Multi-stage phase change recovery and storage device for heat in continuous casting and billet cooling process

A technology of cooling process and phase change energy storage material, which is applied in the field of multi-stage phase change recovery and storage devices, can solve problems such as heat waste, achieve sufficient heat recovery, improve utilization rate, and solve the effects of secondary waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

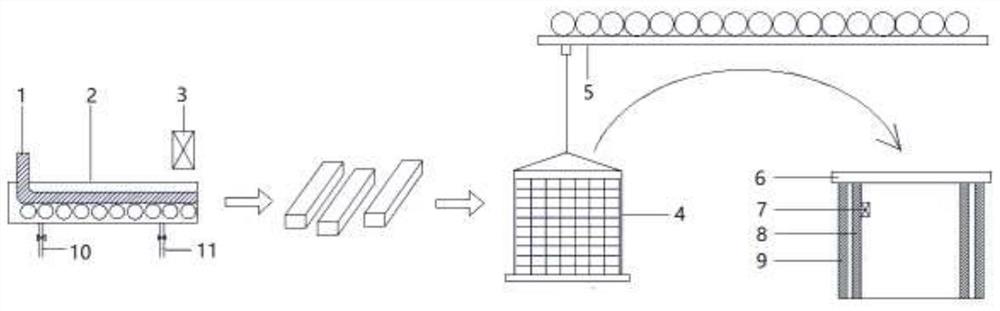

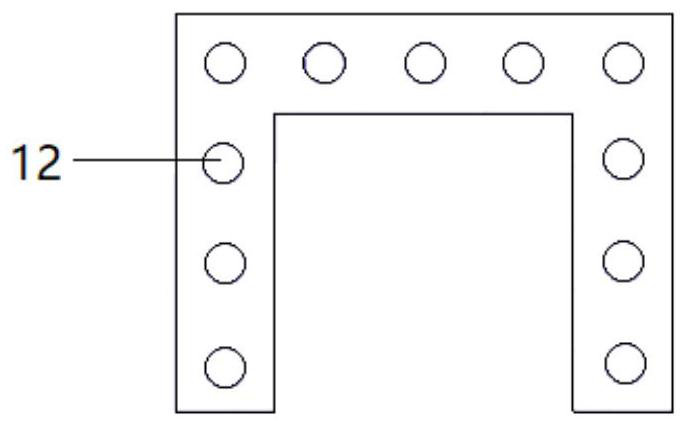

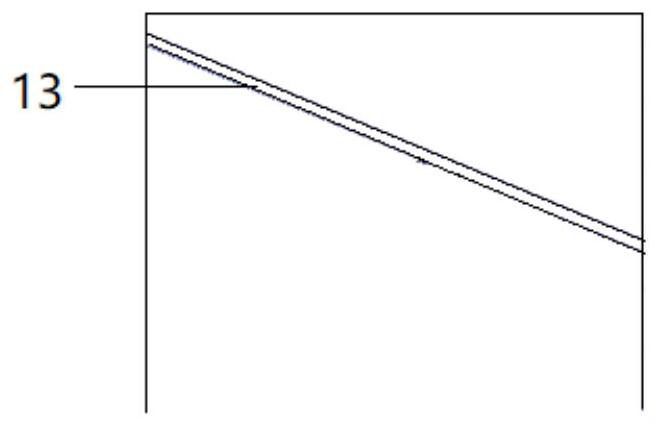

[0062] Such as Figure 1 to Figure 4 As shown, the present invention provides a multi-stage phase change recovery and storage device for continuous casting and billet cooling process heat, which includes a phase change recovery energy storage cover 2 during high temperature continuous casting, a billet transport device, and a billet stacking cooling chamber and control system 7;

[0063] The billet stacking cooling chamber has an inner and outer double-layer structure, the inner layer is a secondary high-temperature phase change recovery energy storage lifting plate 8, and the outer layer is a third-level medium temperature phase change recovery storage wall 9.

[0064] The high-temperature continuous casting process phase change recovery energy storage cover 2 covers the top of the continuous casting device 1 to recover and store heat energy in the continuous casting process;

[0065] The billet transportation device is placed after the continuous casting device 1, and trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com