Quick burnt iron series crystal ceramic tableware and preparation technology thereof

A ceramic and iron-based technology, applied in the field of fast-fired iron-based crystalline ceramic tableware and its preparation technology, can solve the problems of long firing cycle, high cost, and high price, and achieve the effects of light weight, good plasticity, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

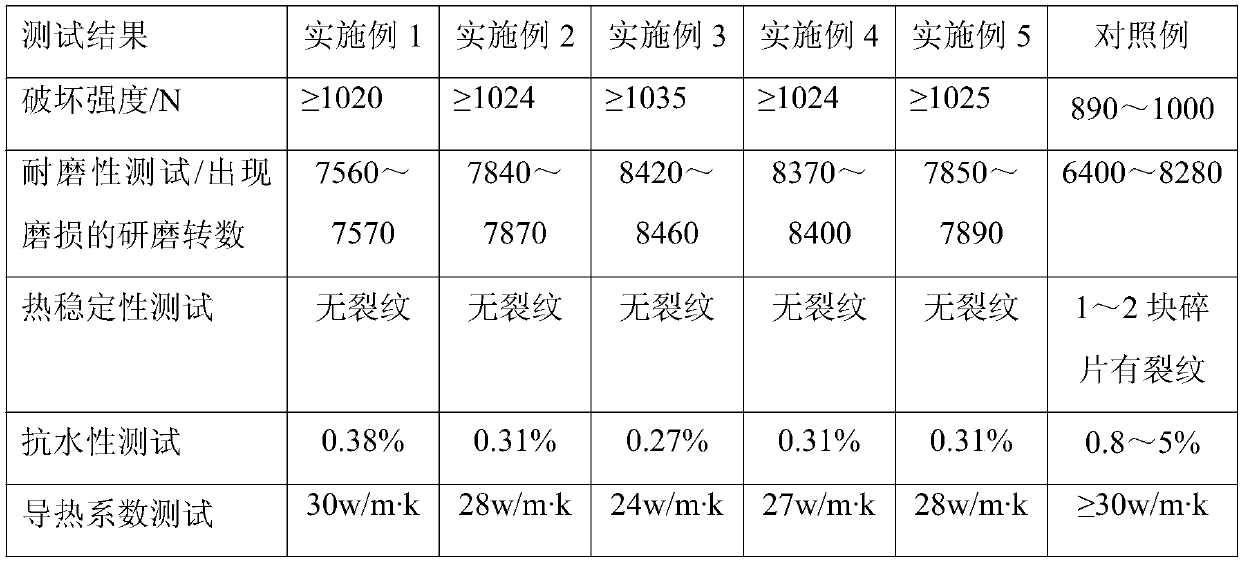

Examples

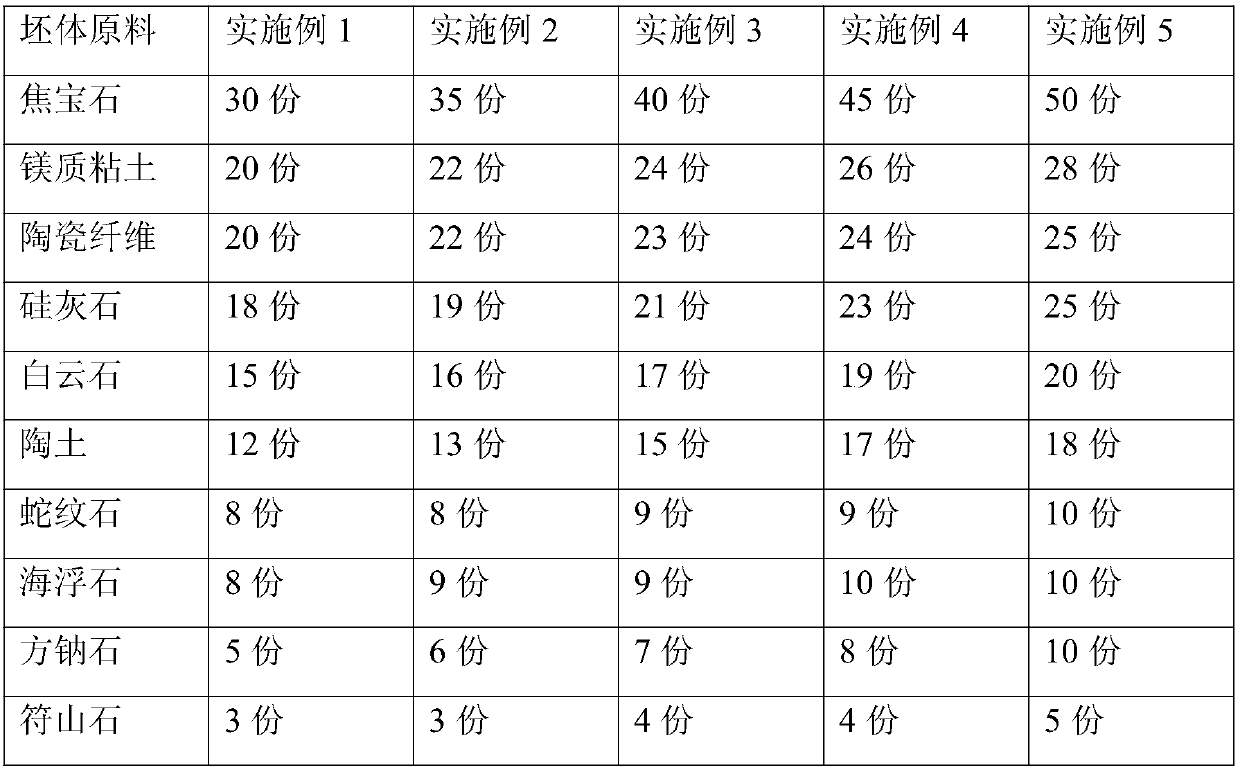

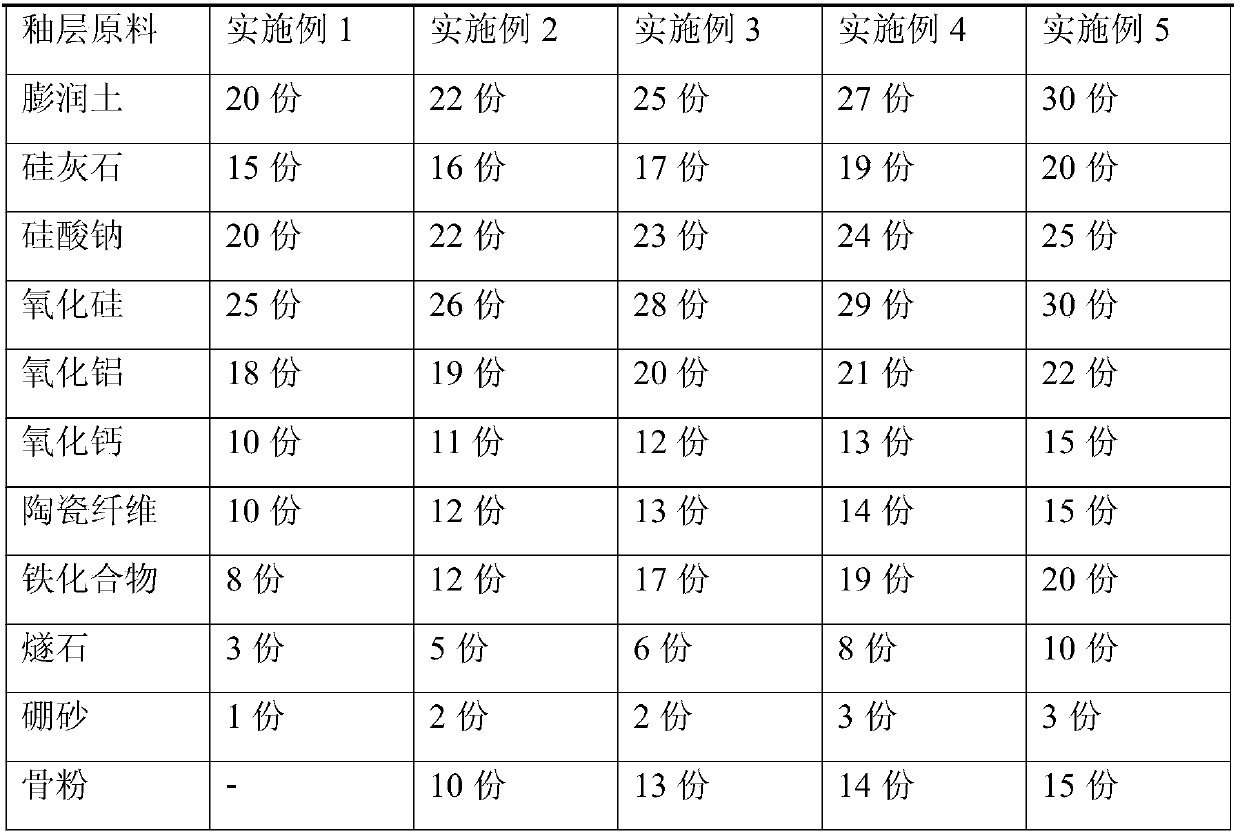

Embodiment 1

[0026] This embodiment provides a fast-fired iron-based crystalline ceramic tableware, comprising a green body and a glaze layer applied on the green body. The green body includes the following raw materials in parts by weight: 30 parts of burnt gems, 20 parts of magnesia clay, ceramic 20 parts of fiber, 18 parts of wollastonite, 15 parts of dolomite, 12 parts of pottery clay, 8 parts of serpentine, 8 parts of pumice, 5 parts of sodalite, and 3 parts of Fushan stone; the glaze layer includes the following parts by weight Raw materials: 20 parts of bentonite, 15 parts of wollastonite, 20 parts of sodium silicate, 25 parts of silicon oxide, 18 parts of aluminum oxide, 10 parts of calcium oxide, 10 parts of ceramic fiber, 8 parts of iron compound, 3 parts of flint, 1 part of borax .

