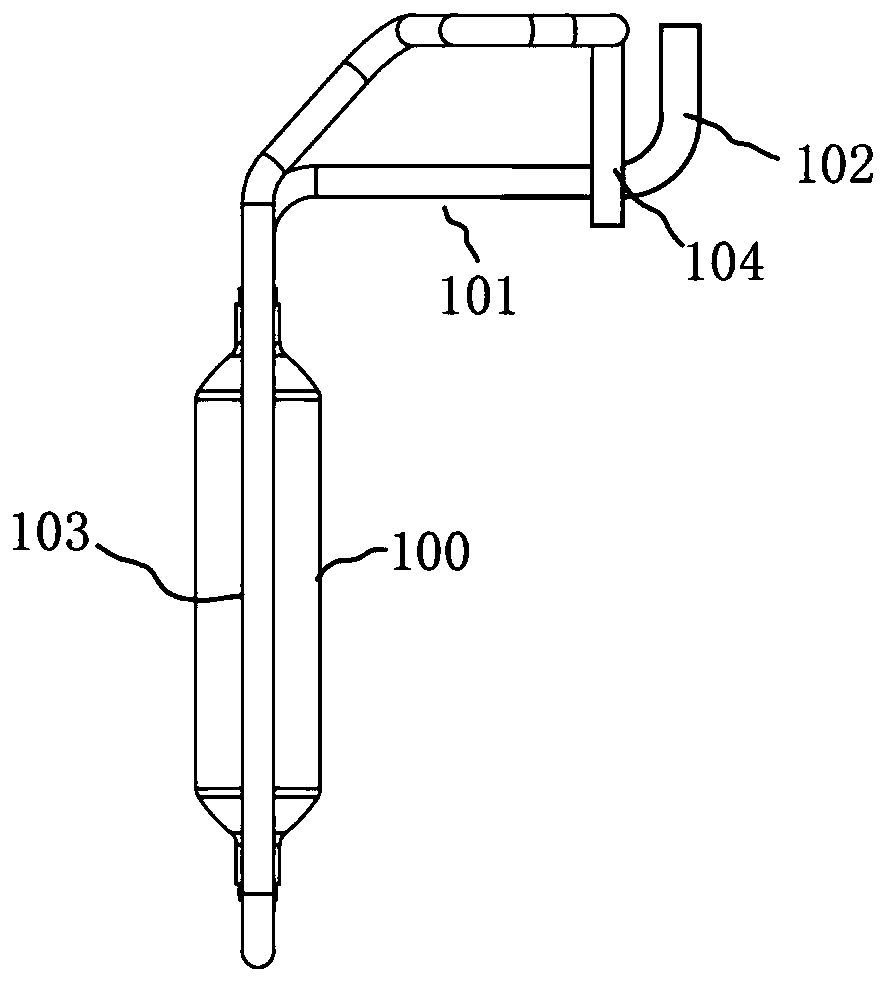

Chained linear automatic brazing machine for air conditioner silencers

A technology of silencer and brazing machine, which is applied in welding equipment, auxiliary devices, applications, etc., can solve the problems of short welding time, poor solder penetration of welding joints, false welding temperature, etc., to achieve high welding efficiency and reduce production labor costs. , Consistent effect of welding quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

