Liquid discharge apparatus

A technology of liquid and ejection parts, which is applied in printing devices, transportation and packaging, thin material processing, etc., and can solve problems such as image quality degradation and ink spraying position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

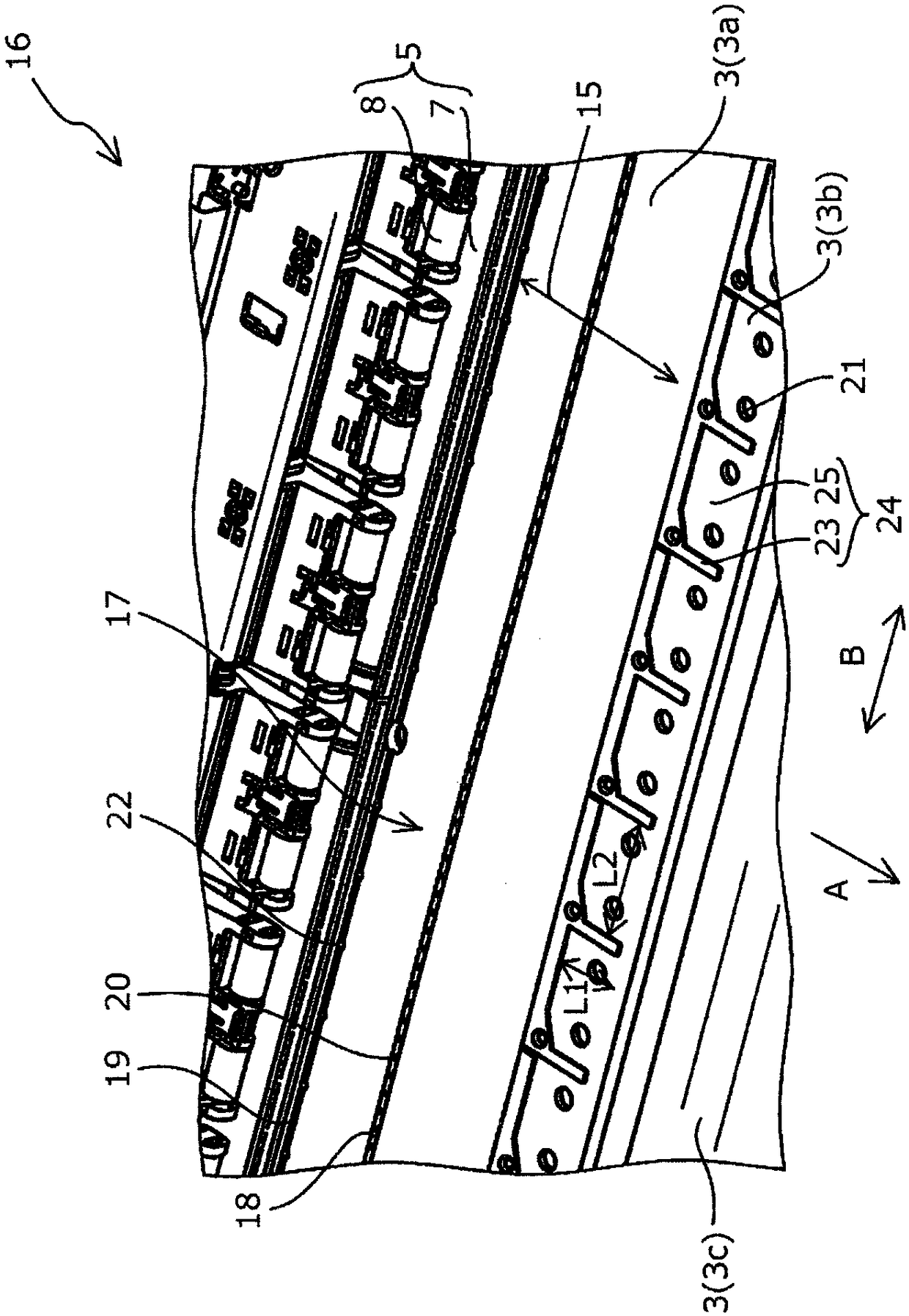

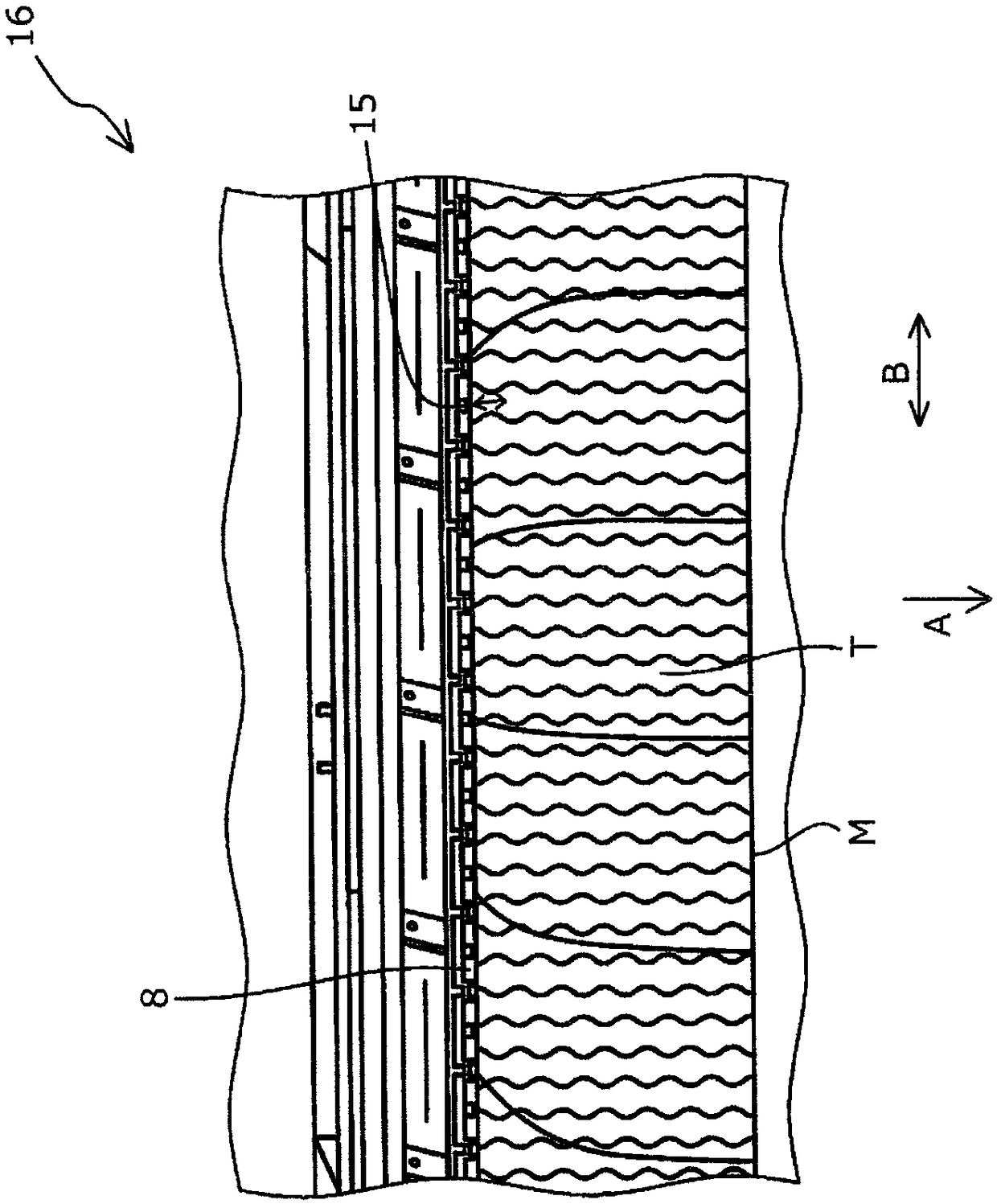

[0042] Example 1 ( Figure 1 to Figure 12 )

[0043] First, an outline of a printing device according to Embodiment 1 of the present invention will be described.

