Efficient plate-type air preheater

An air preheater, high temperature air technology, applied in the direction of heat exchanger type, indirect heat exchanger, fixed plate duct assembly, etc., can solve the direction dispersion of expansion stress, plate surface and weld cracking, heat exchange plate Short service life and other problems, to achieve the effect of increasing strength, reducing heat exchange area, and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

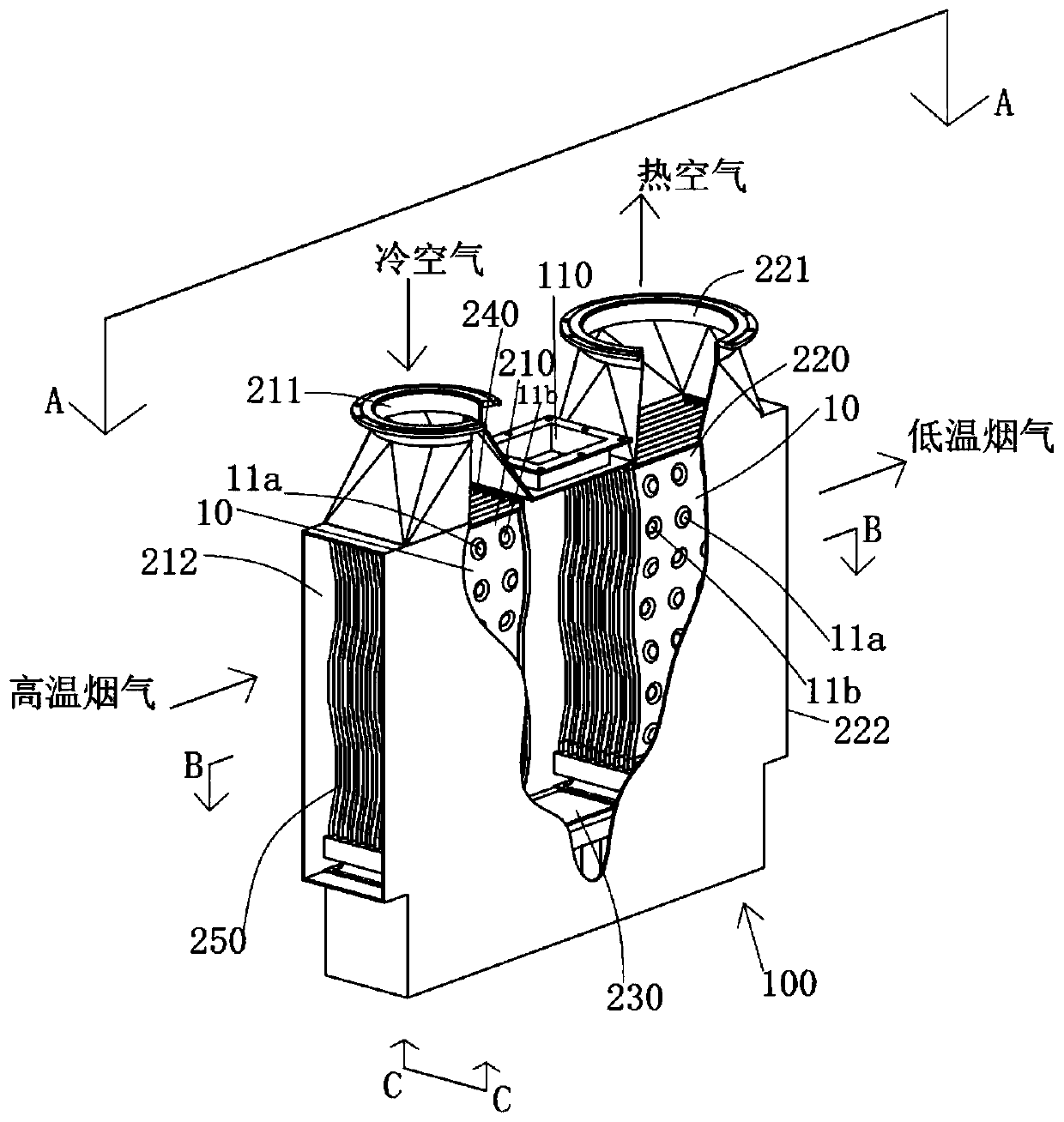

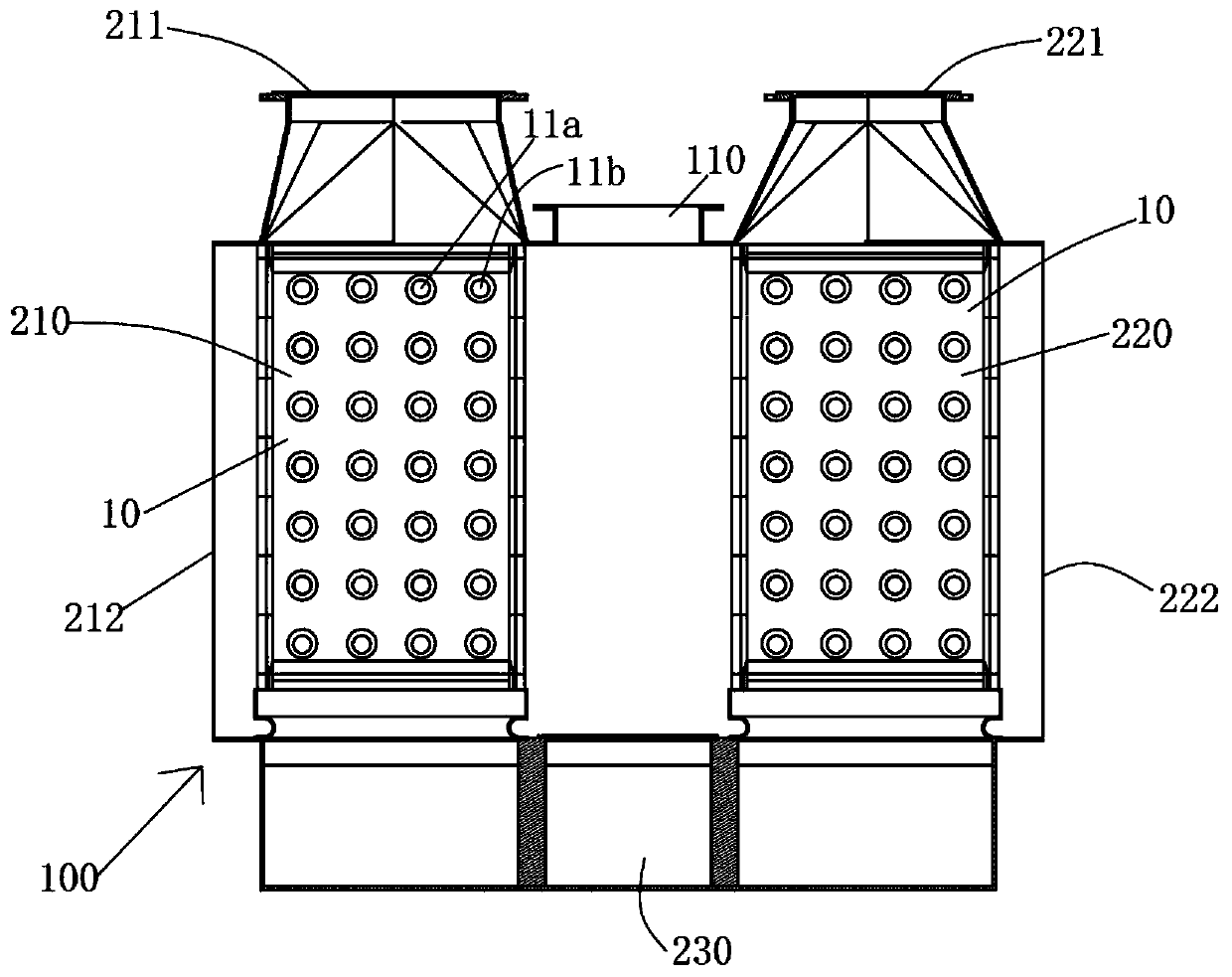

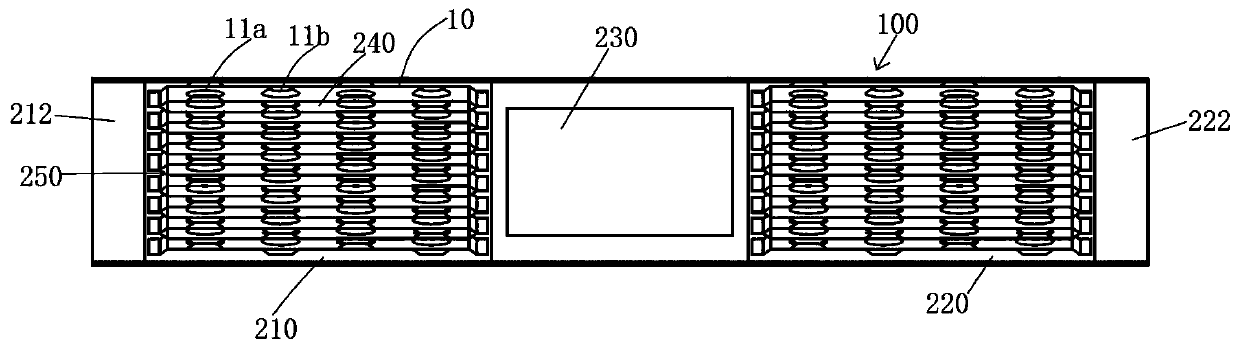

[0026] see Figure 1 to Figure 7 The high-efficiency plate air preheater shown includes a shell 100, and a high-temperature air heat exchange section 210 and a low-temperature air heat exchange section 220 are arranged inside the shell 100. The high-temperature air heat exchange section 210 has an air inlet 211 and a smoke inlet The low temperature air heat exchange section 220 has an air outlet 221 and a smoke outlet 222 . The high-temperature air heat exchange section 210 and the low-temperature air heat exchange section 220 are connected through the air transition channel 230. The high-temperature air heat exchange section 210 and the low-temperature air heat exchange section 220 are plate-type heat exchange sections, which are composed of multiple heat exchange plates 10. An a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com