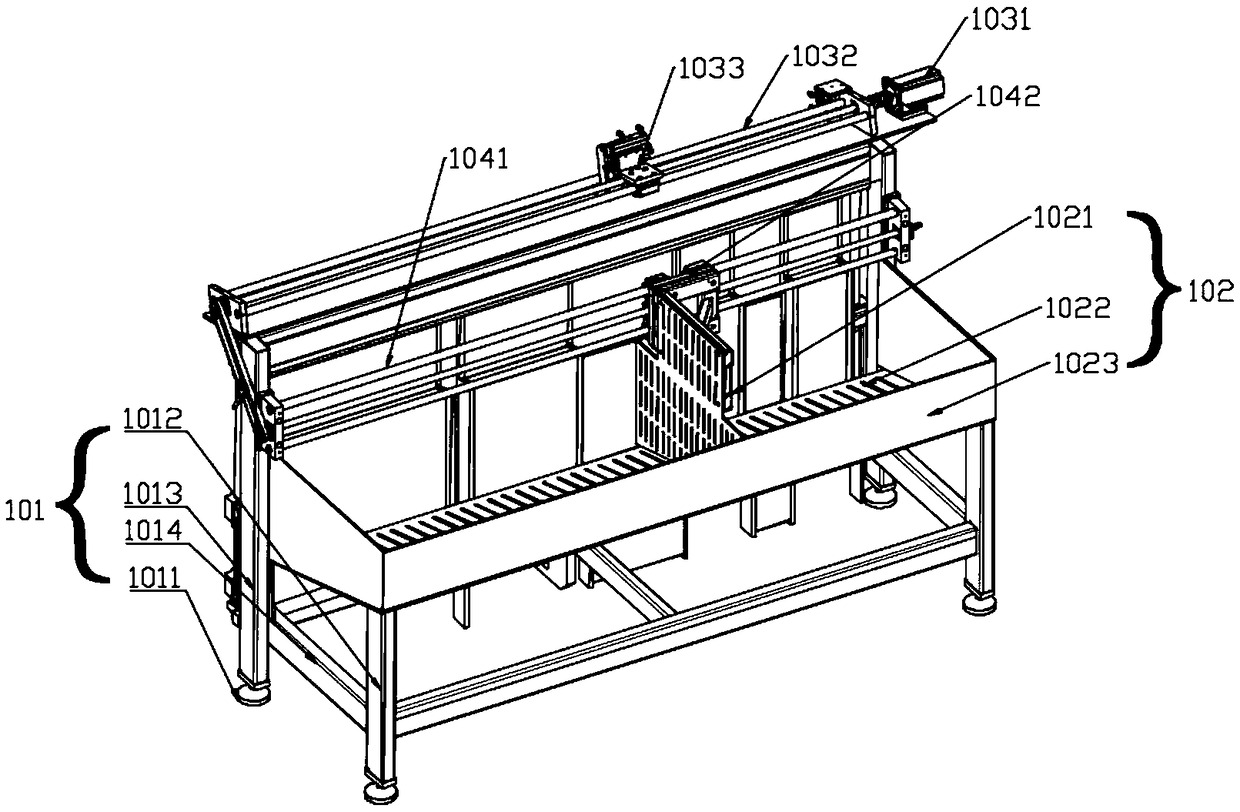

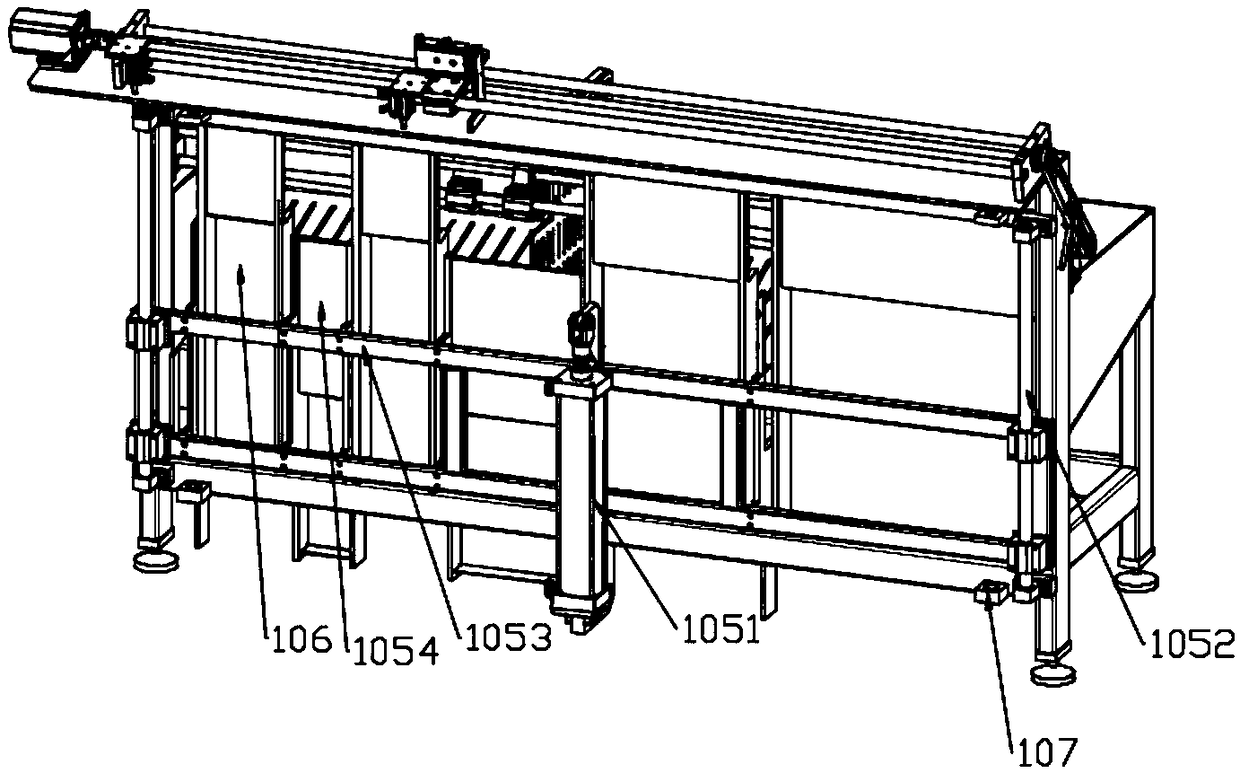

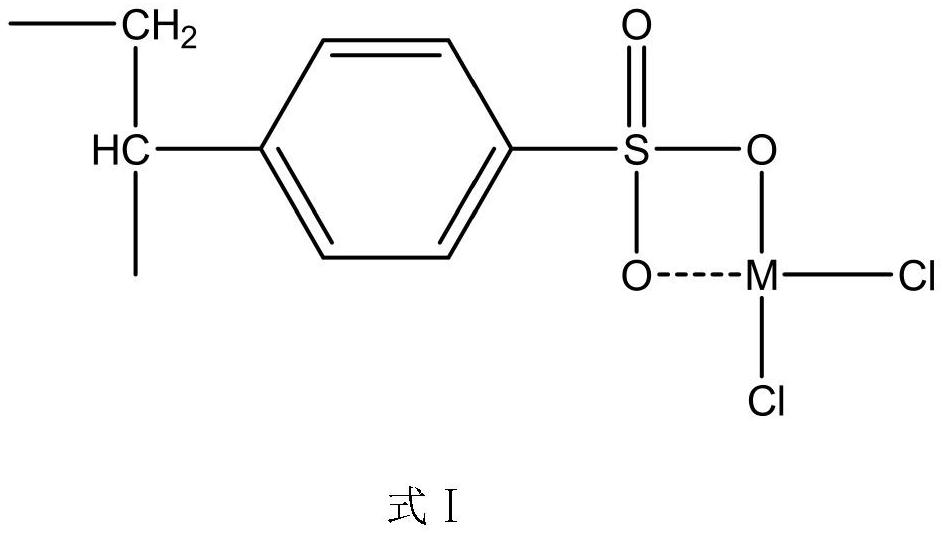

Automatic pipe feeding system

ActiveCN111232635AIncrease productivityReduce production and labor costsConveyorsControl devices for conveyorsControl engineeringProcess engineering

The invention discloses an automatic pipe feeding system. The system comprises a rack, a pipe storage bin, a pipe sorting and conveying mechanism, a pipe lifting mechanism, a pipe grasping and inserting mechanism, a pipe lack detection and tracking mechanism and a control module. The pipe storage bin conveys raw glass pipes to the pipe sorting and conveying mechanism in sequence, the pipe sortingand conveying mechanism arranges the raw glass pipes in a layer and sequentially conveys the raw glass pipes to the pipe lifting mechanism, the pipe lifting mechanism lifts the raw glass pipes, the pipe grasping and inserting mechanism grasps the raw glass pipes on the uppermost layer on the pipe lifting mechanism and inserts the raw glass pipes into pipe lack insertion holes when a pipe supply rotating plate lacks pipes, and the pipe lack detection and tracking mechanism is used for monitoring whether the pipe supply rotating plate lacks the pipes or not, generating pipe lack signals when itis detected that pipe lack happens and position signals of the pipe insertion holes in a pipe lack state and sending the signals to the control module. The system has the advantages that automatic pipe supply and supplementing of the pipe supply rotating plate of a bottle making machine can be achieved without manual work, the glass bottle production efficiency is improved, and the manual cost forglass bottle production is reduced.

