Preparation method of wet-process Maya-blue-like dye

A blue dye, Maya's technology, applied in the direction of organic dyes, can solve the problems of uneven color, poor weather resistance, etc., achieve uniform reaction, and improve the effect of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

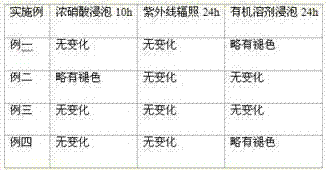

[0019] Example 1: Dissolve 0.1g of indigo in 100mL of ethanol, add 10g of attapulgite clay to absorb at room temperature for 2h under stirring, then add 0.01g of tetraethyl orthosilicate and 0.5mL of ammonia water, heat up to 60°C and continue the reaction for 48h, after cooling to room temperature Filter, wash with ethanol, and dry at 130°C for 10 h to obtain the product. The product stability is shown in Table 1.

Embodiment 2

[0020] Example 2: Dissolve 0.2g of methylene blue in 100mL of water, add 10g of attapulgite clay to absorb at room temperature for 2h under stirring, then add 50mL of ethanol, 0.2g of sodium silicate and 0.5mL of hydrochloric acid, heat up to 80°C and continue the reaction for 26h, cool to room temperature and filter , washed with ethanol, and dried at 190°C for 7 hours to obtain the product. The product stability is shown in Table 1.

Embodiment 3

[0021] Example 3: Dissolve 0.3g of methyl violet in 100mL of toluene, add 10g of attapulgite clay to absorb at room temperature for 2h under stirring, then add 0.2g of vinyltriethoxysilane and 0.5mL of sodium borohydride, and heat up to 90°C to continue the reaction After cooling to room temperature for 10 hours, filter, wash with ethanol, and dry at 220°C for 5 hours to obtain the product. The product stability is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com