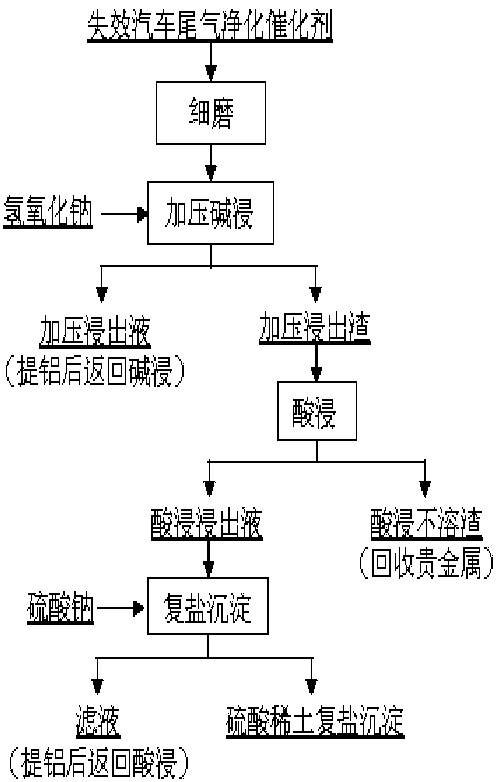

Method for enriching platinum group metal and rare earth in failed automobile exhaust purification catalyst

A technology for purifying catalysts and automobile exhaust, applied in the field of metallurgy, can solve problems such as large energy consumption requirements, and achieve the effects of good operating environment, good benefits, and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Specific components of the catalyst: Al 17.97%, Si 17.78%, La 0.58%, Y 0.28%, Ce 4.02%, Pt 113.5g / t, Pd 212g / t, Rh 73g / t.

[0022] Industrial grade sodium hydroxide, its NaOH content ≥ 96%; industrial grade sodium sulfate, its Na 2 SO 4 content ≥96%; industrial grade hydrochloric acid, its HCl content is 36%~38%; industrial grade hydrazine hydrate, its N 2 h 4 ·H 2 O content is ≥ 80%.

[0023] Take 15.00g of the exhausted automobile exhaust purification catalyst whose particle size is less than 0.149mm after fine grinding, mix it with 12.00g of sodium hydroxide and put it into the autoclave, then add 75mL of deionized water, control the stirring speed to 400rpm, and slowly heat to 150°C , reacted for 3.0h; after the reaction was completed, filter and wash to obtain 200mL of pressurized leaching solution and 19.03g of pressurized leaching residue. The components of the pressurized leaching solution are: Si 2.38g / L, Al 2.47g / L, La 9.50mg / L, Y 2.50mg / L, Ce 10.00mg / L, ...

Embodiment 2

[0027] Specific components of the catalyst: Si 17.82%, Al 17.94%, La 0.60%, Y 0.29%, Ce 4.12%, Pt 115.4g / t, Pd 221.5g / t, Rh 78.2g / t.

[0028]Industrial grade sodium hydroxide, its NaOH content ≥ 96%; industrial grade sodium sulfate, its Na 2 SO 4 content ≥96%; industrial grade hydrochloric acid, its HCl content is 36%~38%; industrial grade hydrazine hydrate, its N 2 h 4 ·H 2 O content is ≥ 80%.

[0029] Take 15.00g of the exhausted automobile exhaust purification catalyst whose particle size is less than 0.149mm after fine grinding, mix it with 30.00g of sodium hydroxide and put it into the autoclave, then add 90mL of deionized water, control the stirring speed to 600rpm, and slowly heat to 200°C , reacted for 4.0h; after the reaction was completed, filter and wash to obtain 200mL of pressurized leaching solution and 19.06g of pressurized leaching residue. The components of the pressurized leaching solution are: Al 2.45g / L, Si 2.41g / L, La 9.98mg / L, Y 3.01mg / L, Ce 14.98mg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com