A method of recovering NdFeB oil sludge using reduction diffusion technology

A technology for recycling NdFeB and NdFeB, applied in the direction of recycling technology, etc., can solve the problems of inability to be applied, magnetic powder has no magnetic properties, etc., and achieve the effect of convenient subsequent processing, avoiding secondary waste, and efficient environmental protection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

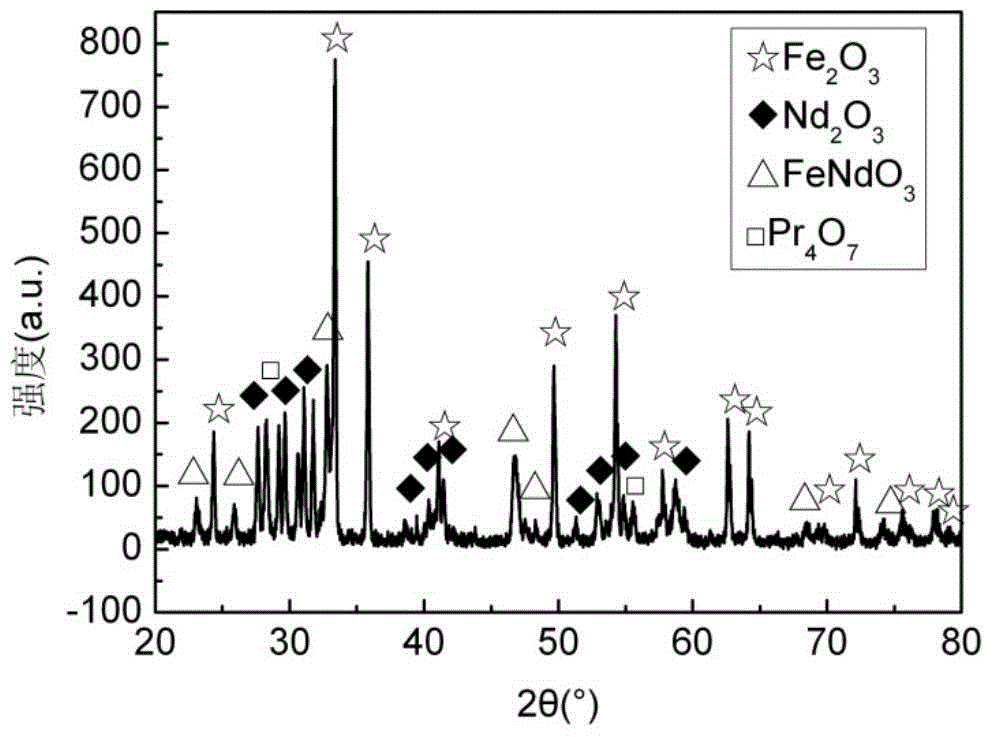

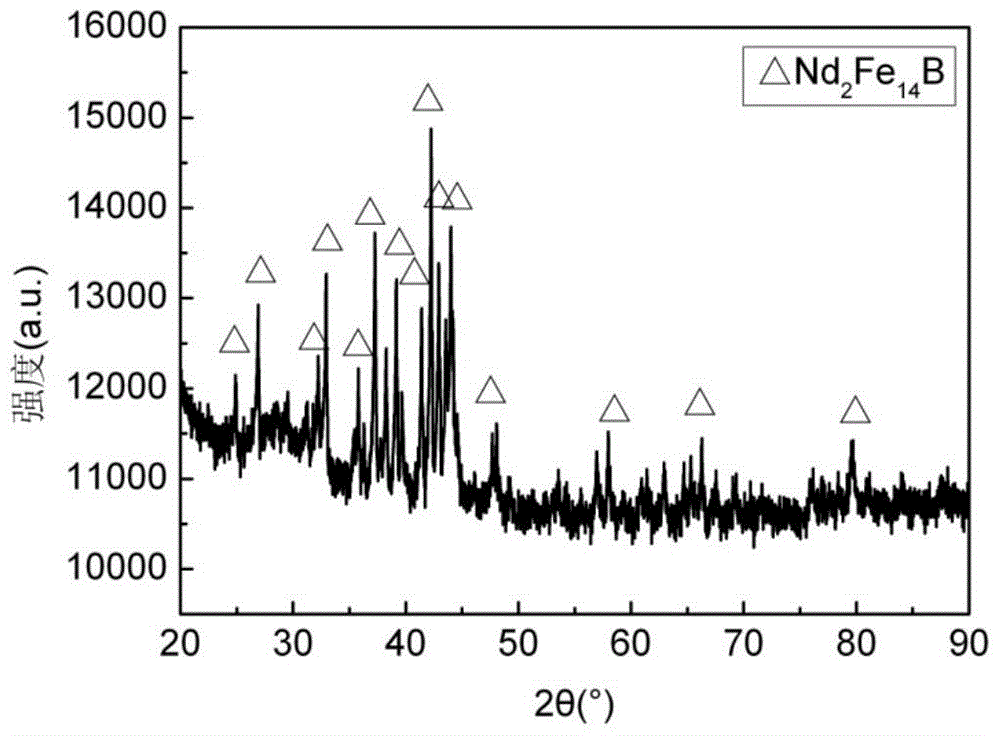

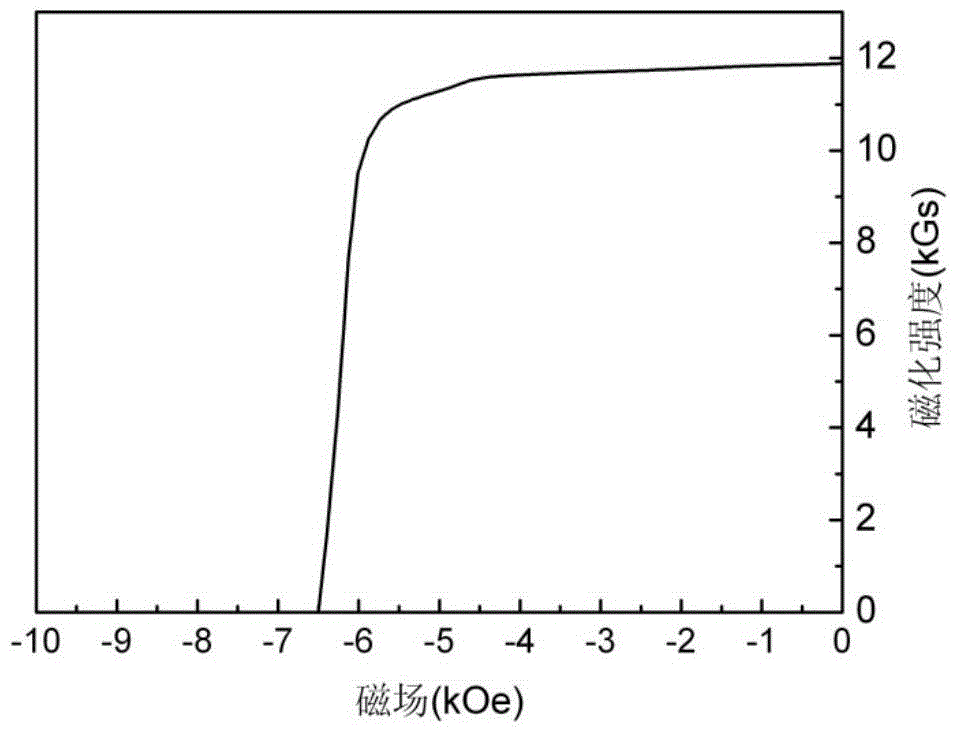

[0023] Weigh 40g of NdFeB sludge waste into a beaker, add 400mL of water, heat and distill in a water bath, and dry to obtain 35.2g of sludge powder; add 469mL to the sludge powder to a concentration of 3mol L -1 Hydrochloric acid solution, heated in a water bath at 60°C to dissolve the acid, kept warm for 20 minutes, filtered, and retained the supernatant; use 7mol L -1 Ammonia solution is adjusted to pH=2.0, and 77g of oxalic acid crystals (H 2 C 2 o 4 2H 2 O), added to the above solution, heated in a water bath at a temperature of 70°C, kept warm for 20min, centrifuged in a centrifuge, and the centrifugal speed was 7500r min -1 , time 10min, washed the precipitate 3 times, and dried to obtain the co-precipitation product; put the co-precipitation product into the muffle furnace for roasting, the roasting temperature was 850°C, and the time was 120min to obtain the mixed oxide; test XRD (such as figure 1 Shown) and XRF (as shown in Table 1). Depend on figure 1It can be...

Embodiment 2

