Patents

Literature

70results about How to "Reduce quality accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

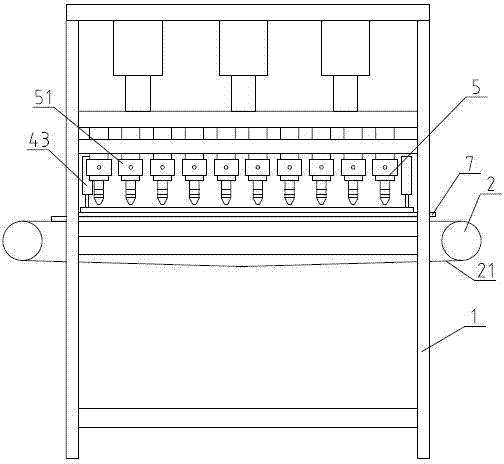

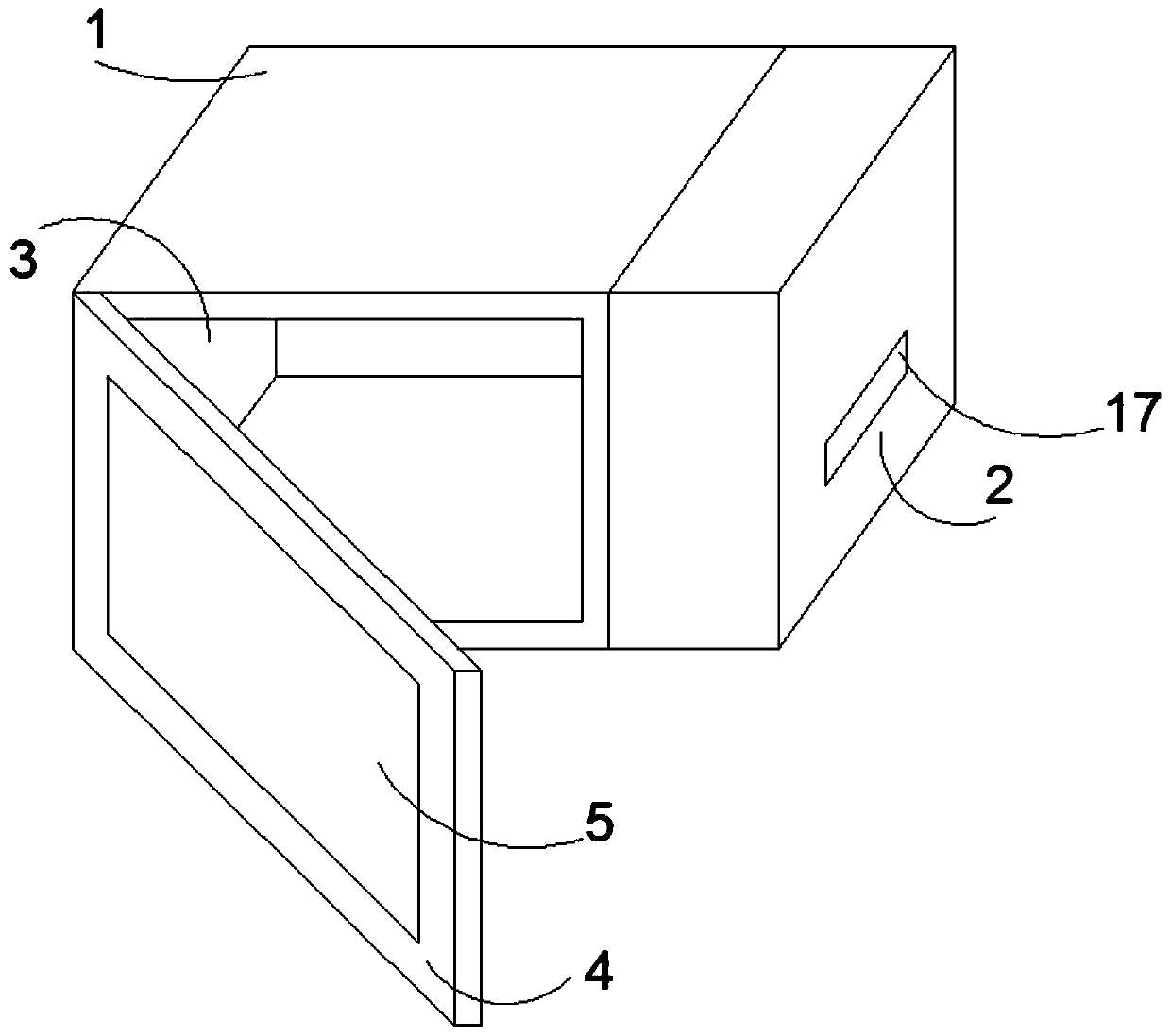

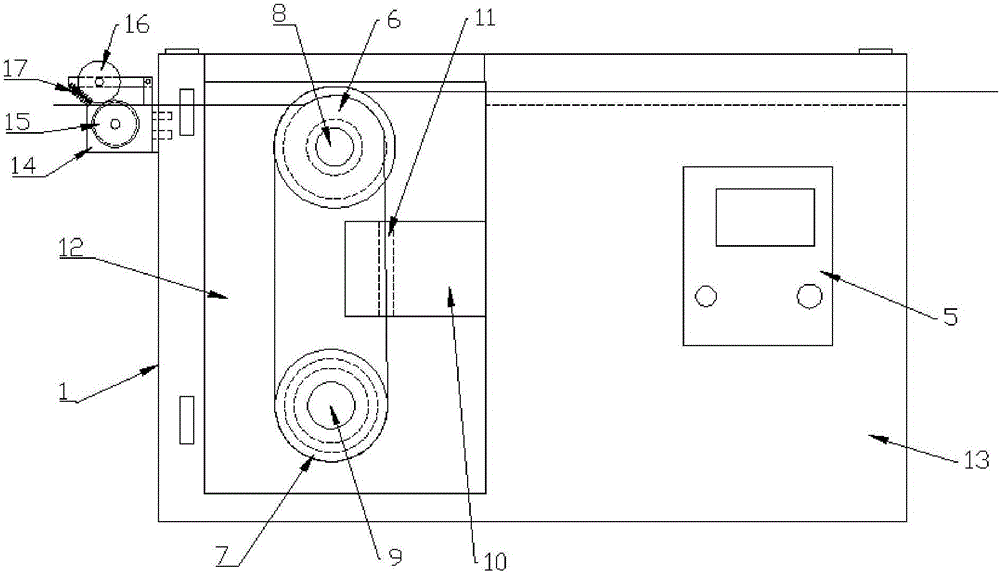

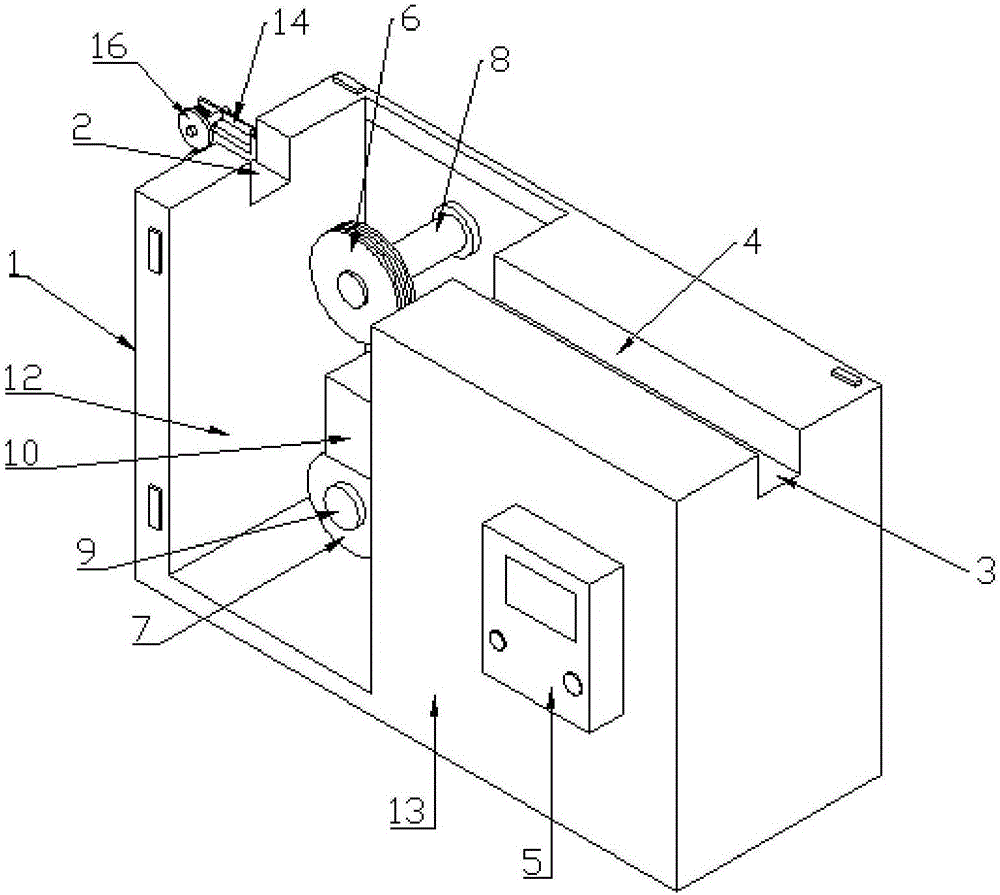

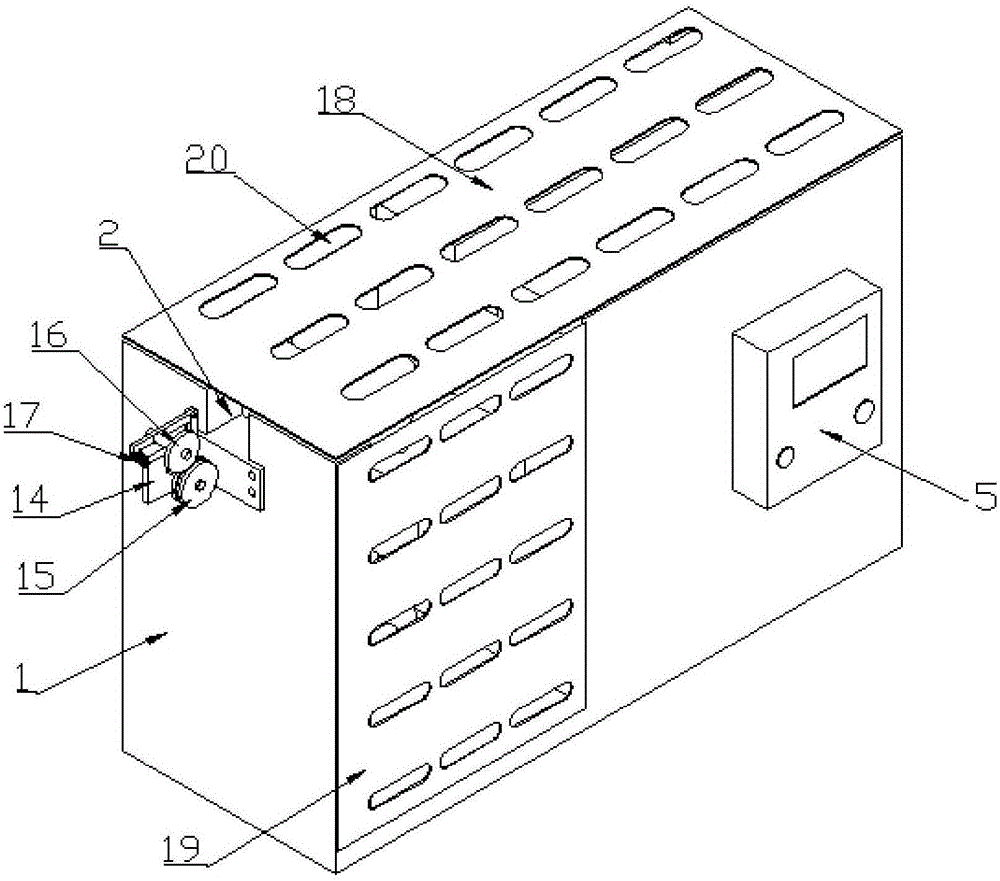

