Discharging device for middle circumferential framework inner hole threaded mold

An inner hole thread and mold technology is applied in the field of dismantling devices for inner hole thread molds of mid-circumferential skeletons, which can solve the problems of small mid-circumferential skeletons, low work efficiency, inflexible operation, etc., so as to improve production efficiency, increase production capacity, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

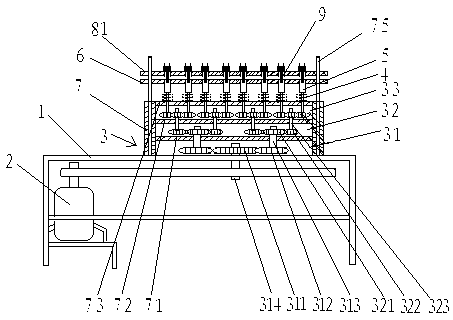

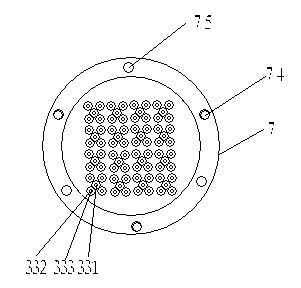

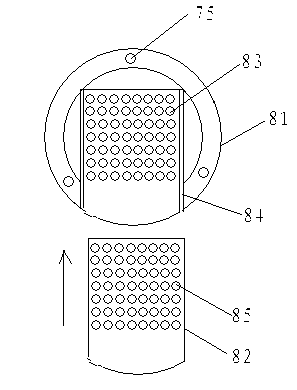

[0020] Such as Figure 1 to Figure 4 As shown, the present invention includes a machine platform 1, a motor 2, a three-stage gear set transmission mechanism 3, a spring 4, an axle sleeve 5 and a pressing plate 6, and the three-stage gear set transmission mechanism 3 is located on a stacked frame 7 above the machine platform 1 Inside, the three-stage gear set transmission mechanism 3 refers to that the driving wheel 311 of the first-stage gear set 31 engages and drives four driven wheels 312, and the gear shafts 313 of the four driven wheels 312 of the first-stage gear set respectively pass through the upper partition plate 71 and the The driving wheels 321 of the secondary gear set 32 are connected, and the driving wheels 321 of the secondary gear set 32 respectively engage and drive four driven wheels 322, and the gear shafts 323 of the sixteen driven wheels 322 of the secondary gear set respectively pass through the upper partition After 72, it is connected with the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com