Owner:NANYANG NORMAL UNIV

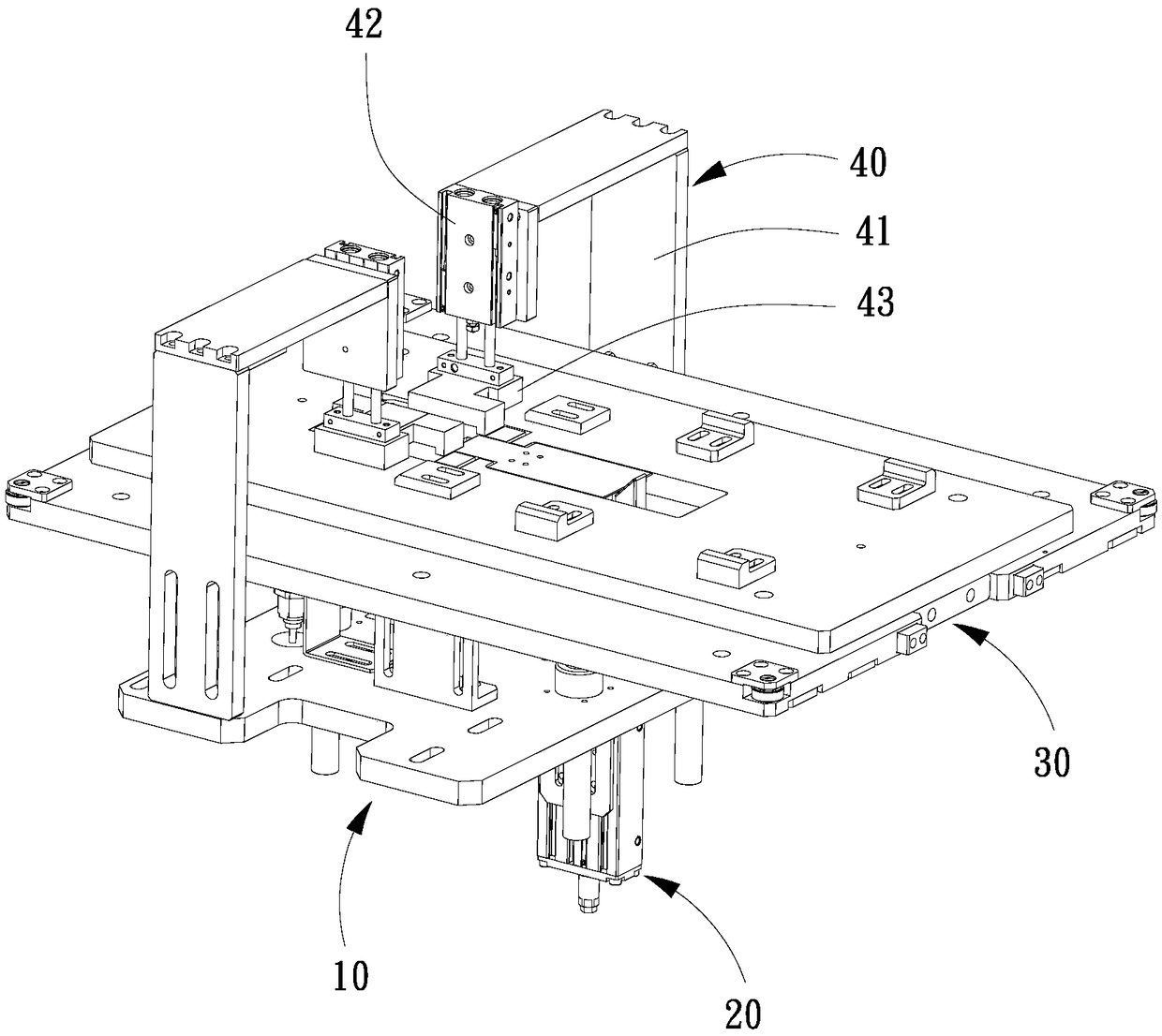

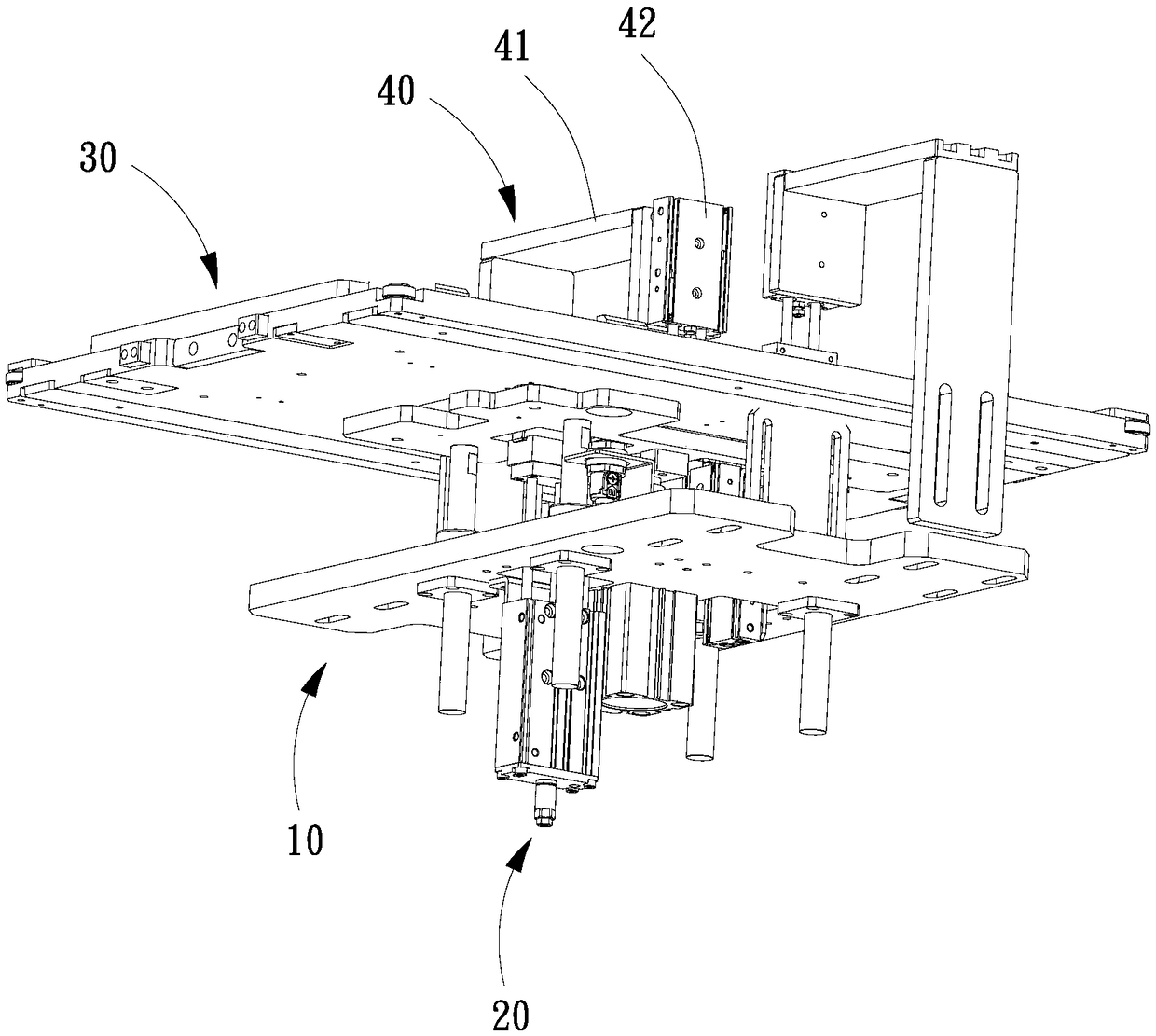

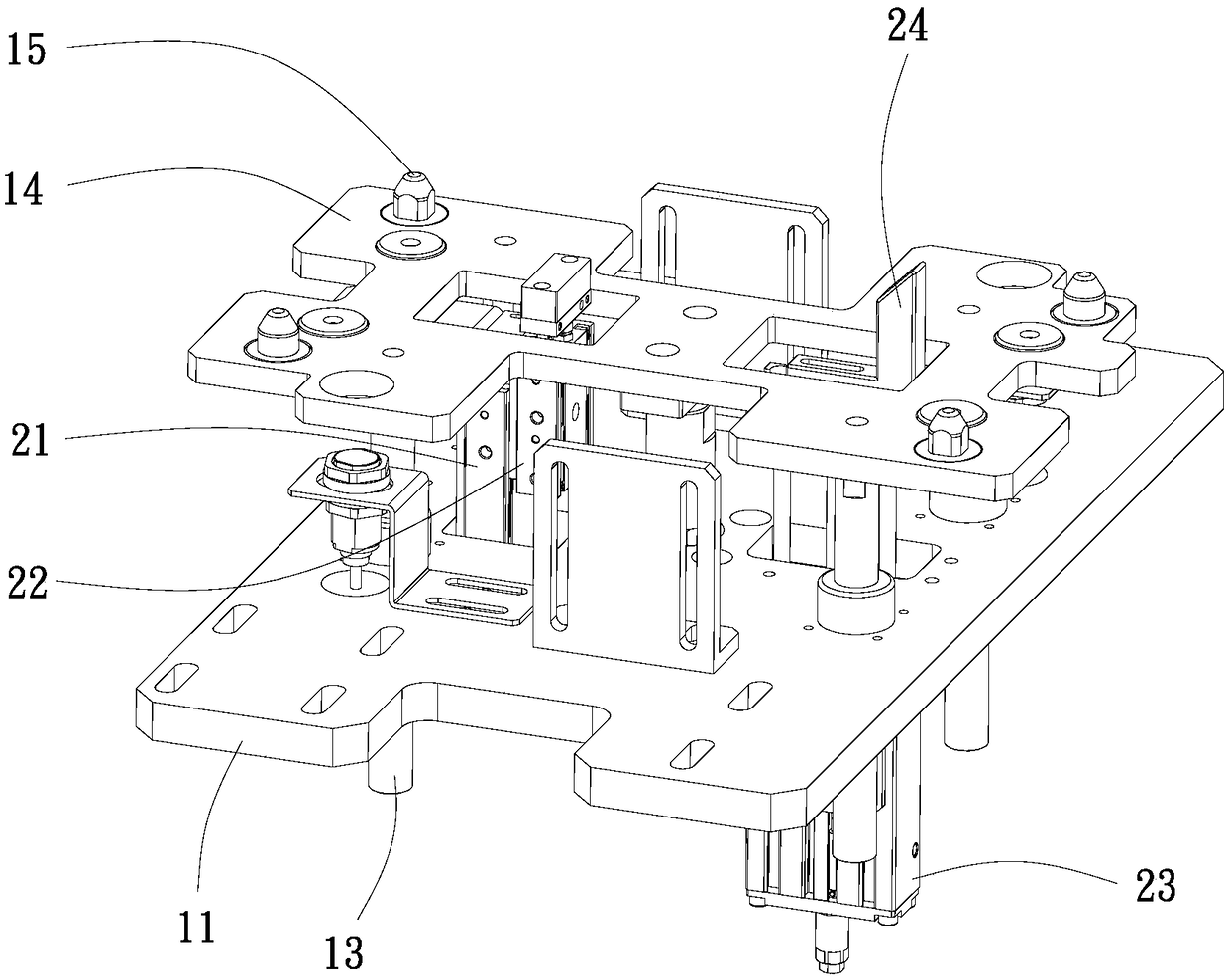

Automatic assembling device

ActiveCN108971950AHigh degree of automationImprove assembly efficiencyMetal working apparatusEngineeringAutomation

The invention relates to an automatic assembling device which comprises a jacking assembly, a push assembly and a jig assembly. The jacking assembly comprises a lifting element and a jacking panel. The push assembly comprises a first driving part, a second driving part, a push element and an ejector rod. The jig assembly comprises a jig carrying plate, a hinge hinged into the jig carrying plate, asliding rail mounted in the jig carrying plate and a push block slidingly connected with the sliding rail. The second driving part is used for driving the hinge to turn over, and the push element isused for pushing the push block. According to the automatic assembling device, a first workpiece and a second workpiece are placed on the jig assembly, the push element drives the push block to extrude a buckle of the first workpiece to deform, the second driving part jacks the hinge, and a cover plate body of the first workpiece is mounted in the second workpiece. The automation degree is high, the assembling efficiency is greatly improved, the production labor cost is reduced, and the yield can be effectively increased.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

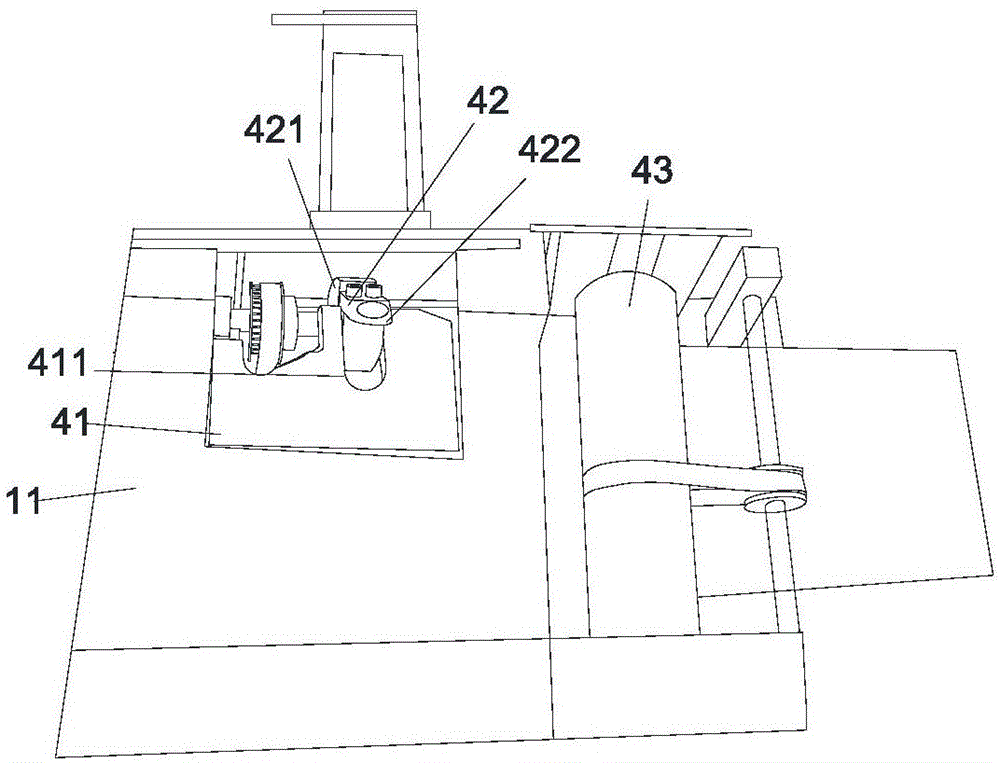

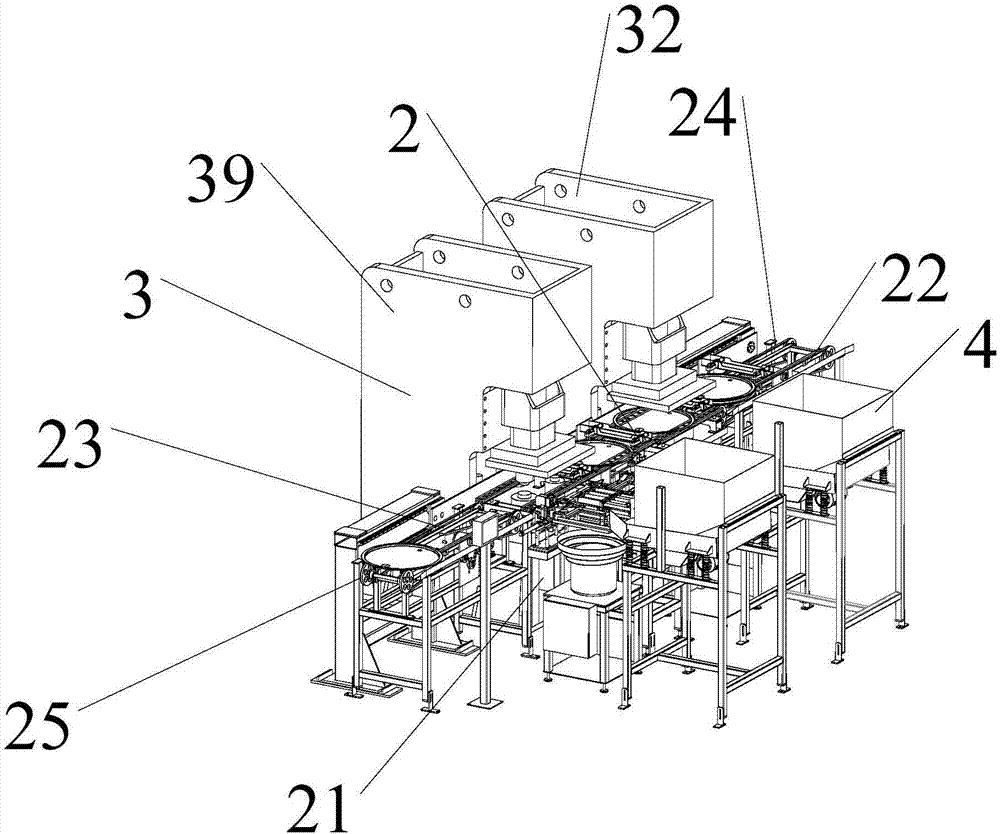

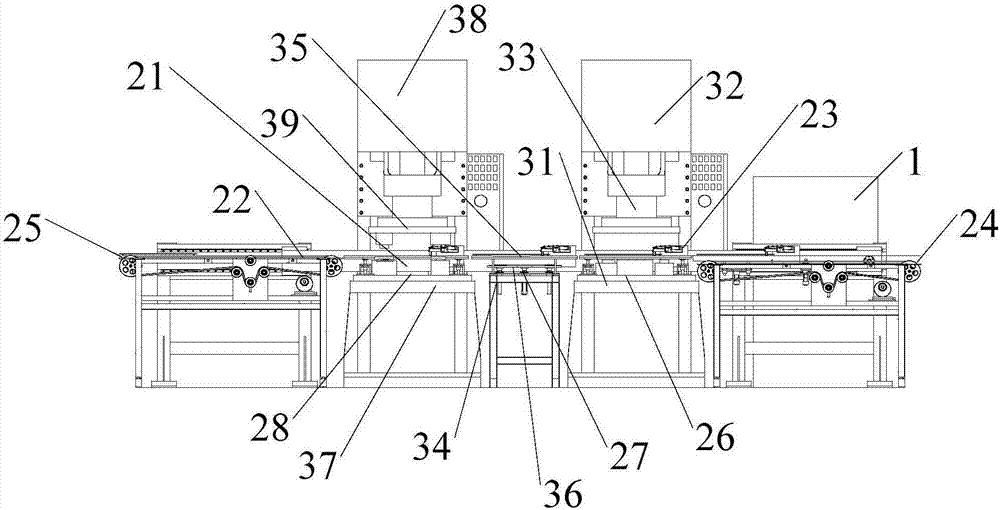

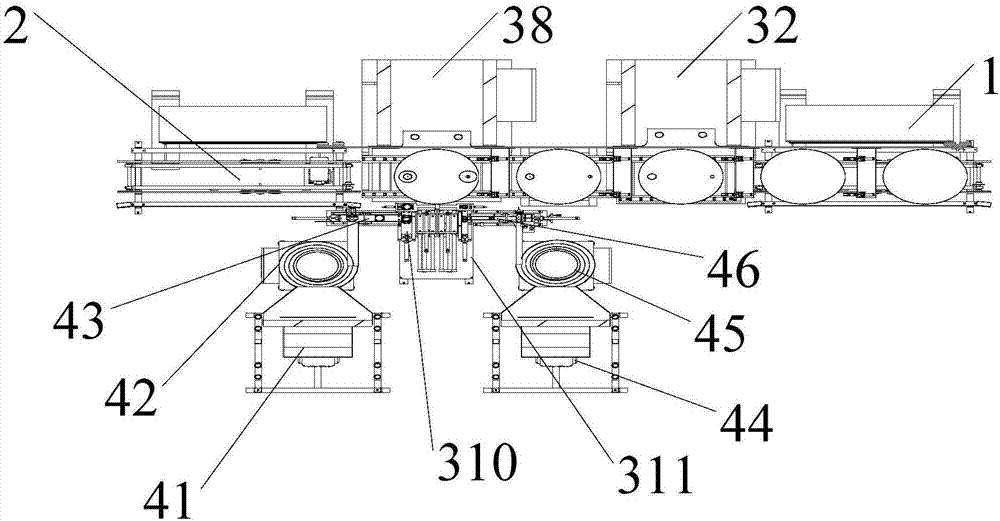

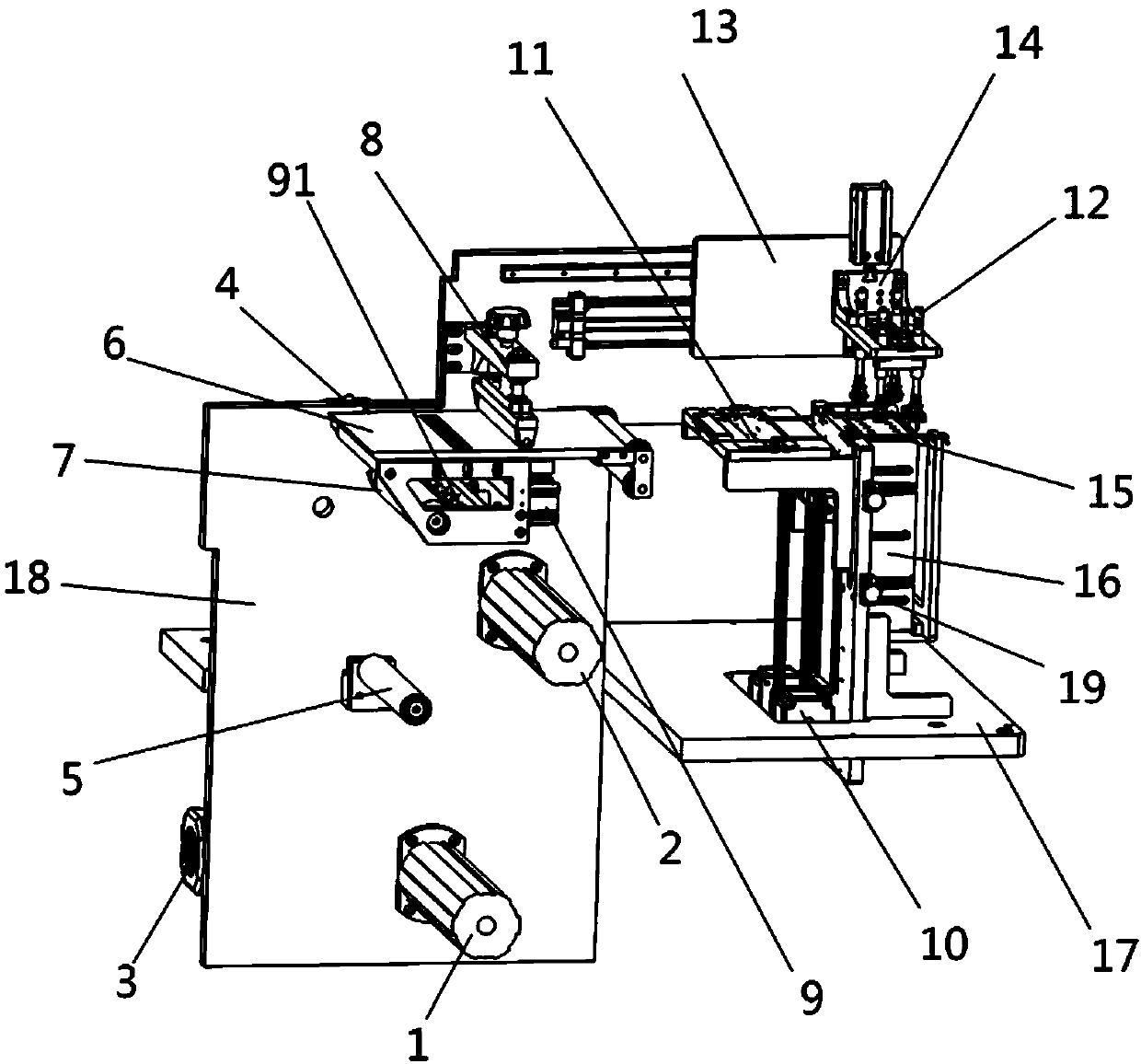

Bucket cover punching locking production system

InactiveCN106862925AImprove machining accuracyIncrease production capacityAssembly machinesMetal working apparatusPunchingEconomic benefits

The invention discloses a barrel lid punching lock production system, which includes an electric control cabinet, etc., a barrel lid conveying module, a barrel lid processing module, and a feeding module are all connected to the electric control cabinet, and the barrel lid punching lock production system passes through The electric control cabinet controls the lid conveying module, the lid processing module, and the feeding module. The lid conveying module includes the system base, etc. The slide rail is fixed on the surface of the system base, and the top cover stepping transfer device is embedded on the slide rail, and the entrance is connected The belt conveyor and the outlet connecting belt conveyor are respectively fixed at both ends of the slide rail, and the first station sensor, the second station sensor and the third station sensor are all fixed on the system base. The invention adopts mechanical automatic production to replace the traditional manual processing of the barrel lid, reduces the production labor cost, greatly improves the processing accuracy and production capacity of the barrel lid production, and improves the economic benefits of the barrel lid production and manufacturing industry.