[0027] This embodiment also provides a process for manufacturing fast-fired iron-based crystalline glaze ceramic tableware, comprising the following steps:

[0028] Step 1, taking the raw materials...

Embodiment 2

[0033] This embodiment provides a fast-fired iron-based crystalline ceramic tableware, comprising a base body and a glaze layer applied on the base body. The base body includes the following raw materials in parts by weight: 35 parts of burnt gems, 22 parts of magnesia clay, ceramic 22 parts of fiber, 19 parts of wollastonite, 16 parts of dolomite, 13 parts of pottery clay, 8 parts of serpentine, 9 parts of sea pumice, 6 parts of sodalite, and 3 parts of Fushan stone; the glaze layer includes the following parts by weight Raw materials: 22 parts of bentonite, 16 parts of wollastonite, 22 parts of sodium silicate, 26 parts of silicon oxide, 19 parts of aluminum oxide, 11 parts of calcium oxide, 12 parts of ceramic fiber, 12 parts of iron compound, 5 parts of flint, 2 parts of borax , 10 parts of bone meal.

[0034] This embodiment also provides a process for manufacturing fast-fired iron-based crystalline glaze ceramic tableware, comprising the following steps:

[0035] Step 1...

Embodiment 3

[0040] This embodiment provides a fast-fired iron-based crystalline ceramic tableware, comprising a base body and a glaze layer applied on the base body, and the base body includes the following raw materials in parts by weight: 40 parts of burnt gemstones, 24 parts of magnesia clay, ceramic 23 parts of fiber, 21 parts of wollastonite, 17 parts of dolomite, 15 parts of clay, 9 parts of serpentine, 9 parts of sea pumice, 7 parts of sodalite, and 4 parts of Fushan stone; the glaze layer includes the following parts by weight Raw materials: 25 parts of bentonite, 17 parts of wollastonite, 23 parts of sodium silicate, 28 parts of silicon oxide, 20 parts of aluminum oxide, 12 parts of calcium oxide, 13 parts of ceramic fiber, 17 parts of iron compound, 6 parts of flint, 2 parts of borax 13 parts, bone meal.

[0041] This embodiment also provides a process for manufacturing fast-fired iron-based crystalline glaze ceramic tableware, comprising the following steps:

[0042] Step 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com