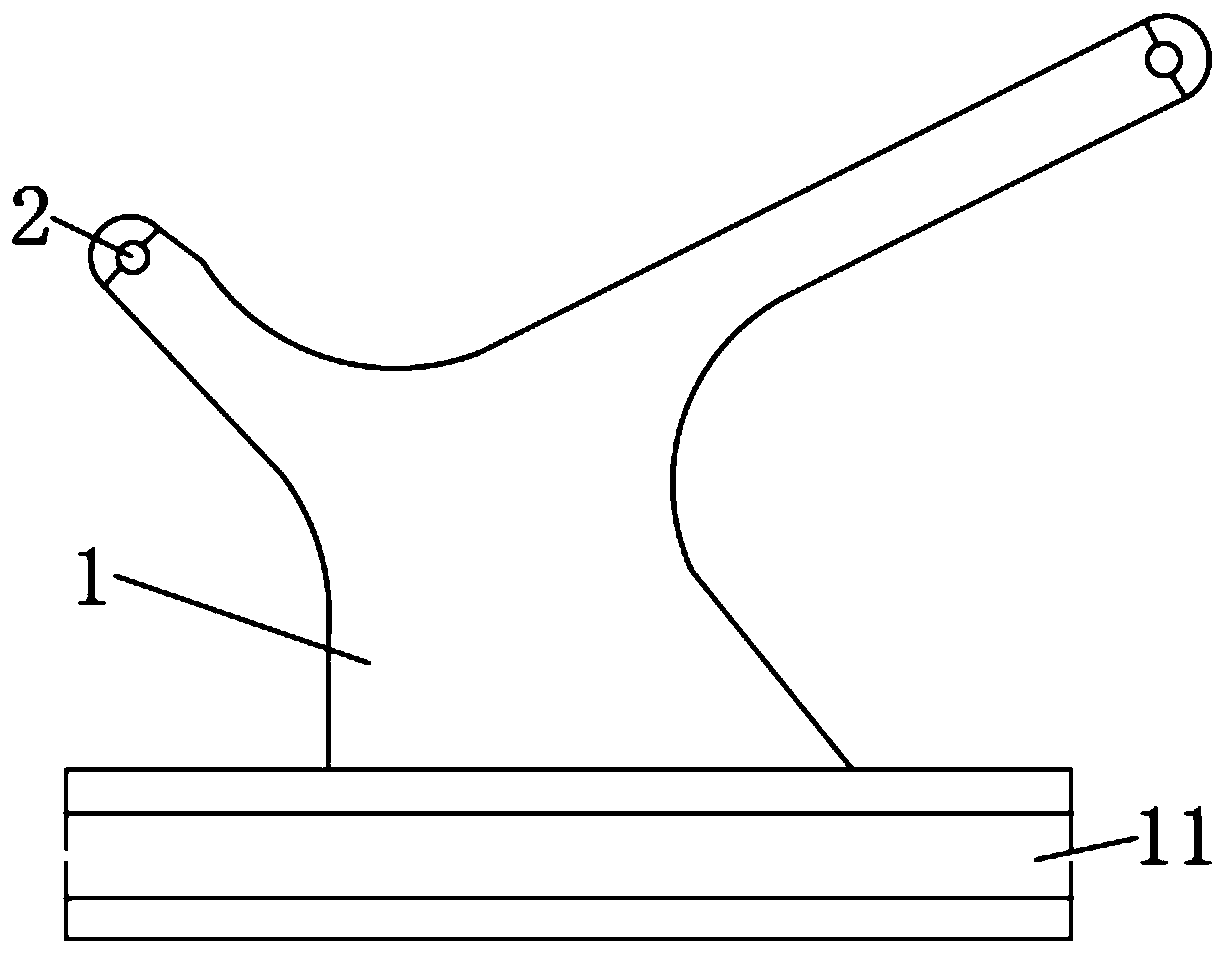

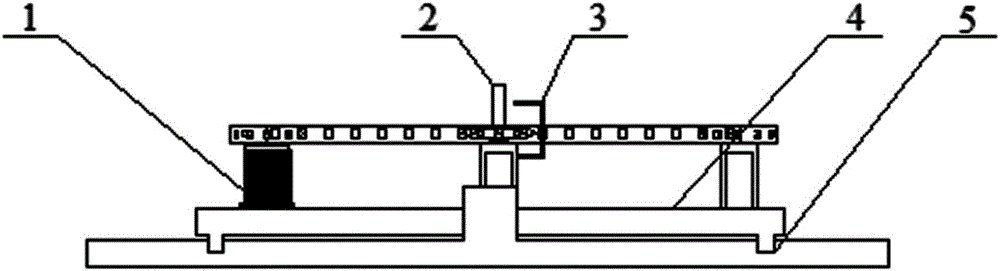

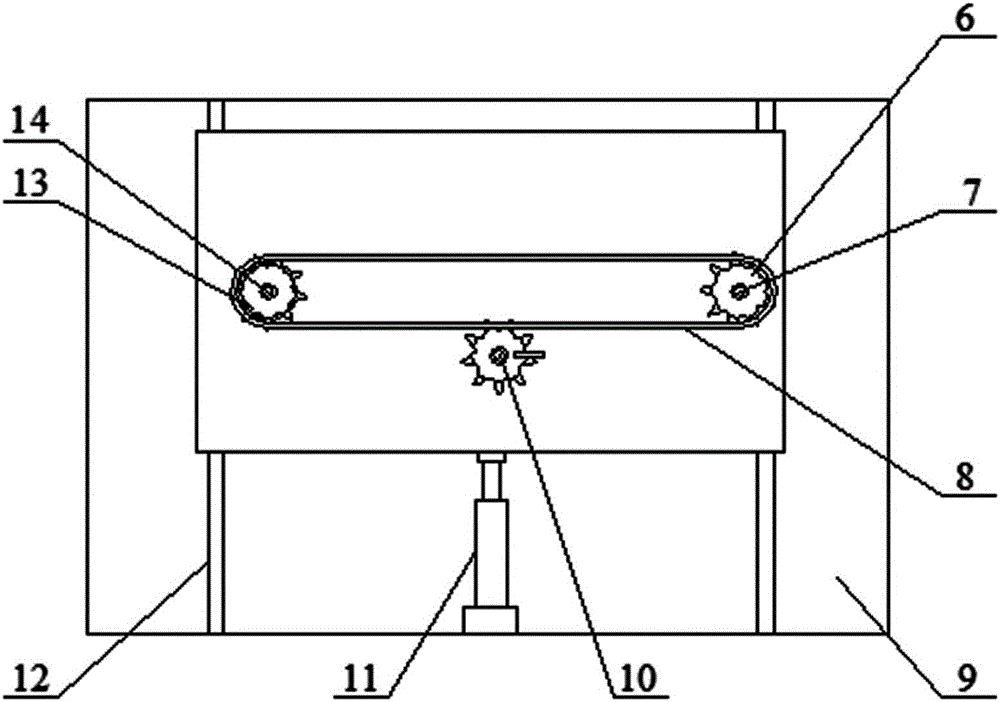

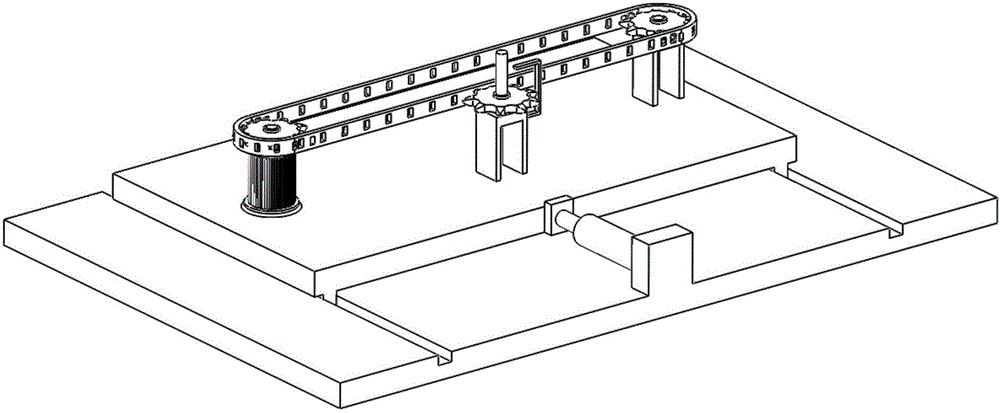

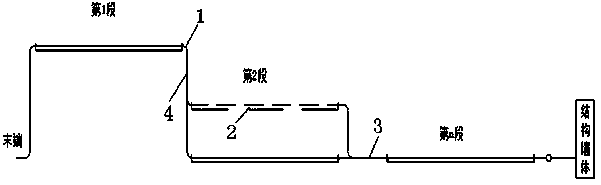

Floorboard nailing device

ActiveCN103612299AReduce quality accidentsReduce labor cost inputStapling toolsNailing toolsProcedural approachFuselage

