Method for extracting melanin from palm meal

A technology for palm meal and melanin, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of affecting the molecular structure of melanin, high cost, and large amount of chemical reagents, and achieve high enzymatic hydrolysis efficiency and mild action conditions. , which is conducive to the effect of subsequent extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

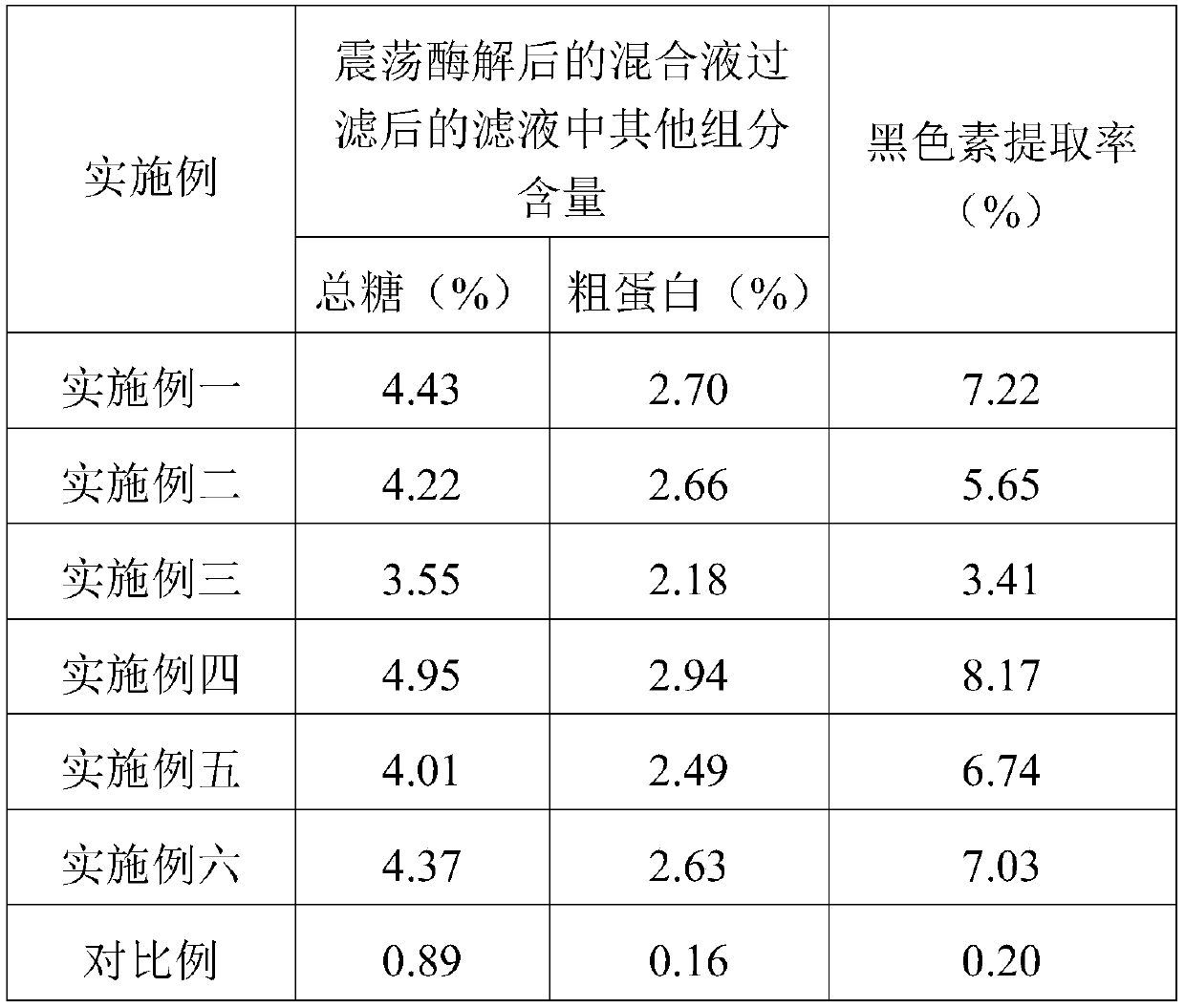

Examples

Embodiment 1

[0028] Crush the palm meal into a powder with a particle size of 60 mesh and add it to soak in water to form a mixed solution. The mass ratio of the palm meal powder to water is 1:10; add β-mannanase that accounts for 4.0% of the mass of the palm meal powder in the compound enzyme preparation , xylanase accounting for 1.0% of the mass of palm meal powder, cellulase accounting for 4.0% of the mass of palm meal powder, pectinase accounting for 1.0% of the mass of palm meal powder, and α-amylase accounting for 1.0% of the mass of palm meal powder , lipase accounting for 3.0% of the mass of palm meal powder and protease accounting for 1.0% of the mass of palm meal powder, carrying out oscillating enzymolysis on the mixed solution at 35° C. for 8 hours, and filtering the mixed solution after oscillating enzymolysis to obtain filter residue and filtrate, After soaking the filter residue with a concentration of 20g / L sodium hydroxide solution, filter and collect the filtrate produced ...

Embodiment 2

[0030] Crush the palm meal into a powder with a particle size of 80 mesh and add it to soak in water to form a mixed solution. The mass ratio of the palm meal powder to water is 1:10; add β-mannanase that accounts for 3.0% of the mass of the palm meal powder in the compound enzyme preparation , Xylanase accounting for 0.5% of the mass of palm meal powder, cellulase accounting for 3.0% of the mass of palm meal powder, pectinase accounting for 0.5% of the mass of palm meal powder, and α-amylase accounting for 1.0% of the mass of palm meal powder , lipase accounting for 2.0% of the mass of palm meal powder and protease accounting for 1.0% of the mass of palm meal powder, carrying out oscillating enzymolysis on the mixed solution at 35° C. for 8 hours, and filtering the mixed solution after oscillating enzymolysis to obtain filter residue and filtrate, After soaking the filter residue with a concentration of 25g / L sodium hydroxide solution, filter and collect the filtrate produced ...

Embodiment 3

[0032] Crush the palm meal into a powder with a particle size of 80 mesh and add it to soak in water to form a mixed solution. The mass ratio of the palm meal powder to water is 1:10; add β-mannanase that accounts for 0.8% of the mass of the palm meal powder in the compound enzyme preparation , Xylanase accounting for 0.2% of the mass of palm meal powder, cellulase accounting for 1.0% of the mass of palm meal powder, pectinase accounting for 0.1% of the mass of palm meal powder, 0.5% of the mass of palm meal powder α-amylase 1. Lipase accounting for 1% of the mass of palm meal powder and protease accounting for 0.5% of the mass of palm meal powder, carrying out oscillating enzymolysis on the mixed solution at 35° C. for 9 hours, and filtering the mixed solution after oscillating enzymolysis to obtain filter residue and filtrate, After soaking the filter residue with a concentration of 15g / L sodium hydroxide solution, filter and collect the filtrate produced after soaking the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com