Treatment method of improving acid-base resistance of mulberry silk

A treatment method, a technology of mulberry silk, is applied in the field of treatment to improve the acid and alkali resistance of mulberry silk, which can solve problems such as poor tolerance to alkali solution, decreased fiber strength, and broken silk protein fiber molecular chains, so as to improve acid and alkali resistance Ability, polymerization degree increase, fibrous structure stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

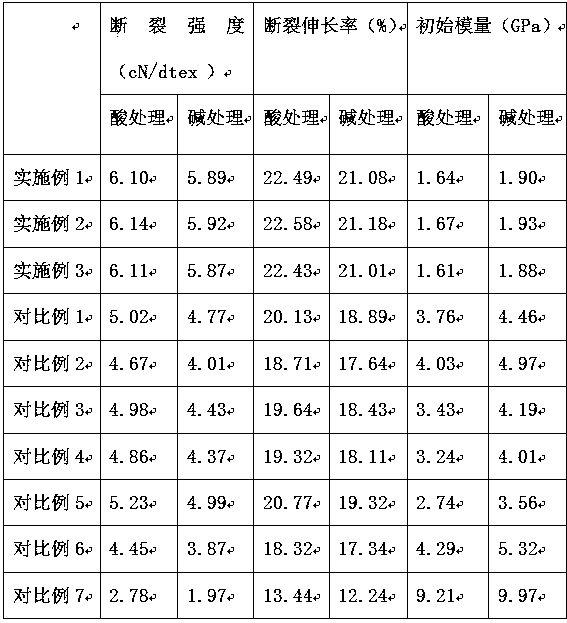

Examples

Embodiment 1

[0016] In the embodiment of the present invention, a kind of processing method of improving acid and alkali resistance of mulberry silk, the specific method is as follows:

[0017] (1) Immerse the mulberry silk in the erythritol aqueous solution at a temperature of 43°C and soak for 50 minutes, drain the liquid, drain until no water drips, and perform magnetization treatment at a vacuum degree of 2.9kPa and a temperature of 34°C Vacuum treatment for 13 minutes under the condition of 1.1kPa and 24 minutes under the condition of vacuum degree of 1.1kPa and temperature of 6°C;

[0018] (2) Submerge the mulberry silk treated in step (1) in the treatment solution for 80 minutes and perform ultrasonic treatment, drain the liquid, drain until no water drips, and perform freezing treatment at a temperature of 84~88°C Under the conditions of constant temperature steam treatment for 22 minutes, microwave drying was carried out under the conditions of temperature 49 ℃ and power 92W;

[...

Embodiment 2

[0025] In the embodiment of the present invention, a kind of processing method of improving acid and alkali resistance of mulberry silk, the specific method is as follows:

[0026] (1) Immerse the mulberry silk in an erythritol aqueous solution at a temperature of 44°C and soak for 55 minutes, drain the liquid, drain until no water drops, and perform magnetization treatment. Vacuum treatment for 14 minutes under the same conditions, and 26 minutes under the conditions of vacuum degree of 1.2kPa and temperature of 6.5°C;

[0027] (2) Submerge the mulberry silk treated in step (1) in the treatment solution for 85 minutes and perform ultrasonic treatment, drain the liquid, drain until there is no water dripping, perform freezing treatment, and put it in the condition of 86°C Under constant temperature steam treatment for 23 minutes, microwave drying was carried out at a temperature of 50°C and a power of 94W;

[0028] The treatment liquid is prepared from the following raw mater...

Embodiment 3

[0034] In the embodiment of the present invention, a kind of processing method of improving acid and alkali resistance of mulberry silk, the specific method is as follows:

[0035] (1) Immerse the mulberry silk in an erythritol aqueous solution at a temperature of 45°C and soak for 60 minutes, drain the liquid until there is no water dripping, and perform magnetization treatment at a vacuum degree of 3.1kPa and a temperature of 36°C Vacuum treatment for 15 minutes under the condition of 1.3kPa and 28 minutes under the condition of vacuum degree of 1.3kPa and temperature of 7℃;

[0036] (2) Submerge the mulberry silk treated in step (1) in the treatment solution for 90 minutes and perform ultrasonic treatment, drain the liquid, drain until no water drips, perform freezing treatment, and put it in the condition of 88°C Under constant temperature steam treatment for 24 minutes, microwave drying was carried out under the conditions of temperature 51 ℃ and power 96W;

[0037] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com