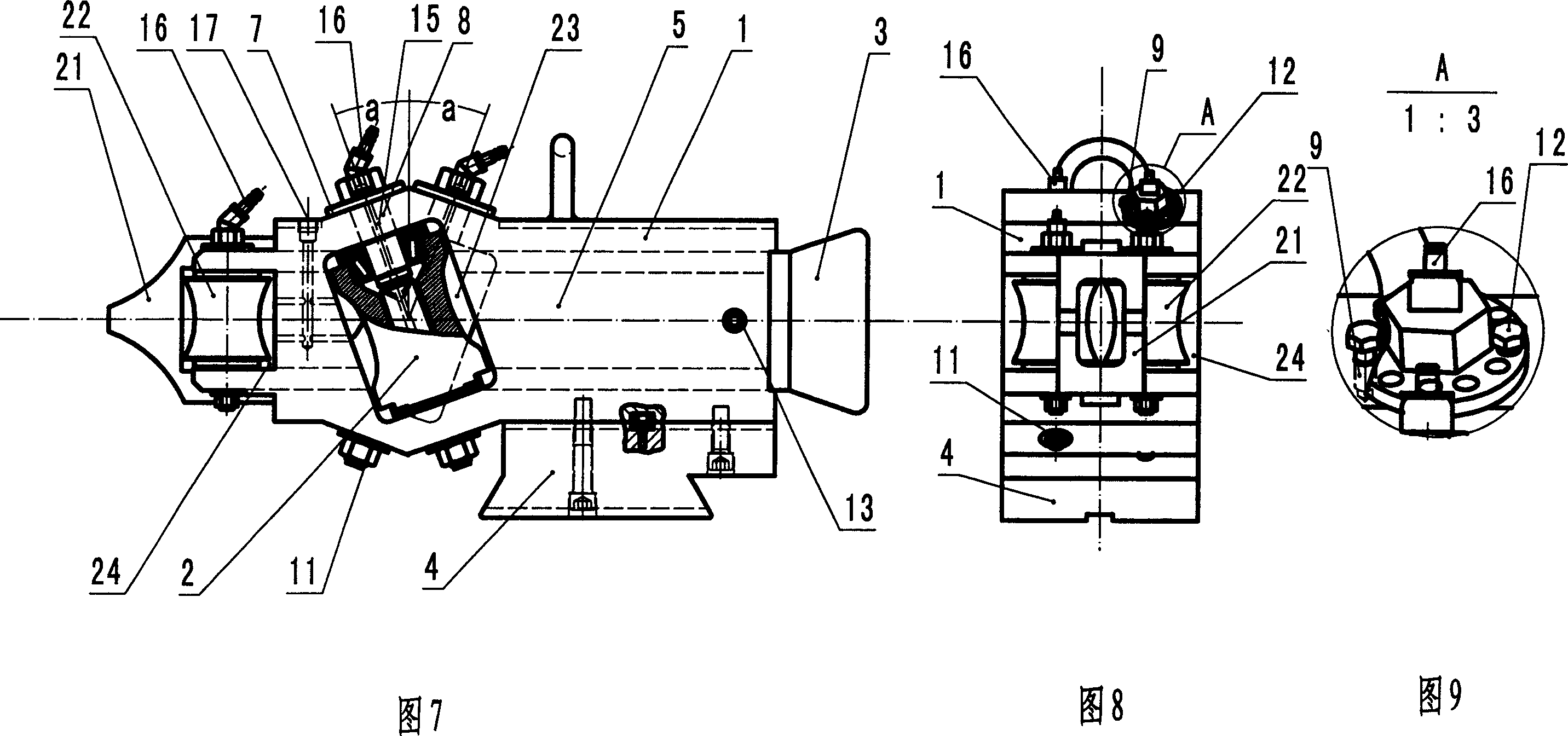

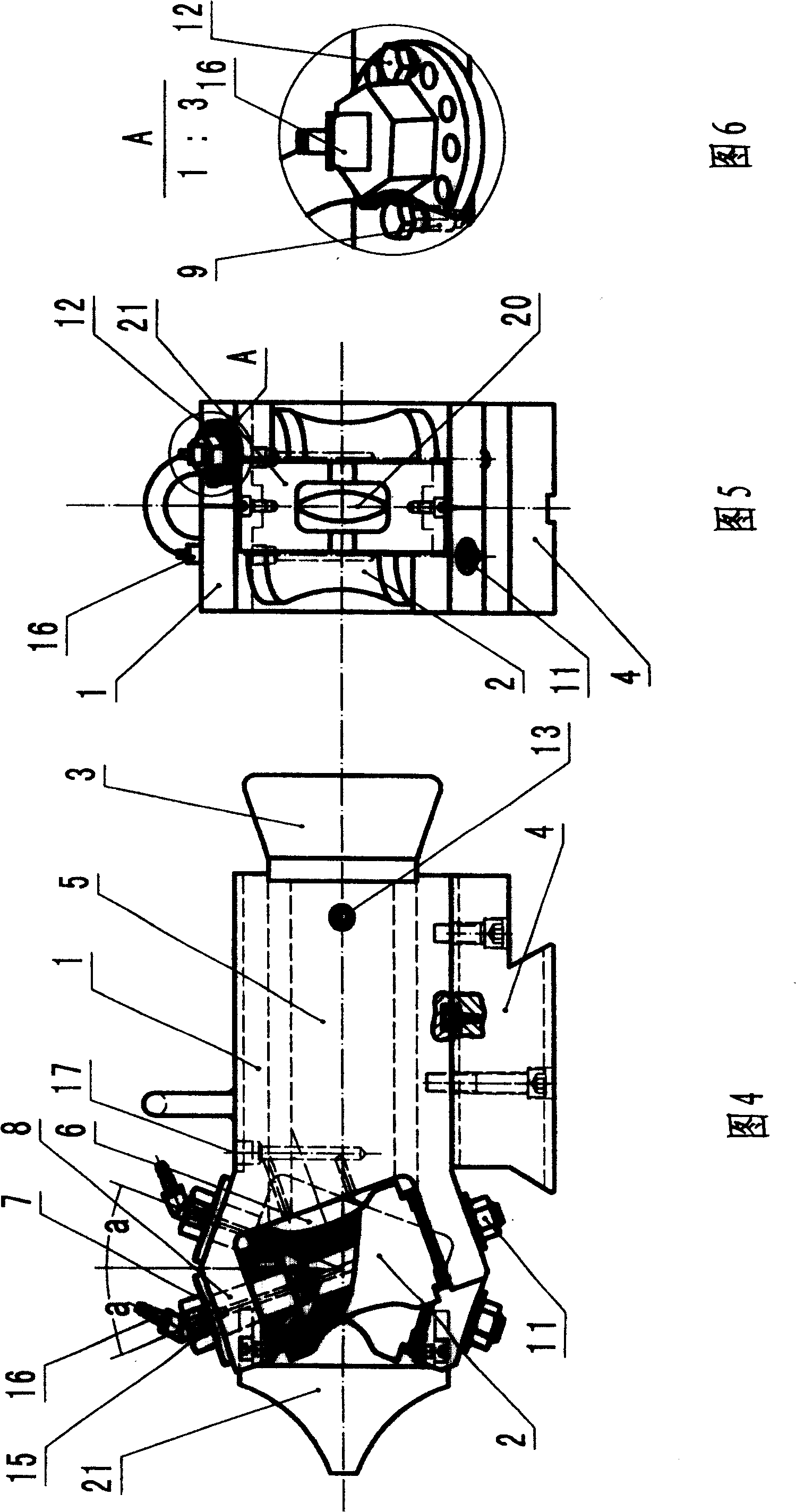

The invention provides a floorboard nailing device which comprises a machine body, a conveying device, a sensing device, a positioning device, a nailing device body and a position regulation device. The conveying device, the sensing device, the positioning device, the nailing device body and the position regulation device are arranged on the machine body. The conveying device is used for conveying floorboards. The sensing device is used for controlling the conveying device. The positioning device is used for positioning and clamping the floorboards. The position regulation device is used for regulating the relative positions of the nailing device body and the floorboards. The floorboard nailing device can be used for completely replacing manual operation. Consequently, quality accidents caused by human factors are reduced, and investment of labor cost is also lowered. The floorboard nailing device is controlled by a computer program and can be perfectly connected with a device in a previous process and a device in a follow-up process in the operating process, so production efficiency is greatly improved. The floorboard nailing device belongs to the field of floorboard production technologies.

Owner:GUANGZHOU HOMEBON WOOD MFG +1

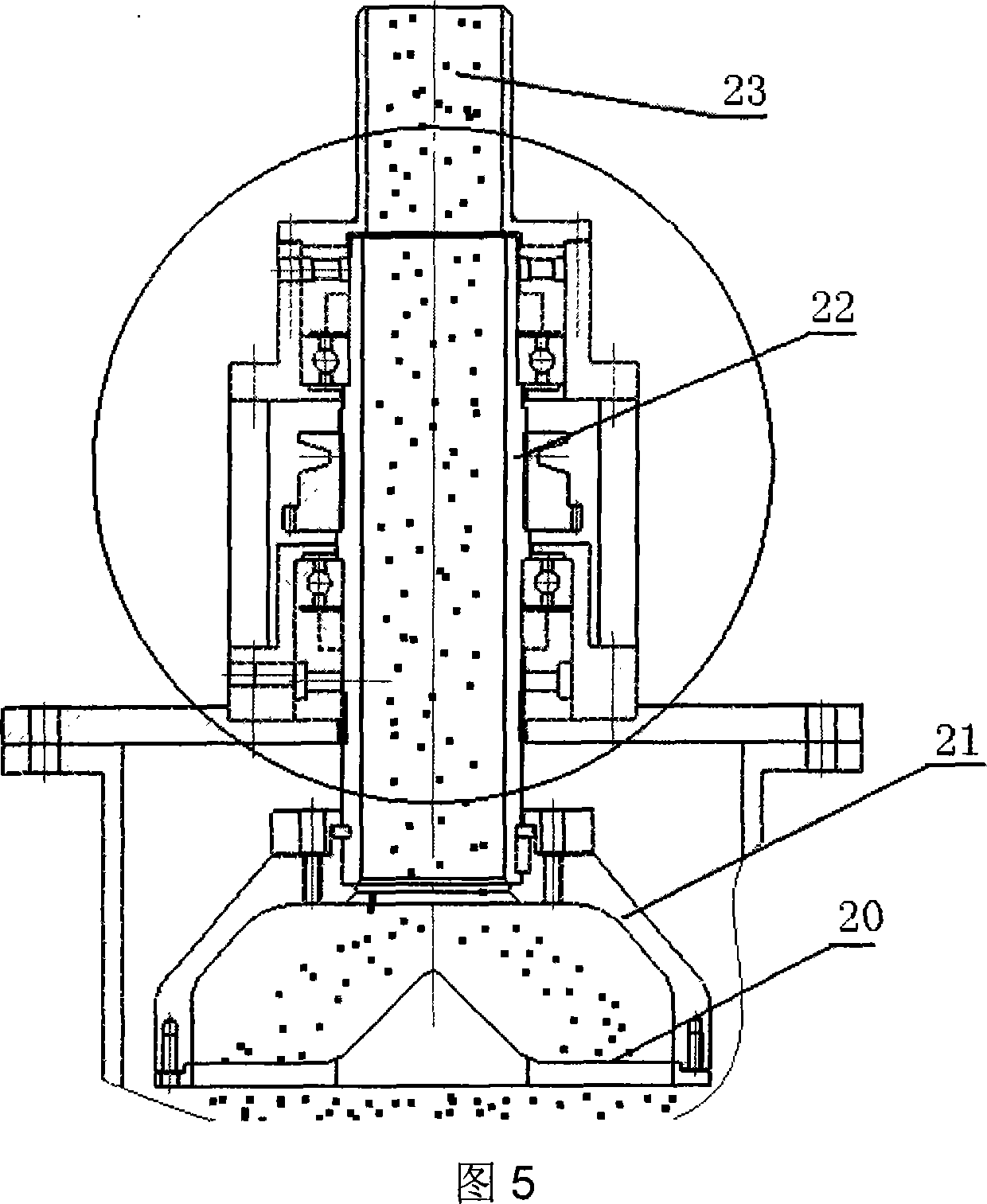

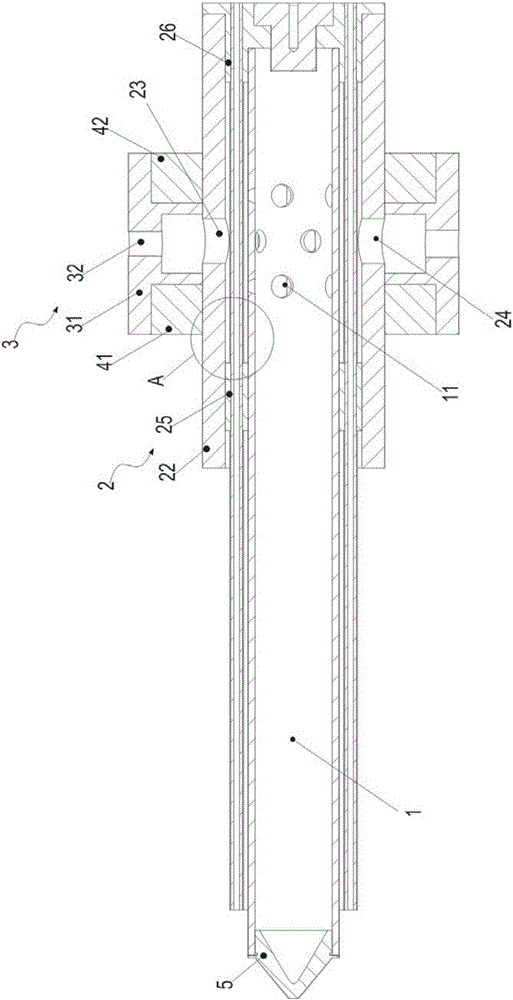

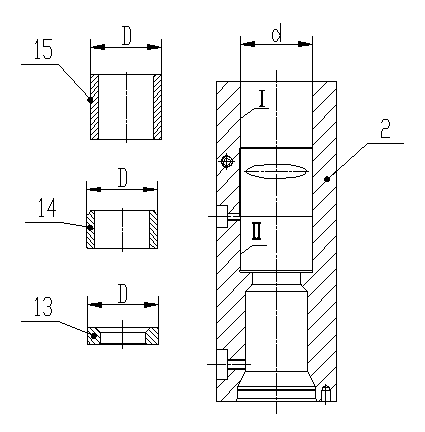

Bidirectional injection moulding method of stator rubber of screw drilling tools

The invention discloses a bidirectional injection moulding method of stator rubber of screw drilling tools, which belongs to the technical field of stator rubber injection of screw drilling tools andcomprises the following steps: grit-blasting; washing and drying; brushing adhesive; assembling a mould core into an internal hole of a steel pipe; putting a stator and an injection moulding mould inan oven and heating; carrying out vacuum negative-pressure rubber injection from two ends to the center of the stator; sealing the stator and putting the stator in a vulcanizing boiler to carry out vulcanization; taking out the stator and cooling; disassembling screw nuts, end caps and shims used for positioning on two ends of the stator, and pushing the mould core out of the rubber layer of the internal hole of the stator so as to be disengaged. The rubber injection method from two ends to the center of the stator prevents rubber from pressing the mould core to cause linear deformation of themould core, fundamentally eliminates the wrapping extent and the core shift of the rubber layer hole in the internal hole of the stator, greatly prolongs the service life of the stator, reduces air bubbles in the rubber layer of the stator and defects on the surface, such as pits, flow marks and the like and increases the qualification rate. The method overcomes the defects of low speed and longtime of rubber injection.