Owner:SHANGHAI JISHENG AUTOMATIC MACHINERY SYST

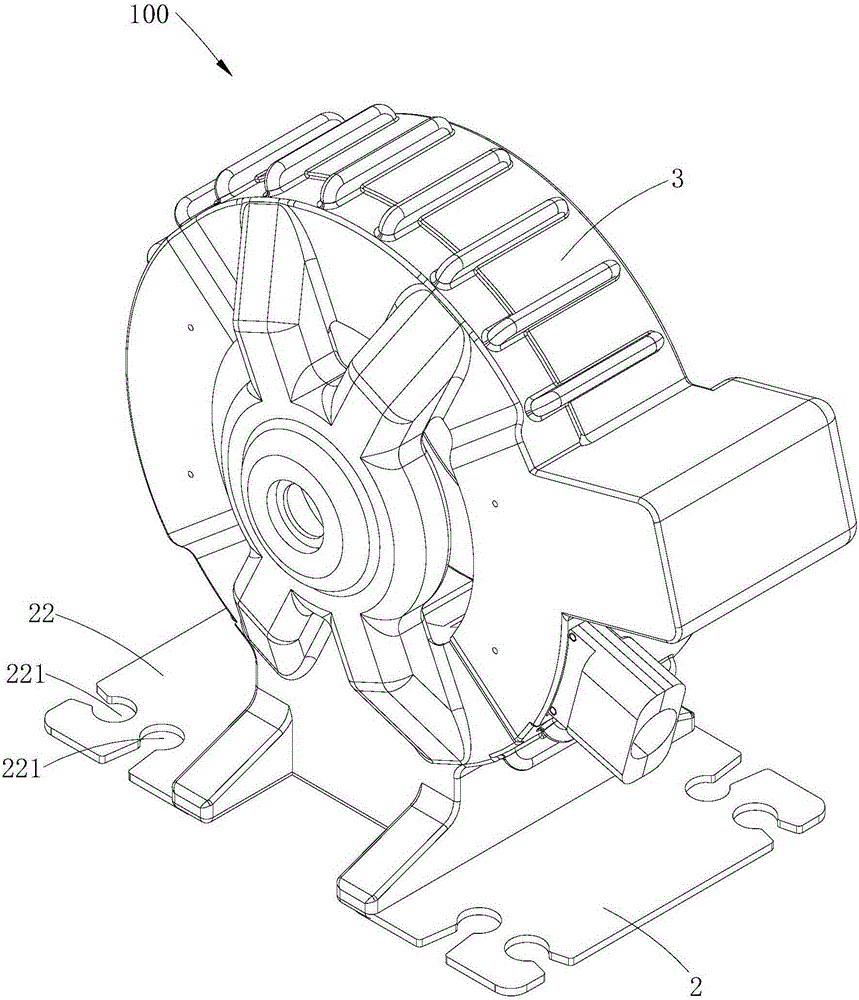

Plastic package coil motor

ActiveCN105207387ASave the follow-up installation processReduced parts countSupports/enclosures/casingsEngineeringInjection molding machine

The invention is suitable for the field of a motor and discloses a plastic package coil motor which comprises a plastic package stator assembly. The plastic package stator assembly comprises a stator assembly, an installation support arranged under the stator assembly and a plastic package housing which is moulded outside the stator assembly and enables the stator assembly to be connected with the installation support into an integrated body in an injection molding manner. The installation support comprises a plastic package connection portion packaged in the plastic package housing and an installation portion protruding out of the plastic package housing. The installation support and the stator assembly are directly connected into the integrated body in the injection molding manner through the plastic package housing, thereby saving the follow-up installation process of the installation support, saving the arrangement of connecting components between the installation support and the stator assembly or the plastic package housing, reducing the number of the components of the plastic package coil motor, simplifying the structure of the plastic package coil motor and reducing material cost of the plastic package coil motor, meanwhile, simplifying production process of the plastic package coil motor, reducing labor cost of the production of the plastic package coil motor, and improving production efficiency of the plastic package coil motor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Mobile phone protective film feeding mechanism

InactiveCN109250540ARealize automatic film applicationRealize automatic feedingArticle separationWebs handlingTectorial membraneSheet film

The invention discloses a mobile phone protective film feeding mechanism, which comprises a roll film mechanism, a sheet film mechanism and a frame; the roll film mechanism is fixedly arranged on theframe; the sheet film mechanism comprises a sucker assembly and a feeding assembly, wherein the sucker assembly is slidably connected to the frame, and the feeding assembly is fixedly arranged on theframe. By collecting the roll material and the sheet material in one device, the automatic feeding of the two protective films of the roll material and the sheet material is achieved, which solves thefeeding problem in the form of a plurality of materials. The automatic film pasting of the mobile phone can be arbitrarily arranged in the automatic equipment, which improves the automation degree ofthe equipment, and reduces the production cost.

Owner:深圳橙子自动化有限公司

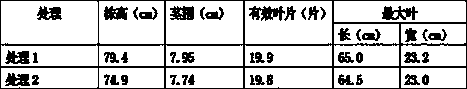

No-tillage aphid-preventing and disease-preventing efficient cultivation method for flue-cured tobacco

InactiveCN103988698AStop the spread of the virusReduce production and labor costsHorticultureCuring of tobaccoAgriculture

The invention relates to a no-tillage aphid-preventing and disease-preventing efficient cultivation method for flue-cured tobacco, and belongs to the field of agriculture cultivation. According to the method, the labor amount can be reduced for tobacco growers, the labor cost can be lowered, the number of aphids flying to tobacco plants during the migratory flight peak season of the aphids can be reduced, the harm of spreading viral diseases by the aphids can be relieved, the yield of the tobacco can be increased, and the quality of the tobacco can be improved. According to the technological means, wheat is planted in a field in October of the first year according to a conventional method; tobacco seedlings are planted between the wheat lines in April of the next year, the row spacing is 50 cm, the line spacing is 1 m, and the depth of a hole for planting the tobacco seedlings is 5-8 cm; the wheat is harvested in June, the wheat stubble is 0.2-0.3 m high and is removed in 25-30 days after the wheat is harvested, fertilization and hilling are carried out on the tobacco plants, and then the field management stage of the flue-cured tobacco begins; after the flue-cured tobacco is harvested in September, the soil is ploughed for planting the wheat.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

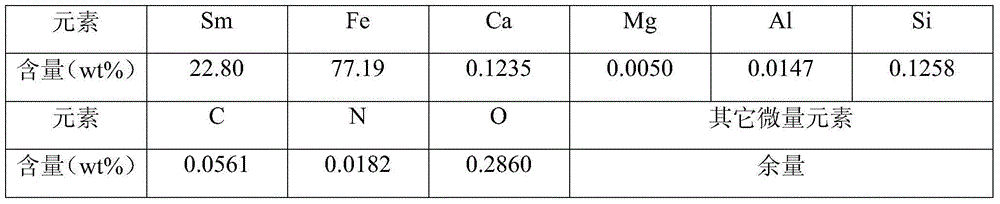

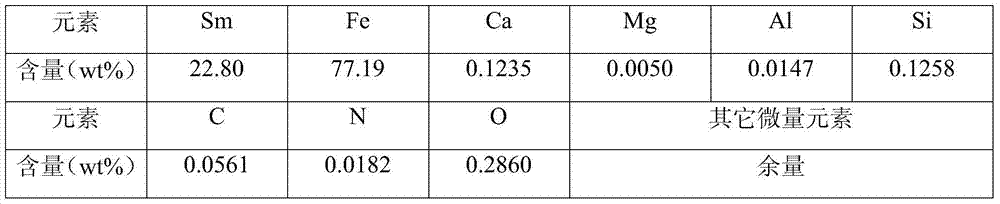

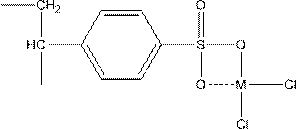

SmFex alloy and preparation method thereof

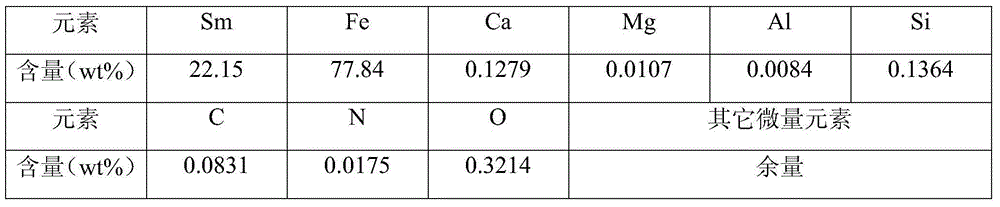

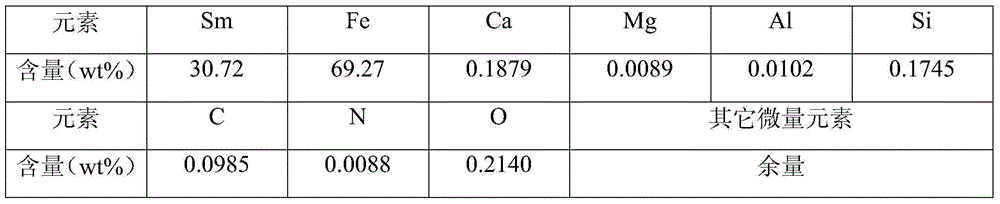

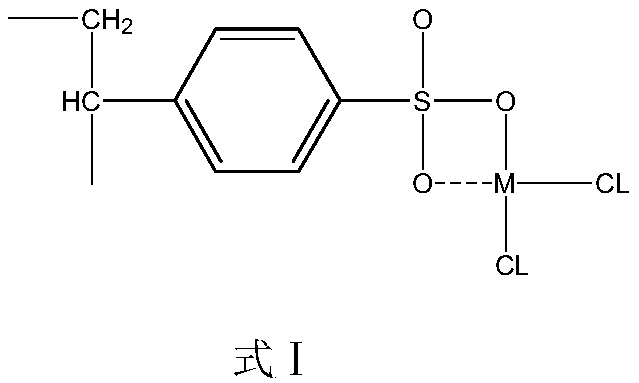

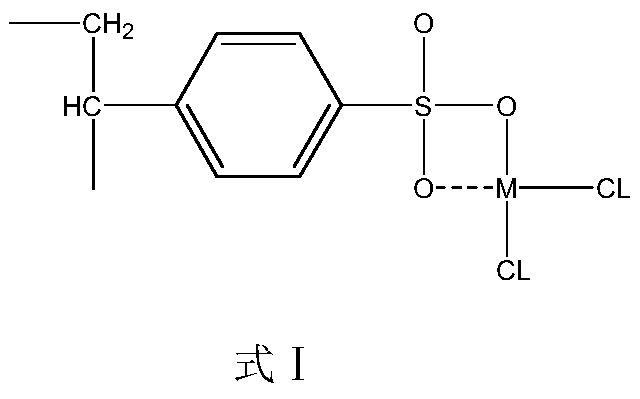

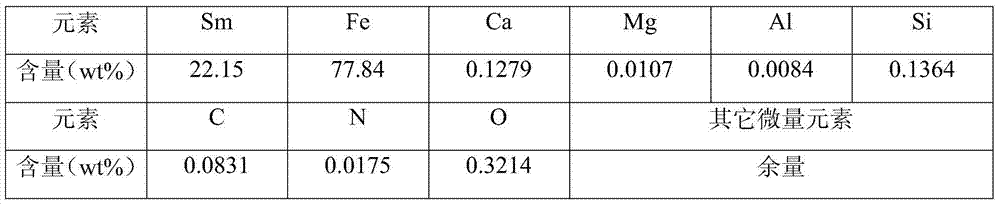

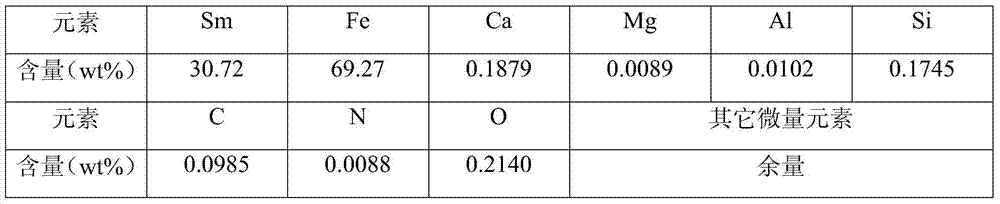

The invention relates to SmFex alloy and a preparation method thereof. The alloy is composed of, by mass, 20-60% of samarium, 40-80% of iron, less than 0.15% of calcium, less than 0.3% of oxygen, less than 0.02% of aluminum, less than 0.02% of magnesium, less than 0.05% of silicon, less than 0.05% of carbon, less than 0.01% of nitrogen, and less than 0.01% of remaining impurities, wherein the sum of the mass percents of the elements is 100%. Sm2O3 and SmCl3 are used as raw materials, the metal calcium is used as a reducing agent, iron powder is used as an alloying element, and the SmFex intermediate alloy is prepared through the reduction-diffusion method. Compared with the prior art, the SmFex alloy and the preparation method thereof have the advantages that the process is simple, the cost is low, the production efficiency is high, and the content of the samarium in the alloy is stable and controllable.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

Green synthetic phosphate preparation method

ActiveCN110054646ANo wall stickingReduce pollutionChemical recyclingPhosphorus organic compoundsChemical synthesisEpoxy

The invention relates to a green synthetic phosphate preparation method which includes the steps: taking a macromolecular lewis acid catalyst as a catalyst; performing esterification reaction on phosphorus oxychloride and an epoxy compound; recycling the epoxy compound in a decompressed manner after complete reaction; filtering reactants to obtain phosphate. Alkali washing and water scrubbing areomitted, production cost is greatly saved, social environments are not polluted, and the preparation method conforms to green chemical synthesis and suitable for industrial popularization and application.

