Sodalite zeolite synthesized by fly ash and synthesis method thereof

A fly ash and synthesis technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of complex process, high cost of raw materials, and many synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

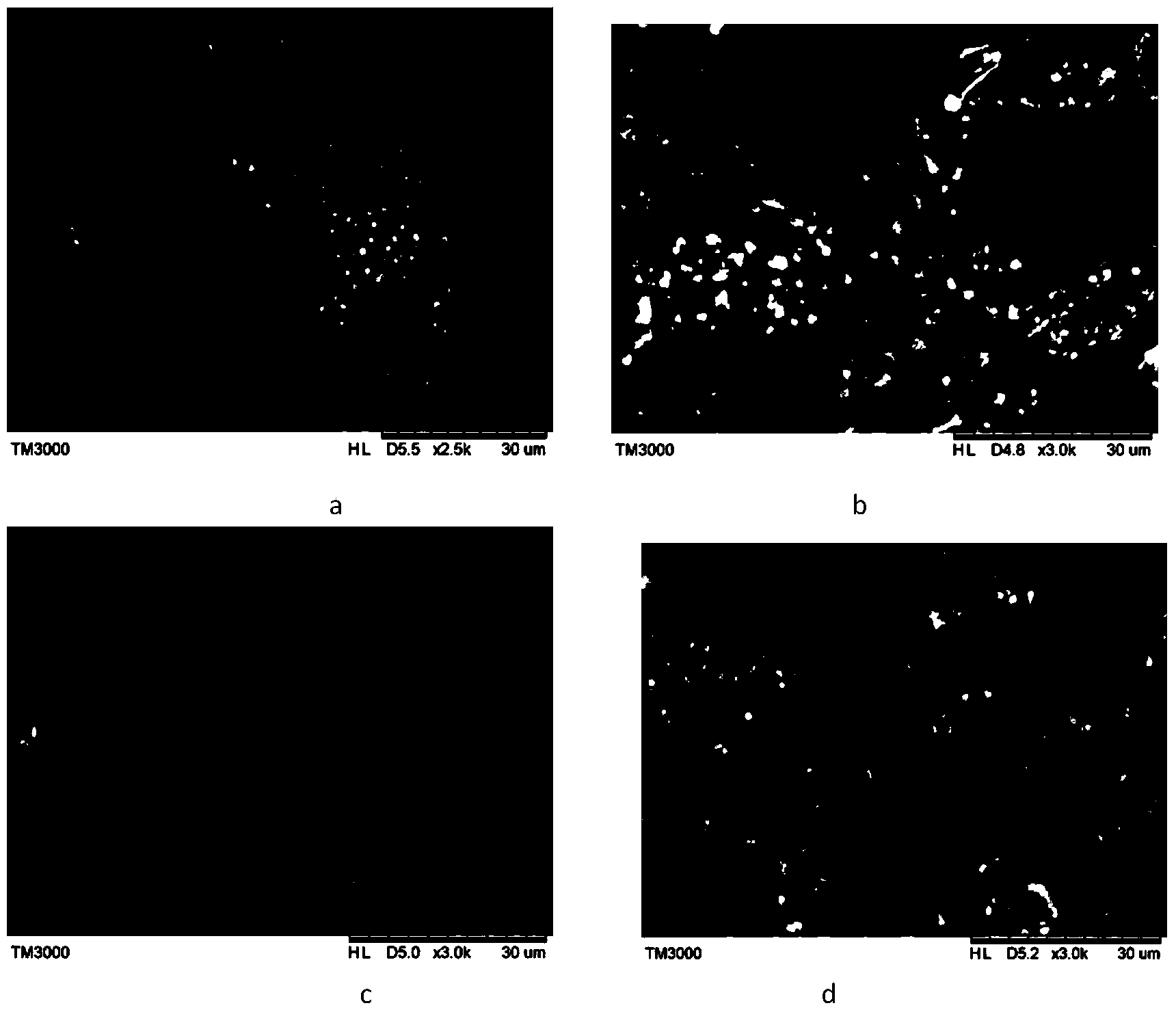

Image

Examples

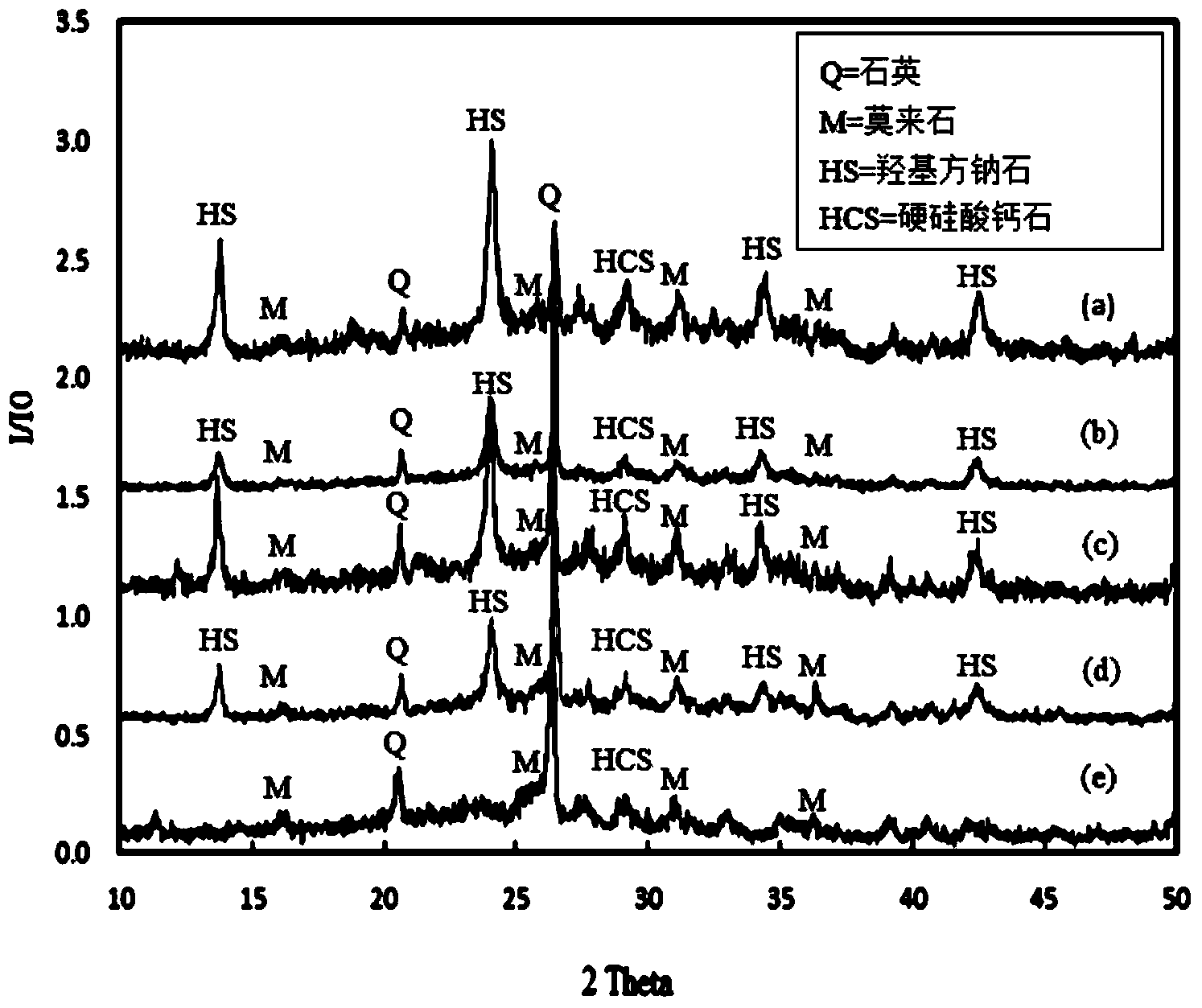

Embodiment 1

[0022] Take 500g of fly ash from a thermal power plant, put it into a 5L container, add an appropriate volume of distilled water to submerge the fly ash, then stir at room temperature for 15-20min, after precipitation, discard the upper turbid solution, then add appropriate amount of water, stir and wash 15-20min, remove the upper solution after precipitation, and repeat the above steps several times until the upper solution is no longer turbid. Then filter, transfer the filter cake to the drying equipment and dry at 100-105°C to constant weight. Transfer the fly ash that has been washed and dried to constant weight into the high-pressure reaction equipment, and add 2500ml of NaOH solution with a concentration of 4mol / L. After stirring for 10-15min, seal the reaction equipment, and heat the reaction equipment to 121°C. Keep the temperature constant for 400 minutes, then cool, filter, and wash with water until the pH of the washing solution reaches 8.5-10, and finally dry the f...

Embodiment 2

[0024] Take 500g of fly ash from a thermal power plant, put it into a 5L container, add an appropriate volume of distilled water to submerge the fly ash, then stir at room temperature for 15-20min, after precipitation, discard the upper turbid solution, then add appropriate amount of water, stir and wash 15-20min, remove the upper