Method for synthesizing pure 4A zeolite, P-shaped zeolite and sodalite with concavo-convex attapulgite clay

A technology of attapulgite clay and synthesis method, which is applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., which can solve the problems of restricting the application field of synthetic zeolite, limiting the source of raw materials, and high production cost, and achieve production Low cost, simple synthesis method, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

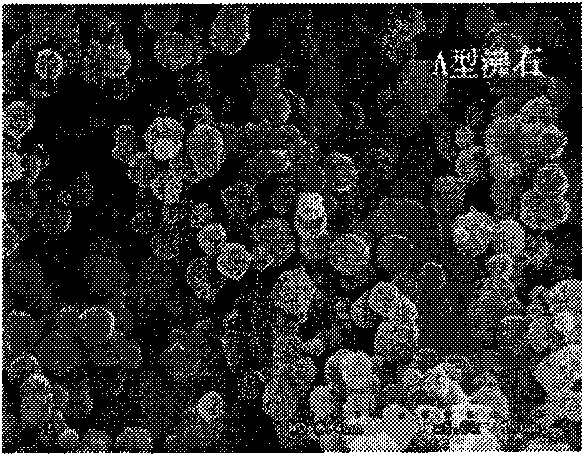

[0016] Use attapulgite clay as raw material to prepare pure 4A zeolite: calcinate attapulgite clay at 800°C for 1h; put 5g of attapulgite clay in 20ml of 5mol / L NaOH solution, stir at 100°C for 1h, filter, get Na 2 SiO 3 The leaching solution; the 2.5gNaAlO 2 Added to 19.23g H 2 Stir evenly in O, pour the aluminum source solution into the above leaching solution, stir for 0.5h, the mixed solution is hydrothermally crystallized at 80°C for 5h, and the product is obtained after filtration, washing and drying; the product sample is characterized by XRD and SEM, and it is cubic pure 4A Zeolite.

Embodiment 2

[0018] Use attapulgite clay as raw material to prepare pure 4A zeolite: calcinate attapulgite clay at 700°C for 2h; put 5g of calcined attapulgite clay in 20ml of 5mol / L NaOH solution, stir at 90°C for 1.5h, filter , get Na 2 SiO 3 The leaching solution; the 3.6gNaAlO 2 Added to 19.23g H 2 Stir evenly in O, pour the aluminum source solution into the above leaching solution, stir for 0.5h, the mixed solution is hydrothermally crystallized at 85°C for 5h, and the product is obtained after filtration, washing and drying; the product sample is characterized by XRD and SEM, and it is cubic pure 4A Zeolite.

Embodiment 3

[0020] Prepare pure 4A zeolite with attapulgite clay as raw material: calcinate attapulgite clay at 600°C for 3h; put 5g of calcined attapulgite clay in 20ml of 5mol / L NaOH solution, stir at 85°C for 2h, filter, get Na 2 SiO 3 The leaching solution; the 5.4gNaAlO 2 Added to 19.23g H 2 Stir evenly in O, pour the aluminum source solution into the above leaching solution, stir for 0.5h, the mixed solution is hydrothermally crystallized at 90°C for 5h, and the product is obtained after filtration, washing and drying; the product sample is characterized by XRD and SEM, and it is cubic pure 4A Zeolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com