Wooden tray nailing equipment

A technology for wooden pallets and equipment, which is applied in nailing tools, nailing staple tools, manufacturing tools, etc., can solve the problems of low work efficiency, irregular nails, unstable depth and other problems, and achieves improved work efficiency and nail depth. Accurate, lower production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

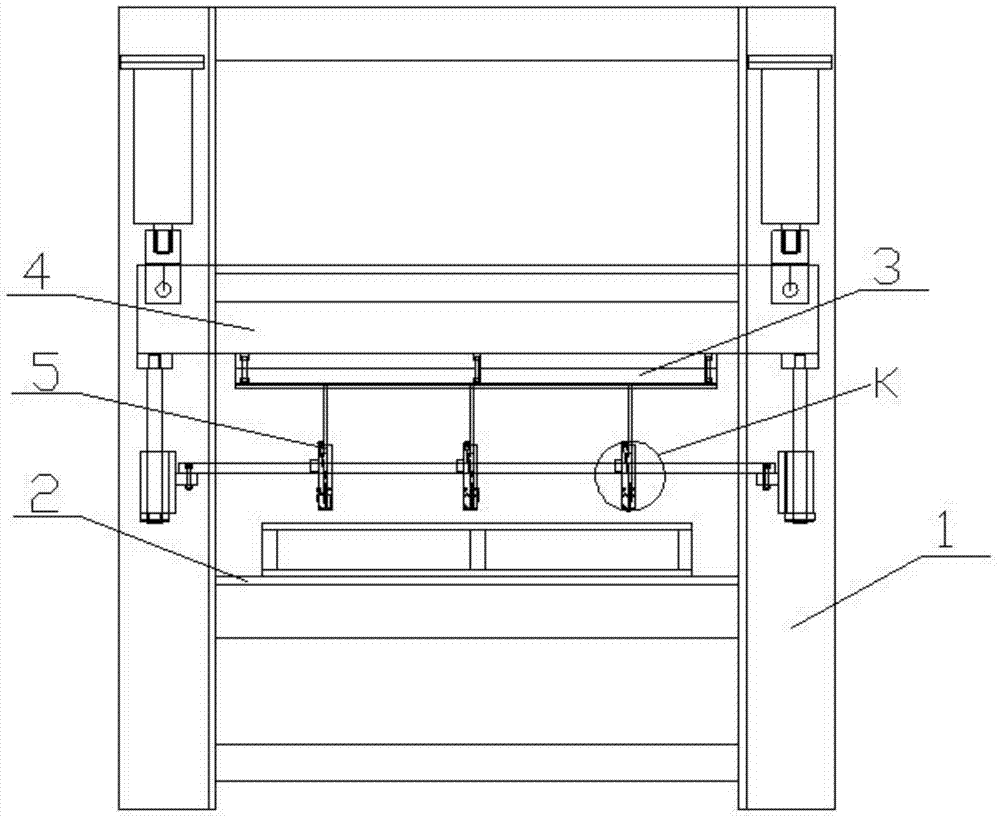

[0029] according to Figure 1 to Figure 6 , the present invention provides a wooden pallet nailing device, comprising a frame 1, a wooden pallet loading platform 2 is arranged on the frame 1, and a guide rail is provided under the wooden pallet loading platform 2, which is used for loading and unloading wooden pallets. For unloading, a nailing device 3 is arranged above the wooden pallet loading platform 2, and a loose nail supply device is arranged above the nailing device 3.