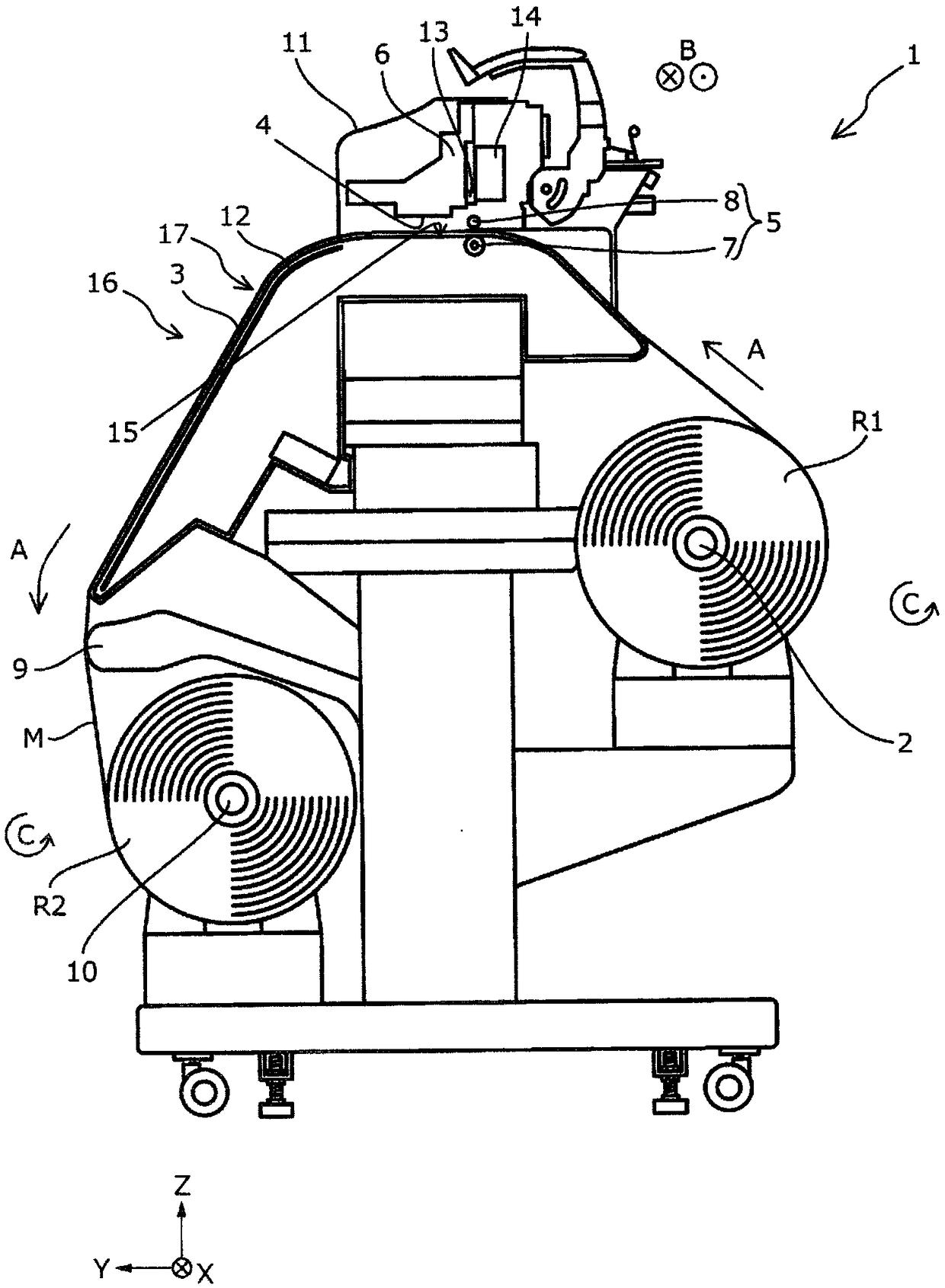

[0044] figure 1 It is a schematic side view of the printing apparatus 1 according to this embodiment.

[0045] The printing apparatus 1 of the present embodiment includes a support shaft 2 that supports a roll R1 of a roll-shaped medium M for printing. Furthermore, when the printing apparatus 1 of this embodiment transports the medium M in the transport direction A, the support shaft 2 rotates in the rotation direction C. As shown in FIG. In addition, although the roll-shaped medium M wound up with the printing surface on the outside is used in this embodiment, in the case of the roll-shaped medium M wound up on the inside with the printing surface Next, the support shaft 2 can also be rotated in a direction opposite to the rotation direction C to feed out the roll R1.

[0046]In addition, although a roll-shape...

Embodiment 2

[0088] (Example 2)( Figure 13 )

[0089] Hereinafter, Example 2, which is a configuration example in which the first support surface 3 a does not adjoin the concave-convex portion 24 of the second support surface 3 b in the conveyance direction A, will be described.

[0090] Figure 13 It is a perspective view around the ejection range 15 of the support part 17 which is the main part of the printing apparatus 1 of this embodiment, and shows the state where the medium M is not set on the conveyance path 16, and is the same as that of the first embodiment. figure 2 corresponding figure. In addition, the components common to those of the first embodiment described above are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0091] In addition, in the printing device 1 of the present embodiment, the structures other than the support surface 3 are the same as those of the printing device 1 of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com