Owner:ZHEJIANG WANSHENG

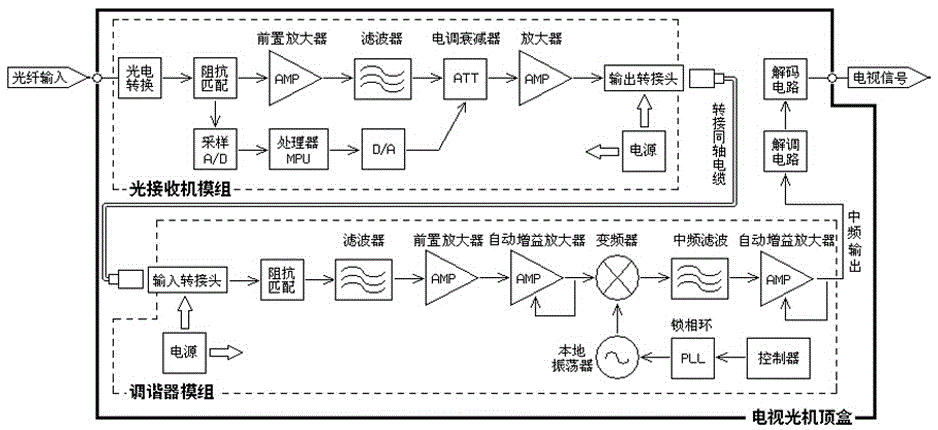

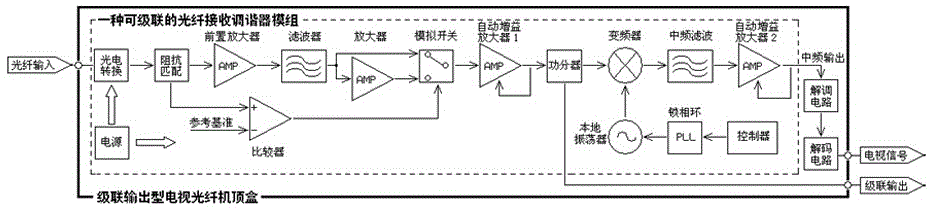

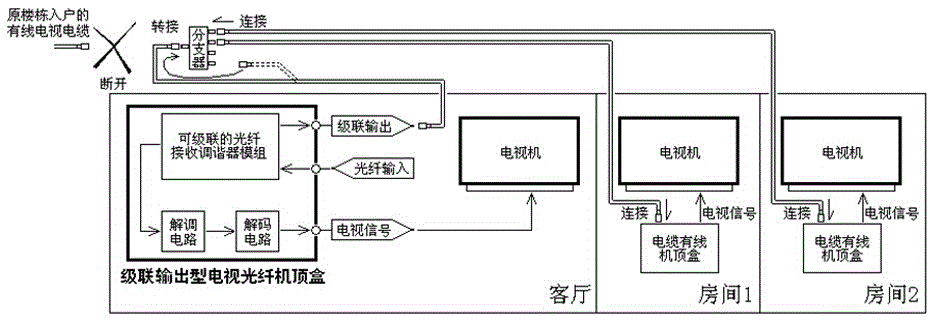

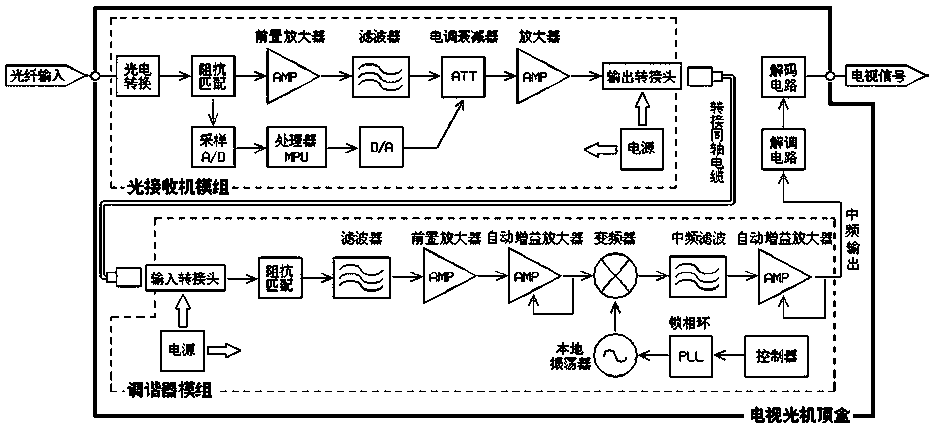

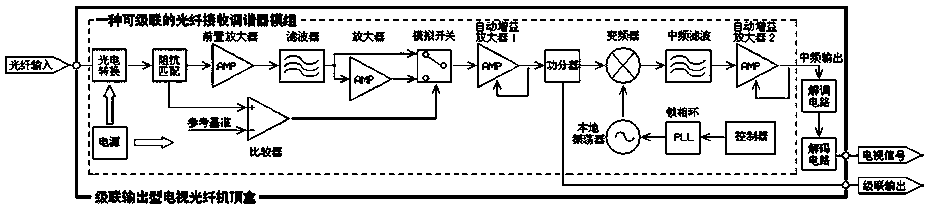

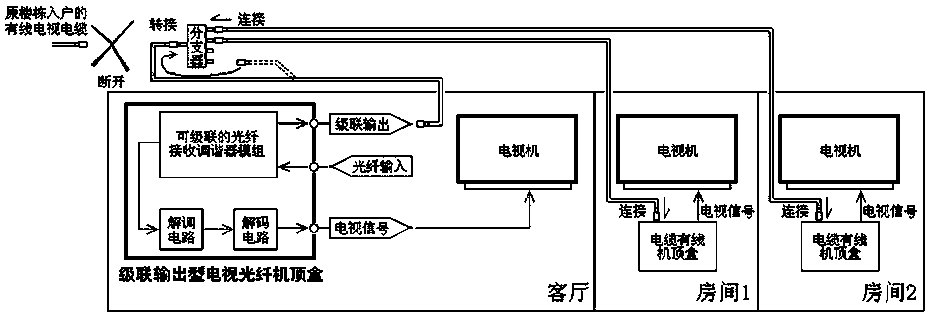

Integrated cascadable optical fiber tuner module

ActiveCN105578158ASimple production processReduce manufacturing costOptical transmission adaptationsElectrical cable transmission adaptationDigital videoIntermediate frequency

The invention discloses an integrated cascadable optical fiber tuner module, relates to the technical field of the digital video broadcast, especially an optical fiber tuner module which is compact in structure, low in cost and supportable in cascading and an optical fiber set top box applying the module. The technical key point of the invention is that the module comprises a light source, an optical fiber access end, a photoelectric conversion circuit, an impedance matching circuit, a preamplifier, a denoising filter, a self-adaption signal enhancement circuit, a first automatic gain amplifier, a power divider, a frequency converter, a local frequency generation circuit, an intermediate-frequency filter, a second automatic gain amplifier, a demodulation circuit, a decoding circuit, a television signal leading-out end and a cascade signal leading-out end; the power supply supplies power to each electric component in the set top box ; the optical fiber access end, the photoelectric conversion circuit, the impedance matching circuit, the preamplifier and the denoising filter are sequentially connected.

Owner:四川九洲智能装备有限公司 +1

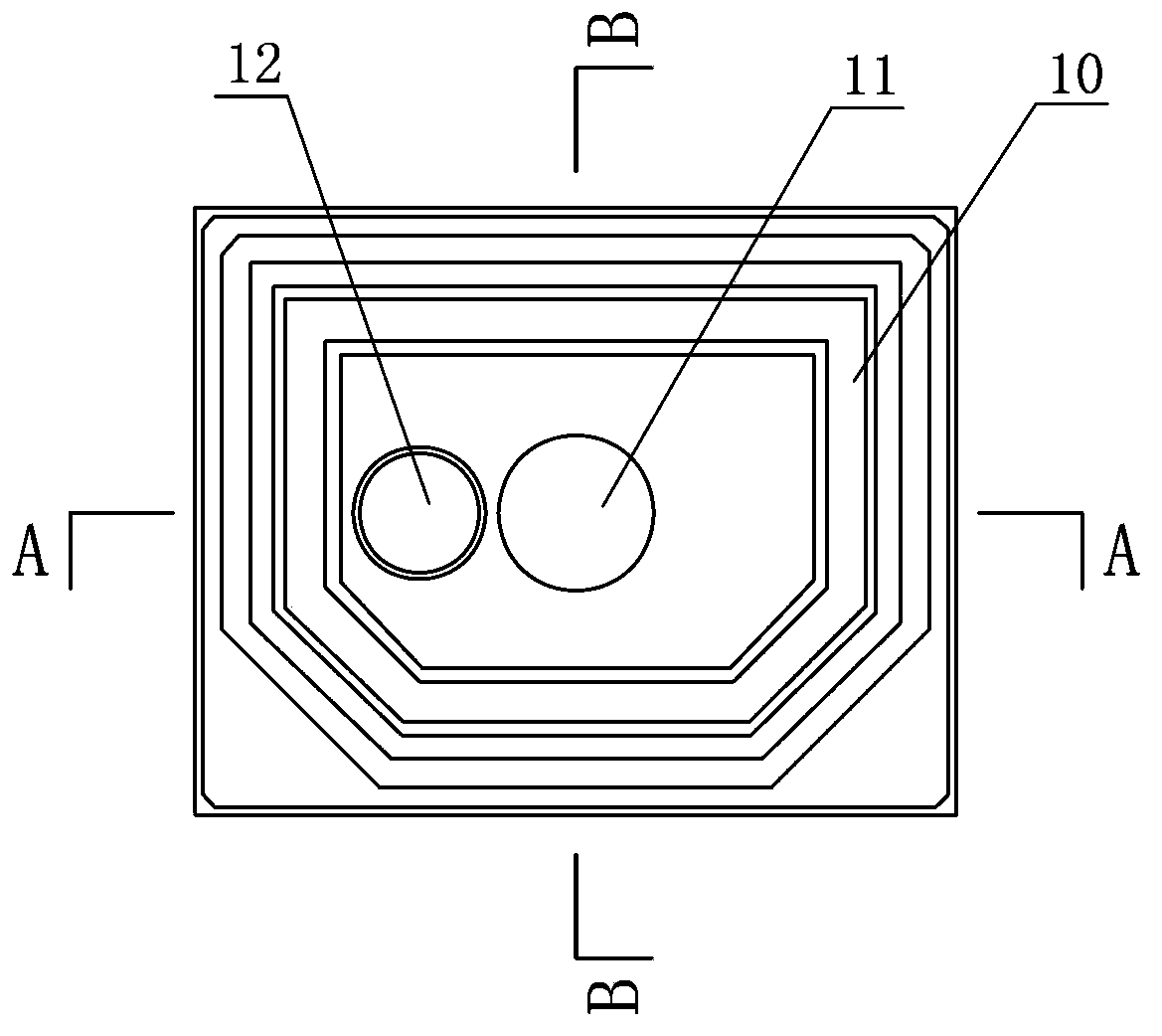

MEMS (micro-electromechanical system) circuit cover and manufacturing method thereof

ActiveCN104340946AIncrease productivityReduce production and labor costsSolid-state devicesFluid speed measurementSupport pointEpoxy

The invention discloses an MEMS (micro-electromechanical system) circuit cover and a manufacturing method thereof. The MEMS circuit cover comprises a cover body formed by injection molding of epoxy resin, wherein a supporting point is arranged in the middle of the cover body and a vent hole is formed in one side of the supporting point. According to the manufacturing method, frame carriers and a plastic seal mould are used; a plurality of vacancies matched with covers in size are arranged on the frame carriers; the plastic seal mould comprises a plurality of mould boxes; the at least one frame carrier can be accommodated in each mould box; holes are formed in the parts of the mould boxes, corresponding to the vacancies on the frame carriers and are matched with the covers in shape. The manufacturing method comprises the following steps: firstly, putting the frame carriers into the mould boxes and enabling the vacancies to correspond to the holes in position; secondly, closing the plastic seal mould, filling the mould boxes with an epoxy resin solution, and filling up all the holes; finally, opening the plastic seal mould and taking out the frame carriers with the covers, so that the operation of manufacturing the covers is finished. Therefore, a full-automatic cover mounting process can be performed, the production efficiency is improved, and the cost is reduced.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

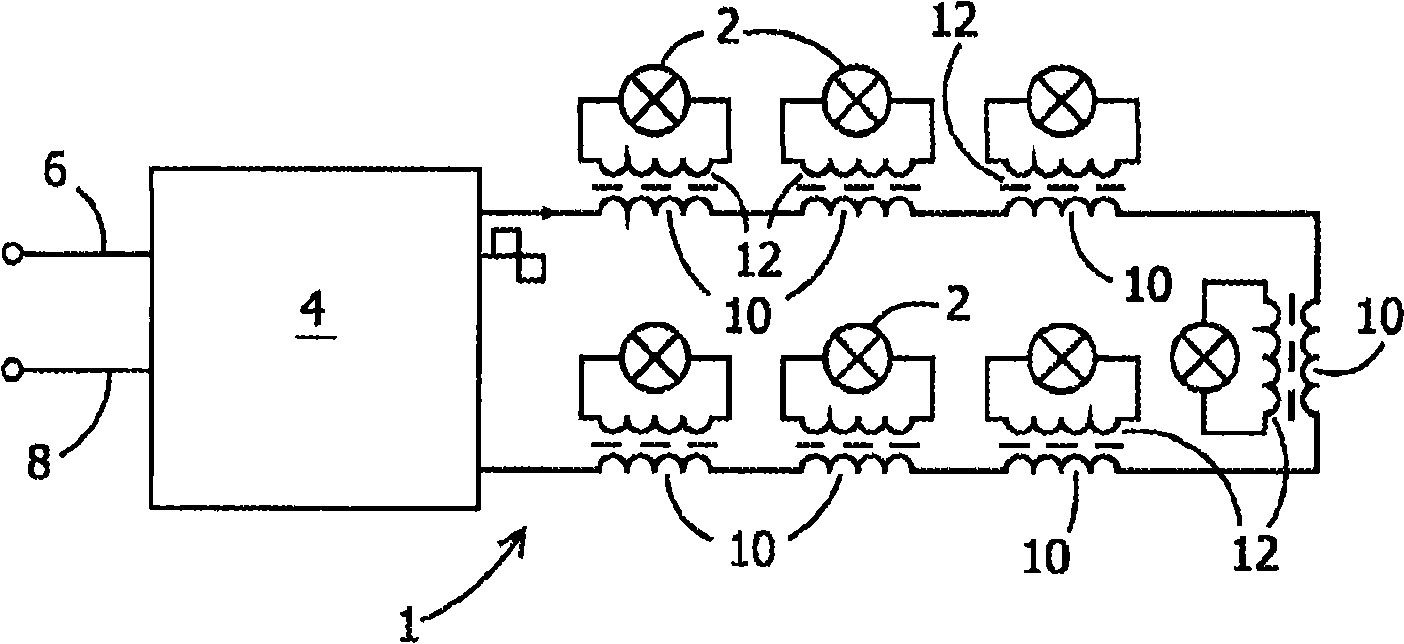

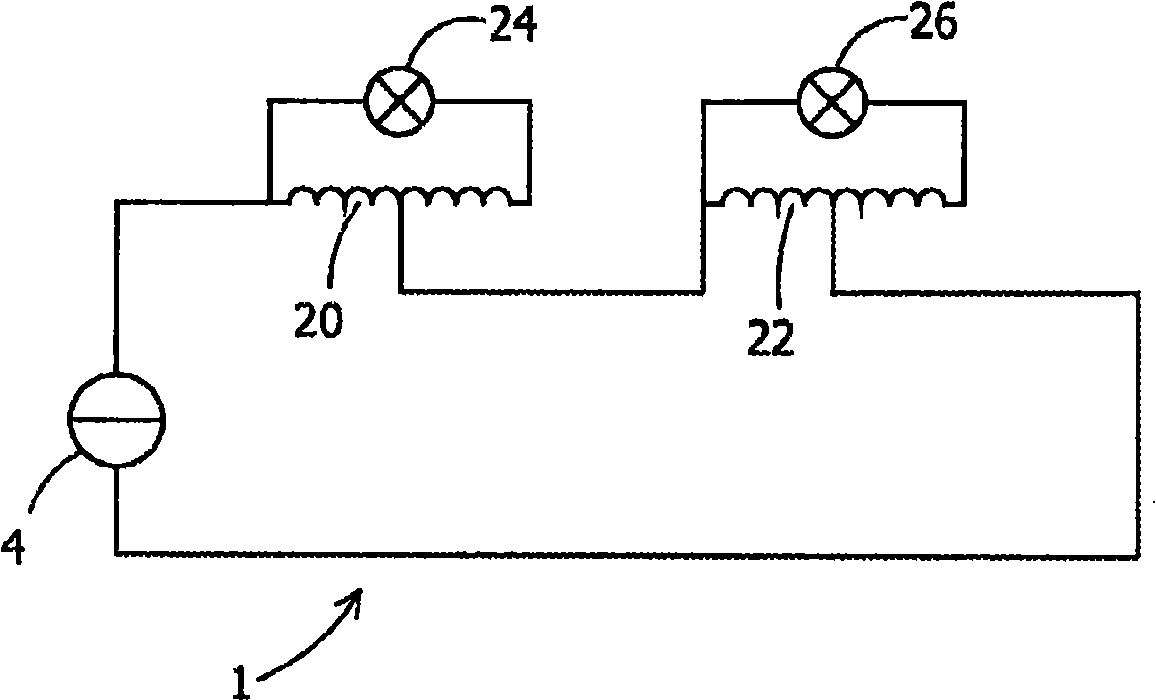

System and method for operating a gas discharge lamp and method of use thereof

InactiveCN101322445AReduced parts countReduce production and labor costsElectrical apparatusElectric lighting sourcesCurrent sourceElectrical and Electronics engineering

