Low-adsorption antibacterial centrifuge tube and application thereof

A centrifuge tube and low-adsorption technology, applied in the field of centrifuge tubes, can solve the problems of ordinary nano-silver particle antibacterial agent oxidation failure, limit the use of domestic materials, waste experimental materials, etc., to improve anti-bioadhesion, film-forming effect and stability Good performance, improve wear resistance and acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

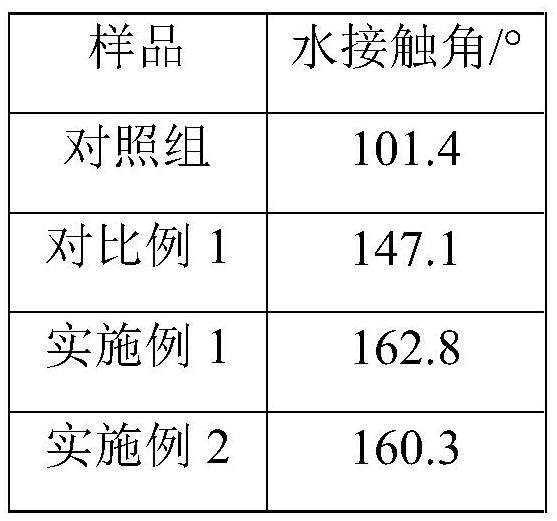

Examples

Embodiment 1

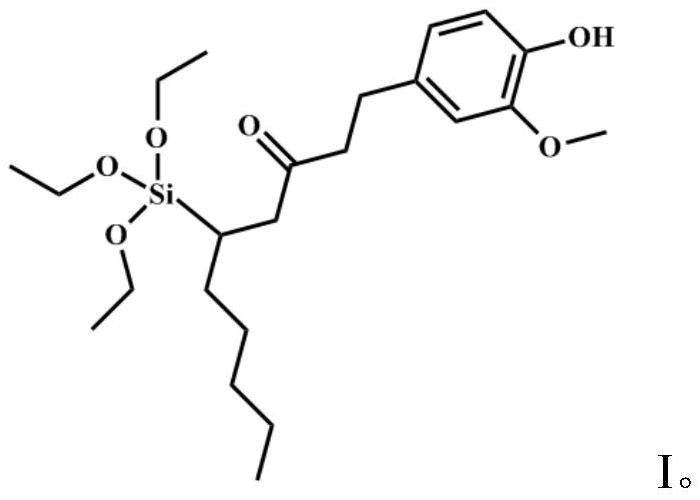

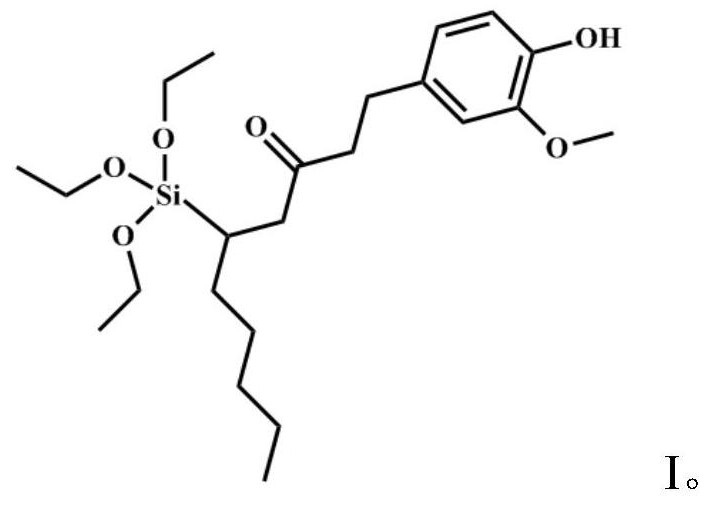

[0028] Preparation of modified silane coupling agent:

[0029] 6-shogalenol was dissolved in toluene (the solid-to-liquid ratio of 6-shogalenol to toluene was 1g: 33mL), the reaction was heated up to 55°C, and the karstedt catalyst was added (the solid-to-liquid ratio of 6-shogalenol to karstedt catalyst 3g: 0.14mL) and continue to stir for 50min; then add triethoxysilane (the mass ratio of 6-shogaol to triethoxysilane is 1:0.51) into the constant pressure dropping funnel, and then slowly add it dropwise to In the solution, react at a constant temperature of 80°C for 23 hours after the dropwise addition; filter while hot, cool to room temperature, spin evaporate, dry, and recrystallize with ethanol to obtain modified triethoxysilane.

[0030] Preparation of a low-adsorption, antibacterial centrifuge tube:

[0031] Surface pretreatment of centrifuge tubes, wash commercially available centrifuge tubes several times with detergent to remove most of the oil on the surface, then f...

Embodiment 2

[0034] The difference between the preparation of the modified silane coupling agent and Example 1 is that the mass ratio of 6-shogaol to triethoxysilane is 1:0.58; the solid-to-liquid ratio of 6-shogaol to the karstedt catalyst is 3g : 0.17mL.

[0035] The difference between the preparation of a low-adsorption and antibacterial centrifuge tube is that the modified silane coupling agent is prepared in this embodiment.

Embodiment 3

[0037] The difference between the preparation of modified silane coupling agent and Example 1 is: the mass ratio of 6-shogaol to triethoxysilane is 1:0.55; the solid-to-liquid ratio of 6-shogaol to karstedt catalyst is 3g : 0.19mL.

[0038] The difference between the preparation of a low-adsorption and antibacterial centrifuge tube is that the modified silane coupling agent is prepared in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com