Owner:南京金三力橡塑有限公司

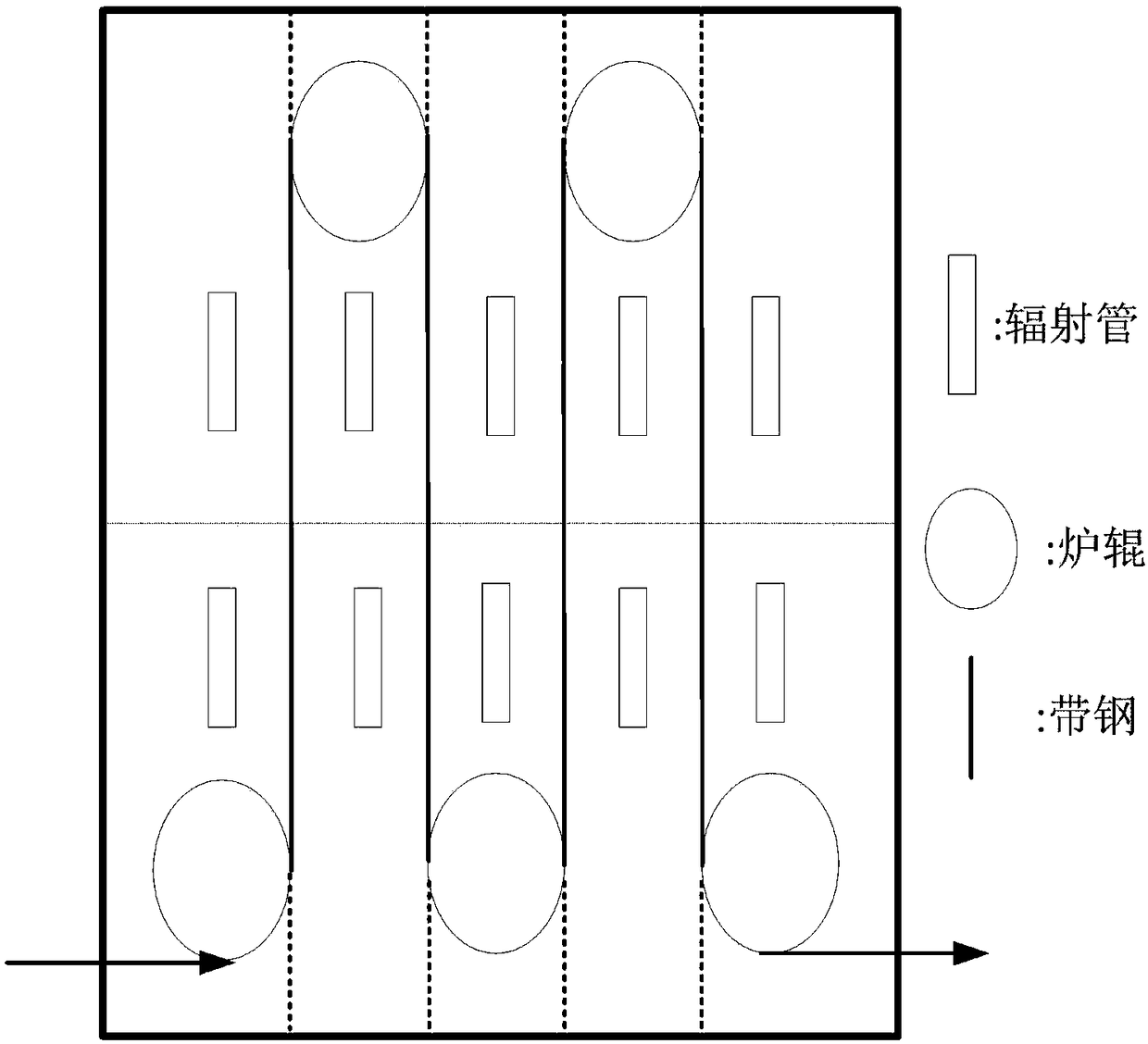

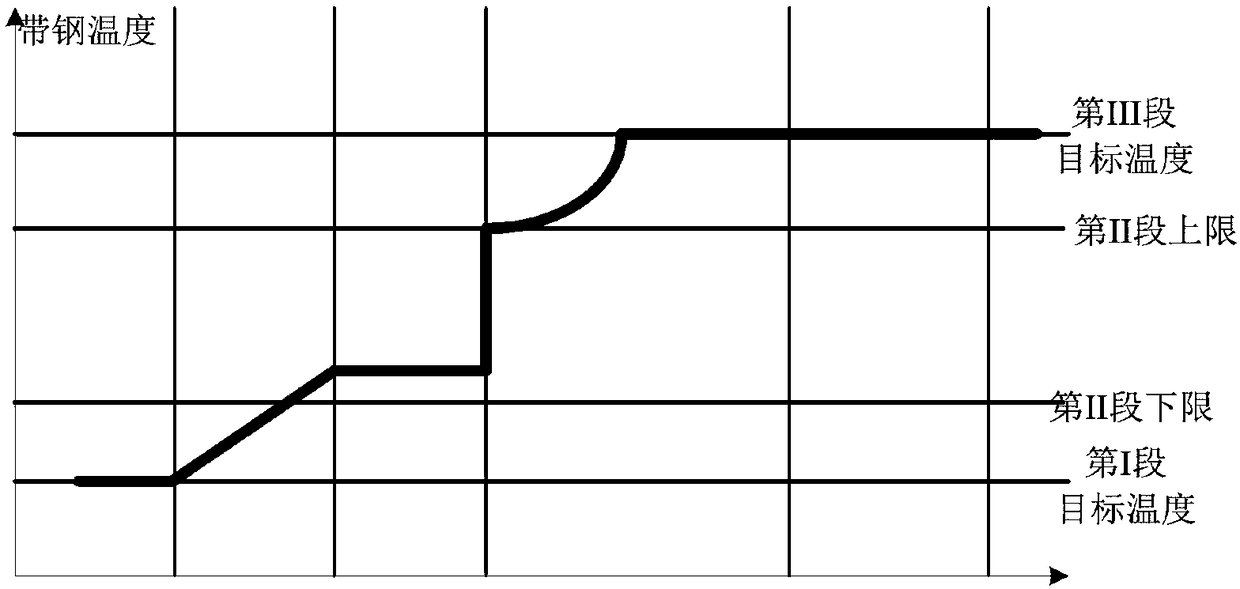

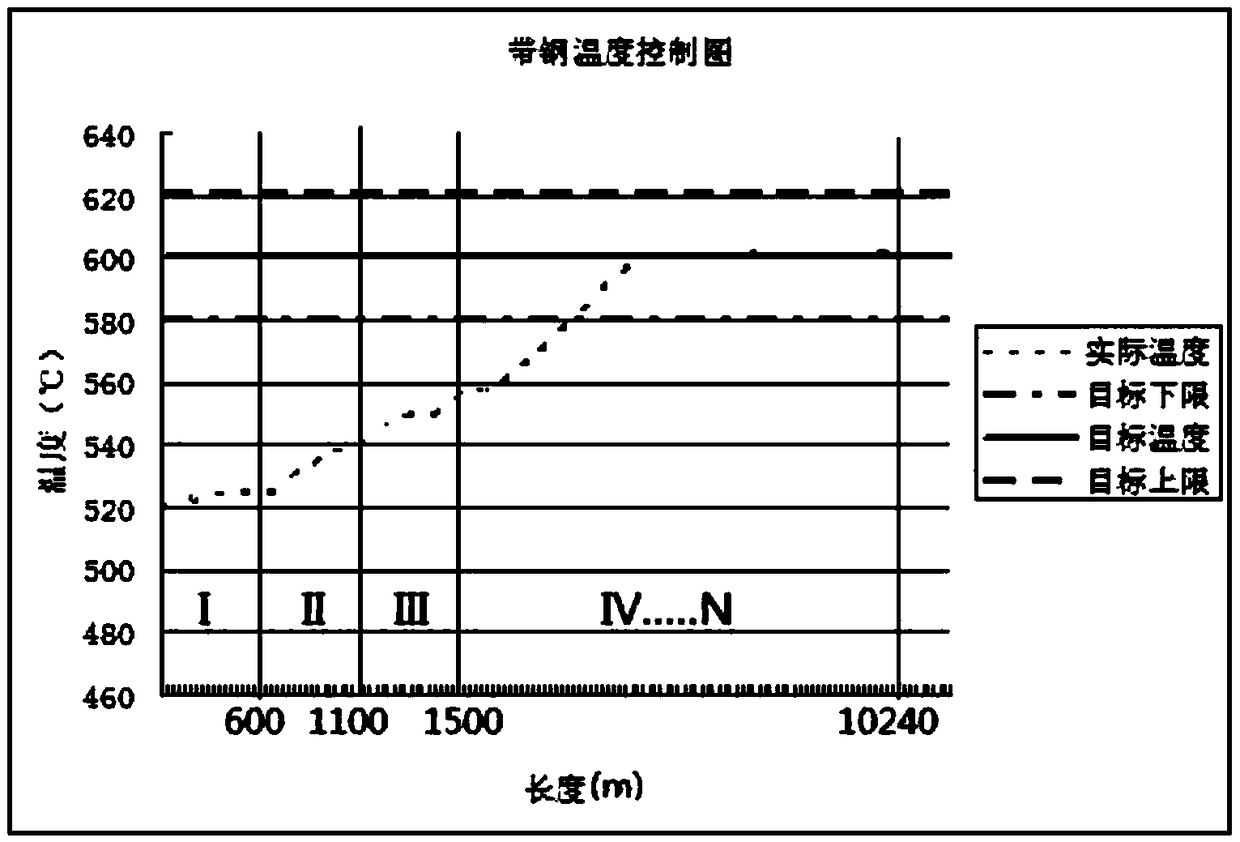

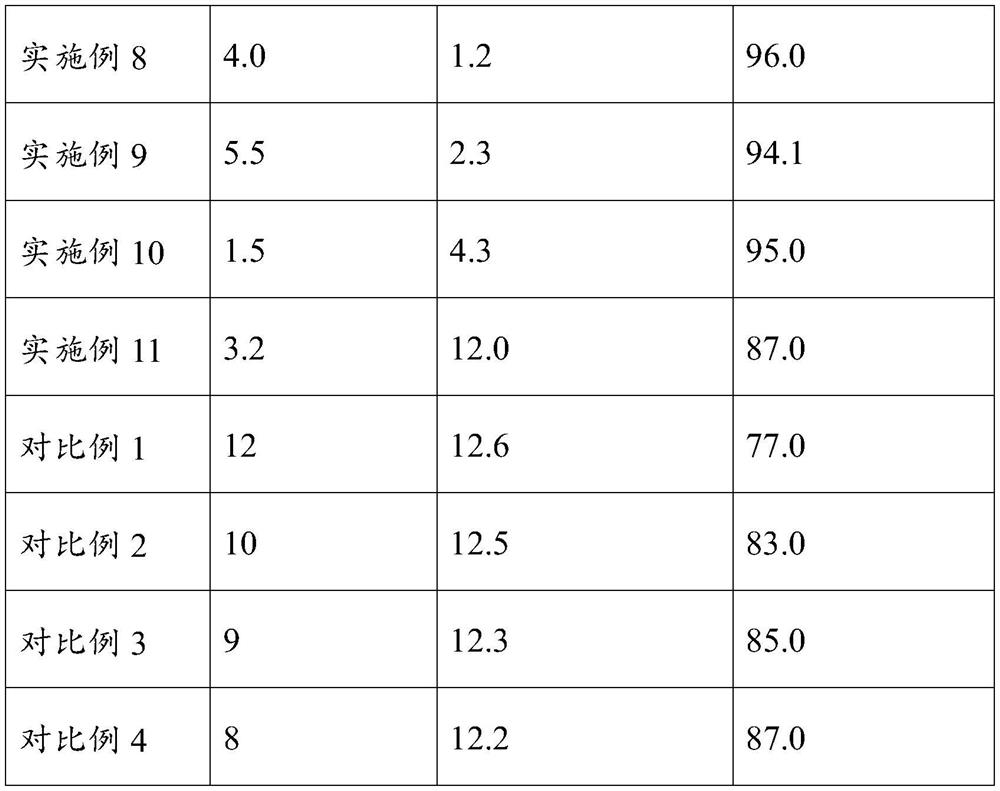

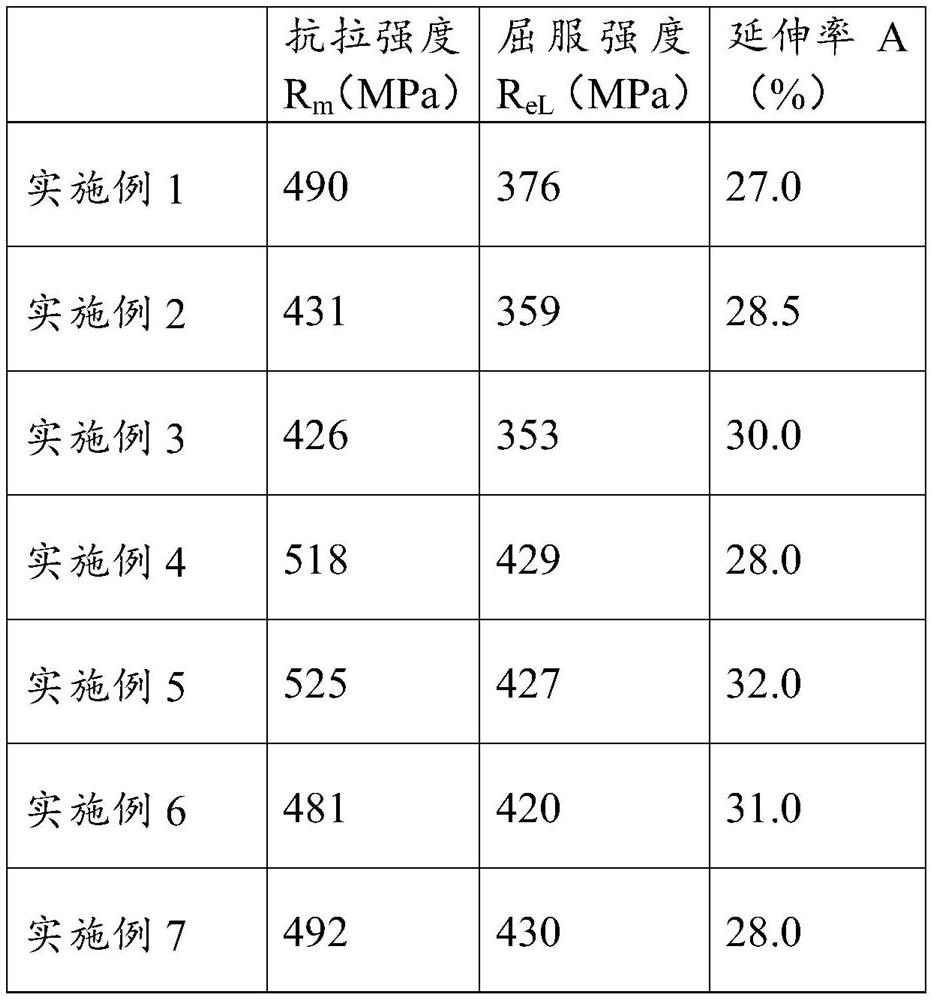

Dynamic subsection control method of tinned product annealing temperature

ActiveCN109022757AImprove heating uniformityHigh yieldFurnace typesHeat treatment process controlTemperature controlAutomatic control

The invention relates to a dynamic subsection control method of a tinned product annealing temperature. The dynamic subsection control method is characterized by comprising the following steps: 1, setting and calculating the temperature of a first heating section of strip steel in a furnace; and 2, setting and calculating the temperature of the nth heating section of strip steel in the furnace, wherein n is greater than 1. According to the technical scheme, the dynamic subsection type control thinking can be applied to the existing continuous annealing automatic control system, the strip steeltemperature and the heating temperature in the furnace are set in a dynamic subsection manner in the length direction of strip steel, the high-efficiency numerical computation method is adopted to apply the genetic factor of control of each section to the feedforward control of the strip steel, and the power of a radiant tube is subjected to dynamic fine adjustment through the feedforward calculation result to adjust the surface temperature of strip steel, so that the temperature control of the strip steel is more precise.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

