A short process method for preparing high-performance sintered NdFeB magnets from sintered NdFeB sludge waste

A high-performance NdFeB technology, which is applied in the fields of magnetic objects, recycling technology, inductance/transformer/magnet manufacturing, etc., can solve the problems that cannot be applied, and the magnetic powder has no magnetic properties, so as to facilitate subsequent processing and avoid secondary Waste and reduce the effect of milling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

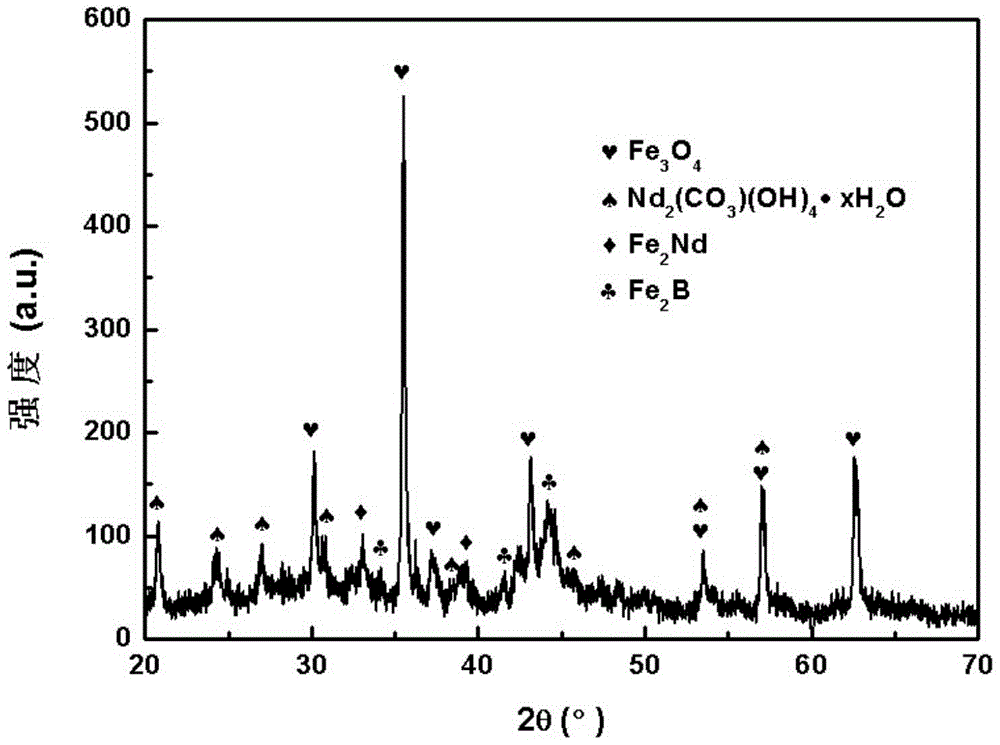

[0021]Put 30ml of NdFeB sludge waste into a flask, add 450ml of distilled water, and use a rotary evaporator to carry out water bath distillation. Under vacuum conditions, the temperature is raised stepwise, starting from 30°C, and the temperature is raised by 5°C every 5 minutes until it reaches 80°C. After the internal liquid was evaporated to dryness, the operation was repeated 3 times to obtain 26.42 g of distilled powder. Add 52ml of acetone to the distilled powder, ultrasonically clean 3 times, then add absolute ethanol, ultrasonically clean 2 times, each ultrasonic time is 10min, after removing the lotion, dry it under vacuum at 50°C to obtain the pretreated powder; test XRD (such as figure 1 Shown), XRF (as shown in Table 1). Depend on figure 1 It can be seen that the powder after pretreatment is mainly Fe 3 o 4 , Nd(CO 3 )(OH) 4 ·xH 2 O, Fe 2 Nd and Fe 2 b. The XRF results are shown in Table 1.

