Method for producing micro crystal glass

A technology of glass-ceramic and production method, which is applied in the direction of glass production, etc., can solve the problems of long production cycle, the ratio of crystal phase depends on the overall crystallization ability of the basic glass, low production efficiency and yield rate, etc., and achieve huge economic benefits and social benefits. Benefits, shortening the time of nucleation and crystallization, and improving the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

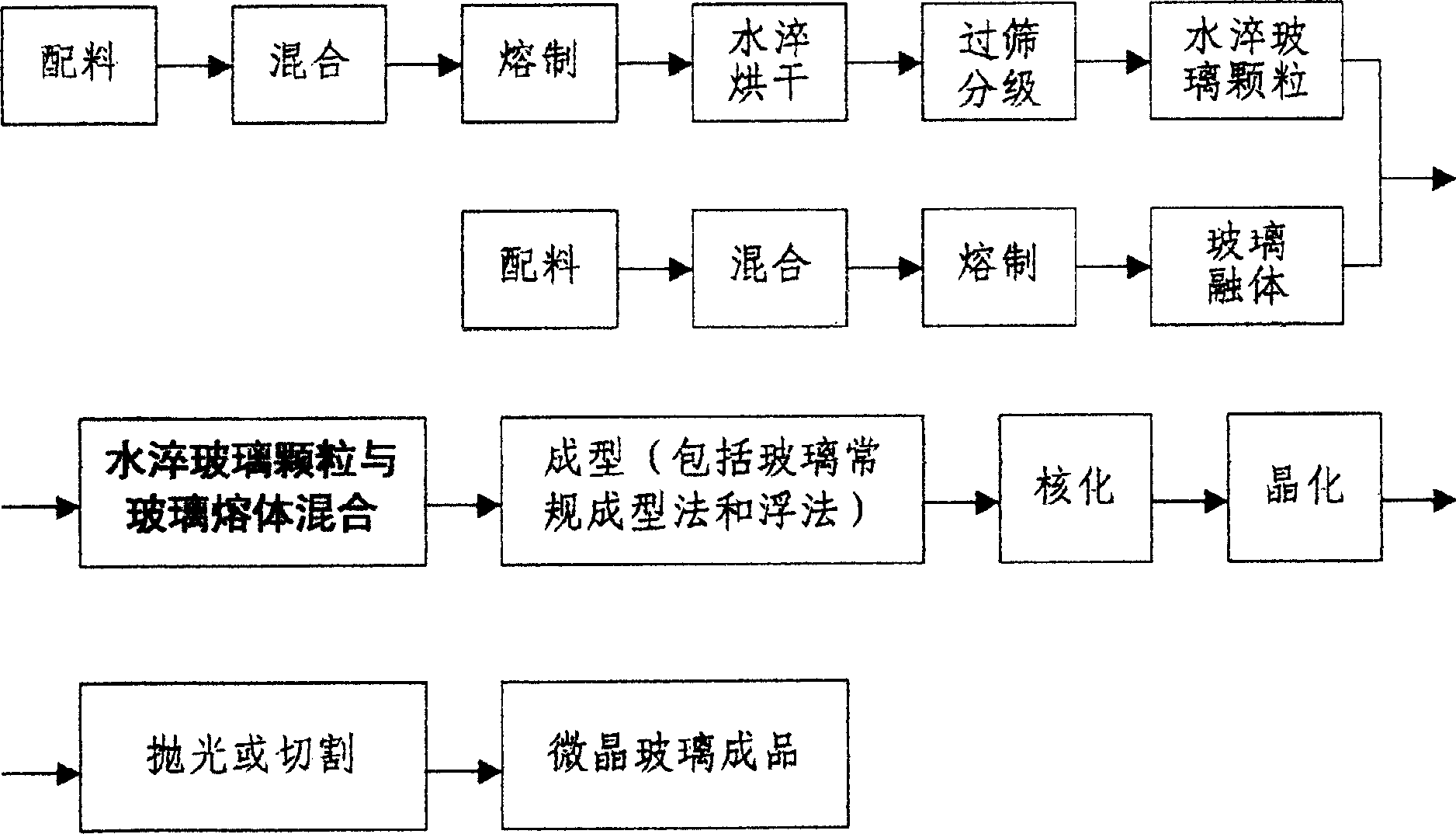

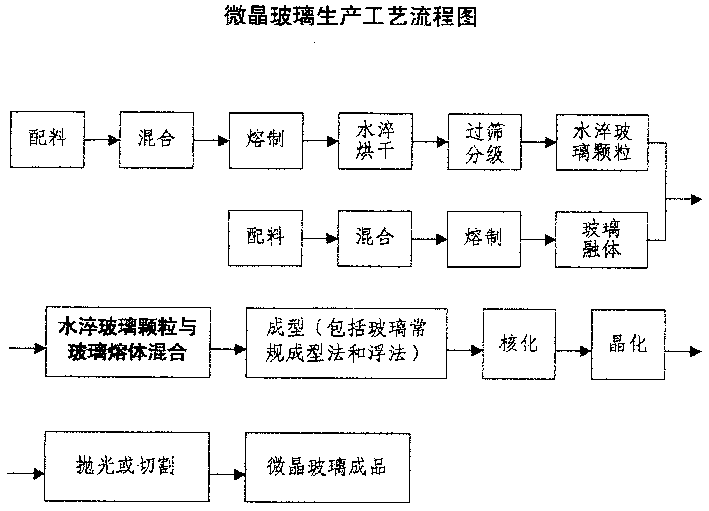

Image

Examples

Embodiment 1

[0012] Select the formula of the base glass by weight percentage: SiO 2 41.87%, Al 2 o 3 9.62%, CaO 31.41%, Na 2 O 15.70%, Fe 2 o 3 0.07%, MgO 0.02%, K 2 O 1.28%, Li 2 O 0.03%; Weigh various raw materials according to the formula of the basic glass, and then mix them uniformly to obtain glass batch materials. After the glass batch materials are filled in a crucible, they are melted in a silicon-molybdenum rod electric furnace at a melting temperature of 1400 ° C and kept for 2 hours. A part of the melted glass liquid is made into water-tempered glass particles and then dried and classified. The particle gradation is 10 mesh to 80 mesh. The other part of the melted glass melt is mixed evenly to obtain the mother glass. Then the mother glass prepared by the particle melt mixing method is kept at 650±50°C for 2 hours to nucleate, and then the temperature is raised to 800±50°C for 15- 30min for crystallization. The results show that the glass-ceramics prepared by the par...

Embodiment 2

[0014] Select the formula of the base glass by weight percentage: SiO 2 57.02%, Al 2 o 3 13.10%, CaO 15.56%, Na 2 O 12.44%, Fc 2 o 3 0.07%, MgO 0.02%, K 2 O 1.75%, Li 2 O 0.04%; Weigh various raw materials according to the formula of the basic glass, and then mix them uniformly to obtain glass batch materials. After the glass batch materials are filled in a crucible, they are melted in a silicon-molybdenum rod electric furnace at a melting temperature of 1400 ° C and kept for 2 hours. A part of the melted glass liquid is made into water-tempered glass particles and then dried and classified. The particle gradation is 10 mesh to 80 mesh. The other part of the melted glass is mixed evenly to obtain the mother glass. Then, the mother glass prepared by the particle melt mixing method is kept at 900±50°C for 2 hours for nucleation, and then the temperature is raised to 1100±50°C for 15-30 minutes for crystallization. The results show that the glass-ceramics prepared by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com