Automatic cloth tape loading machine for zipper heads of bags and suitcases

A technology of zipper head and cloth tape, applied in the field of automatic tape loading machine, can solve the problems of production and supply unable to meet actual demand, difficulty in ensuring work efficiency, high labor cost, etc., to shorten the waiting time of the process, reduce production labor costs, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

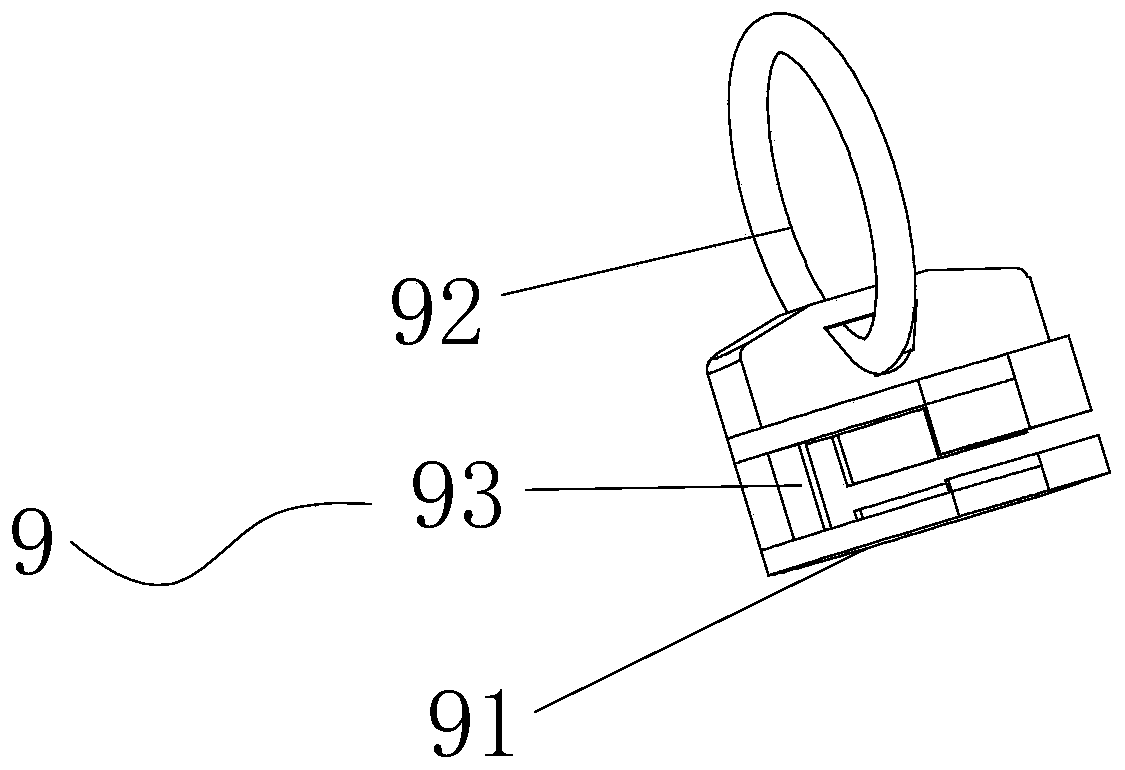

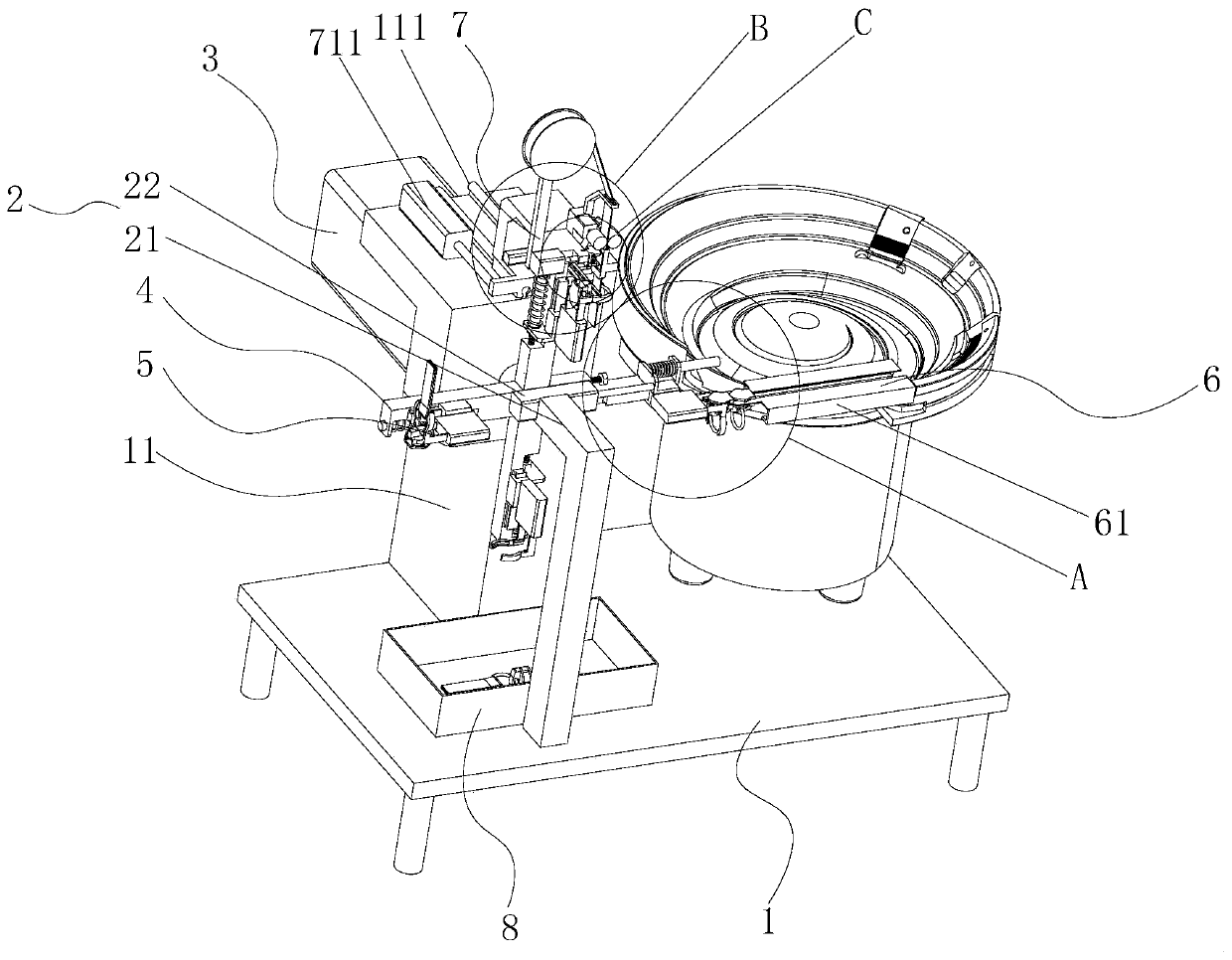

