Rare earth magnetostriction material and preparation method thereof

A magnetostriction and stretching technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, self-solidification method, etc., can solve the uneven structure of magnetostrictive rods, there is no better solution, and the influence of alloys Solidification process and other issues, to achieve the effect of good crystallization performance, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

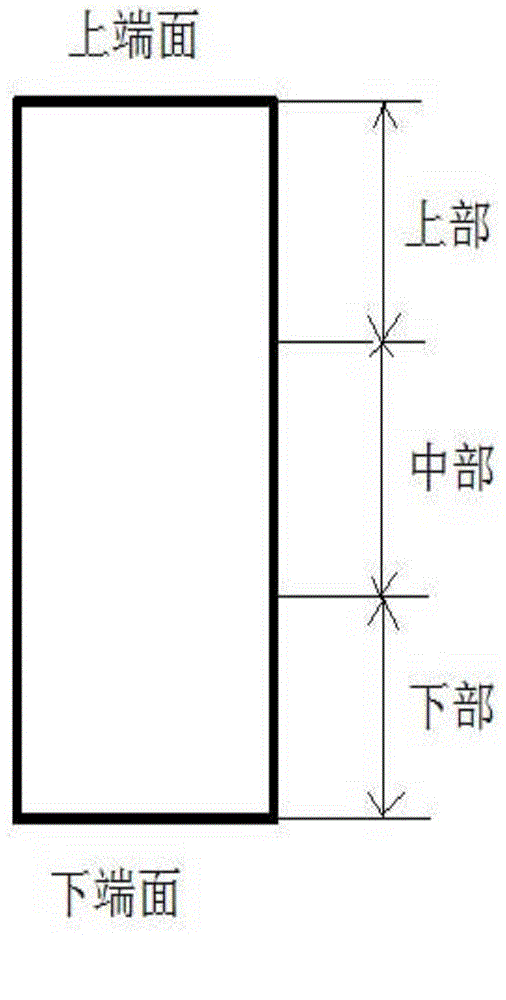

[0039] According to the stoichiometric formula Tb 0.3 Dy 0.7 Fe 1.95 The proportion of ingredients, wherein the excess of Dy is 3%, put the weighed alloy raw materials Tb, Dy, Fe into the melting crucible, and the furnace is vacuumed to 1.0×10 -2 Below Pa, fill with argon, and the pressure of argon is 0.05Mpa. Turn on the intermediate frequency power supply for smelting, the smelting power is 60kW, and the smelting time is 25 minutes. After the raw materials are completely melted, refine for 5 minutes. Then, the molten alloy is poured into the quartz tube in the heat preservation bucket through the pouring system. The size of the quartz tube is Φ30mm×200mm. At this time, the temperature of the heat preservation bucket is 1450°C. After the alloy melt is completely poured into the quartz tube, the pull-down system is started, and the quartz tube on the base of the pull-down rod moves vertically downward along with the pull-down rod, and gradually moves out of the insulation b...

Embodiment 2

[0041] According to the stoichiometric formula Tb 0.3 Dy 0.7 (Fe 0.9 Al 0.1 ) 1.95 The proportion of ingredients, wherein the excess of Dy is 3%, put the weighed alloy raw materials Tb, Dy, Fe into the melting crucible, and the furnace is vacuumed to 1.0×10 -2 Below Pa, fill with argon, and the pressure of argon is 0.03Mpa. Turn on the intermediate frequency power supply for smelting, the smelting power is 60kW, and the smelting time is 25 minutes. After the raw materials are completely melted, refine for 5 minutes. Then, the molten alloy is poured into the quartz tube in the heat preservation barrel through the pouring system. The size of the quartz pipe is Φ30mm×200mm. At this time, the temperature of the heat preservation barrel is 1450°C. After the alloy melt is completely poured into the quartz tube, the pull-down system is started, and the quartz tube on the base of the pull-down rod moves vertically downward along with the pull-down rod, and gradually moves out of ...

Embodiment 3

[0043] According to the stoichiometric formula Tb 0.3 Dy 0.7 (Fe 0.85 mn 0.15 ) 1.95 The proportion of ingredients, wherein the excess of Dy is 3%, put the weighed alloy raw materials Tb, Dy, Fe into the melting crucible, and the furnace is vacuumed to 1.0×10 -2 Below Pa, fill with argon, and the pressure of argon is 0.03Mpa. Turn on the intermediate frequency power supply for smelting, the smelting power is 60kW, and the smelting time is 25 minutes. After the raw materials are completely melted, refine for another 5 minutes. Then, the molten alloy is poured into the quartz tube in the heat preservation bucket through the pouring system. The size of the quartz tube is Φ50mm×300mm. At this time, the temperature of the heat preservation bucket is 1450°C. After the alloy melt is completely poured into the quartz tube, the pull-down system is started, and the quartz tube on the base of the pull-down rod moves vertically downward along with the pull-down rod, and gradually mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com