Plastic package coil motor

A coil motor and coil sealing technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of cumbersome installation process, large number of parts, high material cost, etc., simplify the production process, improve structural reliability, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

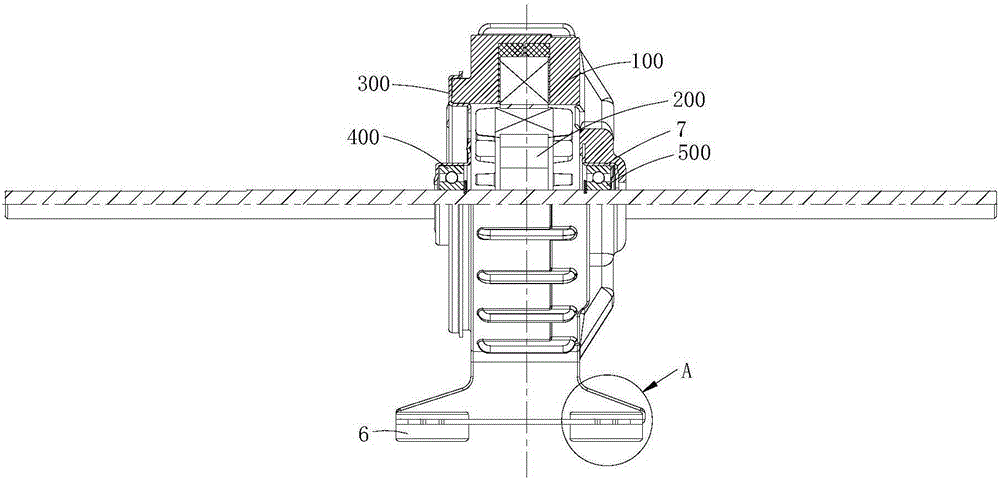

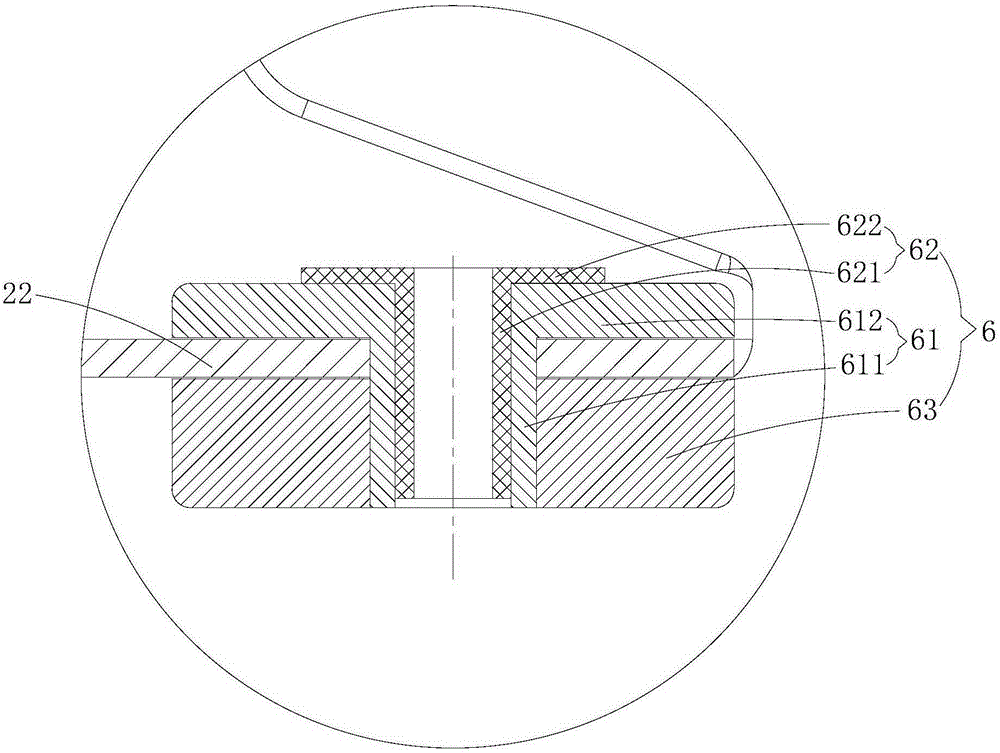

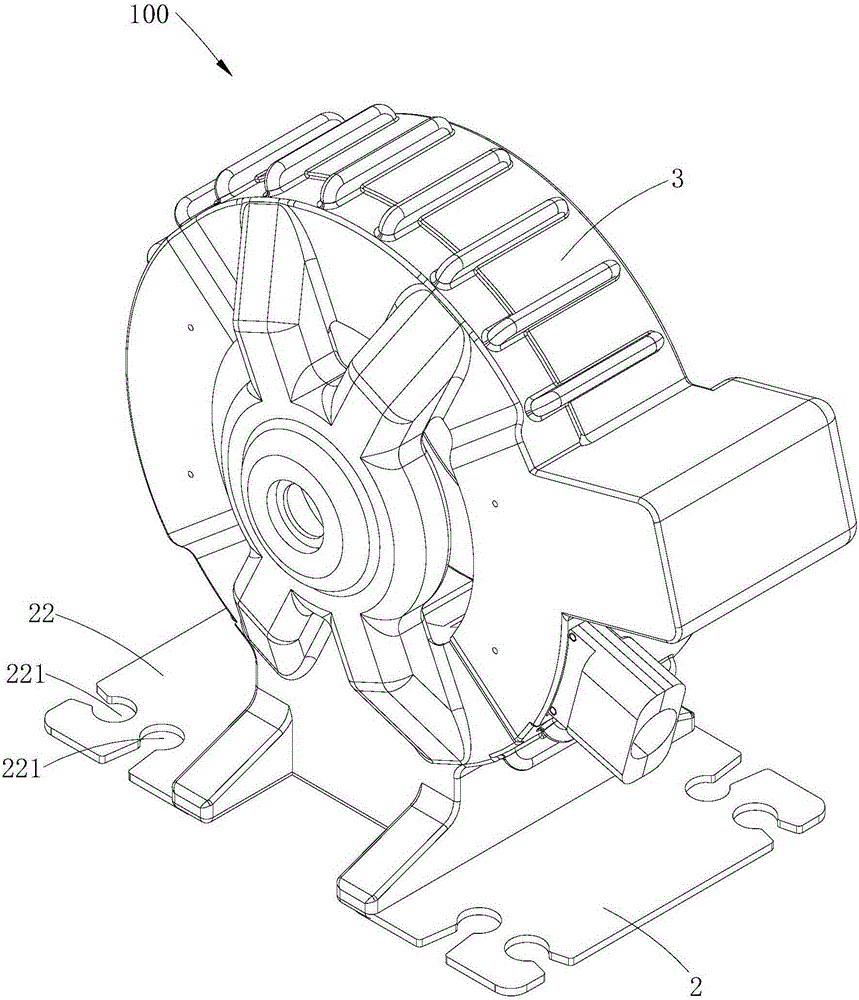

[0031] like Figure 1-5 As shown, the plastic-encapsulated coil motor provided by Embodiment 1 of the present invention includes a plastic-enclosed stator assembly 100, a rotor assembly 200 installed inside the plastic-enclosed stator assembly 100 and rotated with the plastic-enclosed stator assembly 100, and a plastic-enclosed The outer end cover 300 at one axial end of the stator assembly 100 and the outer bearing 400 disposed inside the outer end cover 300, the plastic-encapsulated stator assembly 100 includes a stator assembly 1, a mounting bracket 2 arranged below the stator assembly 1, and a plastic sealing molded on the stator assembly 100. Outside the component 1, the stator component 1 and the mounting bracket 2 are injection-molded into an integral plastic casing 3. The plastic casing 3 is specifically injection-molded by BMC plastic sealing material (bulk molding compound). The mounting bracket 2 includes a The plastic-encapsulated connecting portion 21 and the moun...

Embodiment 2

[0045] like Image 6 As shown, the main difference between the plastic coil motor provided in this embodiment and the first embodiment is that the shape of the mounting bracket 2 is different. Specifically, the same as the first embodiment, in this embodiment, the mounting bracket 2 is also The