Automatic pipe feeding system

A pipe system and automatic technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as harsh working environment, high labor costs, and affecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

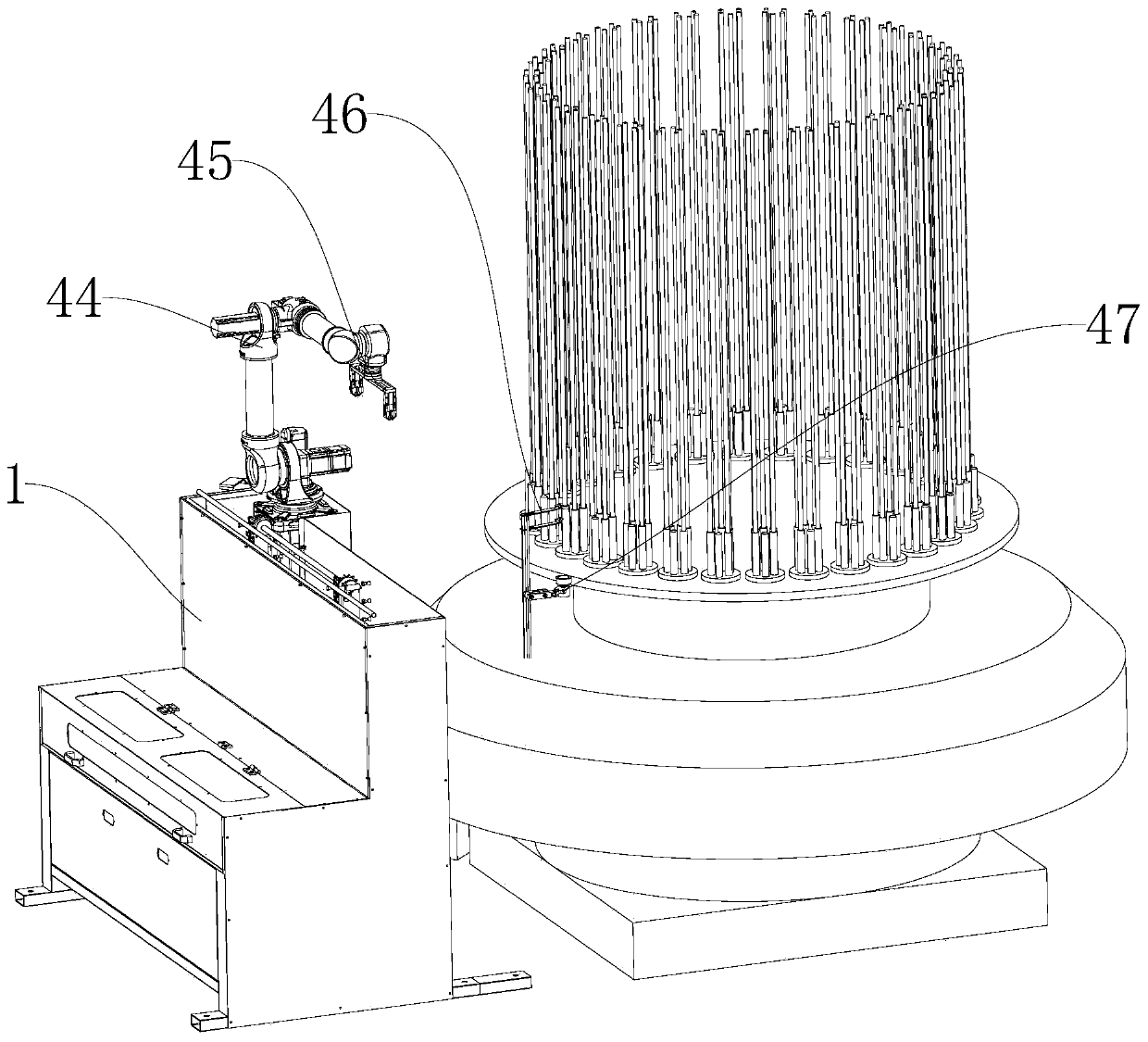

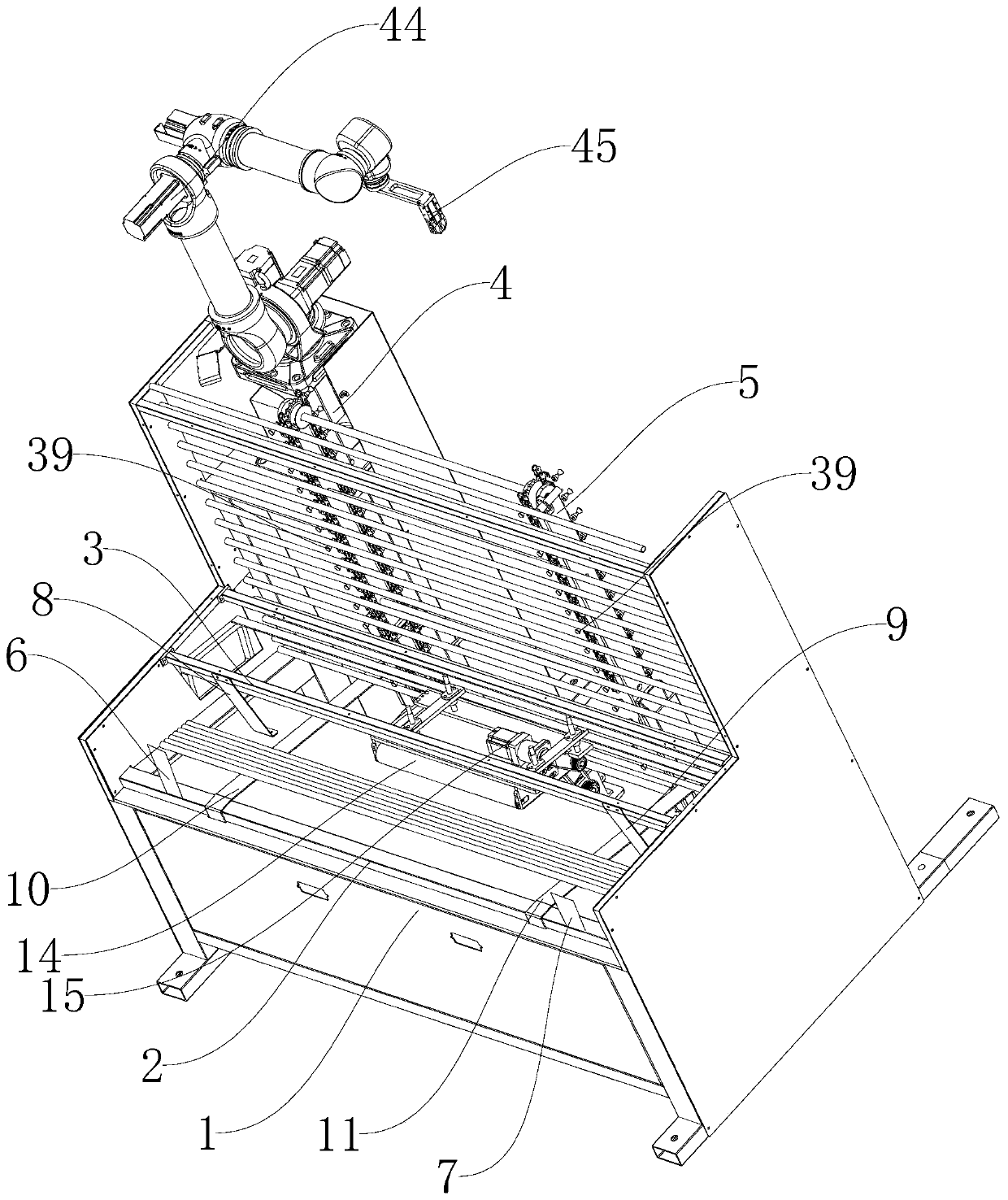

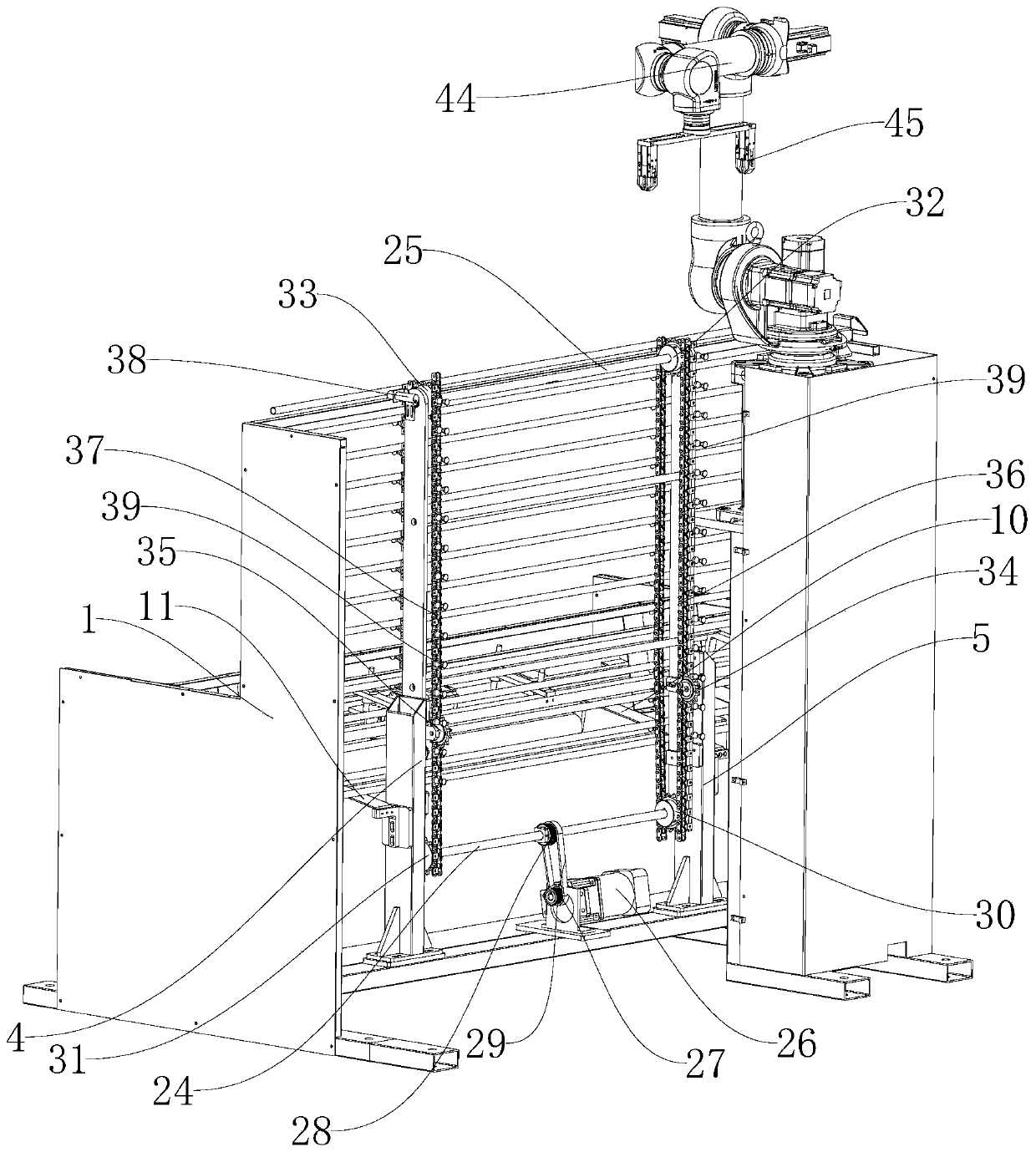

[0023] Embodiment: As shown in the figure, an automatic pipe loading system includes a frame 1, a material pipe storage bin, a material pipe sorting transmission mechanism, a material pipe lifting mechanism, a material pipe grasping and inserting mechanism, a material shortage detection and tracking mechanism and The control module, the material tube storage bin, the material tube sorting and conveying mechanism, the material tube lifting mechanism and the material tube grabbing and inserting mechanism are respectively installed on the frame 1, and the material tube storage bin is used to store the rough glass tube and store it The blank glass tubes are sent to the material tube sorting and conveying mechanism in sequence. The material tube sorting and transmitting mechanism is used to arrange the raw glass tubes sent there into a layer and then send them to the material tube lifting mechanism in sequence. The material tube lifting mechanism It is used to lift the blank glass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com