A kind of preparation method of synthetic phosphoric acid ester

A phosphate ester and Lewis acid technology, applied in chemical instruments and methods, phosphorus organic compounds, compounds of Group 5/15 elements of the periodic table, etc., can solve problems that have not yet been reported on the application of polymer Lewis acid catalysts, Achieve the effect of reducing production labor costs, reducing environmental pollution, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

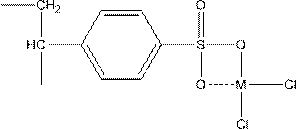

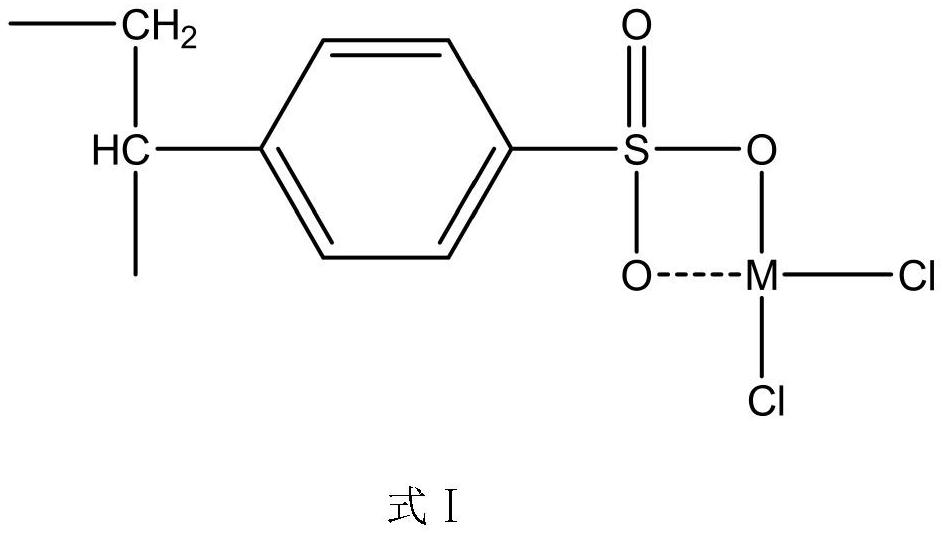

Image

Examples

Embodiment 1-3

[0048] Embodiment 1-3 relates to the preparation of polymer Lewis acid catalyst:

Embodiment 1

[0050] 1. Weigh 1000 g of macroporous spherical cation exchange resin (hereinafter referred to as macromolecular resin) generated by the copolymerization of styrene and divinylbenzene, wash with distilled water, and vacuum-dry at 100-105° C. for 15 hours after washing, and set aside;

[0051]2. Weigh 8g of dried macromolecular resin, 50ml of carbon disulfide, and 24g of tin tetrachloride into a four-necked flask, heat and reflux for 4-5 hours, cool to room temperature, slowly add 50ml of water dropwise, and stir for 30 minutes , filtered, and washed with acetone to obtain a polymer Lewis acid catalyst, which was vacuum-dried at 100-105° C. for 5 hours, and determined by an atomic absorption spectrometer, and the tin content was 8.5%.

Embodiment 2

[0053] Weigh 8g of dried macromolecular resin, 50ml of carbon disulfide, and 20g of titanium tetrachloride into a four-neck flask, heat and reflux for 4-5 hours, cool to room temperature, slowly add 50ml of water dropwise, stir for 30 minutes, and filter , washed with acetone to obtain a polymer Lewis acid catalyst, vacuum-dried at 100-105° C. for 5 hours, and determined by an atomic absorption spectrometer, the titanium content was 8.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com