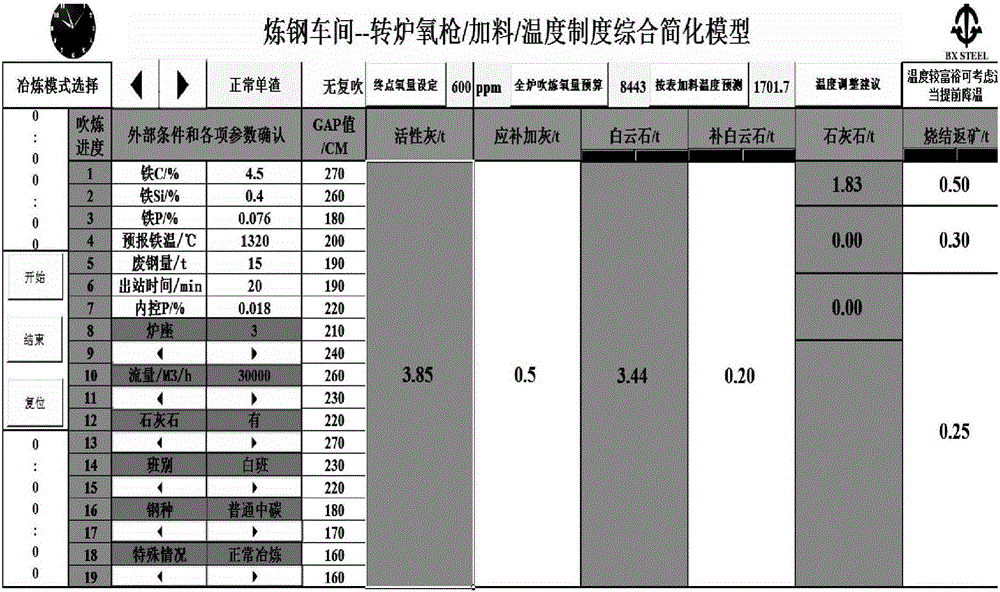

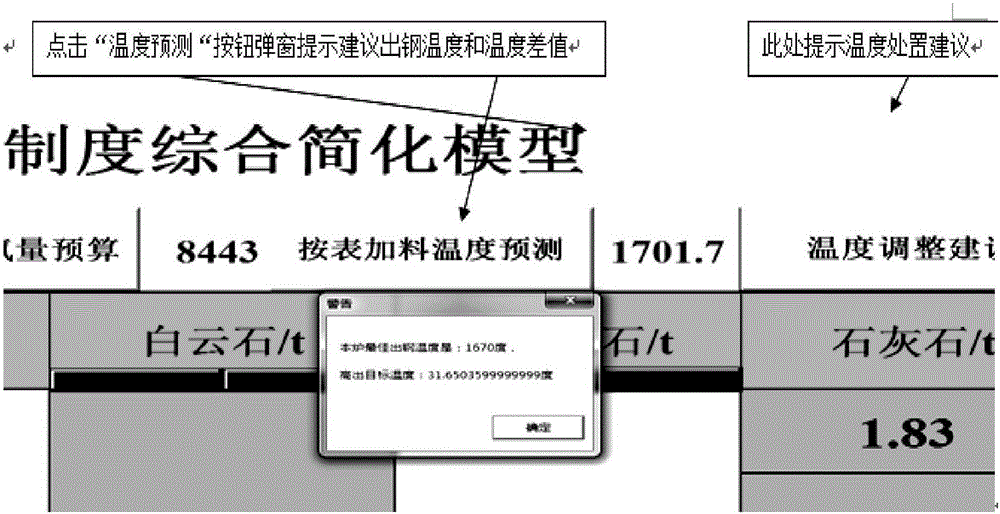

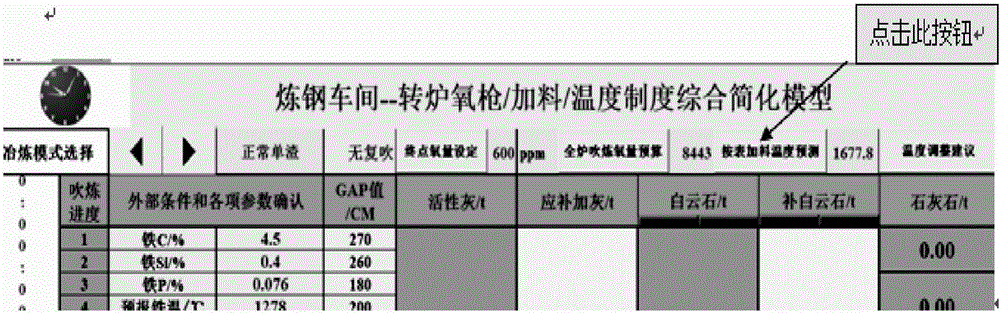

Converter oxygen gun/charging/temperature institution comprehensive simplified model system and operation method

InactiveCN105714014AReduce workloadPracticalManufacturing convertersProcess efficiency improvementModel systemCalculation error

The invention relates to a converter oxygen gun / charging / temperature institution comprehensive simplified model system and an operation method. The operation method comprises the following steps: according to each chemical element, a temperature and a molten iron quantity of molten iron conditions, a waste steel number and influence of each external condition on the temperature, a target oxygen and tapping temperature is set according to a steel type terminal point, and various material quantities are predicted, calculated and added; when the predicted temperature is badly insufficient to influence the tapping temperature safety, the blowing flow and the waste steel are reduced for making up according to a difference between the predicted terminal temperature and a theoretic tapping temperature; and gun positions of oxygen guns are respectively calculated according to different slagging modes. The operation method is developed according to actual parameters of a converter technological process, is suitable for scene demands, is higher in practicability, is high in intelligent comprehensive degree, relieves the working burden of operators, and reduces quality accidents caused by manual calculation errors.

