Composition containing sodalite and polyester composite

A polyester composite material and sodalite technology, applied in the field of sodalite-containing compositions, can solve the problems of abrasion of grinding equipment, affect the mechanical properties of the final product, affect the stability of polyester materials, etc. Excellent effect of infrared emissivity and ultraviolet protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

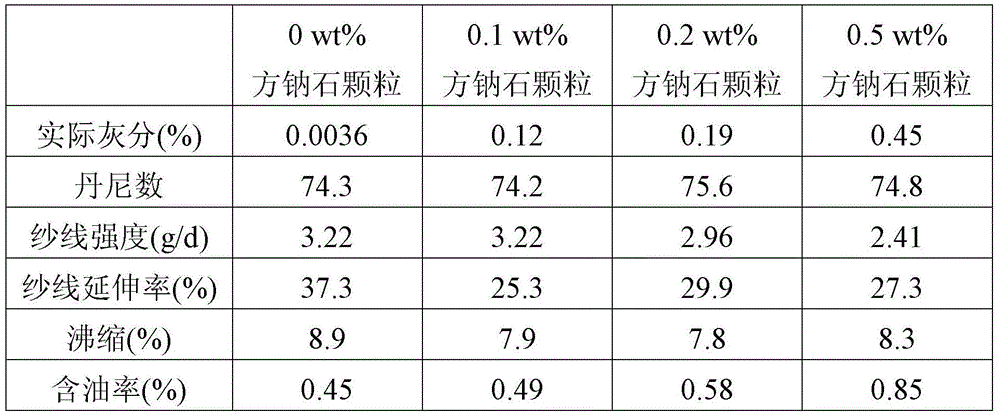

Examples

Embodiment Construction

[0014] The sodalite-containing composition of the present invention includes 55-98.5wt% of glycols, polycarboxylic acids and 0.5-20wt% of sodalite particles. According to differences in preparation methods, the sodalite-containing compositions in some embodiments The product further contains water accounting for less than 5 wt% of the total weight.

[0015] Glycol is the main solvent in the sodalite-containing composition. If the content of the glycol is low, the sodalite-containing composition is likely to become gel (solidified colloid) or sol-like (flowing) Sexual colloid), if the content of dibasic alcohol is higher, then the sodalite composition is usually a true solution (truesolution, hereinafter referred to as solution) and has good fluidity, and the dibasic alcohol in the solution is generally greater than 65wt at this moment %. In the present invention, suitable dihydric alcohols may be, but not limited to, ethylene glycol, 1,3-propanediol, 1,4-butanediol or mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com