The invention relates to a system for operating at least one gas discharge lamp comprising: a square wave current source for producing a substantially square wave current; and at least one transformer having a primary winding and at least one secondary winding; the at least one secondary winding being connectable to at least one gas discharge lamp; the square wave current source being directly coupled to the primary winding of the at least one transformer for directly providing the square wave current thereto.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

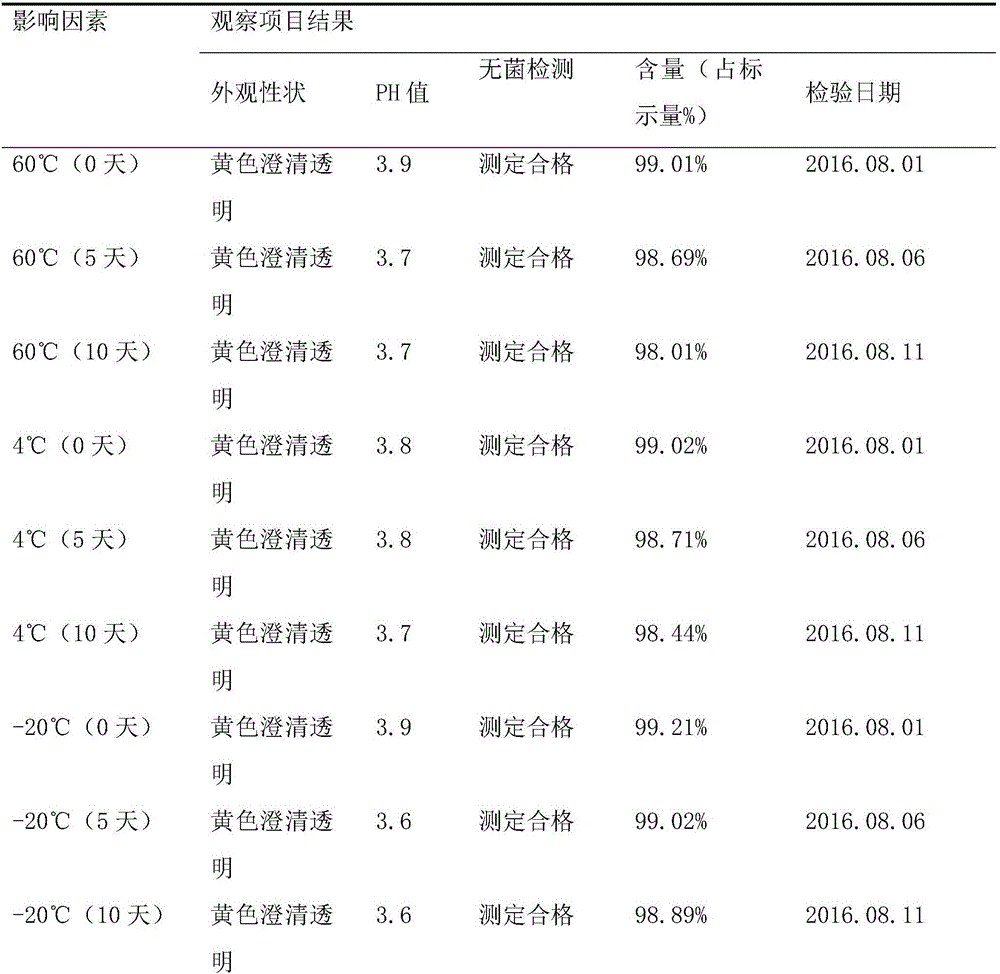

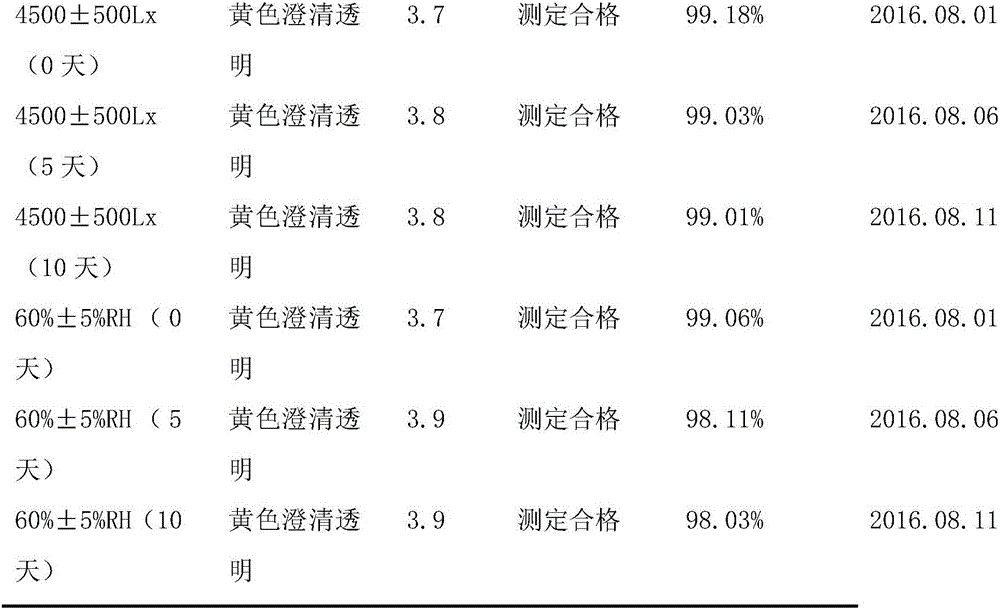

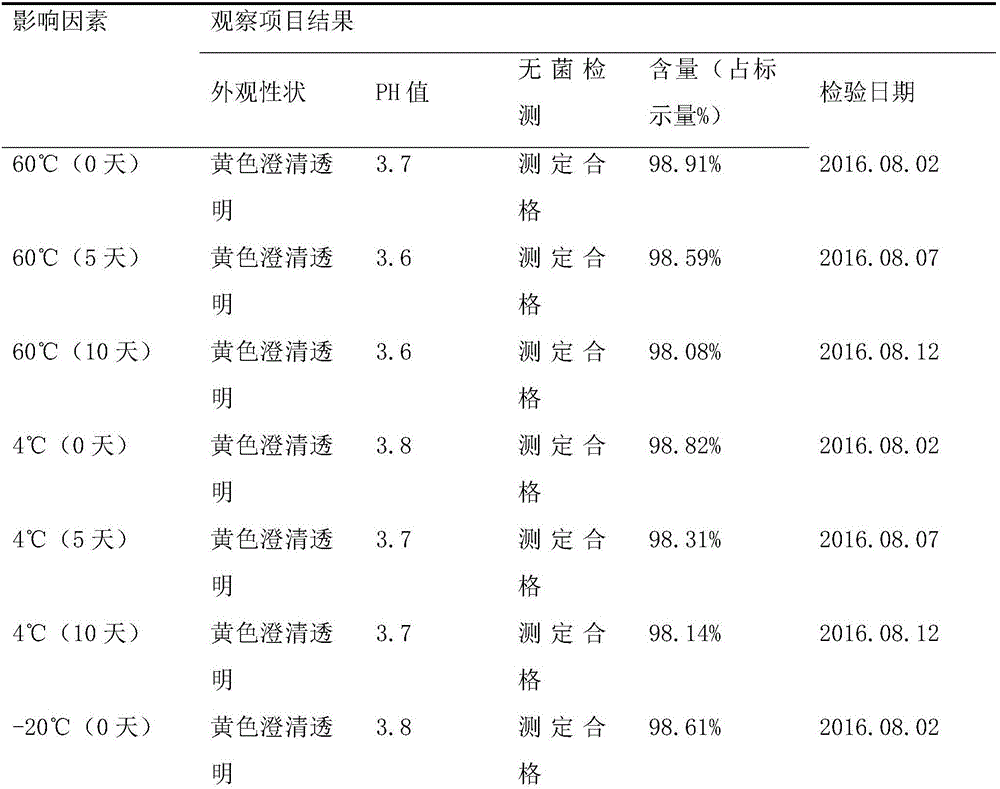

Monepantel oral solution as well as preparation method and application thereof

InactiveCN106821975AStrong specificityNot prone to cross-resistancePharmaceutical delivery mechanismAntiparasitic agentsNematodeBioavailability

The invention provides a monepantel oral solution, which is applicable to both the treatment and the control of nematodes in gastrointestinal tracts of a cow and a sheep, and is particularly quite applicable to the prevention and the treatment for a milk cow. The monepantel oral solution provided by the invention is convenient to use, and can be directly drunk after being diluted according to a proportion. The monepantel oral solution provided by the invention is high in bioavailability and high in parasite expelling effect; medication times can be reduced; thus, the medication cost is decreased. The synergistic effect is obvious; moreover, the monepantel oral solution can be used for expelling and killing parasites of the nematodes, worms and the likes at the same time; therefore, a preparation of the monepantel oral solution is high in practicability, convenient to medicate, and has quite great market potential and competitiveness. The invention also provides a preparation method and application of the monepantel oral solution.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

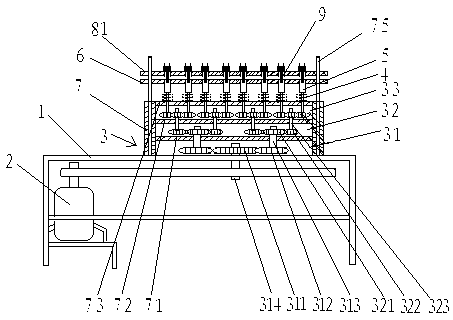

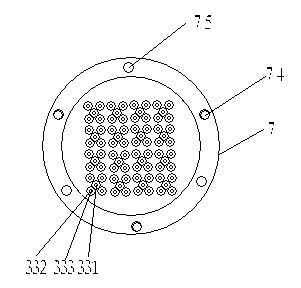

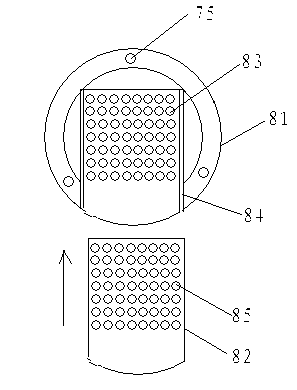

Discharging device for middle circumferential framework inner hole threaded mold

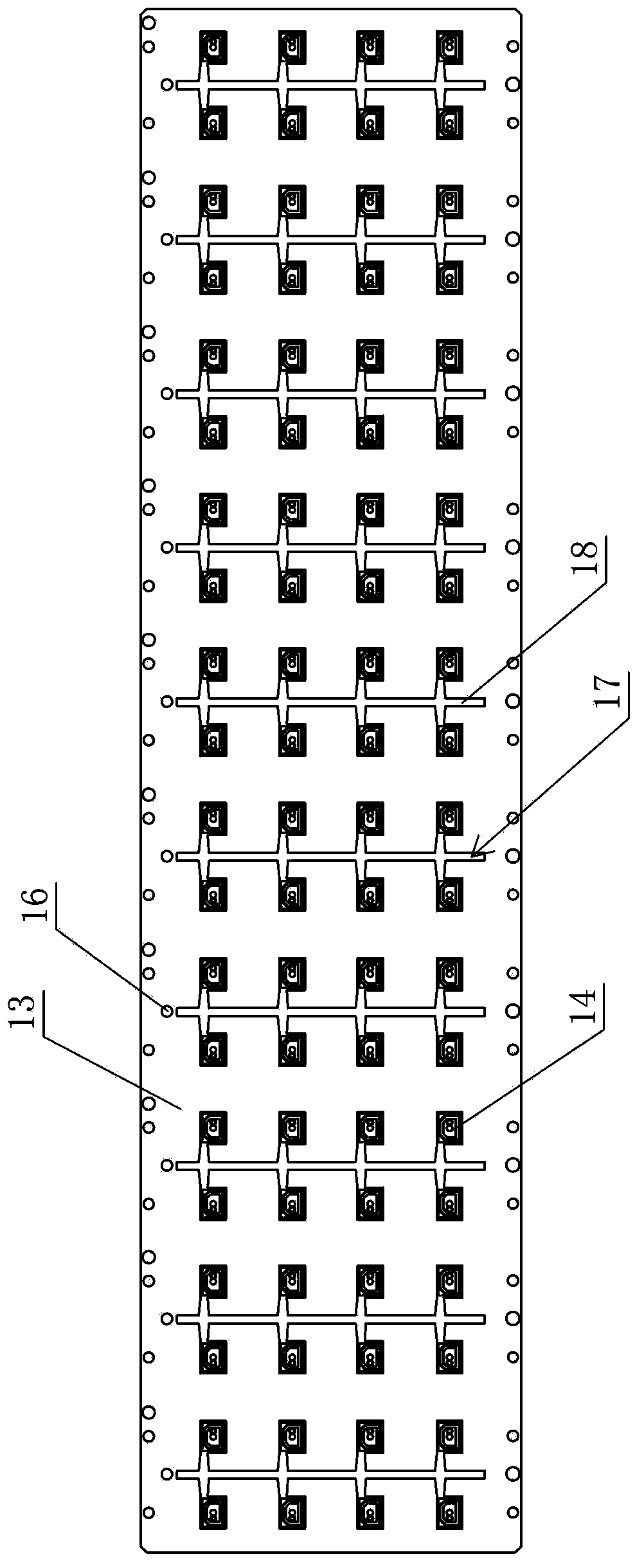

The invention discloses a discharging device for a middle circumferential framework inner hole threaded mold, which comprises a machine station, a motor, a multi-stage gear set transmission mechanism, springs, shaft sleeves and a press plate, wherein the multi-stage gear set transmission mechanism is arranged in an laminated frame above the machine station, and adopts the structure that the driving wheel of a primary gear set is meshed with and used for driving a plurality of driven wheels, the gear shafts of the driven wheels of the primary gear set are connected with the driving wheel of a secondary gear set after penetrating an upper layer baffle plate respectively, the driving wheel of the secondary gear set is respectively meshed with and used for driving a plurality of driven wheels, and multiple stages of gear sets are in transmission connection with each other in sequence stage by stage; after the gear shafts of the driven wheels of the gear set on the upmost layer penetrate the upper layer baffle plate respectively, the springs and the shaft sleeves are sleeved on the gear shafts; holes, through which the middle circumference framework inner hole threaded mold can penetrate, are formed in the press plate and clamped in one-to-one correspondence with the shaft sleeves; the motor is arranged below the machine station; and the gear shaft of the driving wheel of the primary gear set penetrates downwards through the machine station, and is in transmission connection with the motor. According to the invention, the production efficiency is greatly improved.

Owner:HUAIAN HENGXING ELECTRONICS

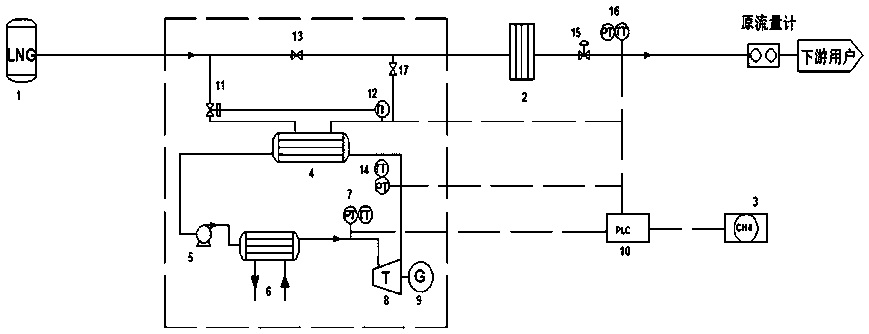

Intelligent small cold energy power generation device and control method thereof

PendingCN108252759AReduce production and labor costsIncrease plant revenueSteam engine plantsSatellitePower generation system

The invention discloses an intelligent small cold energy power generation device and a control method thereof. The intelligent small cold energy power generation device comprises an LNG storage tank,a first stop valve, a gasifier, a pressure adjusting valve, a flow meter, an LNG cold energy transmission system, a cold energy power generation system and an intelligent control system. The LNG coldenergy transmission system comprises a first heat exchanger arranged on a main pipeline in a series connection manner or a side connection manner. The cold energy power generation system comprises a low-temperature pump, a second heat exchanger, an expander and a power generator. The intelligent control system comprises a PLC, a first temperature pressure transmitter, a second temperature pressuretransmitter, a third temperature pressure transmitter, a temperature transmitter, an online methane monitor and an electromagnetic valve, all of which are connected through a circuit. The intelligentsmall cold energy power generation device is simple in structure, is highly integrated, can serve as a power support for a remote powerless and power-shortage satellite station and can also serve asfield station power supply supplementing or an emergency channel when a main pipeline breaks down. The safety automation degree is high, energy industry upgrading is assisted, and good social benefitsare achieved.