Owner:BENGANG STEEL PLATES

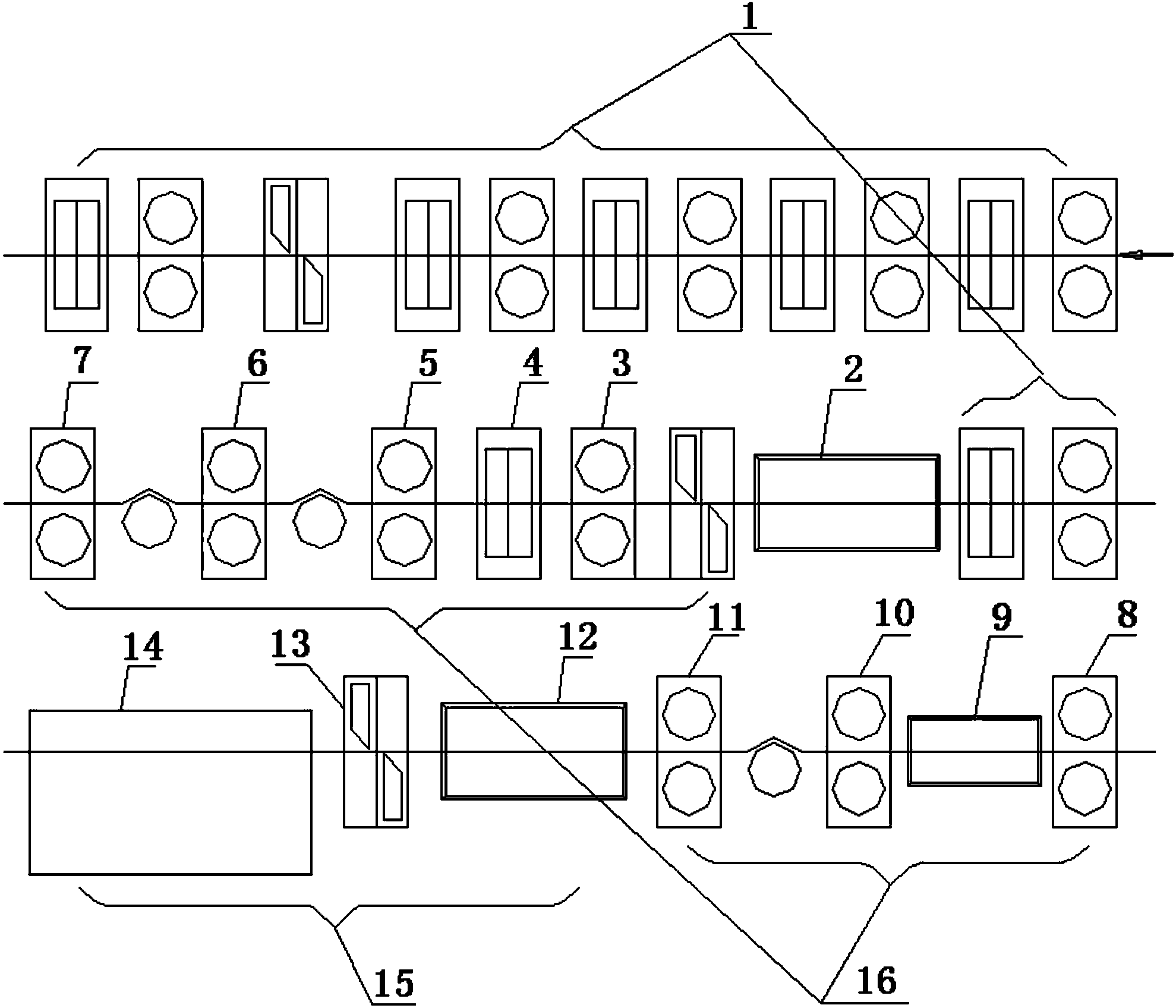

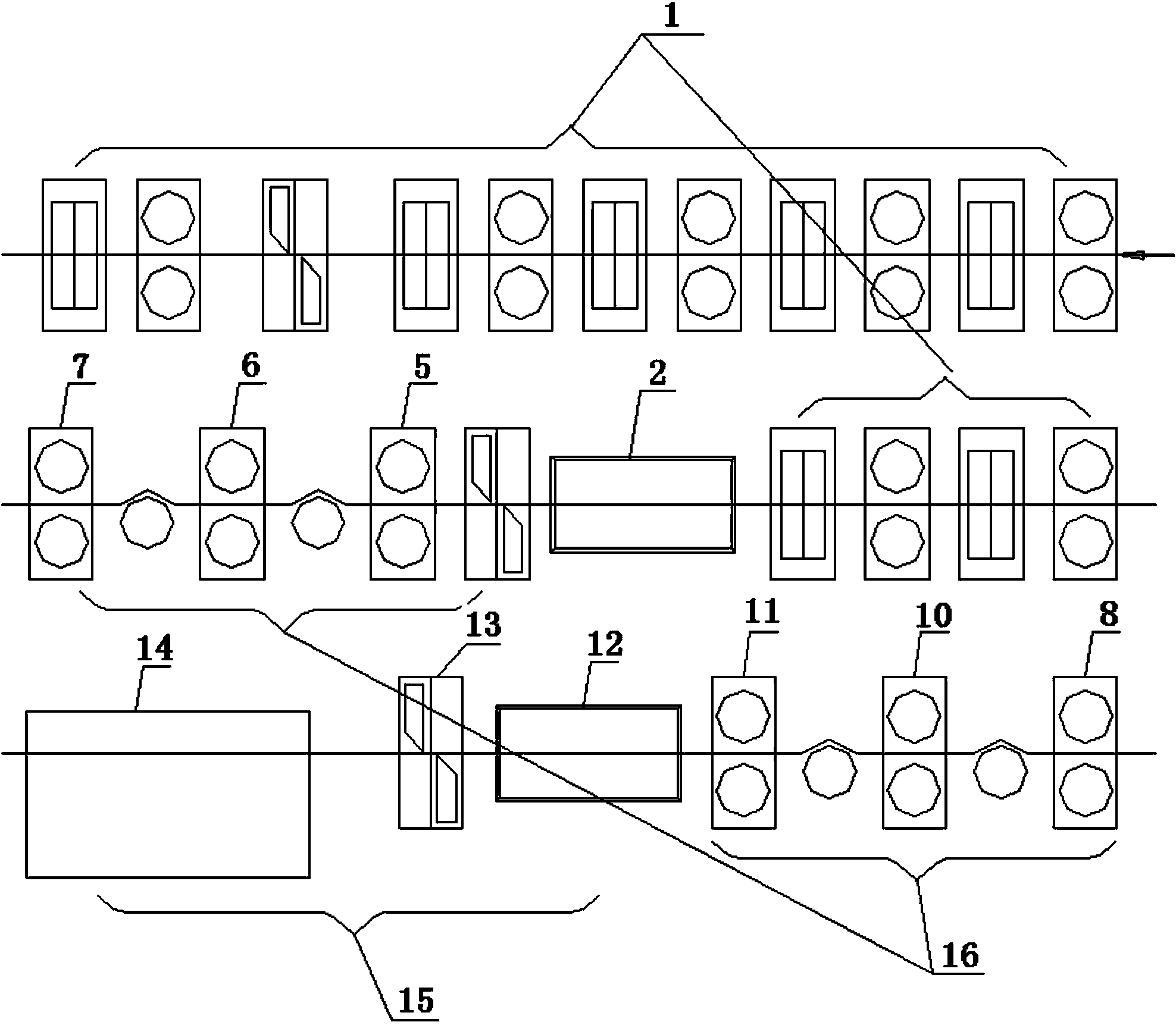

Bar continuous rolling production line

InactiveCN103722009AReduce quality accidentsSolve the failure rateMetal rolling arrangementsProduction lineTemperature control

The invention discloses a bar continuous rolling production line, relates to the field of bar rolling devices, and provides the bar continuous rolling production line which is suitable for producing fine-grained reinforcing steel bars through the bar segmenting method. The bar continuous rolling production line comprises a rough and intermediate rolling unit, an intermediate and finish rolling temperature control and cooling system, a finish rolling unit and an after-rolling processing unit. The finish rolling unit comprises a horizontal rolling machine, a vertical rolling machine, a pre-cut process rolling machine, a segmenting process rolling machine, an ellipse process rolling machine, a circle process rolling machine, a finish rolling temperature control and cooling system, a before-forming process rolling machine and a product finishing process rolling machine. The bar continuous rolling production line can be applied to the bar continuous rolling production line design and can be used for improving an existing rolling machine as well.

Owner:PANZHIHUA GANGCHENG GROUP

Concrete curing device and method

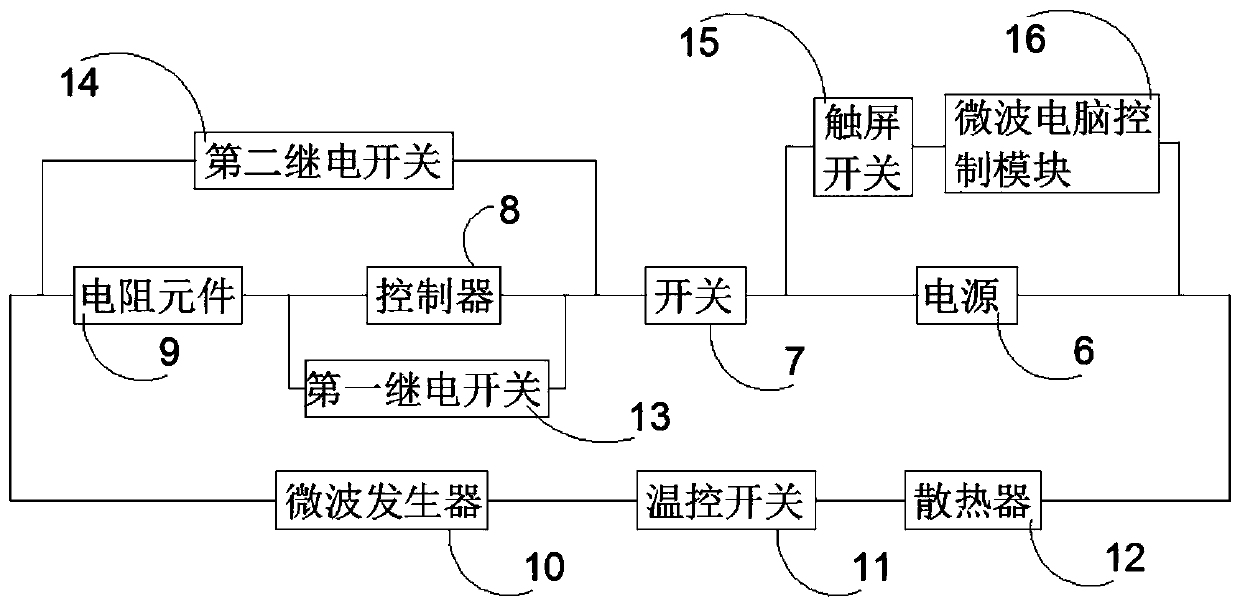

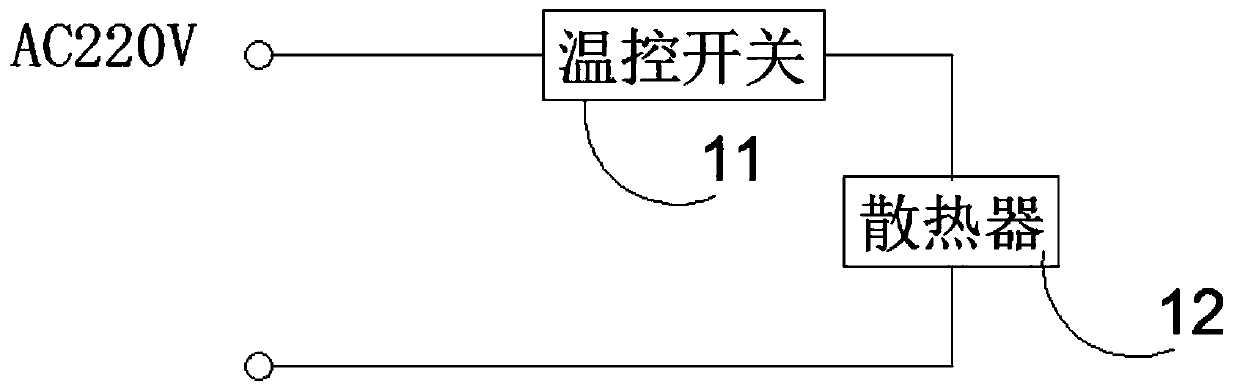

PendingCN110281367AReduce quality accidentsImprove maintenance speedCeramic shaping apparatusTemperature controlMicrowave oven

The invention discloses a concrete curing device and method in the technical field of concrete curing. The concrete curing device comprises a microwave oven body, wherein a control box is arranged at the right side of the microwave oven body; an inner furnace is arranged at the left side of the inner cavity of the microwave oven body; a cover door is hinged to the left side of the front surface of the microwave oven body; the cover door is lapped with the outer edge of the inner furnace; an observation window is embedded in the center of the surface of the cover door; and a power supply, a switch, a controller, a resistor element, a microwave generator, a temperature control switch and a heat dissipator are arranged in the control box separately. According to the concrete curing device and method, through a microwave curing test method, the curing speed is effectively increased; and moreover, the novel test method capable of achieving the design requirements of GB / T50080, GB / T14902 and GB / T50081 saves the space while increasing the working efficiency, saves the cost, and effectively reduces the occurrence of building concrete quality accidents.