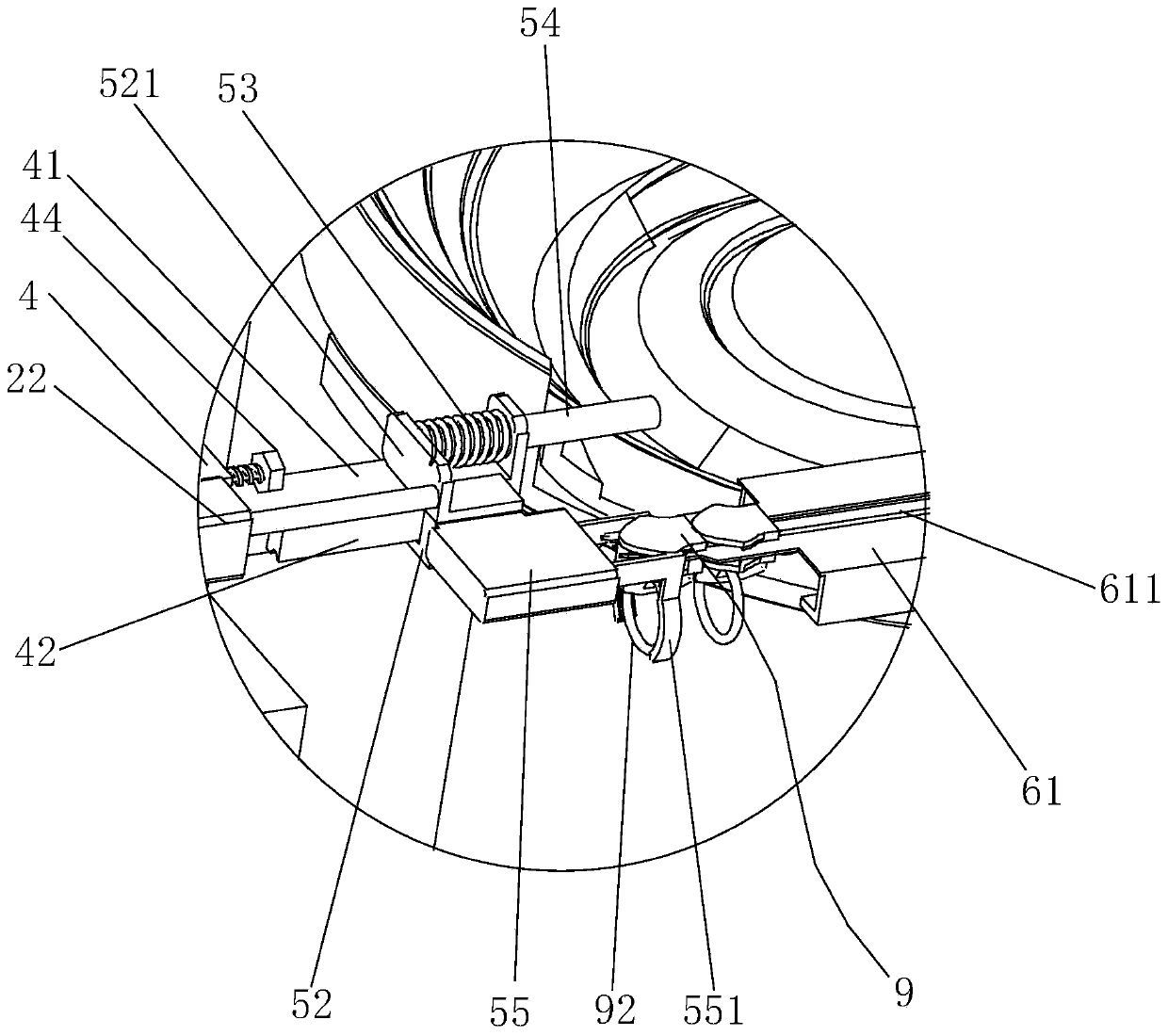

[0051] like Figures 1 to 8 As shown in one of them, the present invention is an automatic tape loading machine for the zipper pull of luggage, and is used for the zipper pull to wear the tape 10. The zipper pull 9 has a pull ring 92 and a guide post 93. The scheme of this embodiment Specifically include:

[0052] machine 1;

[0053] The first bracket 11 is vertically arranged on the upper end surface of the machine table 1;

[0054] The rotating motor 3 is fixed on one side of the first support 11 and its driving end passes through the first support 11 and extends to the other side of the first support 11;

[0055] The second bracket 4 is fixedly connected with the driving end of the rotating motor 3, and the rotating motor 3 drives the second bracket 4 to rotate;

[0056] The input mechanism 6 is arranged on the machine platform 1 and is located on the side of the first bracket 11, its output end faces the second bracket 4 and is used for inputting the zipper puller 9 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com