Method for Ultrasonic Water Vapor Atomization Cooling Aluminum Coil

A water vapor atomization and atomization cooling technology, which is applied to furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of long time and low cooling efficiency of large-diameter aluminum coils, so as to reduce the center of gravity, the treatment method is simple and practical, and the cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

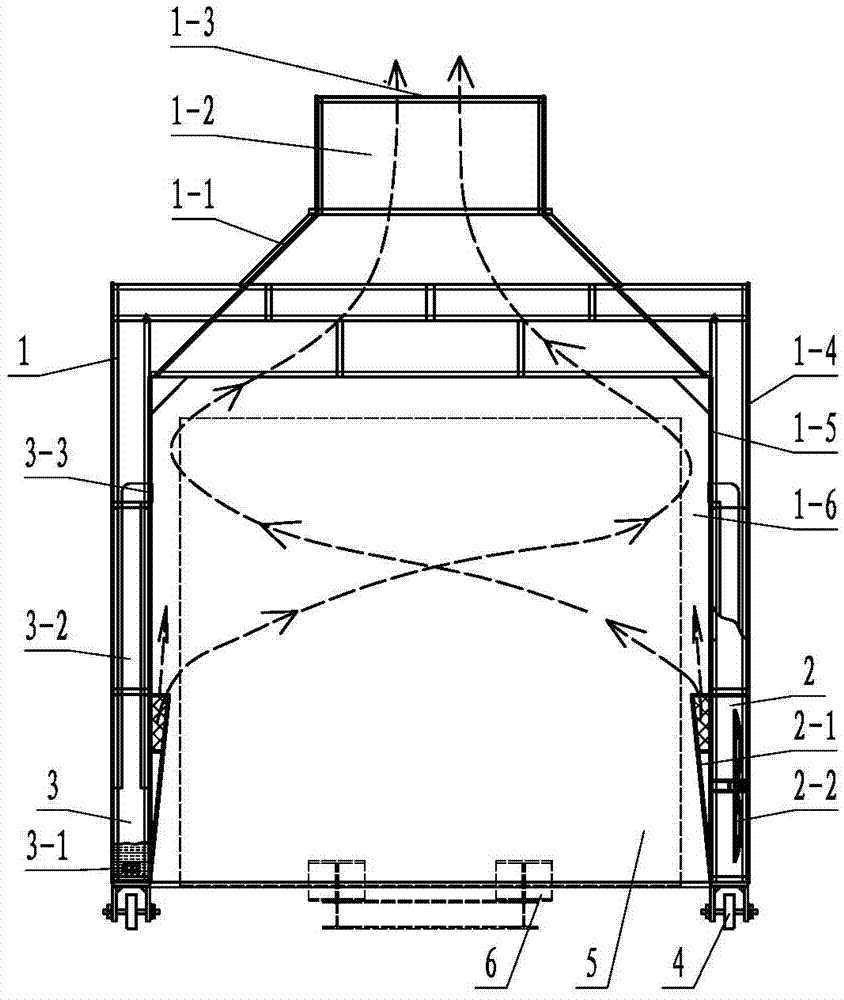

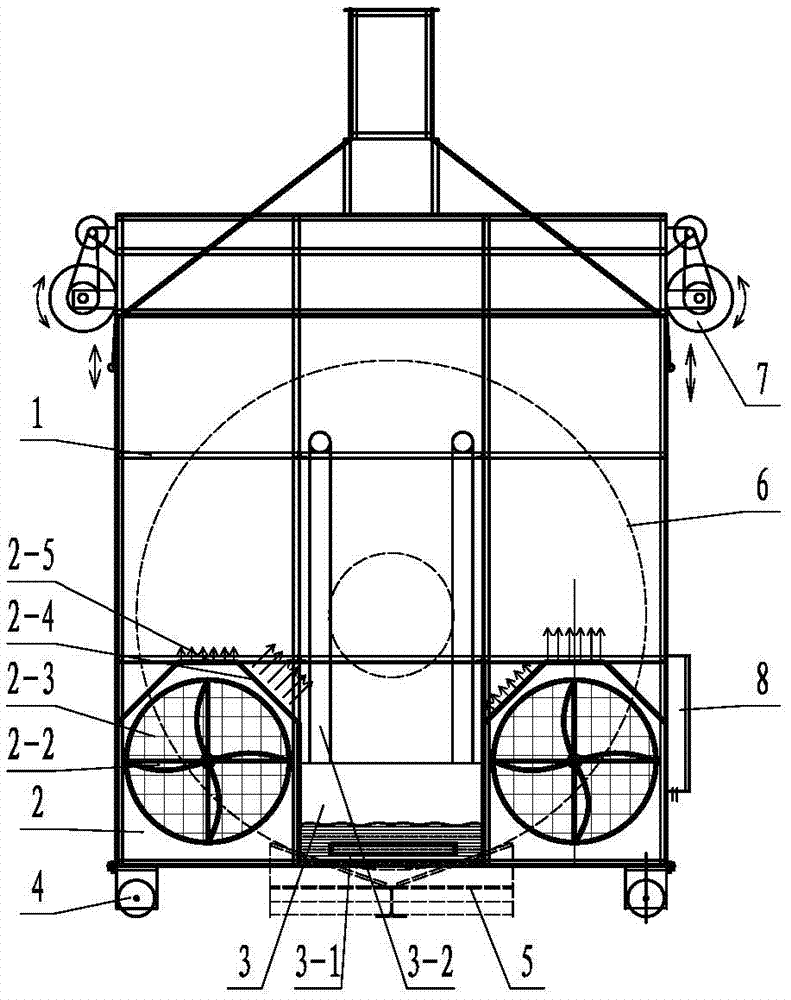

[0027] figure 1 with figure 2 The atomization cooling equipment shown mainly includes a door frame 1 with a cover, a bellows 2, a fan 2-2, a water tank 3, an ultrasonic atomizer 3-1, an atomization nozzle 3-2, a temperature sensor, and a door curtain 7 , Control box 8. The two facing side frames of the portal frame 1 are double-layer and multi-span structures formed by welding angle steel. They are all packaged with aluminum skins to form the outer cover 1-4 and the inner cover 1-5. All the aluminum skins are riveted with aluminum rivets and the angle steel frame. The two sides, the top slope and the exhaust channel 1-2 aluminum skins form an integrated smooth surface. Streamlined airflow guide surface, the inner top surface of the door frame 1 is a conical exhaust guide plate 1-1, the conical exhaust guide plate 1-1 gradually gathers upwards to form a constriction, and the constriction extends vertically upwards to the air exhaust outlet 1 -3 forms the exhaust passage 1-2...

Embodiment 2

