Lithium battery separator coating and preparation method thereof

A lithium battery separator and coating technology, applied in the field of lithium battery separator coating and its preparation, can solve the problem of high ionic conductivity, and achieve the effects of enhancing bonding effect, ensuring conductivity and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

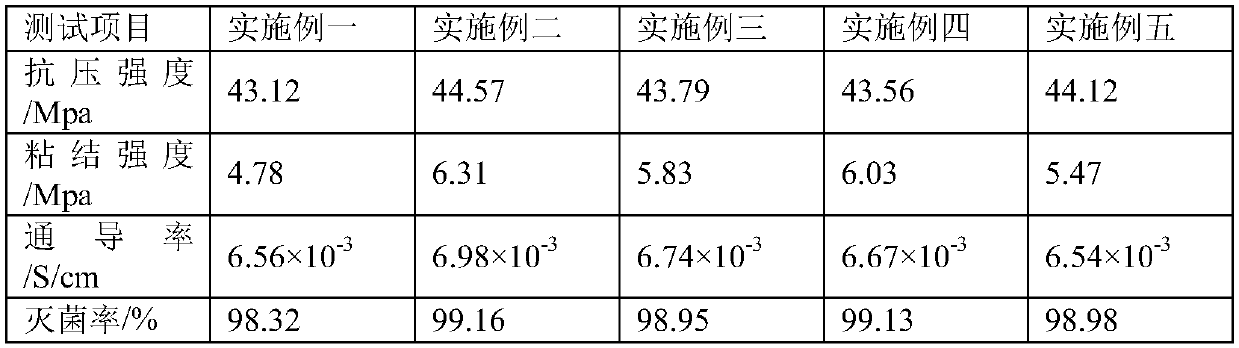

Examples

Embodiment 1

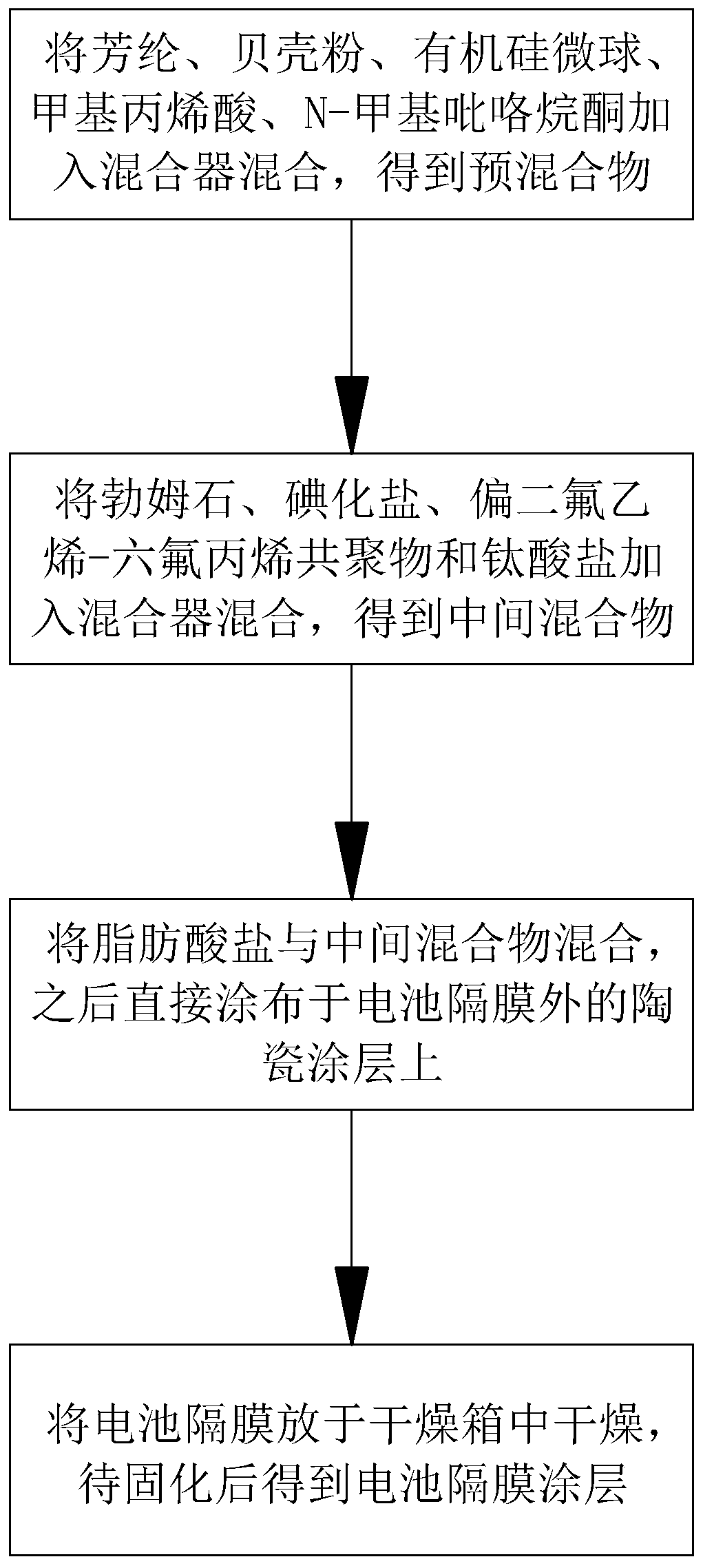

[0041] A preparation method for a lithium battery diaphragm coating, comprising the steps of:

[0042] Step 1. Add 23kg of aramid fiber, 8kg of shell powder, 15kg of silicone microspheres, 15kg of methacrylic acid, and 15kg of N-methylpyrrolidone into the mixer, and start the mixer to mix at a speed of 50rpm to obtain a premix;

[0043] Step 2: Add 4kg of boehmite, 3kg of lithium iodide, 12kg of vinylidene fluoride-hexafluoropropylene copolymer and 6kg of calcium titanate into the mixer of step 1 to carry out with the premix, and the mixing speed is 80rpm , to obtain an intermediate mixture;

[0044] Step 3: Mix 8 kg of higher fatty acid sodium with the intermediate mixture at a mixing speed of 200 rpm, and then directly apply it to the ceramic coating on the outside of the battery diaphragm;

[0045] Step 4. Put the battery separator in step 3 in a drying oven, and use an inert gas, especially argon gas for drying, and obtain a battery separator coating after being cured.

...

Embodiment 2

[0049] A preparation method for a lithium battery diaphragm coating, comprising the steps of:

[0050] Step 1. Add 31kg of aramid fiber, 12kg of shell powder, 19kg of silicone microspheres, 17kg of methacrylic acid, and 15kg of N-methylpyrrolidone into the mixer for mixing, and start the mixer to mix at a speed of 50rpm to obtain a premixed thing;

