Barium zirconate fiber and method for preparing same

A barium zirconate and fiber technology, applied in the field of barium zirconate fiber and its preparation, can solve the problems of barium zirconate fiber technology, poor thermal shock resistance stability, low thermal conductivity of barium zirconate, etc. Stable and reliable fiber quality, resistance to mechanical vibration, uniform and stable sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: prepare barium zirconate fiber with acetic acid as acid source

[0037] (1) Weigh 31.80g of basic zirconium carbonate and 19.74g of barium carbonate in a beaker, then add 24g of glacial acetic acid and 24g of methanol, and heat and stir at 60°C until dissolved to prepare a barium zirconate precursor solution.

[0038] (2) The obtained barium zirconate fiber solution was concentrated under reduced pressure at 40° C. to remove the solvent to obtain a barium zirconate precursor sol with a viscosity of 60 Pa·s, which was aged for 1 hour to obtain a spinning solution.

[0039] (3) At a temperature of 25°C, a humidity of 30%, a rotating speed of 18,000r / min, and a spinning hole diameter of 0.2mm, inject the obtained spinning solution into a high-speed spinning disk, and draw it into silk under the action of high-speed centrifugation , to obtain barium zirconate precursor fibers. The photo of the barium zirconate precursor fiber obtained by centrifugal spinning ...

Embodiment 2

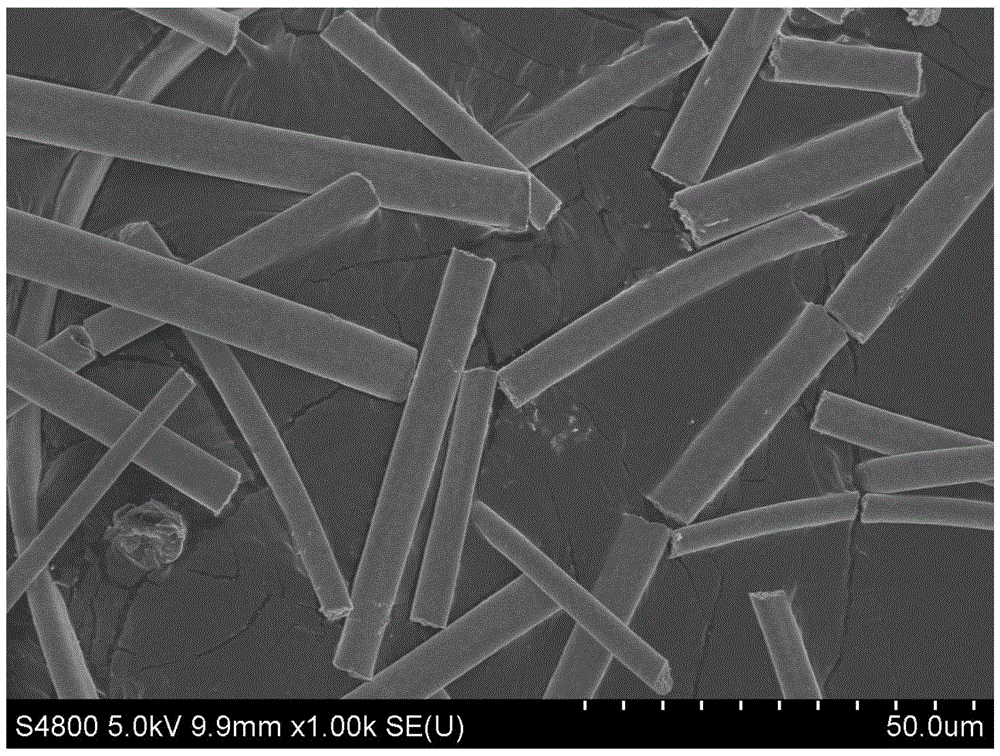

[0044] As described in Example 1, the difference is step (4): the obtained barium zirconate precursor fiber is heated up to 600 ° C at a heating rate of 1 ° C / min, and kept at 30 min; then heated to 1500 ° C at 3 ° C / min ℃, keep it warm for 2 hours, and cool down naturally, you can get barium zirconate fiber, its SEM picture is as follows Figure 4 shown. Barium zirconate fibers can still maintain good shape and no sintering adhesion occurs between fibers.

Embodiment 3

[0045] Embodiment 3: prepare barium zirconate fiber with trifluoroacetic acid as acid source:

[0046] As described in Example 1, the difference is that the acid source was changed from glacial acetic acid to trifluoroacetic acid, and 45.6 g of trifluoroacetic acid was weighed and dissolved in a solvent, and then added to basic zirconium carbonate and barium carbonate. The spinning solution preparation, centrifugal spinning and sintering process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com