[0026] Weigh 40g of NdFeB sludge waste into a beaker, add 400mL of water, heat and distill in a water bath, and dry to obtain 36.2g of sludge powder; add 483mL to the sludge powder to a concentration of 3mol L -1 hydrochloric acid solution, heated in a water bath at 80°C to dissolve the acid, kept warm for 30 minutes, filtered, and retained the supernatant; use 7mol L -1 Ammonia solution is adjusted to pH=2.0, and 80g of oxalic acid crystals (H 2 C 2 o 4 2H 2 O), added to the above solution, heated in a water bath at a temperature of 90°C, kept warm for 30min, centrifuged in a centrifuge, and the centrifugal speed was 7500r min -1 , for 10 minutes, washed the precipitate with water three times, and dried to obtain the co-precipitated product; put the co-precipitated product into a muffle furnace for roasting at a temperature of 900°C for 180 min to obtain a mixed oxide; test XRF, and the results are shown in Table 2.

[0027] According to the mass ratio of rare earth eleme...

Embodiment 3

[0029] Weigh 40g of NdFeB sludge waste into a beaker, add 400mL of water, heat and distill in a water bath, and dry to obtain 33.8g of sludge powder; add 451mL to the sludge powder to a concentration of 3mol L -1 Hydrochloric acid solution, heated in a water bath at 70°C to dissolve the acid, kept warm for 25 minutes, filtered, and retained the supernatant; use 7mol L -1 Ammonia solution is adjusted to pH=2.0, and 74g oxalic acid crystals (H 2 C 2 o 4 2H 2 O), added to the above solution, heated in a water bath at a temperature of 80°C, kept warm for 25min, centrifuged in a centrifuge, and the centrifugal speed was 7500r min -1 , for 10 minutes, washed the precipitate with water three times, and dried to obtain the co-precipitated product; put the co-precipitated product into a muffle furnace for roasting at a temperature of 870°C for 150 min to obtain a mixed oxide; test XRF, and the results are shown in Table 3.

[0030] According to the mass ratio of rare earth elements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com