Connector for printed wiring board

A technology for printed wiring boards and connectors, which is applied to printed circuit components, structural connections of printed circuits, printed circuits, etc., and can solve problems such as easy wear, easy deformation of the shell, and reduced connection strength between the shell and the skeleton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

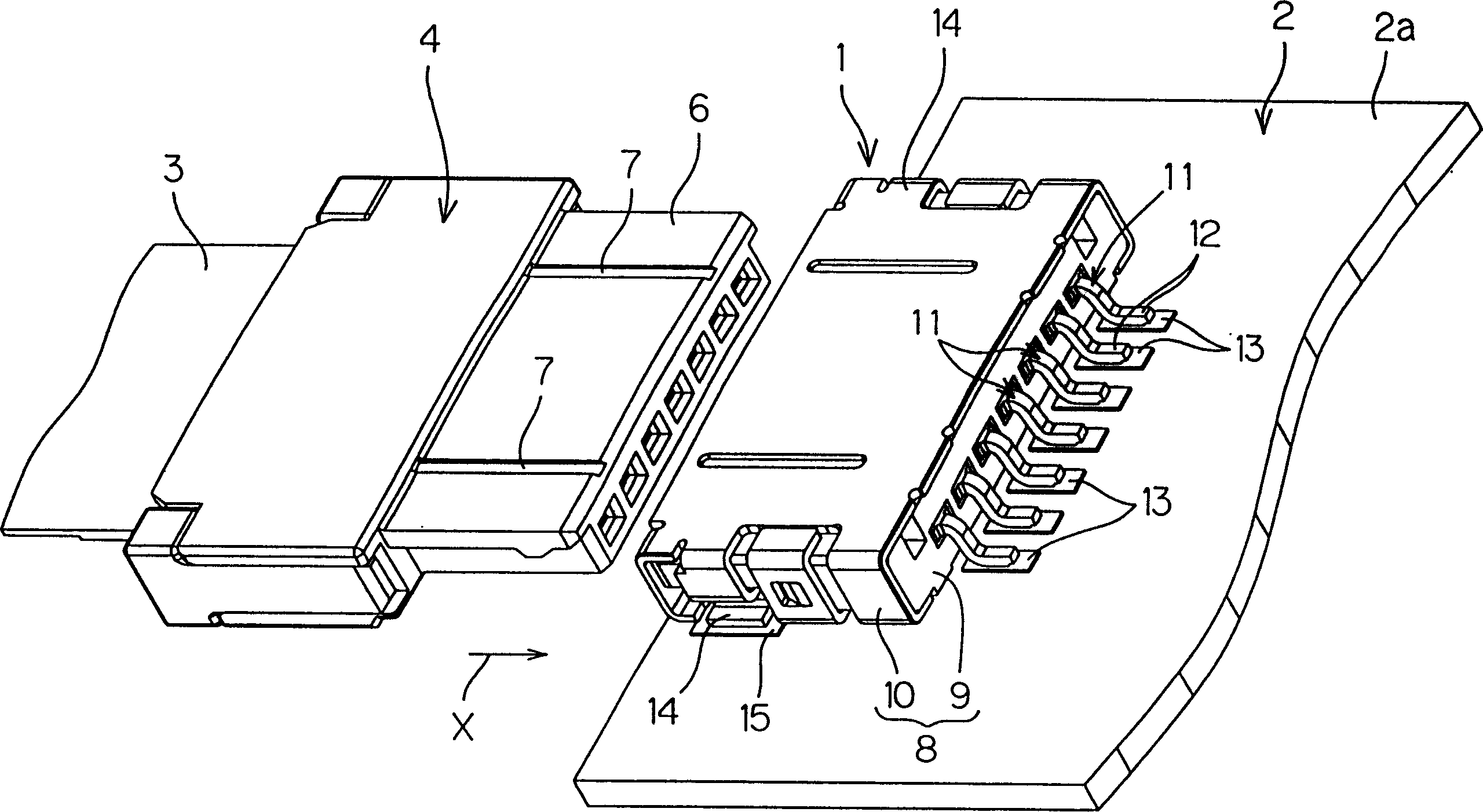

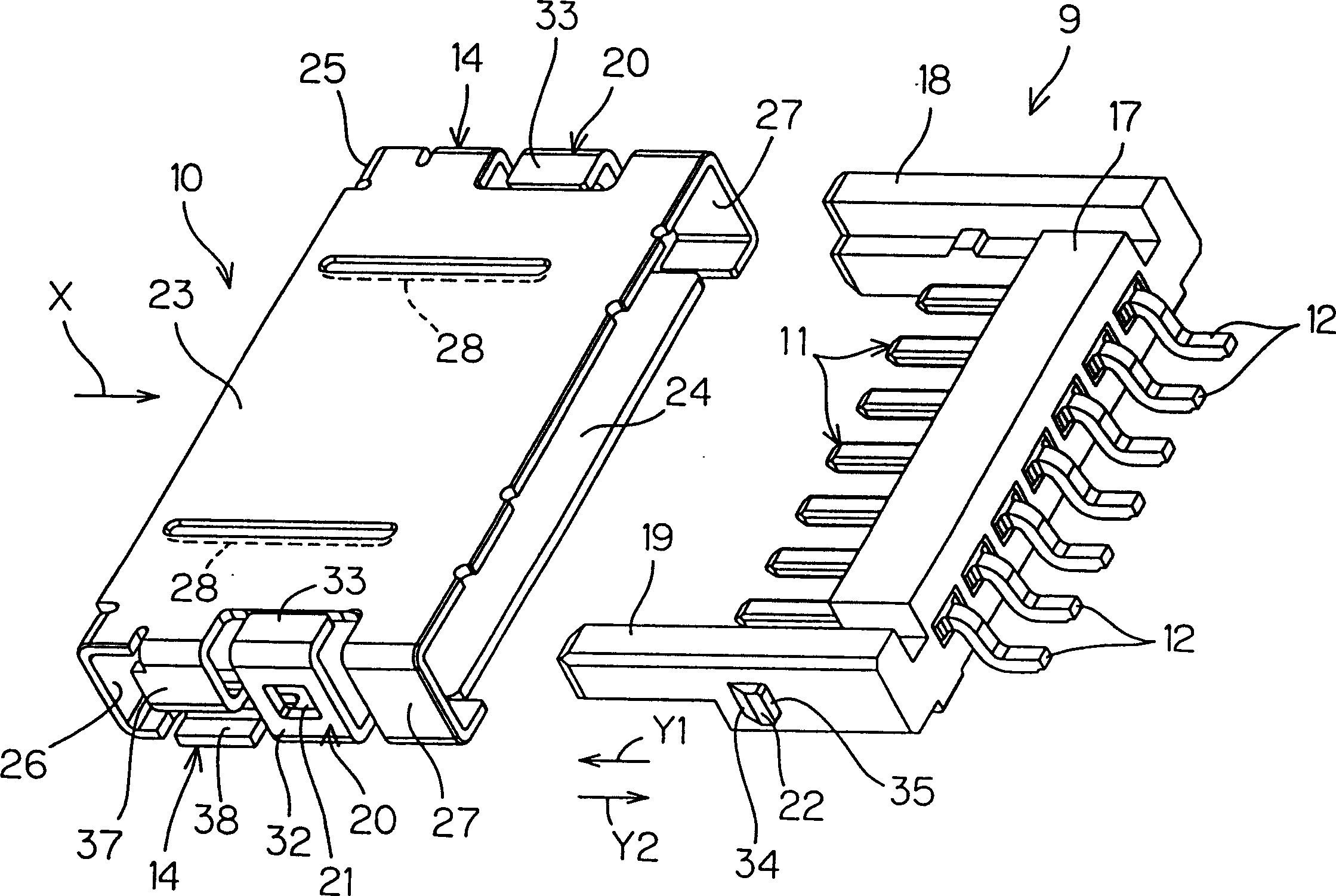

[0030] refer to figure 1 , the base connector 1 is arranged along the surface of the printed wiring board 2, and is connected to the opposite socket connector 4 connected to the end of the flexible printed circuit board 3 called FPC. The socket connector 4 has an insertion space 5 (refer to Image 6 ) The insertion protrusion 6 for insertion and extraction. A pair of left and right grooves 7 extending parallel to the insertion direction X of the socket connector 4 are formed on the upper surface of the insertion protrusion 6 .