integrally formed bent plate also includes a middle transverse plate body 211, two vertically folded plate bodies 212 that are bent and extended downward along the two ends of the middle transverse plate body 211, and two vertically folded plate bodies 212 that are respectively extended along the bottom of the two vertically folded plate bodies 212. The horizontally folded plate body 22 extending laterally away from the middle horizontal plate body 211, the middle horizontal plate body 211 and the two vertically folded plate bodies 212 also constitute the plastic sealing connection part 21, and the two horizontally folded plate bodies 22 are also the installation part 22, The length of ...

Embodiment 3

[0049] like Figure 7 As shown, the main difference between the plastic coil motor provided in this embodiment and the first embodiment is that the shape of the mounting bracket 2 is different. Specifically, in this embodiment, the mounting bracket 2 is not a bent plate, but integrally formed For the flat plate, the middle part of the flat plate is a plastic sealing connection part 21 , and the two ends of the flat plate are installation parts 22 . In this embodiment, the installation bracket 2 is set as a flat plate, which can also realize the separate connection of the installation bracket 2 and the plastic casing 3 and the installation structure of the application. Compared with Embodiment 1, the combination reliability of the mounting bracket 2 and the plastic casing 3 in this embodiment is slightly worse, but the mounting bracket 2 in this embodiment has a simple structure and is easier to manufacture and shape.

[0050] Preferably, the middle part of the plate is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com