Owner:广州莱仑特种装备有限公司 +2

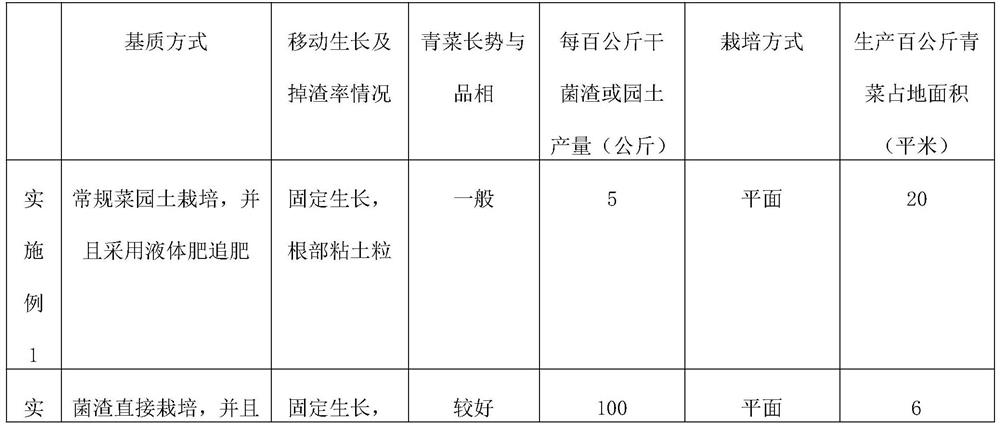

Formed mushroom dreg matrix block

PendingCN112970557ACultivation is simpleClosely connectedGrowth substratesCulture mediaFiberEdible mushroom

A formed mushroom dreg matrix block is prepared from the following raw materials in parts by weight: 70-90 parts of crushed mushroom dregs, 3-10 parts of macromolecular organic plastic particles, 3-5 parts of adhesive chemical short fibers, 3-5 parts of a nitrogen-phosphorus-potassium compound fertilizer and 3-5 parts of other nutrients. In the edible mushroom cultivation process, nutritional ingredients with high nitrogen content, such as bran, cottonseed hulls and soybean meal, and mineral substances, such as gypsum and magnesium sulfate, are added, mushroom dregs remained after edible mushroom cultivation are fully crushed by a crusher, the crushed mushroom dregs are put into a screening machine to screen out mushroom dreg fine powder with the diameter of 1-3 mm, the mushroom dreg fine powder formed after screening, the macromolecular organic plastic particles and the adhesive chemical short fibers are fully stirred at the high temperature of 150-300 DEG C, the mixture is pressed into a required block or container shape through a mold after being stirred while hot, a plurality of holes are formed in the surface of the matrix block, the matrix block is fully dried or air-dried after being cooled and shaped, and finally the formed mushroom dreg matrix block or container is formed.

Owner:丽水市瑞芝食用菌科技有限公司

A single-opening, double-opening Chinese-style armored door and its manufacturing and installation process

ActiveCN105298335BAvoid damage phenomenonSolving the Wasted White Space ConundrumFrame fasteningWindow/door framesEngineeringBuilding construction

The invention discloses a single-leaf Chinese-style armored door, which is composed of a door frame, a door leaf, a door lock side wrapping, a hinge side wrapping, a door lock, a hinge and a door core. A double-opening Chinese-style armored door is composed of a door frame, a child and a mother door leaf, a door lock side wrapping, a hinge side wrapping, a door lock, a hinge, a child and a mother door core. A single-opening Chinese-style armored door production and installation process includes the following steps: making a door frame; making a door core; making an edge and a cover plate; assembling the door frame and door core; making a decorative panel; assembling a decorative panel. A production and installation process of a double-opening Chinese-style armored door, comprising the following steps: making a door frame; making child and mother door cores; making wrapping and cover plates; assembling the door frame and door core; making child and mother decorative panels; and assembling decorative panels. The invention solves the door panel damage phenomenon in the cross construction process; solves the secondary waste of replacement and maintenance of the whole door after damage, and is beneficial to environmental protection; the production and construction procedures are simplified, the labor cost is reduced by 40%, and the sealing, sound insulation and heat insulation effects are improved it is good.

Owner:上海璞玉门业有限公司

A device for detecting the length and inclination of a single crystal silicon rod and its detection method

ActiveCN107764188BLow efficiencyHigh measurement accuracyUsing optical meansIncline measurementEngineeringMonocrystalline silicon

Owner:杭州慧翔电液技术开发有限公司

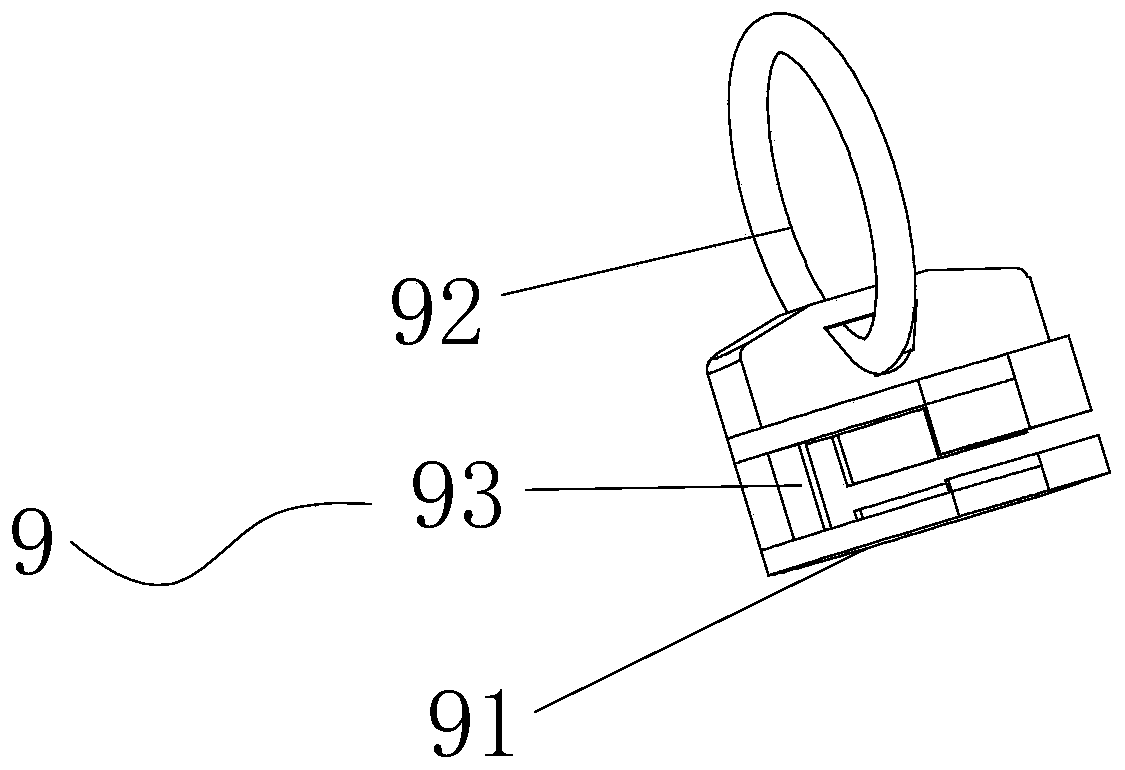

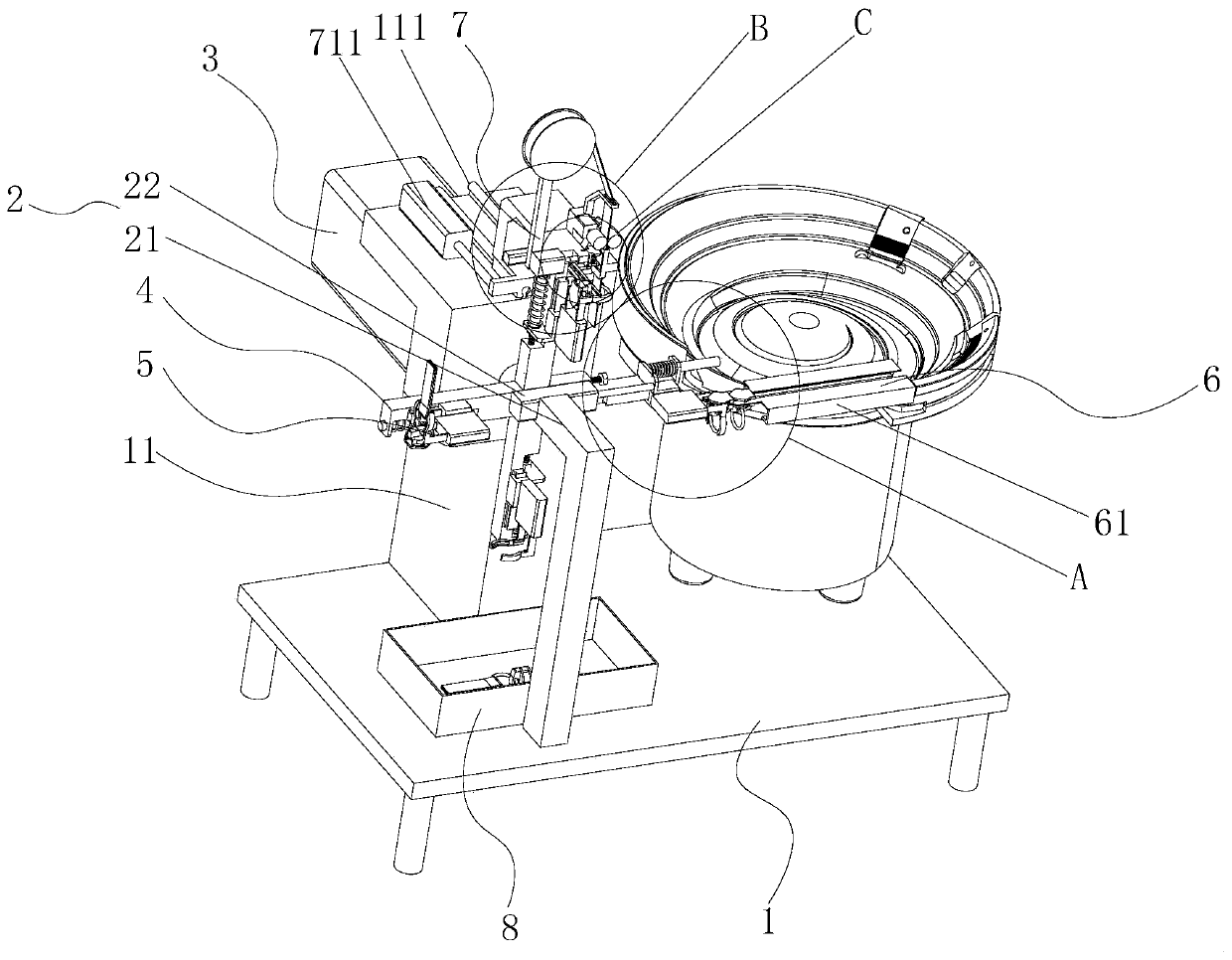

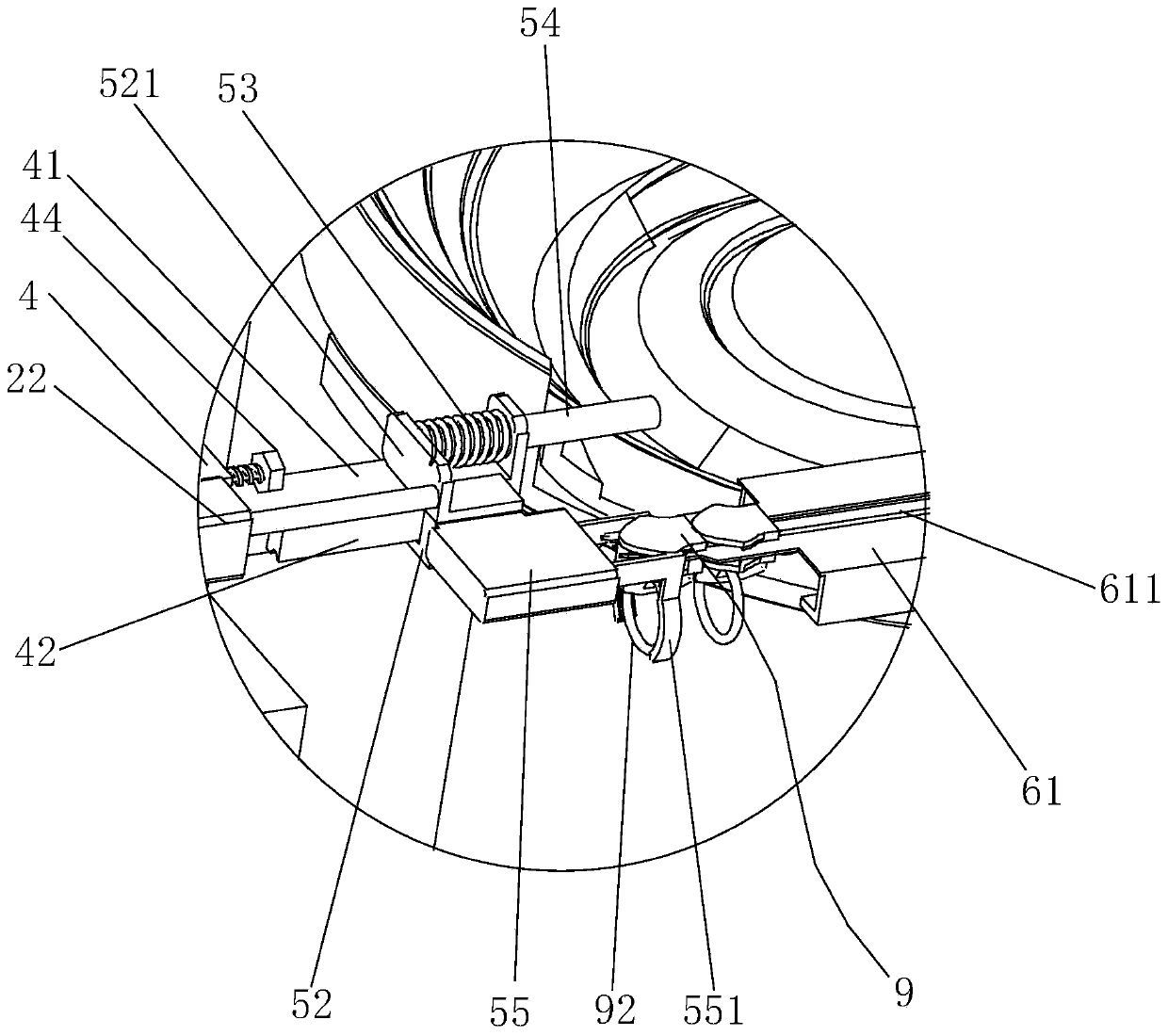

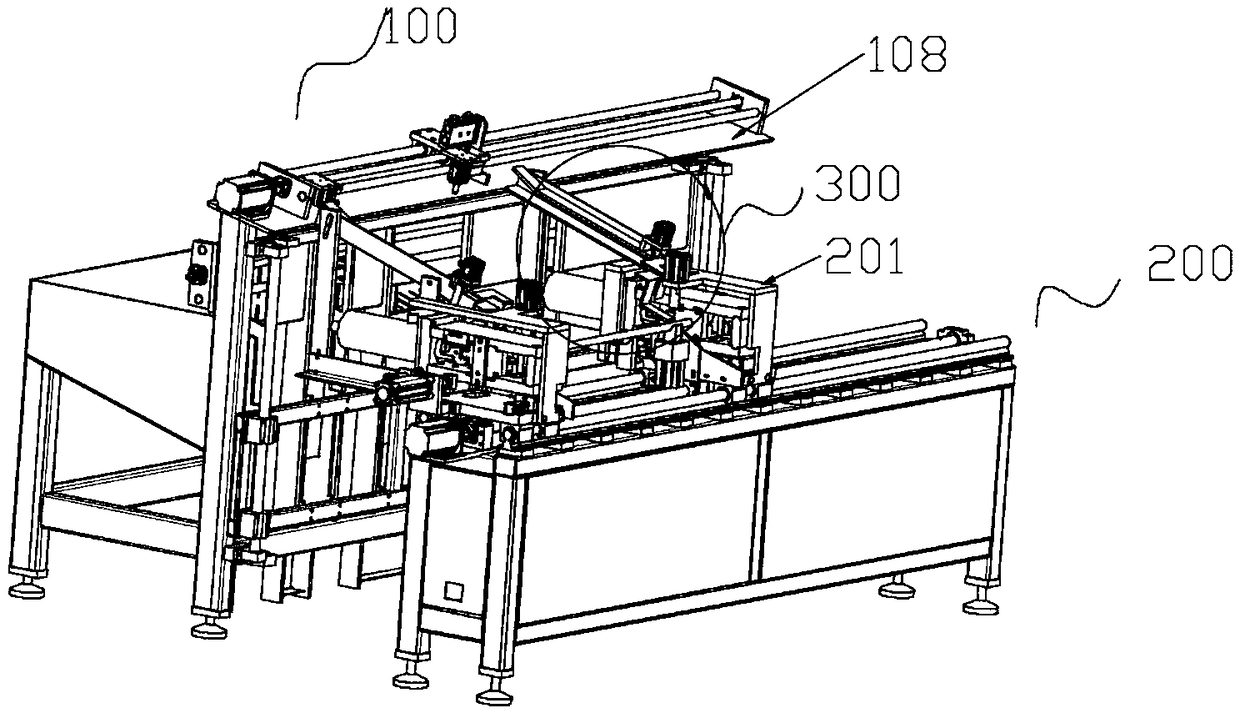

Automatic cloth tape loading machine for zipper heads of bags and suitcases

ActiveCN111232634AReduce process waiting timeImprove efficiencyConveyor partsElectric machineryEngineering

The invention discloses an automatic cloth tape loading machine for zipper heads of bags and suitcases. The automatic cloth tape loading machine is used for enabling the zipper heads to pass through cloth tapes. The zipper head comprises a pull ring and a guide post. The automatic cloth tape loading machine comprises a machine table, a first support, a rotating motor, a second support, an input mechanism, a cloth tape output mechanism, a plurality of pickup mechanisms, an auxiliary pushing mechanism and a shaping mechanism. According to the technical scheme, the input mechanism is ingeniouslyused for inputting the zipper heads, and then the pickup mechanisms arranged on the second support cooperates with a first pushing air cylinder on a third support to pick up the zipper heads input bythe input mechanism; the second support is driven to rotate by the rotating motor, so that after the pickup mechanisms pick up the zipper heads on the input mechanism, the pickup mechanisms are drivenby the rotating motor to move to a position below the cotton tape output mechanism, and the cotton tapes output by the cotton tape output mechanism are controlled to pass through the pull rings of the zipper heads clamped on the pickup mechanisms; and the shaping mechanism is used for shaping the cotton tapes, so that the cotton tapes are folded and are restrained and fixed in the pull rings of the zipper heads. The automatic cloth tape loading machine improves the production capacity and reduces the production cost.