Owner:衡水积土科技有限公司

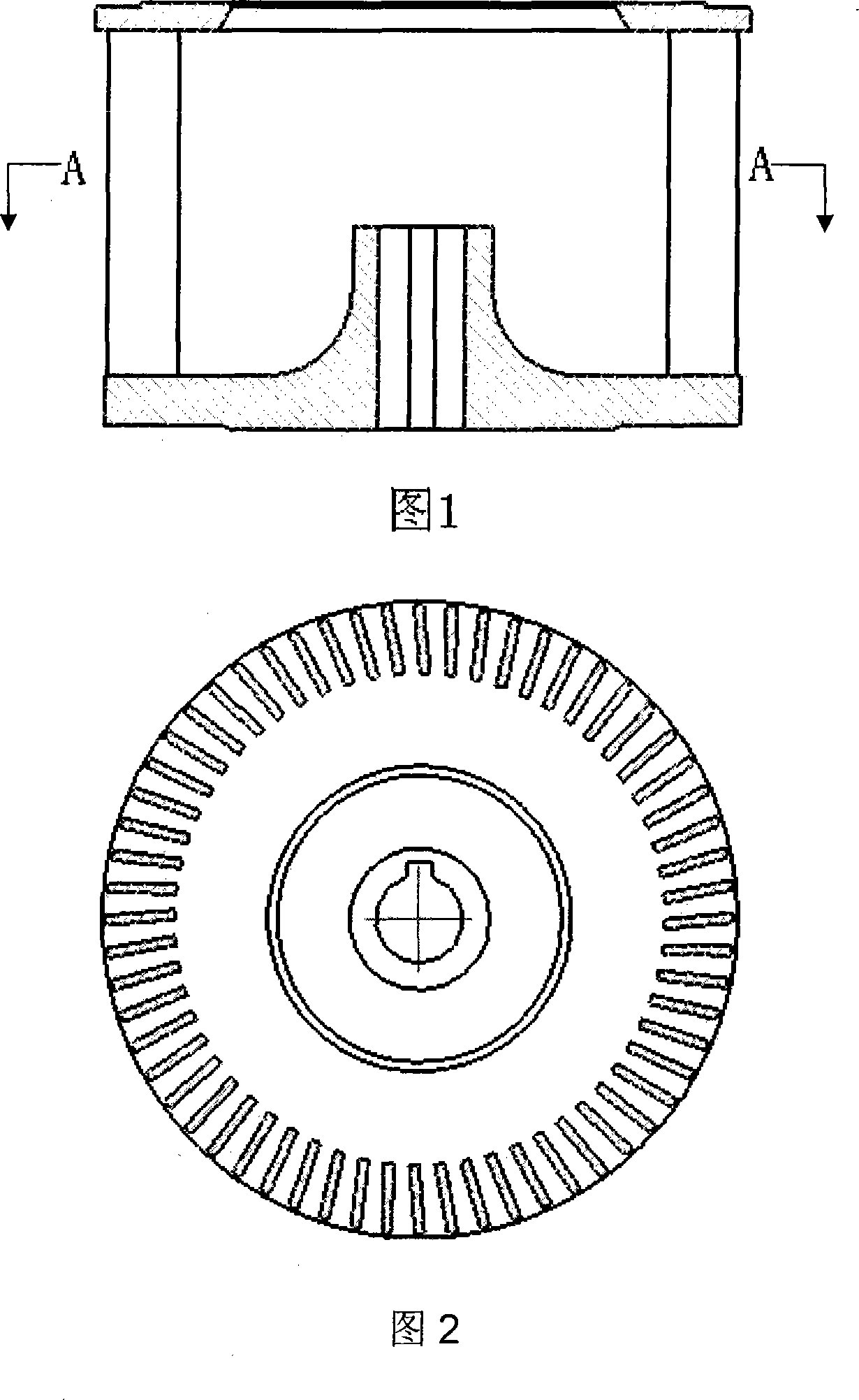

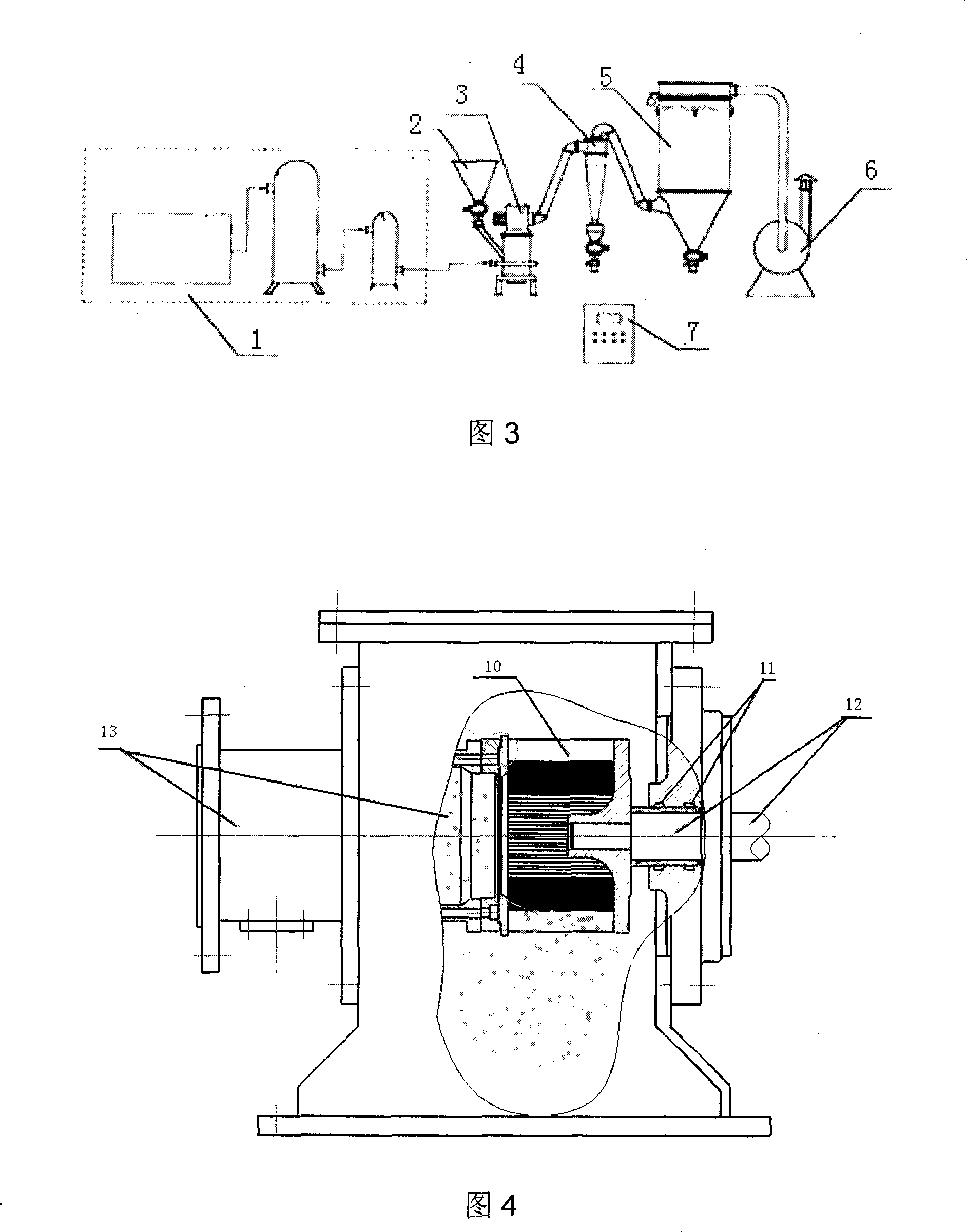

Classifying system for airflow mill

ActiveCN101164707ALow costEasy to useGas current separationGrain treatmentsWear resistantMetallic materials

The present invention relates to a sorting system of pneumatic mill. It includes sorting wheel, transion chamber and drive main shaft system. The sorting wheel is a plate blade sorting wheel made of wear-resistant metal material, on the plate blade sorting wheel 40-100 slotted eyes are uniformly distributed; the lower end of said transion chamber is connected with plate sorting wheel, its upper end is fixedly connected with drive main shaft, the middle of upper end surface has a projection for preventing material from piling up; the drive main shaft system has a cleaning dust-proofing device, in the cleaning dust-proofing device, between the drive main shaft and mill chamber they are sealed by using screw-seal and gas seal combination, drive main shaft material outlet cleaning is sealed by using labyrinth disk seal and the bearing is sealed by using rotating shaft combination seal. Said invention also provides the working principle of said sorting system and its concrete operation method.

