Preparation method of phosphorus position partly substituted iron lithium phosphate powder

A technology of lithium iron phosphate and powder, which is applied in the field of electrochemical power material preparation, can solve the problems of weakening Fe-O bond, reducing open circuit voltage, and crystal structure without lithium insertion-storage, etc., and achieves good crystallization performance and high composition Uniform, broad-spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a partially substituted phosphorus lithium iron phosphate lithium ion battery positive electrode material that significantly improves the performance of the matrix basic battery by partially replacing the phosphorus element in the phosphorus position in lithium iron phosphate with boron, tungsten, sulfur and silicon elements Powder preparation method. Said lithium ion battery cathode material lithium iron phosphate uses molecular formula LiFeP 1-y D. y o 4 Indicates that D is a substitute, 0<y≤0.5;

[0026] The specific preparation method of the phosphorus partially substituted lithium iron phosphate powder is as follows:

[0027] Lithium salt, ferrous salt, phosphate and substituents are mixed once at a molar ratio of Li:Fe:P:D=1:1:(1-y):y, and then deionized water, industrial alcohol and no At least one of water and ethanol is used as a mixing medium for ball milling for 6 to 12 hours, and dried at 40 to 70°C; after drying, the powde...

Embodiment 1

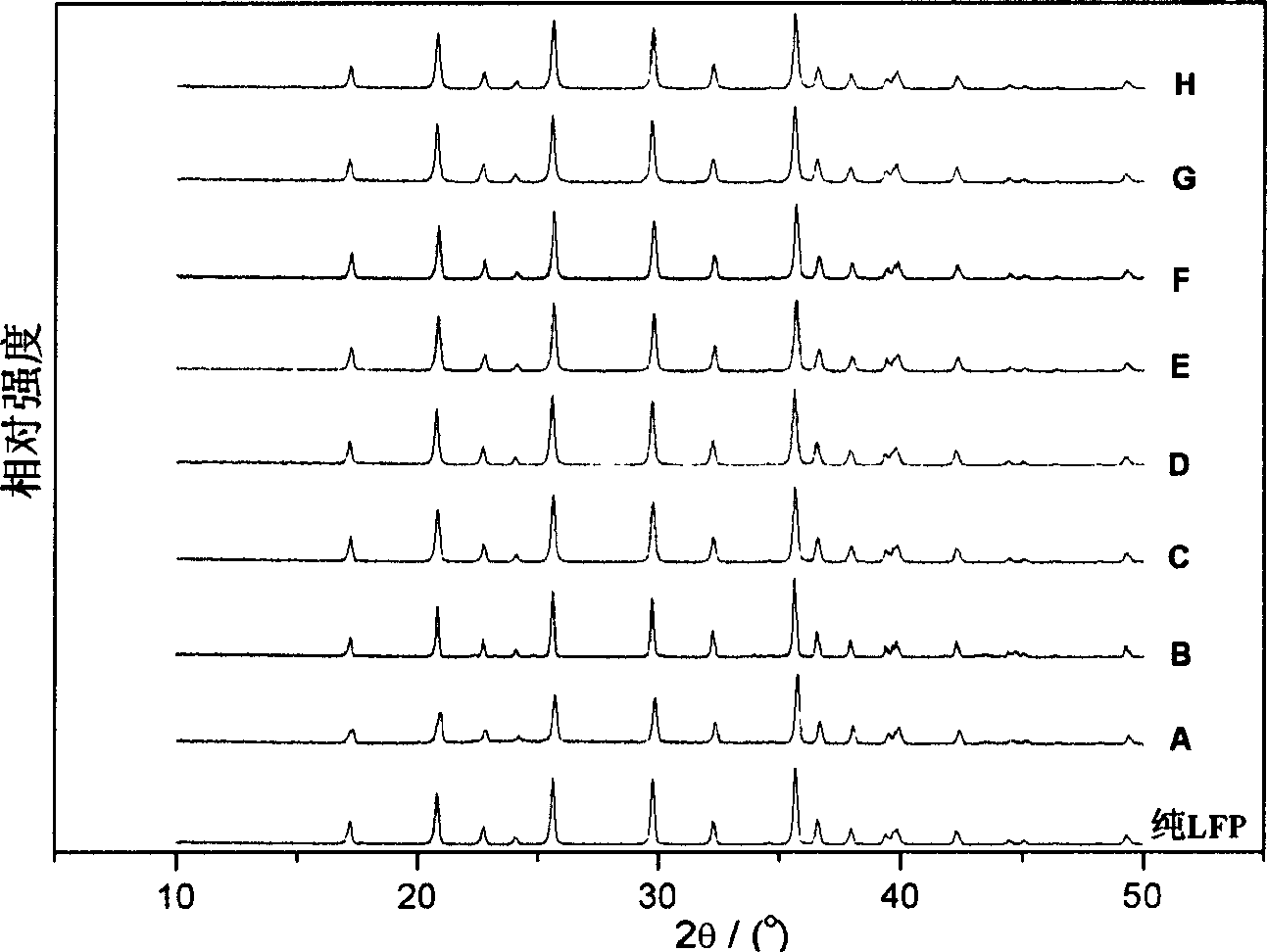

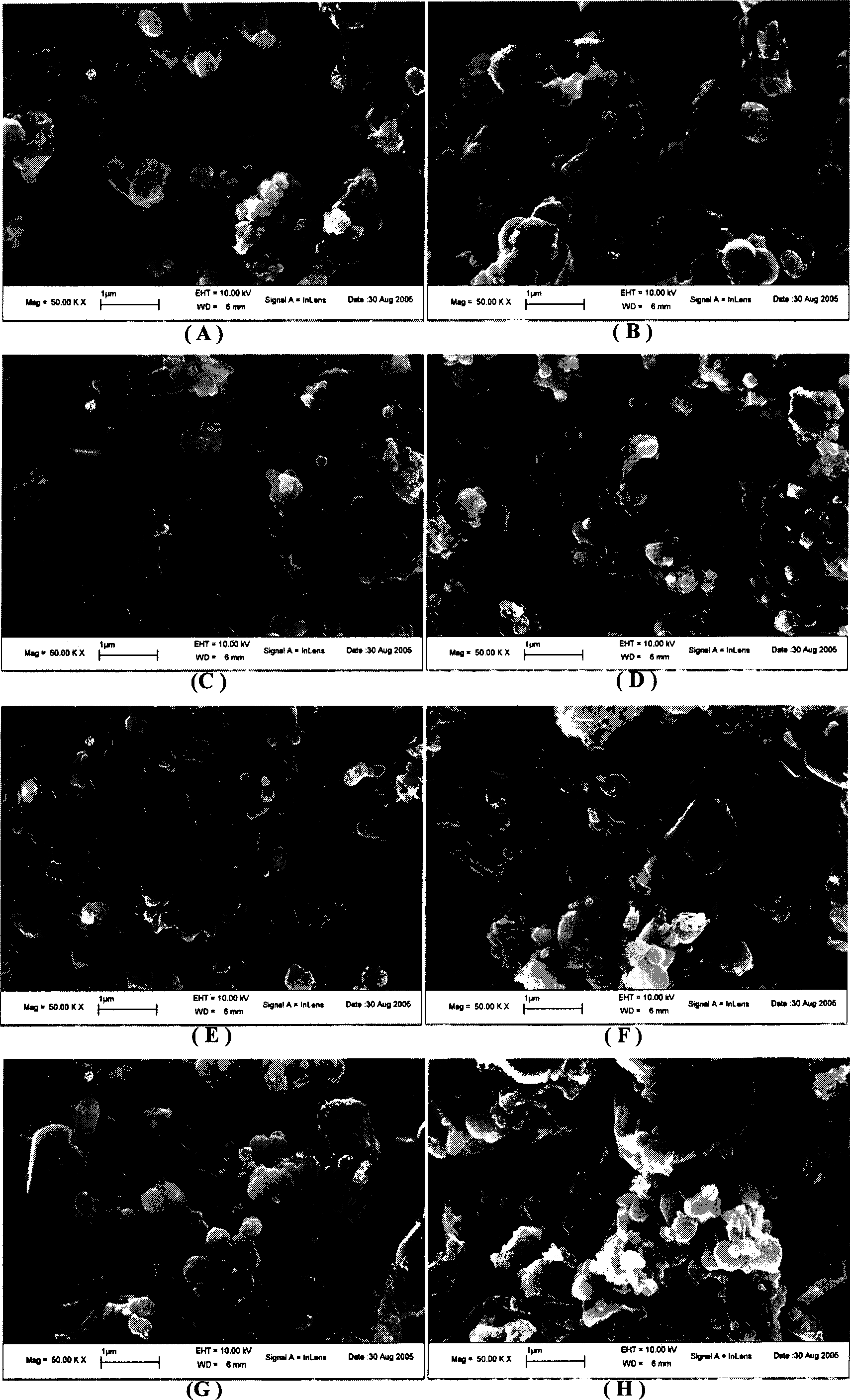

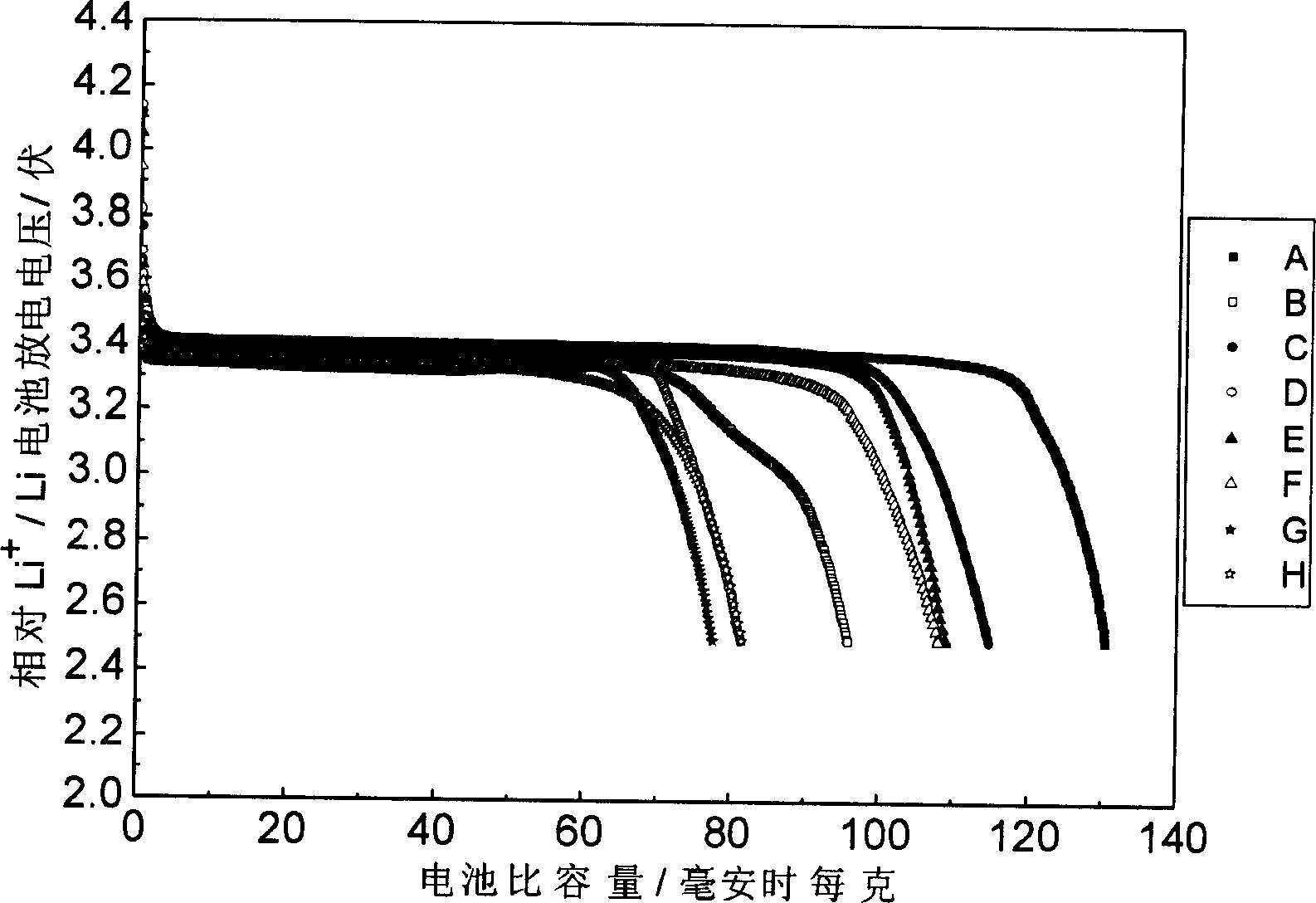

[0040] 0.05 mol lithium carbonate Li 2 CO 3 , 0.1 mole ferrous oxalate Fe(C 2 o 4 )·2H 2 O and 0.0975 moles of ammonium dihydrogen phosphate NH 4 h 2 PO 4 and 0.0025 moles of boric acid H 3 BO 4 Mix, add to a polyester tank, add 55ml of absolute alcohol, seal and mix on a planetary ball mill for 10 hours, discharge and dry under a nitrogen atmosphere of 0.3 liters / minute, and raise the temperature to 400°C, keep warm for 8 hours, cool down to room temperature with the furnace to obtain pre-burned material; then use industrial alcohol as the medium for ball milling for 6 hours, and after drying the material, in a nitrogen atmosphere of 0.3 liters / min, the temperature rises at a rate of 4°C / min The rate was raised to 700°C, kept at this temperature for 8 hours, and cooled to room temperature with the furnace, and the obtained positive electrode material LiFe(P 0.975 B 0.025 o 4 ) is recorded as sample A. figure 1 In A is the resulting LiFe(P 0.975 B 0.025 o 4 ) XR...

Embodiment 2

[0043] 0.1 lithium hydroxide LiOH·H 2 O, 0.1 mole of ferrous oxalate and 0.07 mole of diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 and 0.03 mole of trimethyl borate (CH 3 O) 3 B is mixed, put into a polyester tank, add 40ml of absolute alcohol, seal it and mix it on a planetary ball mill for 6 hours. to 430°C, keep at this temperature for 7.5 hours, and cool to room temperature with the furnace. Take out the calcined material, add an appropriate amount of deionized water, and seal the ball mill for 10 hours. After the discharge is dried, in a nitrogen-hydrogen mixed atmosphere of 0.3 liters / minute (nitrogen: hydrogen = 9: 1, volume ratio), at 4 ° C / minute The heating rate rose to 720 °C, kept at this temperature for 7 hours, and cooled to room temperature with the furnace, and the obtained positive electrode material LiFe(P 0.7 B 0.3 o 4 ) is recorded as sample B. figure 1 In B is obtained LiFe(P 0.7 B 0.3 o 4 ) XRD pattern, the addition of boron did not change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com