Method of preparing high-strength wear-resisting glass ceramics by utilizing iron tailings

A technology for glass-ceramic and iron tailings, which is applied in the field of preparing high-strength and wear-resistant glass-ceramic by using iron tailings, can solve the problems of high cost, complicated process, reducing the density of glass-ceramic, mechanical properties and service performance, etc. The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. A method for preparing high-strength wear-resistant glass-ceramic by using iron tailings, the following steps are carried out in sequence:

[0030] 1) Ingredients:

[0031] The raw material is composed of the following components by weight: 35 parts of iron tailings, 25 parts of quartz, 10 parts of magnesium carbonate, 15 parts of aluminum oxide, 3 parts of calcium oxide, 6 parts of titanium oxide, 5 parts of boron oxide and 1 part of antimony oxide.

[0032] 2) Mix the above raw materials by mechanical ball milling, and the ball milling time is 6 hours;

[0033] 3) Melting the mixed raw materials obtained in step 2) at 1450-1500°C for 4 hours;

[0034] 4) Press or calender the molten glass to prepare plate glass (length, width and thickness are 100mm, 40mm and 5mm respectively);

[0035] 5) Send the above plate glass to an annealing furnace for annealing, the annealing temperature is 580°C, anneal for 1 hour and then cool with the furnace; annealed glas...

Embodiment 2

[0038] Embodiment 2, a kind of method utilizing iron tailings to prepare high-strength wear-resistant glass ceramics,

[0039] The ingredients are:

[0040] The raw material is composed of the following components by weight: 40 parts of iron tailings, 20 parts of quartz, 12 parts of magnesium carbonate, 13 parts of aluminum oxide, 4 parts of calcium oxide, 7 parts of titanium oxide, 3 parts of boron oxide and 1 part of antimony oxide.

[0041] The preparation method is the same as in Example 1.

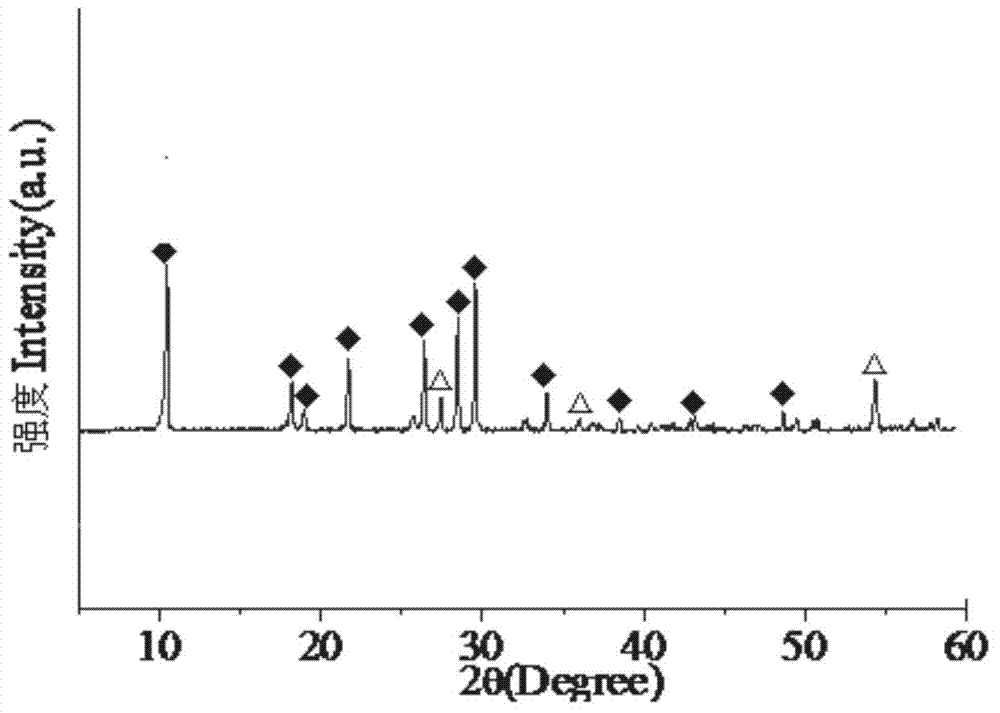

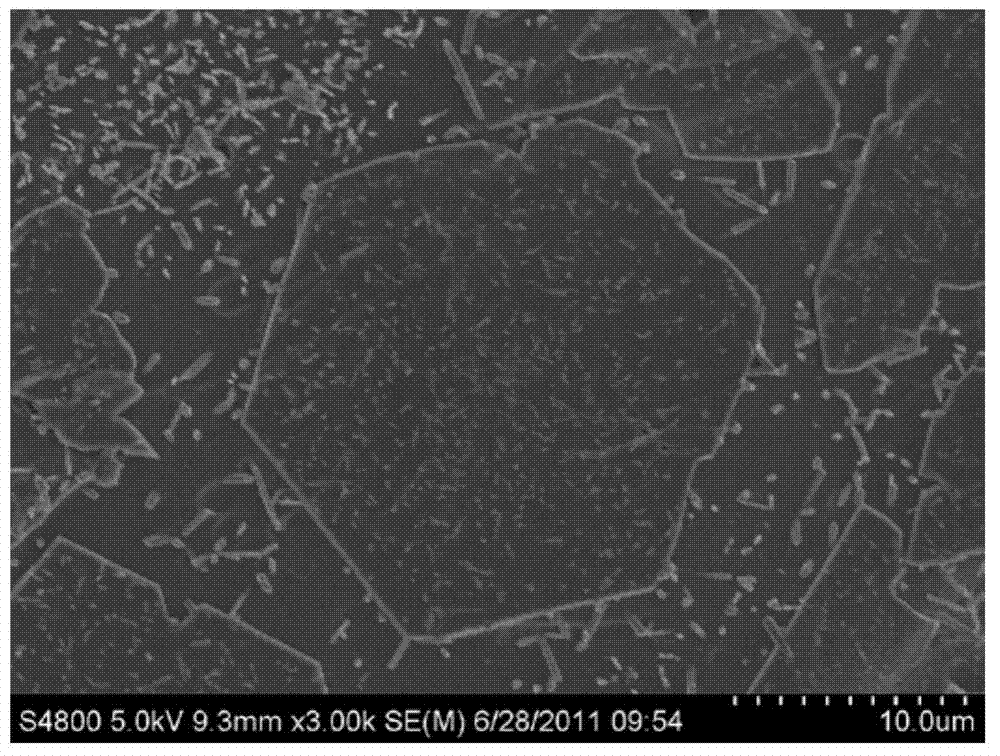

[0042] The main crystal phase of the prepared glass-ceramic product is hexagonal cordierite, the grain size is about 10 microns, the overall crystallization, black appearance, good gloss, Vickers hardness ≥ 8.2GPa, flexural strength ≥ 125MPa .

Embodiment 3

[0043] Example 3: A method for preparing high-strength wear-resistant glass-ceramic by using iron tailings,

[0044] The ingredients are:

[0045] The raw material is composed of the following components by weight: 37 parts of iron tailings, 23 parts of quartz, 11 parts of magnesium carbonate, 14 parts of aluminum oxide, 4 parts of calcium oxide, 6 parts of titanium oxide, 4 parts of boron oxide and 1 part of antimony oxide.

[0046] The preparation method is the same as in Example 1.

[0047] The main crystal phase of the prepared glass-ceramic product is cordierite in the hexagonal crystal phase, the grain size is about 10 microns, the overall crystallization, black appearance, good gloss, Vickers hardness ≥ 8.8GPa, flexural strength ≥ 134MPa .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com