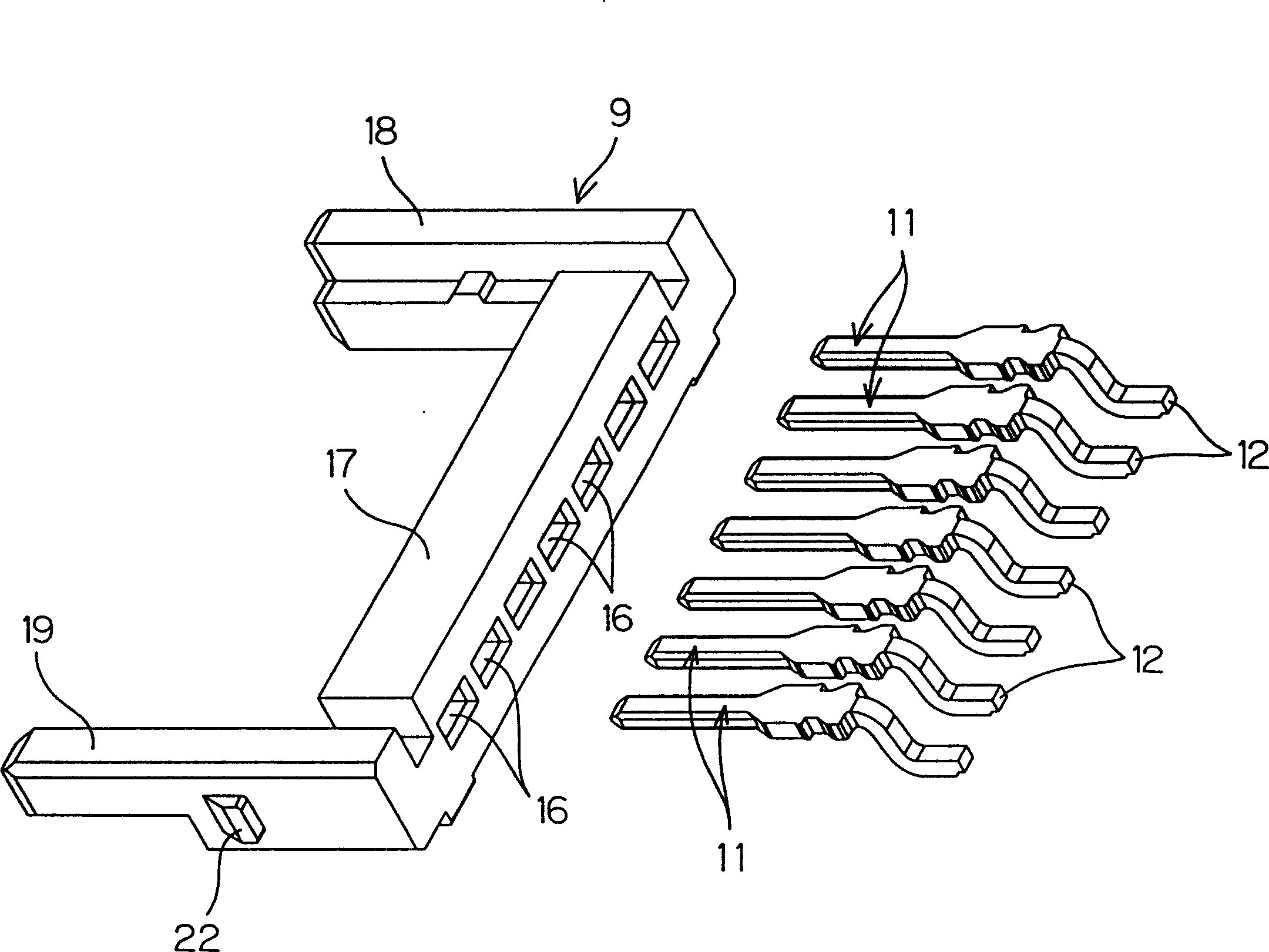

[0031] refer to figure 1 and figure 2 The base connector 1 includes a connector body 8 having a frame 9 made of synthetic resin and a shell 10 serving as an electromagnetic shield made of a thin metal plate.

[0032] refer to figure 1 The base connector 1 is fixed by soldering the reeds 12 of the exposed contacts 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com