Owner:肇庆市丰威实业有限公司

a smfe x Alloy and its preparation method

The invention relates to SmFex alloy and a preparation method thereof. The alloy is composed of, by mass, 20-60% of samarium, 40-80% of iron, less than 0.15% of calcium, less than 0.3% of oxygen, less than 0.02% of aluminum, less than 0.02% of magnesium, less than 0.05% of silicon, less than 0.05% of carbon, less than 0.01% of nitrogen, and less than 0.01% of remaining impurities, wherein the sum of the mass percents of the elements is 100%. Sm2O3 and SmCl3 are used as raw materials, the metal calcium is used as a reducing agent, iron powder is used as an alloying element, and the SmFex intermediate alloy is prepared through the reduction-diffusion method. Compared with the prior art, the SmFex alloy and the preparation method thereof have the advantages that the process is simple, the cost is low, the production efficiency is high, and the content of the samarium in the alloy is stable and controllable.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

Fabricating method of special last fixing shoe

ActiveCN101543328BSimple processReduce production processing timeInsolesUpperEngineeringWork in process

The invention discloses a fabricating method of a special last fixing shoe, which comprises the following steps: (1) lathing a sized upper with an internal middle base sheet with an iron core fixed at the bottom; (2) driving a toe last into the upper, lathing an outer welt at the edge of the outer side of the bottom of the semi-finished shoe made by the step 1; (3), placing a filling layer at thebottom of the internal middle base sheet and sticking a thin bottom; (4), lathing the thin bottom with the outer welt together; (5), sticking a big bottom; and (6), edging and arranging. The invention leads the shoe-making process to be more convenient without three procedures of lasting, driving nails and edging, shortens the production time, and lowers the input cost of a device and the production labor cost. The invention omits the lasting procedure, accordingly saves the edge leather preserved at the upper because of the lasting, and lowers the material cost. The defects of shoe cap breaking, unsmooth upper, easy crinkling and the like easily caused by the lasting can be avoided, and the quality of the finished shoe can be further improved.

Owner:何树滋

Automatic feeding double arc stamping machine

PendingCN108971370AImprove creative designImprove versatilityMetal-working feeding devicesPositioning devicesEngineeringTransverse beam

The invention discloses an automatic feeding double arc stamping machine which comprises a double arc stamping machine body and an automatic feeding device. The double arc stamping machine body is connected with the automatic feeding device through a guide mechanism, the automatic feeding device comprises a rack, a material bin fixed above the rack and a lifting mechanism, the material bin comprises a baffle and a base plate, the rack comprises a first stand column, a second stand column and a plurality of transverse beams, the first stand column is higher than the second stand column, a gap is formed in the end, close to the first stand column, of the base plate, a feeding plate is arranged above the first stand column, and the feeding plate is arranged in an inclined manner; the feedingplate is provided with a first positioning mechanism; and a second positioning mechanism is further arranged on the side wall of the first stand column, and the first positioning mechanism is connected with the second positioning mechanism through an adjusting mechanism. By means of the automatic feeding double arc stamping machine, automatic and continuous feeding is achieved, the production efficiency is improved, and labor cost is saved.

Owner:JIANGXI ZENG XIN HUSBANDRY TECH CO LTD

An integrated cascadable optical fiber receiver tuner module

ActiveCN105578158BSimple production processReduce manufacturing costOptical transmission adaptationsElectrical cable transmission adaptationDigital videoIntermediate frequency

Owner:四川九洲智能装备有限公司 +1

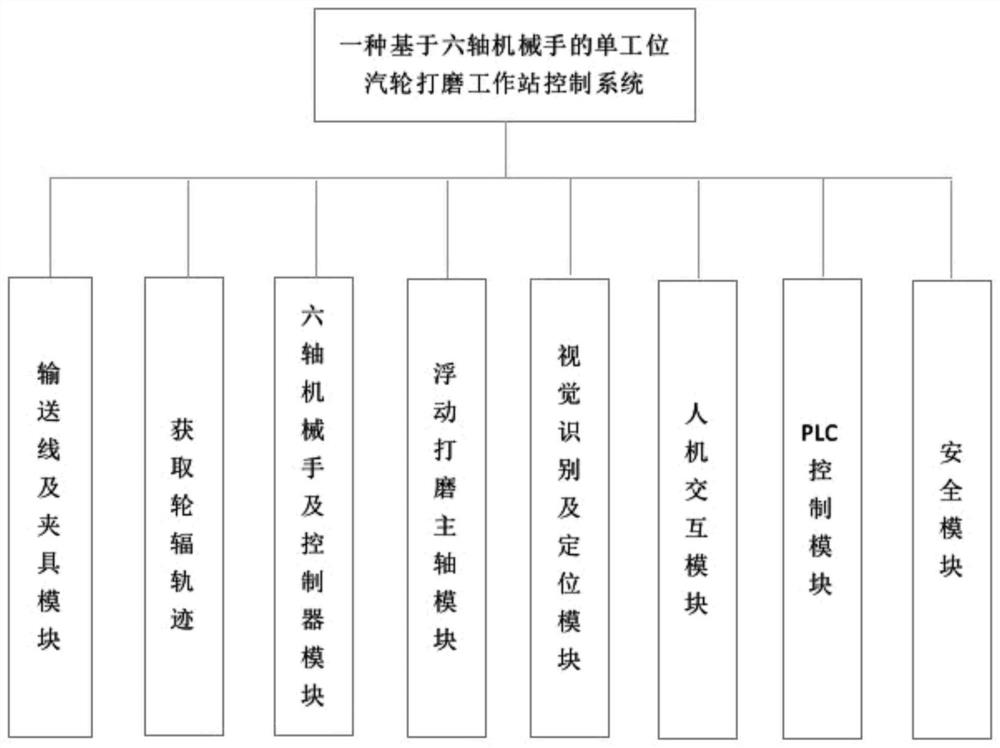

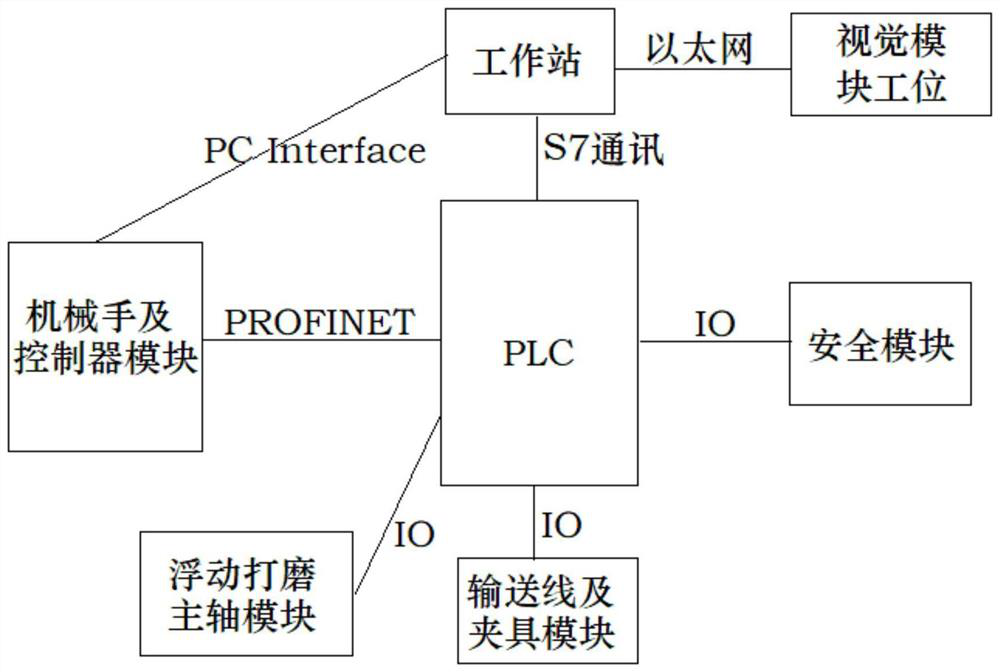

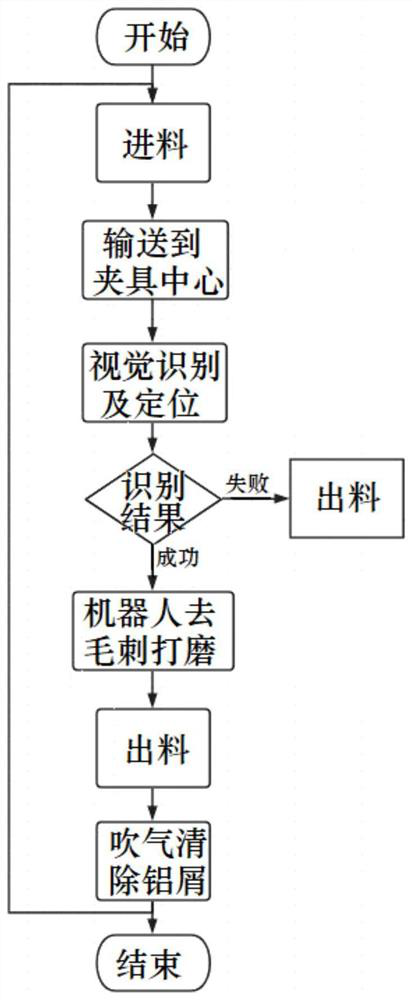

Turbine grinding workstation control system based on industrial robot

PendingCN114227434AIncrease productivityAvoid harmEdge grinding machinesAutomatic grinding controlDevice formControl system

The invention discloses a steam turbine polishing work station control system based on an industrial robot, a manipulator is arranged in a work station, a polishing module is fixed on the manipulator, and a conveying line extends into the work station from the outside of the work station and is used for conveying a hub to be polished into and out of the work station. The end portion of the conveying line in the work station is provided with a clamp used for clamping a hub, the work station is internally provided with a visual identification module used for obtaining hub information, the visual identification module is connected with and outputs induction signals to a PLC, and the PLC is connected with and outputs driving signals to a controller module of the mechanical arm, a polishing module, the conveying line and the clamp. The polishing device formed based on the six-axis mechanical arm is a single-station steam turbine polishing work station control system, manual polishing can be replaced, the polishing efficiency is improved, and the polishing quality is guaranteed.

Owner:哈尔滨工业大学芜湖机器人产业技术研究院

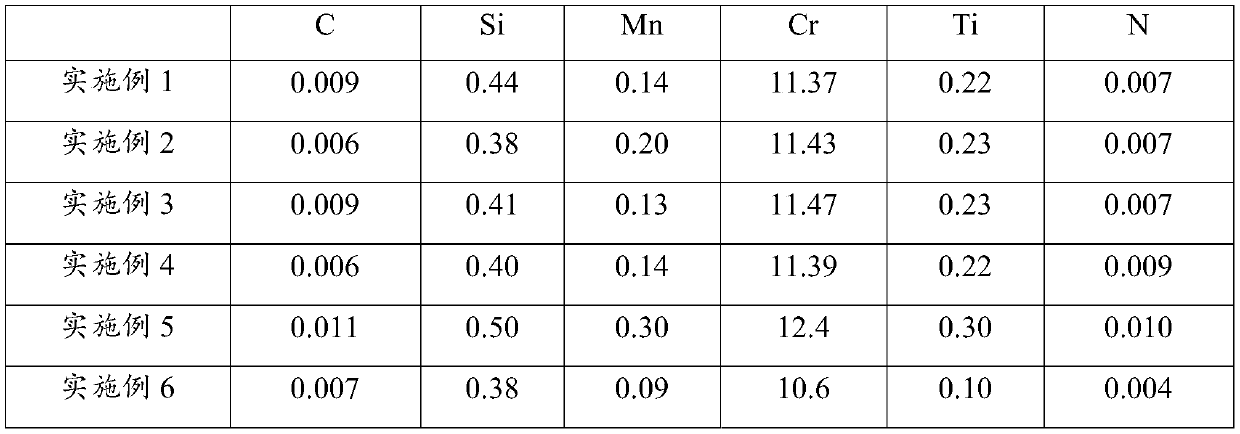

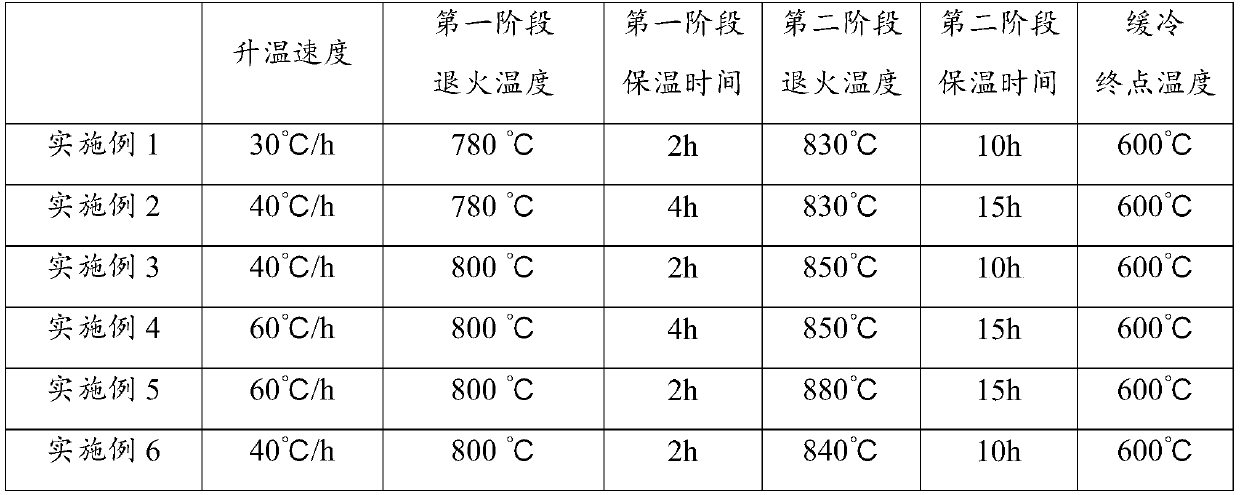

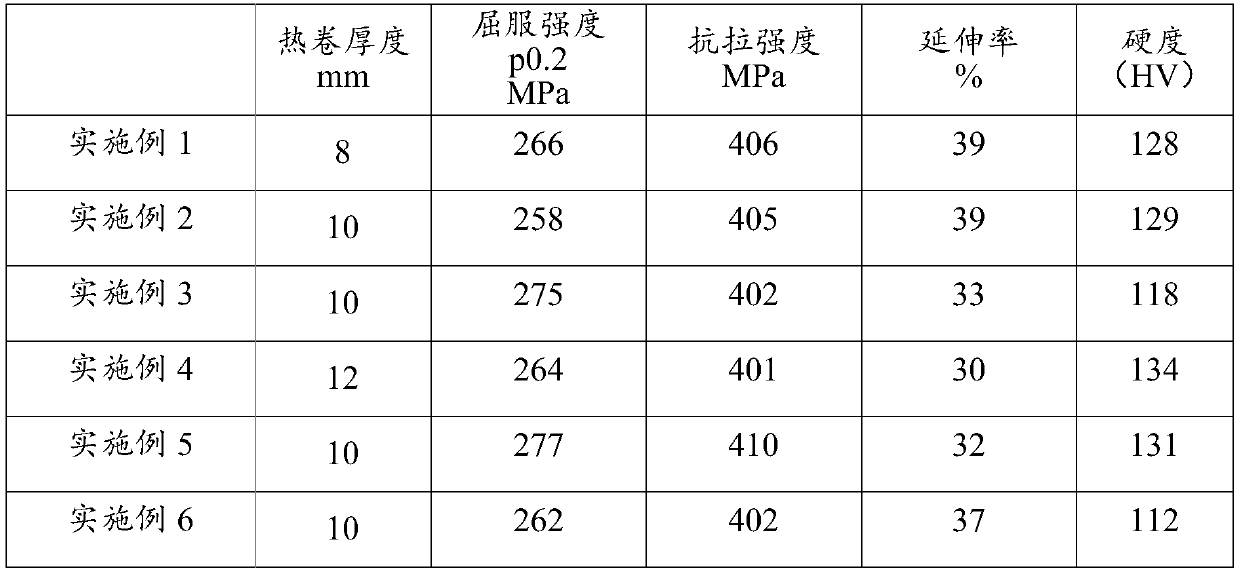

Heavy-gauge low-chromium ferritic stainless steel hot roller blind cover furnace annealing method

