Bucket cover punching locking production system

A production system and barrel cover technology, applied in metal processing, assembly machines, household appliances, etc., can solve the problems of high production labor costs, inability to meet the large-volume demand for metal packaging steel barrels, and low production capacity, so as to reduce production labor costs , improve processing accuracy and production capacity, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

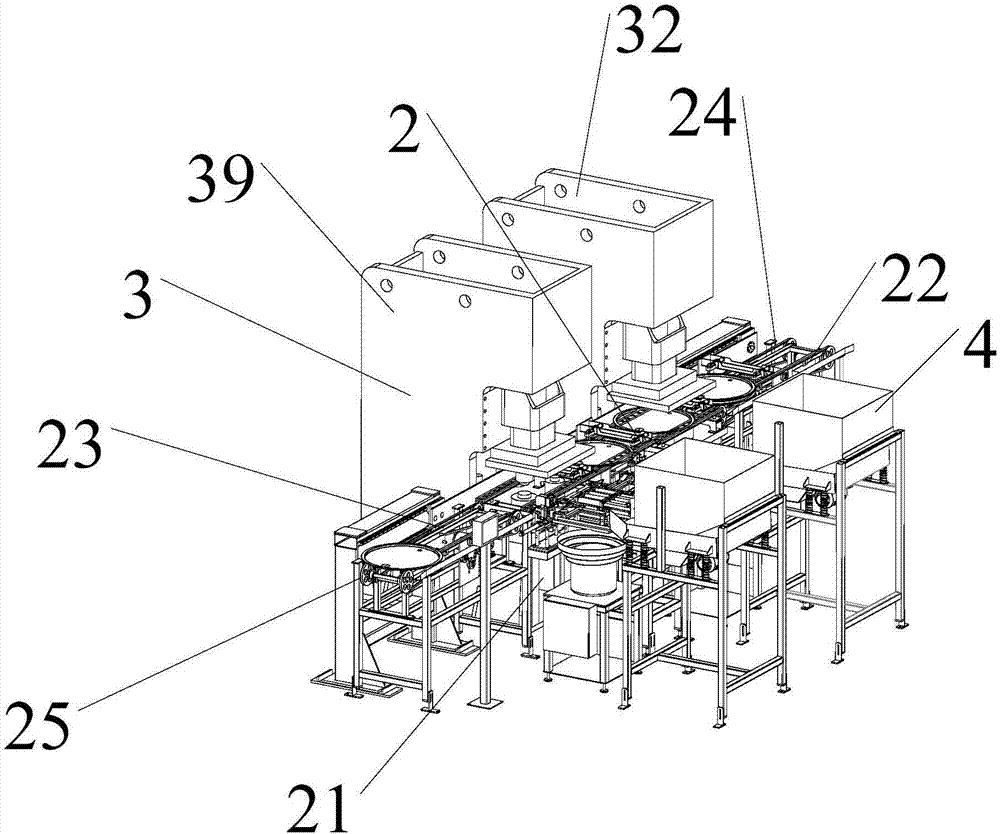

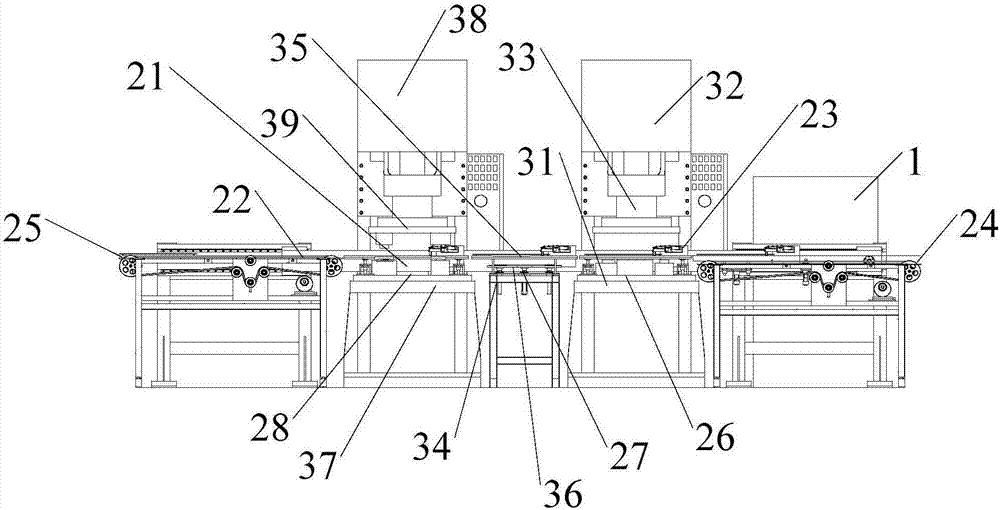

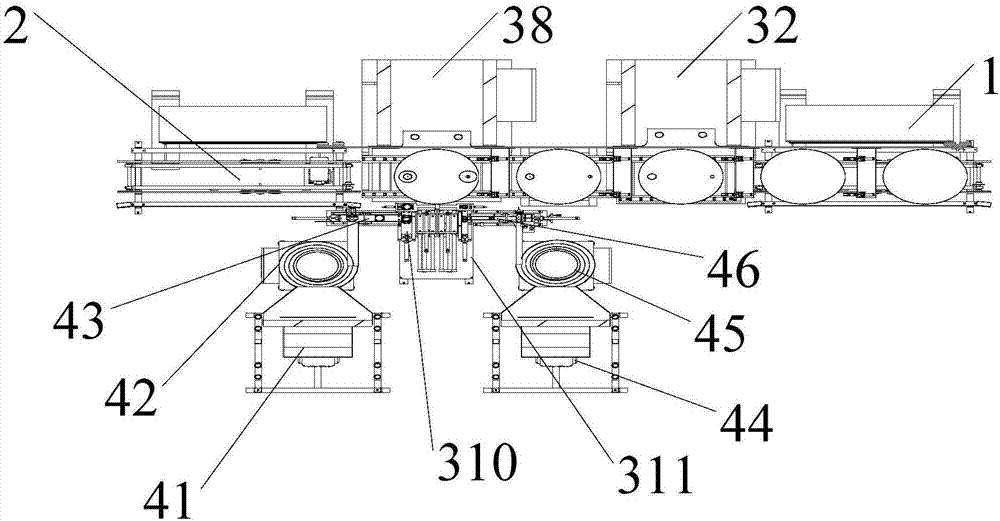

[0014] Such as Figure 1 to Figure 3 As shown, the bung punching and locking production system of the present invention comprises an electric control cabinet 1, a bung conveying module 2, a bung processing module 3, a feeding module 4, a bung conveying module 2, a bung processing module 3, and a feeding module 4 Both are connected with the electric control cabinet 1. The lid punching lock production system controls the lid conveying module 2, the lid processing module 3, and the feeding module 4 through the electric control cabinet 1. The lid conveying module 2 includes a system base 21 and a slide rail. 22. Top cover step transfer device 23, entrance connecting belt conveyor 24, exit connecting belt conveyor 25, first station sensor 26, second station sensor 27, third station sensor 28,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com