solution after precipitation, and repeat the above steps several times until the upper solution is no longer turbid. Then filter, transfer the filter cake to the drying equipment and dry at 100-105°C to constant weight. Transfer the fly ash that has been washed and dried to constant weight into the high-pressure reaction equipment, and add 2000ml of NaOH solution with a concentration of 4mol / L, stir for 10-15min, seal the reaction equipment, and heat the reaction equipment to 121°C. Keep the temperature constant for 400 minutes, then cool, filter, and wash with water until the pH of the washing solution reaches 8.5-10, and finally dry the filter cake...

Embodiment 3

[0026] Take 500g of fly ash from a thermal power plant, put it into a 5L container, add an appropriate volume of distilled water to submerge the fly ash, then stir at room temperature for 15-20min, after precipitation, discard the upper turbid solution, then add appropriate amount of water, stir and wash 15-20min, remove the upper solution after precipitation, and repeat the above steps several times until the upper solution is no longer turbid. Then filter, transfer the filter cake to the drying equipment and dry at 100-105°C to constant weight. Transfer the fly ash that has been washed and dried to constant weight into the high-pressure reaction equipment, and add 3000ml of NaOH solution with a concentration of 4mol / L, stir for 10-15min, seal the reaction equipment, and heat the reaction equipment to 121°C. Keep the temperature constant for 400 minutes, then cool, filter, and wash with water until the pH of the washing solution reaches 8.5-10, and finally dry the filter cake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com