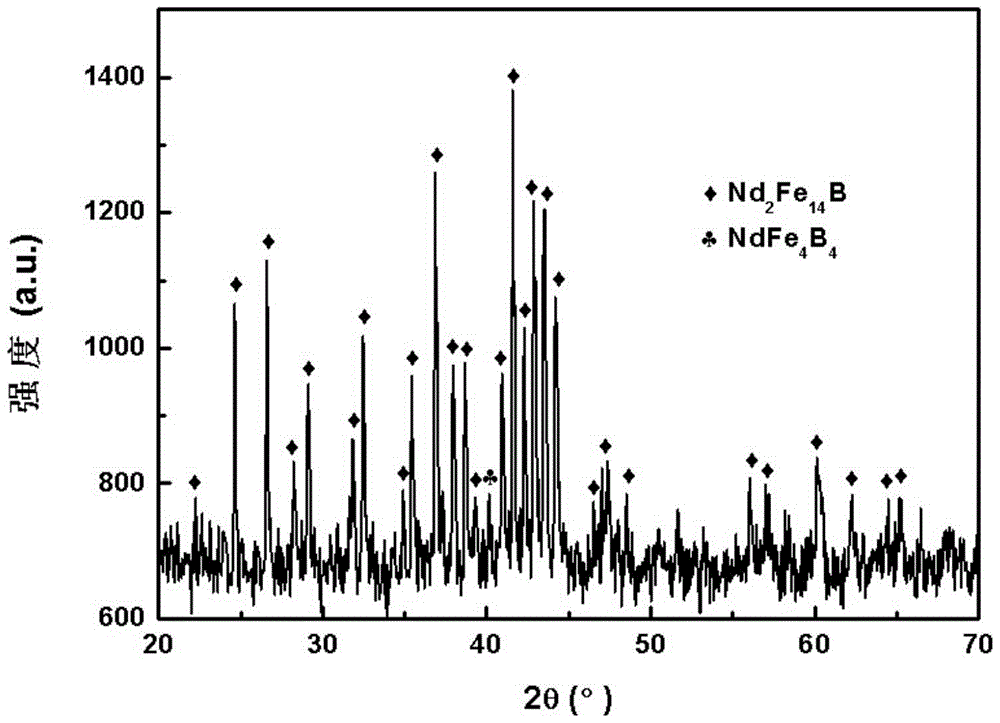

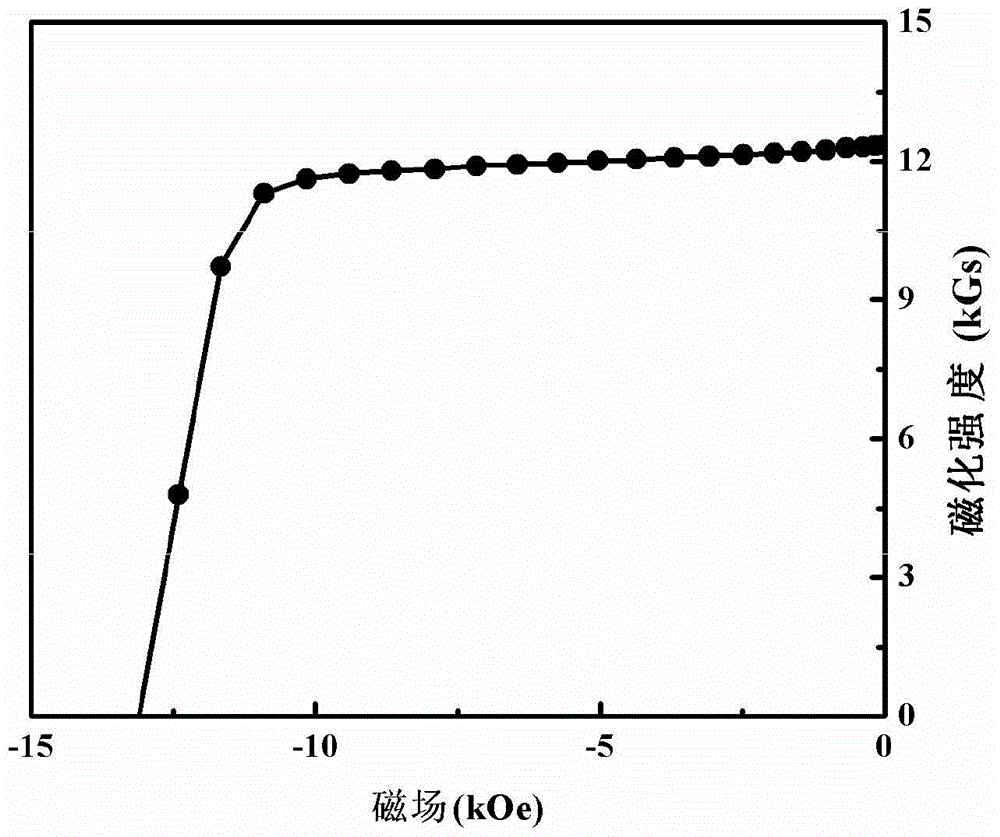

[0022] According to the element content in Table 1 and accord...

Embodiment 2

[0024] Put 30ml of NdFeB sludge waste into a flask, add 450ml of distilled water, and use a rotary evaporator to carry out water bath distillation. Under vacuum conditions, the temperature is raised stepwise, starting from 30°C, and increasing the temperature by 5°C every 8 minutes until 80°C. After the internal liquid was evaporated to dryness, the operation was repeated twice to obtain 25.64 g of distilled powder. Add 51ml of acetone to the distilled powder, ultrasonically clean it 3 times, then add absolute ethanol, and ultrasonically clean it once under a magnetic field, and the ultrasonic time is 12min each time. After removing the lotion, dry it under vacuum at 50°C to obtain Powder after pretreatment; test XRF, the results are shown in Table 2.

[0025] According to the element content in Table 2 and RE 2 Fe 14 B stoichiometric ratio, adding Nd before reaction 2 o 3 Make the total amount of rare earth up to 40%, add FeB to make the B content in the powder excessive ...

Embodiment 3

[0027] Put 30ml of NdFeB sludge waste into a flask, add 450ml of distilled water, and use a rotary evaporator to carry out water bath distillation. Under vacuum conditions, the temperature is raised stepwise, starting from 30°C, and increasing the temperature by 5°C every 10 minutes until 80°C. After the internal liquid was evaporated to dryness, the operation was repeated 3 times to obtain 25.26 g of distilled powder. Add 50.5ml of acetone to the distilled powder, ultrasonically clean 3 times, then add absolute ethanol, ultrasonically clean 2 times, each ultrasonic time is 15min, after removing the lotion, dry it under vacuum at 50°C to obtain pretreatment Back powder; Test XRF, the results are shown in Table 3.

[0028] According to the element content in Table 3 and RE 2 Fe 14 B stoichiometric ratio, adding Nd before reaction 2 o 3 Make the total amount of rare earth up to 40%, add FeB to make the B content in the powder excessive 8%, CaH 2 The mass of CaO is 1.3 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com