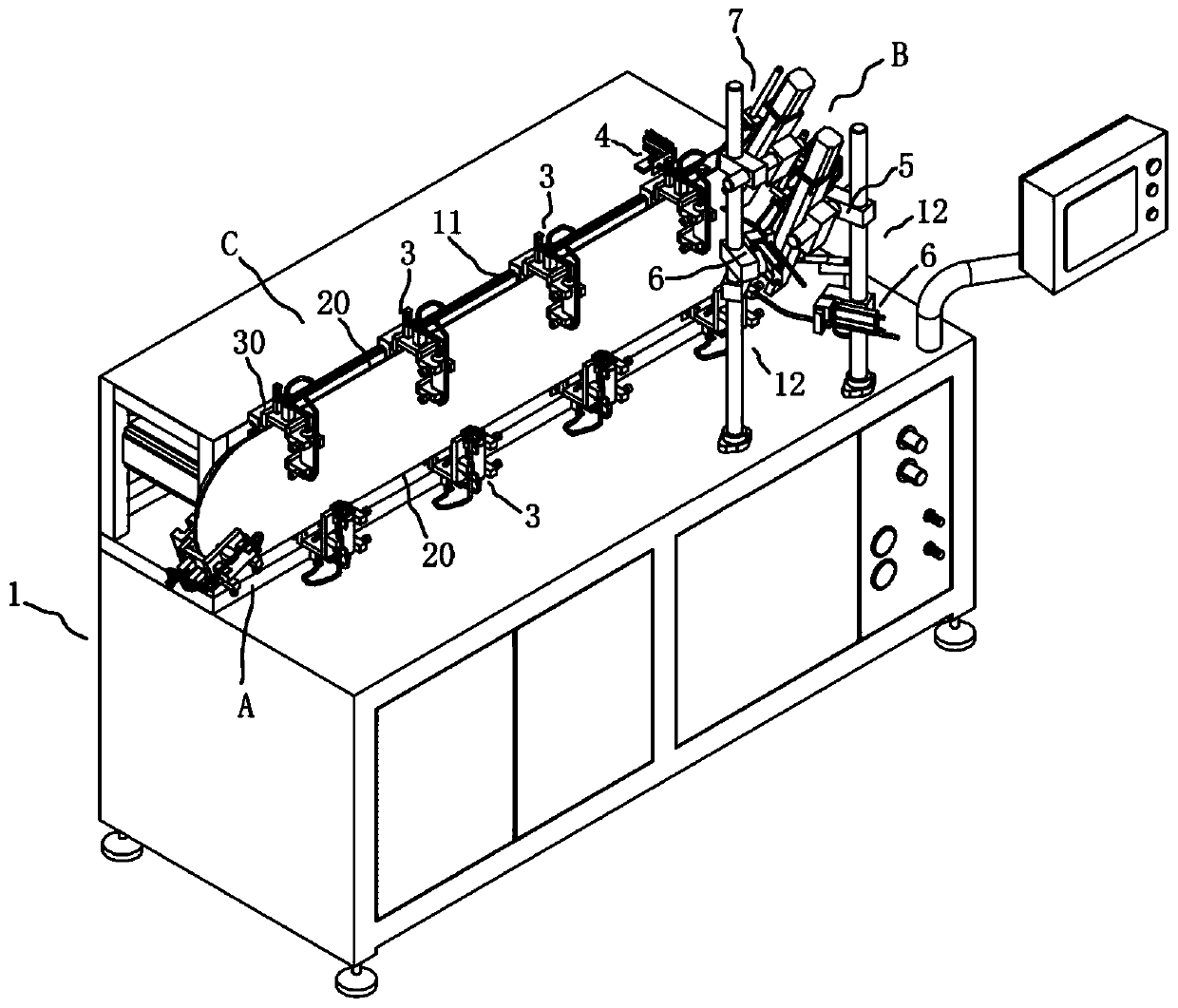

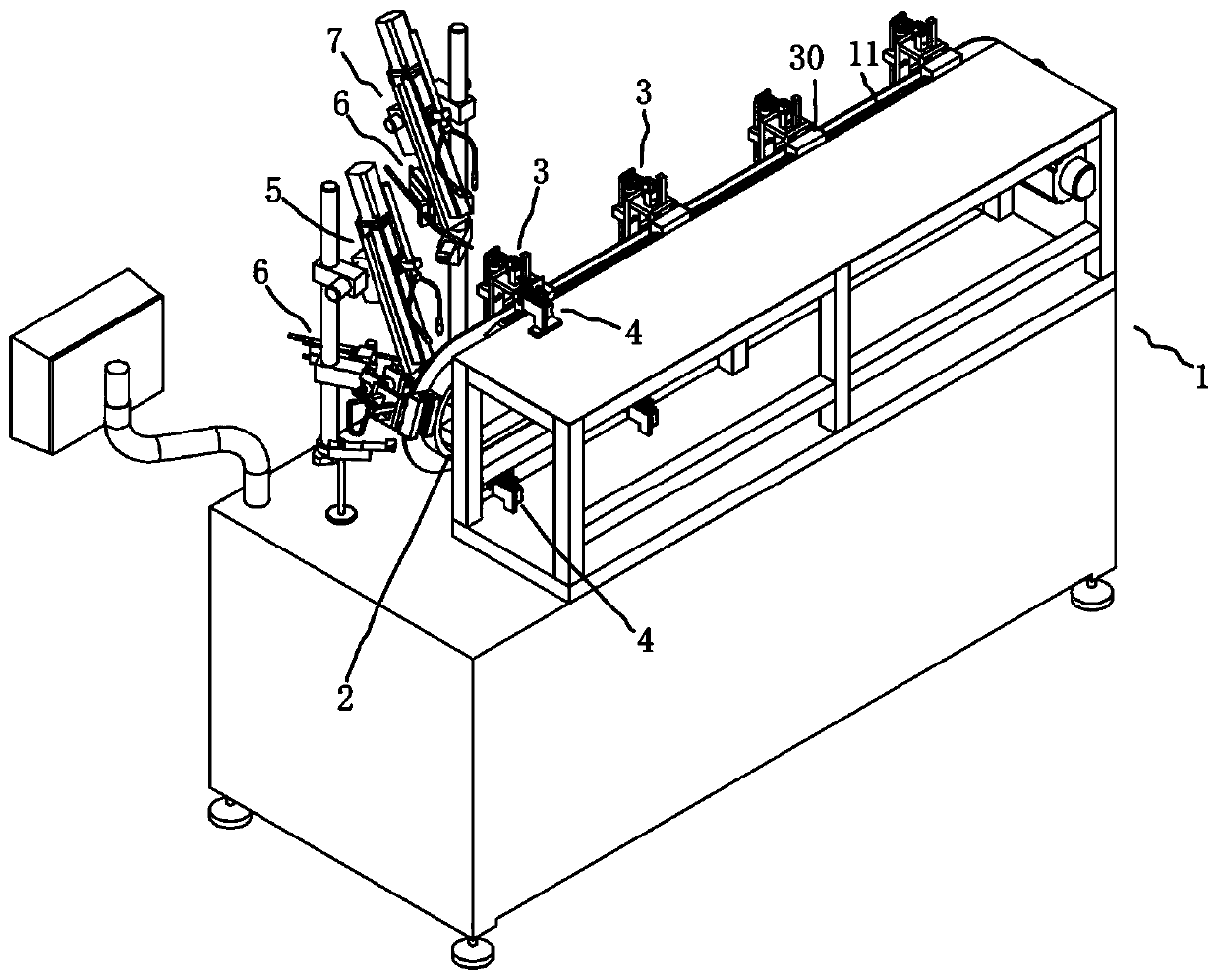

[0025] Hereinafter, the present invention will be further described with reference to the accompanying drawings and specific embodiments to facilitate a clearer understanding of the technical ideas claimed by the present invention.

[0026] Such as Figure 2-10 A chain type linear automatic brazing machine for air conditioner silencer of the present invention is shown, comprising a frame 1, on which a circulating towline 2 is installed, and the circulating towline 2 has a pair of parallel linear conveying sections 20, on the frame 1 The linear guide rail 11 is installed corresponding to the linear conveying section 20, the fixture 3 is uniformly installed on the circulating drag chain 2, and the slide block 30 is installed on the fixture 3, and the fixture 3 on the linear conveying section 20 of the circulating drag chain 2 passes through the slide block 30 It is slidably connected with the linear guide rail 11 to realize the linear conveying movement. The structure of the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com