Greystone fiber modified porous light active calcium silicate highly radioactive wastewater treatment agent and preparation method

A technology of basalt fiber and active calcium silicate, which is applied in the directions of radioactive purification, chemical instruments and methods, and other chemical processes, can solve the problems of thermal stability, acid resistance and poor leaching resistance, and achieves improved adsorption effect and improved Heat-resistant stability, the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

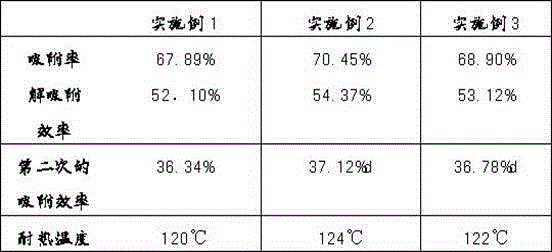

Examples

Embodiment 1

[0017] A basalt fiber modified porous light active calcium silicate high radioactive waste water stable treatment agent, the composition includes the following raw materials by weight (kg): basalt fiber 12, porous light active calcium silicate 40, silicon magnesium Glue 21, epoxy-based magnetic polymer microspheres 10, modified attapulgite 20, cetyltrimethylammonium bromide 3, sodium hydroxide 6, tetraethyl orthosilicate 3, modified iron oxide zeolite 21. Cationic surfactant cetyltrimethylammonium bromide ionic liquid 6.5 Polyacrylate fiber 35. A proper amount of deionized water, a proper amount of ethanol, and a proper amount of water.

[0018] A preparation method of a basalt fiber modified porous light active calcium silicate highly radioactive wastewater stabilizing treatment agent, comprising the following steps:

[0019] (1) Mix basalt fiber, modified attapulgite and ethanol with a total weight of 1.5 times, heat and stir at 200° C. for 3 hours, and obtain modified attap...

Embodiment 2

[0024] A basalt fiber modified porous light active calcium silicate highly radioactive waste water stable treatment agent, the composition includes the following raw materials by weight (kg): basalt fiber 13, porous light active calcium silicate 41, silicon magnesium Glue 20.5, epoxy-based magnetic polymer microspheres 11, modified attapulgite 21, cetyltrimethylammonium bromide 3.5, sodium hydroxide 5.5, tetraethyl orthosilicate 3, modified iron oxide zeolite 20.5, cationic surfactant cetyltrimethylammonium bromide ionic liquid 6.5, polypropylene fiber 35, appropriate amount of deionized water, appropriate amount of ethanol, appropriate amount of water.

[0025] A preparation method of a basalt fiber modified porous light active calcium silicate highly radioactive wastewater stabilizing treatment agent, comprising the following steps:

[0026] (1) Mix basalt fiber, modified attapulgite and ethanol with a total weight of 1.5 times, heat and stir at 200° C. for 3 hours, and obta...

Embodiment 3

[0031] A basalt fiber modified porous light active calcium silicate highly radioactive waste water stable treatment agent, the composition includes the following raw materials by weight (kg): basalt fiber 14, porous light active calcium silicate 42, silicon magnesium Glue 20, epoxy-based magnetic polymer microspheres 12, modified attapulgite 22, cetyltrimethylammonium bromide 4, sodium hydroxide 5, tetraethyl orthosilicate 3, modified iron oxide zeolite 20. Cationic surfactant cetyltrimethylammonium bromide ionic liquid 6.5, polypropylene fiber 35, appropriate amount of deionized water, appropriate amount of ethanol, appropriate amount of water.

[0032] A preparation method of a basalt fiber modified porous light active calcium silicate highly radioactive wastewater stabilizing treatment agent, comprising the following steps:

[0033] (1) Mix basalt fiber, modified attapulgite and ethanol with a total weight of 1.5 times, heat and stir at 200° C. for 3 hours, and obtain modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com