InactiveCN110331261AReduce plasticityBrittleBell type furnacesHeat treatment furnacesHardnessSS - Stainless steel

The invention belongs to the technical field of ferritic stainless steel, and particularly relates to a heavy-gauge low-chromium ferritic stainless steel hot roller blind cover furnace annealing method which comprises the following steps of (1) adopting a hot roller blind cover furnace for heating a low-chromium ferritic stainless steel hot roll coil to 750 to 800 DEG C at the speed of 30 to 60 DEG C / h, and preserving heat for 2 to 5 hours; (2) continuously heating the low-chromium ferritic stainless steel hot roll coil to 830 to 880 DEG C, and preserving heat for 10 to 16 hours; and (3) slowly cooling a hot roll coil heat-preservation cover to 500 DEG C to 600 DEG C, rapidly cooling, discharging, and finally obtaining a low-chromium ferritic stainless steel product. According to the heavy-gauge low-chromium ferritic stainless steel hot roller blind cover furnace annealing method provided by the invention, through optimizing a cover furnace annealing technology, the heavy-gauge low-chromium ferritic stainless steel hot roller has a low hardness value and excellent strength.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

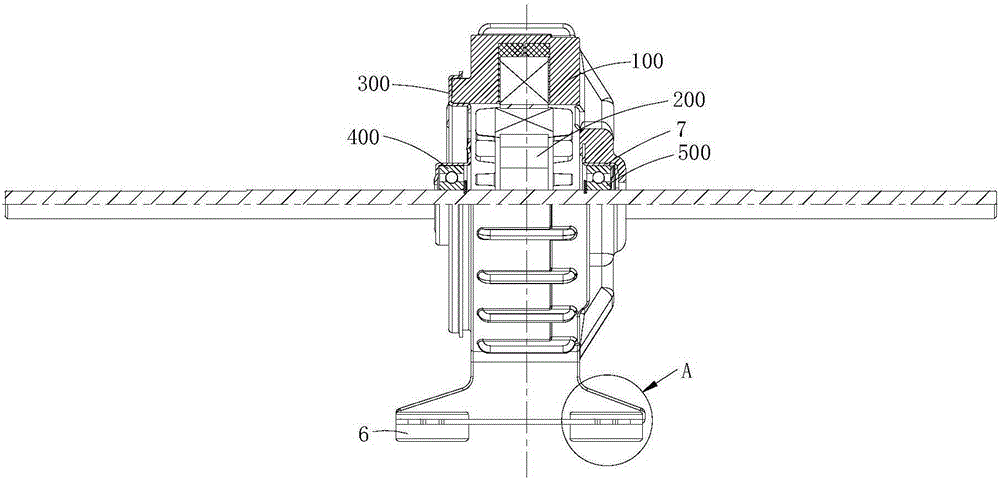

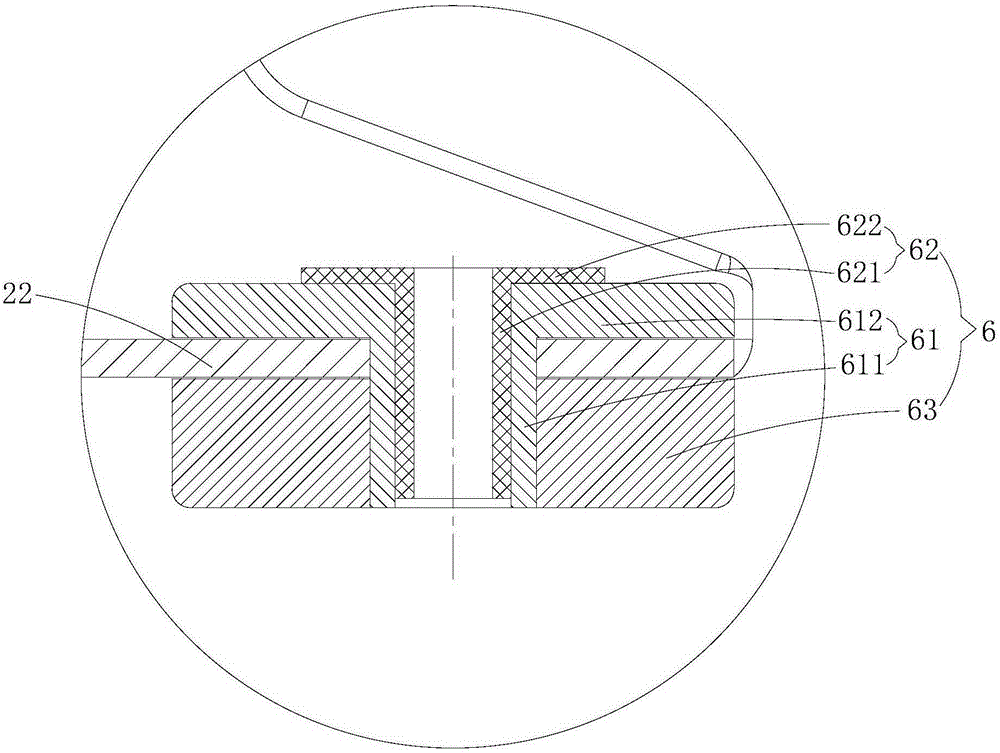

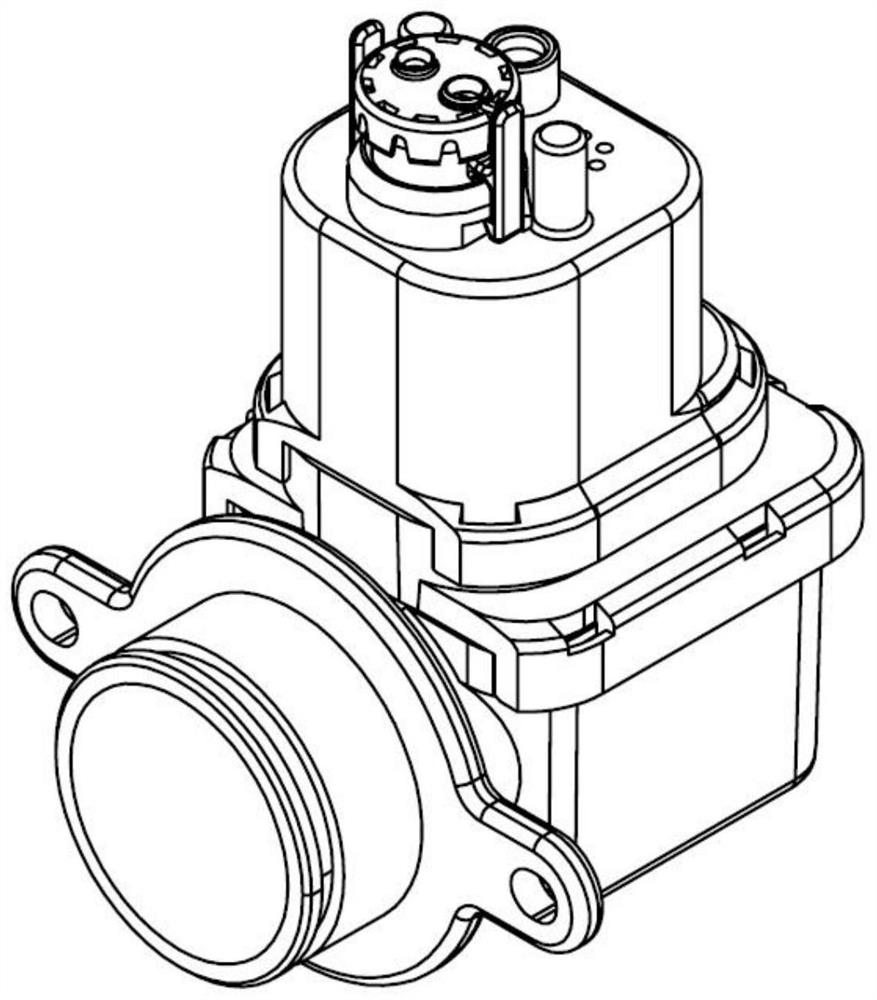

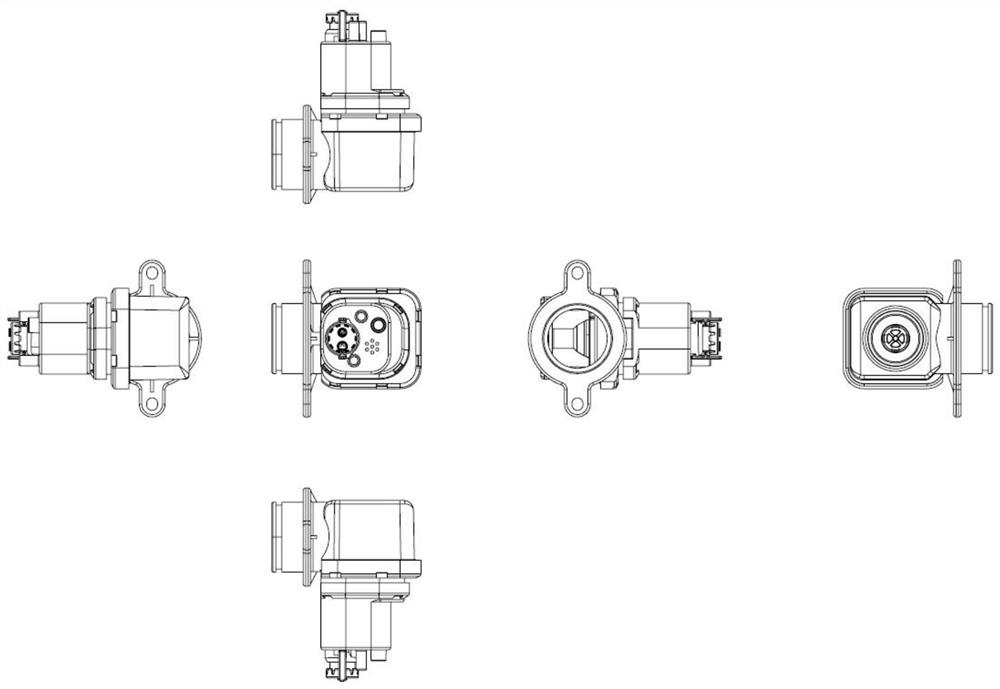

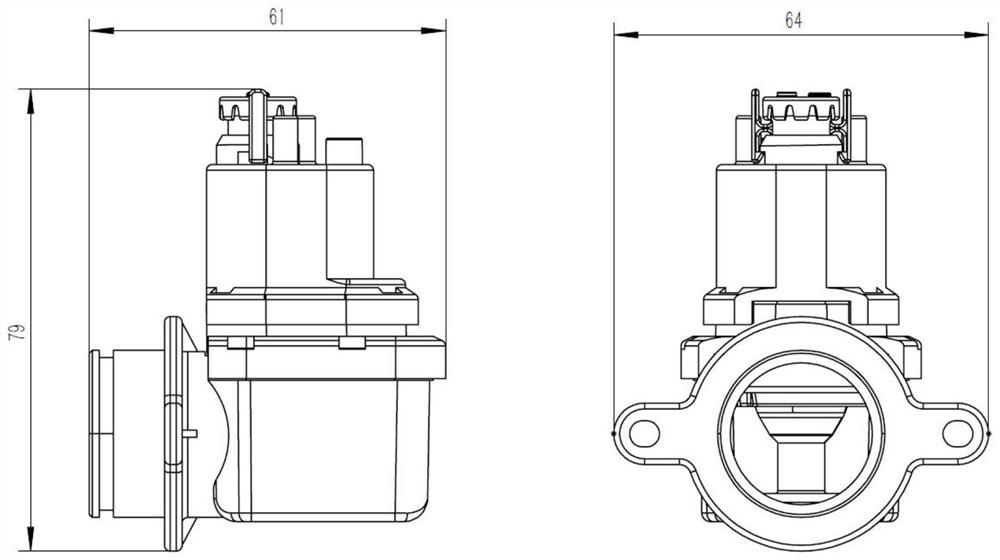

Novel multifunctional gas meter valve

InactiveCN112728194AMonitor temperature in real timeMonitor pressure in real timeEngine sealsOperating means/releasing devices for valvesElectric machineryGas meter

The invention discloses a novel multifunctional gas meter valve. A valve motor is fixed on a valve structure assembly; a PCB fixing adapter support is fixed with the valve motor through a buckle, a temperature and pressure sensor PCB assembly is arranged on the PCB fixing adapter support, and a temperature and pressure sensor and a contact pin are arranged on the temperature and pressure sensor PCB assembly; a temperature and pressure sensor sealing rubber cap and a contact pin sealing rubber cap are arranged on the temperature and pressure sensor and the contact pin respectively; a valve rear cover is buckled with the valve structure assembly; a quick release plug is arranged on the valve rear cover and is matched with the contact pin; and a rubber plug is matched with an air leakage detection hole formed in the valve rear cover for final sealing. According to the novel multifunctional gas meter valve, the temperature and pressure sensing modules are integrated on the basis of basic functions of a valve, temperature and pressure data inside the gas meter can be monitored in real time, the detachable socket design is adopted, production and assembly are more convenient and faster, the process procedure flexibility is improved, the production efficiency is improved, and the production labor cost is effectively reduced.

Owner:ZHEJIANG WEIXING INTELLIGENT METER STOCK

A kind of preparation method of synthetic phosphoric acid ester

ActiveCN110054646BReduce pollutionExtended reaction timeChemical recyclingPhosphorus organic compoundsPhosphoric Acid EstersPtru catalyst

Owner:ZHEJIANG WANSHENG

Chained linear automatic brazing machine for air conditioner silencers

PendingCN111168190AImprove welding efficiencyConsistent welding quality standardsMetal working apparatusTubular articlesControl engineeringProcess engineering

The invention discloses a chained linear automatic brazing machine for air conditioner silencers. The end, away from a first brazing device and a second brazing device, of a rack is a feeding and discharging area A, and the air conditioner silencers are positioned and fixed to tool clamps which are distributed and fixed to a circulating drag chain by a worker in the feeding and discharging area A;the air conditioner silencers are conveyed to the first brazing device and the second brazing device through the circulating drag chain, namely a welding area B is used for synchronously welding an expansion pipe, an air inlet pipe, an expansion pipe and an air outlet pipe of the air conditioner silencers on the tool clamps on the pair of parallel linear conveying sections of the circulating dragchain correspondingly; after the welded air conditioner silencers are linearly conveyed by the circulating drag chain to pass through a cooling area C, namely a linear guide rail area of the rack tobe cooled, a worker takes out the welded air conditioner silencers in the feeding and discharging area A and installs the new air conditioner silencer to be welded; and therefore air conditioner silencer welding machining is continuously and automatically completed, the welding efficiency is high, the welding quality standard is consistent, one-man operation is achieved, and the production labor cost is reduced.

Owner:佛山市高明德健五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com