[0030]The method of cooling the aluminum coil in this embodiment is as follows: transport the annealed high-temperature aluminum coil to the aluminum coil atomization cooling equipment, measure the temperature of the aluminum coil, and when the temperature of the aluminum coil is greater than 300°C, start the blower and control the air volume to 4000m 3 / h, the air blower blows out from the upper air outlet and side air outlet of the air box from the lower part of the cooling equipment to produce a rotating updraft to cool the aluminum coil, and the hot air formed by the air flow passing through the aluminum coil is discharged from the exhaust outlet on the top of the equipment; when the temperature of the aluminum coil In the range of 150 ~ 300 ℃, keep the air volume at 8000m 3 / h, at the same time, turn on the ultrasonic atomization device to generate mist with atomized particles of 1-3um. When the temperature is lower than 150°C and greater than 130°C, in order to ensure th...

Embodiment 3

[0032] The method of cooling the aluminum coil in this embodiment is as follows: transport the annealed high-temperature aluminum coil to the aluminum coil atomization cooling equipment, measure the temperature of the aluminum coil, and when the temperature of the aluminum coil is greater than 300°C, start the blower and control the air volume to 6000m 3 / h, the air blower blows out from the upper air outlet and side air outlet of the air box from the lower part of the cooling equipment to generate the rotating updraft to air-cool the aluminum coil, and the hot air formed by the air flow passing through the aluminum coil climbs out from the exhaust outlet on the top of the equipment; when the aluminum coil When the temperature is in the range of 150 ~ 300 ℃, keep the air volume at 12000m 3 / h, at the same time, turn on the ultrasonic atomization device to generate mist with atomized particles of 1-3um. When the temperature is lower than 150°C and higher than 130°C, in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com