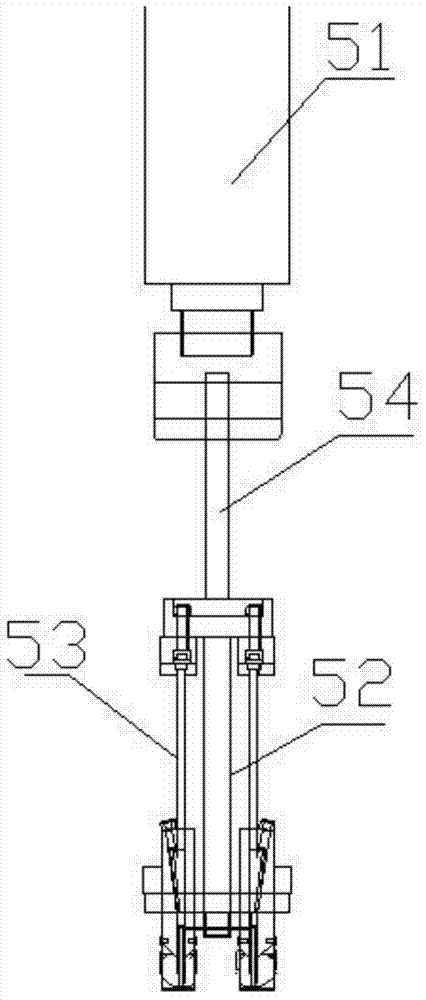

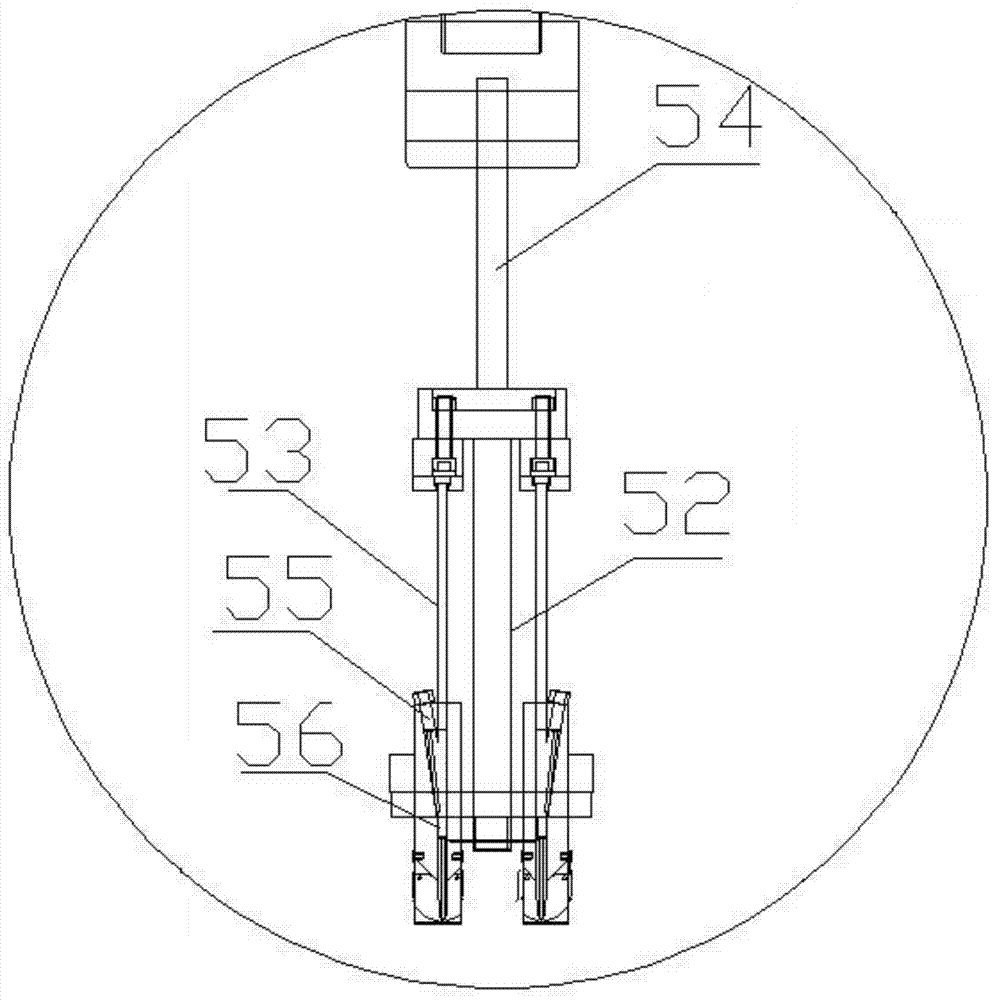

[0030] The nailing device 3 is installed on the frame by the mounting bracket 4, the nailing device 3 includes several nailing lines, each nailing line includes several nailers 5, and the nailer 5 includes a hydraulic cylinder 51 and a nailing gun The head 52, the hydraulic cylinder 51 and the nailer head 52 are connected through a vertical slide bar 54. There are three limit switches on one side of the hydraulic cylinder 51, which respectively control the initial position of the nailing, and the press...

Embodiment 2

[0035] The first cylinder is changed into the first eccentric, and the second cylinder is changed into the second eccentric, and others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com