[0051] Step 2: Add 6kg boehmite, 5kg lithium iodide, 16kg vinylidene fluoride-hexafluoropropylene copolymer and 12kg ferric titanate into the mixer of step 1 and mix with the premix. The mixing speed is 80rpm, obtain intermediate mixture;

[0052] Step 3, mix 12kg of higher fatty acid sodium with the intermediate mixture, the mixing speed is 200rpm, and then directly apply it on the ceramic coating outside the battery diaphragm;

[0053] Step 4. Put the battery separator in step 3 in a drying oven for drying. The dry gas is inert gas, especially argon gas. After curing, the battery separator coating is obtained.

[0054] Among t...

Embodiment 3

[0057] A preparation method for a lithium battery diaphragm coating, comprising the steps of:

[0058] Step 1. Add 27kg of aramid fiber, 10kg of shell powder, 17kg of silicone microspheres, 16kg of methacrylic acid, and 17kg of N-methylpyrrolidone into the mixer for mixing, and start the mixer to mix at a speed of 50rpm to obtain a premixed thing;

[0059] Step 2. Add 5kg boehmite, 4kg lithium iodide, 14kg vinylidene fluoride-hexafluoropropylene copolymer and 9kg lithium metatitanate to the mixer in step 1 and mix with the premix. Be 80rpm, obtain intermediate mixture;

[0060] Step 3: Mix 10 kg of higher fatty acid sodium with the intermediate mixture at a mixing speed of 200 rpm, and then directly apply it to the ceramic coating outside the battery diaphragm;

[0061] Step 4. Put the battery separator in step 3 in a drying oven for drying. The dry gas is inert gas, especially argon gas. After curing, the battery separator coating is obtained.

[0062] Among them, the prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com