Owner:NINGBO KONIT IND +1

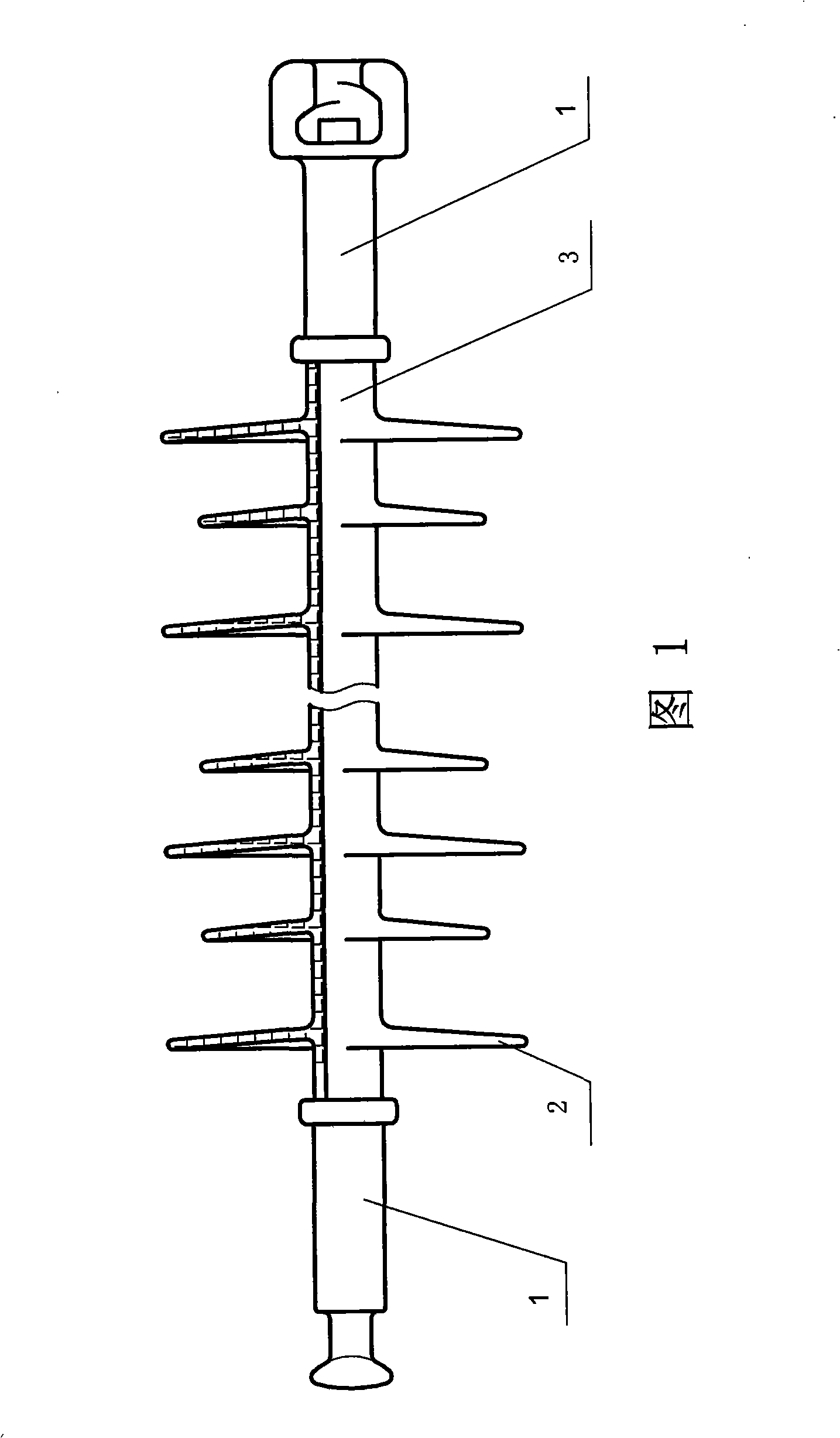

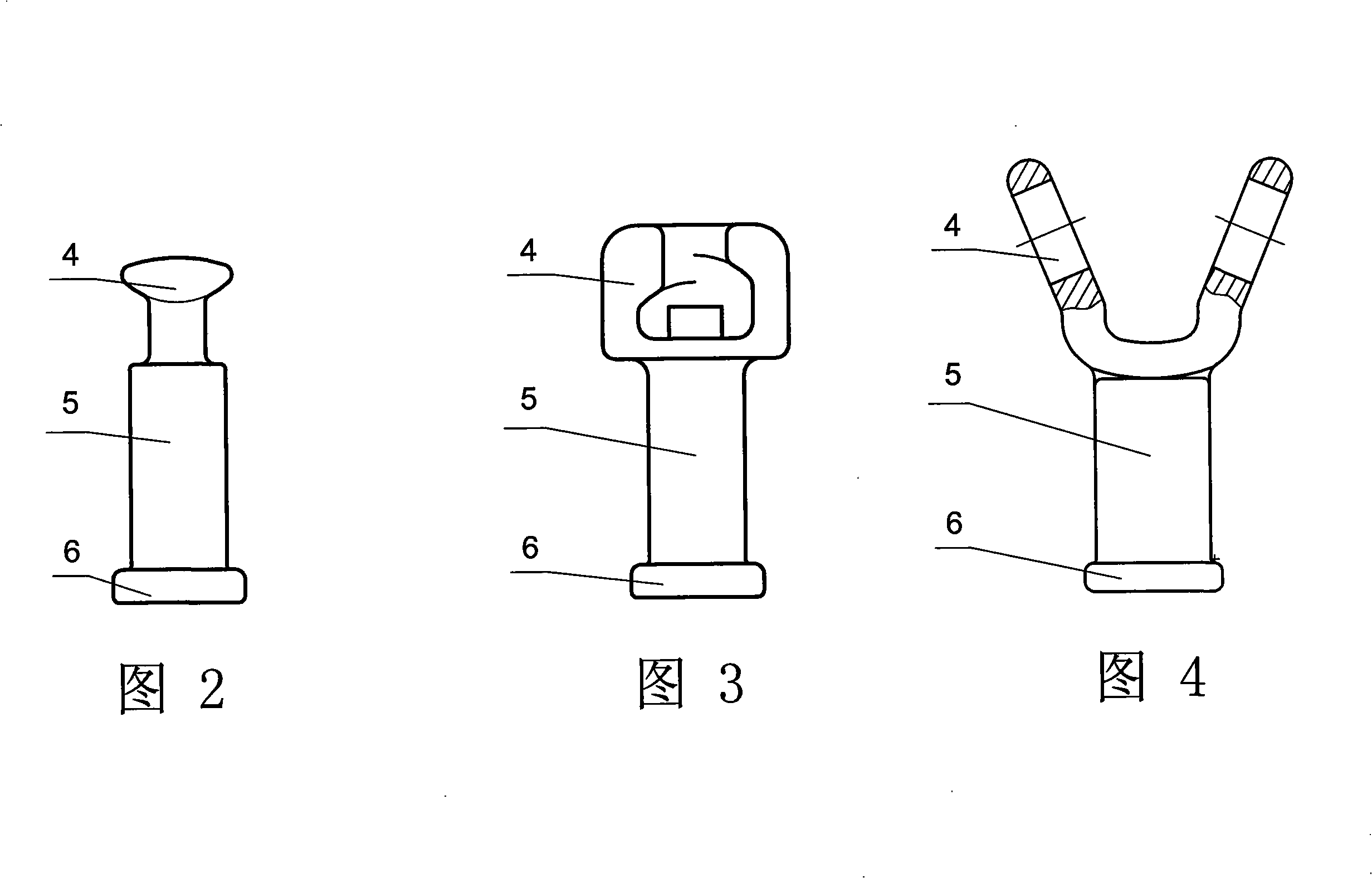

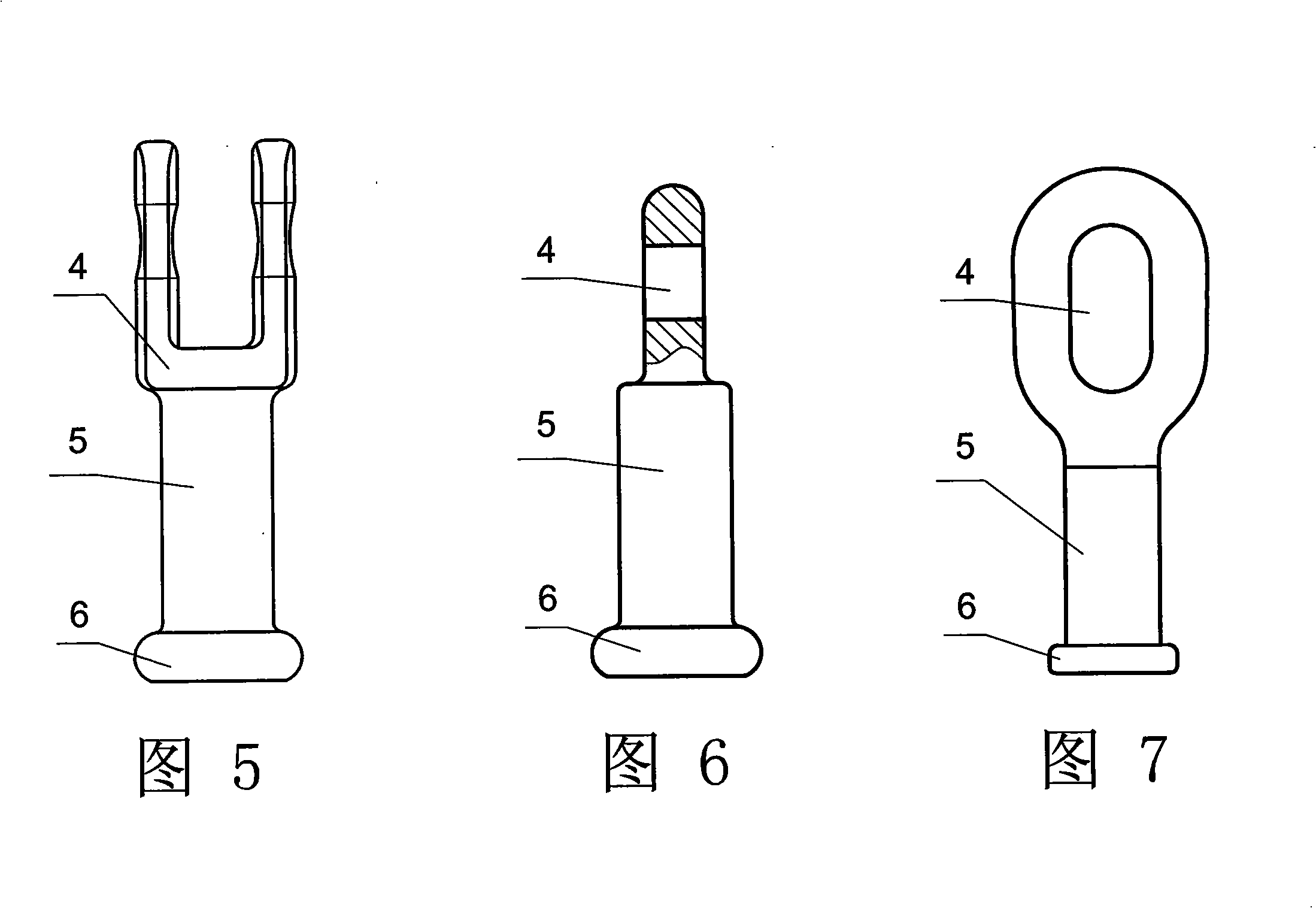

Combined insulator gold tool and method for manufacturing the same

InactiveCN101303925AEasy to industrializeImprove qualitySuspension/strain insulatorsFriction weldingEngineering

The invention discloses a piece of combined insulator hardware and a production method thereof. A standard joint of the combined insulator hardware and a connection bar adopt a split type structure and are fixed together by friction welding. The connection bar and a seal-adhesive seat of the insulator adopt an integrated structure or a split type structure; the connection bar and the seal-adhesive seat are fixed together by friction welding if the connection bar and the seal-adhesive seat adopt a split type structure. The standard joint is a Y-shaped double-ear or a ball head or a ball socket or a U-shaped double-ear or a straight line shaped single ear or a hanging ring-shaped single ear. The production method is that: according to the application characteristics of the specific parts of the hardware, a piece of hardware is divided into two or three parts and respectively produced to satisfy different strength and hardness requirements; then all the parts are fixedly welded together by friction welding technique. By adopting the invention, industrialization of the production of the insulator hardware can be easily realized, product quality and qualified rate in production are enhanced, the working efficiency is improved, the management difficulty in production is reduced and good social and economical benefits can be achieved.

Owner:ZHENGZHOU JINGWEI ELECTRIC POWER TECH

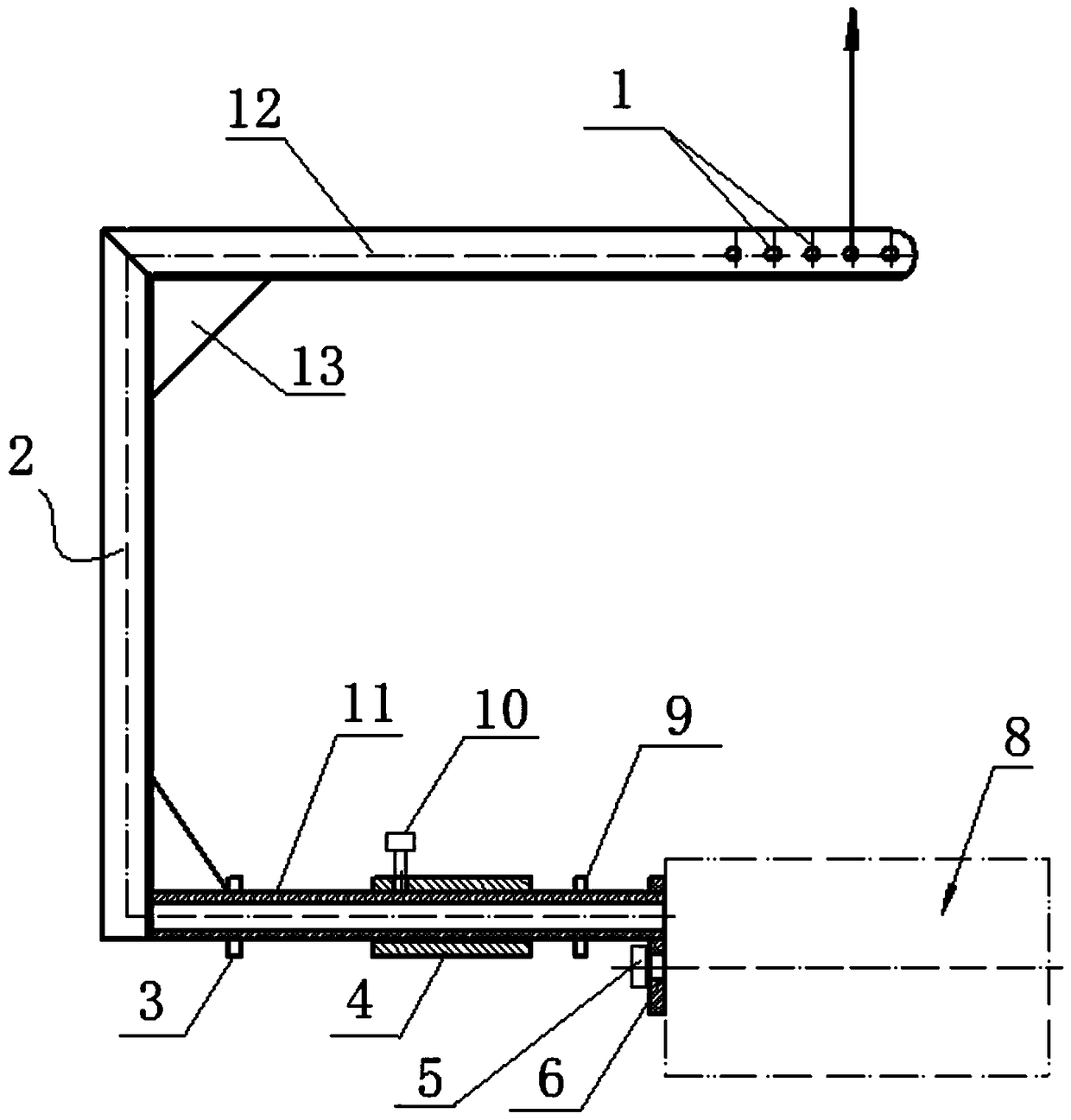

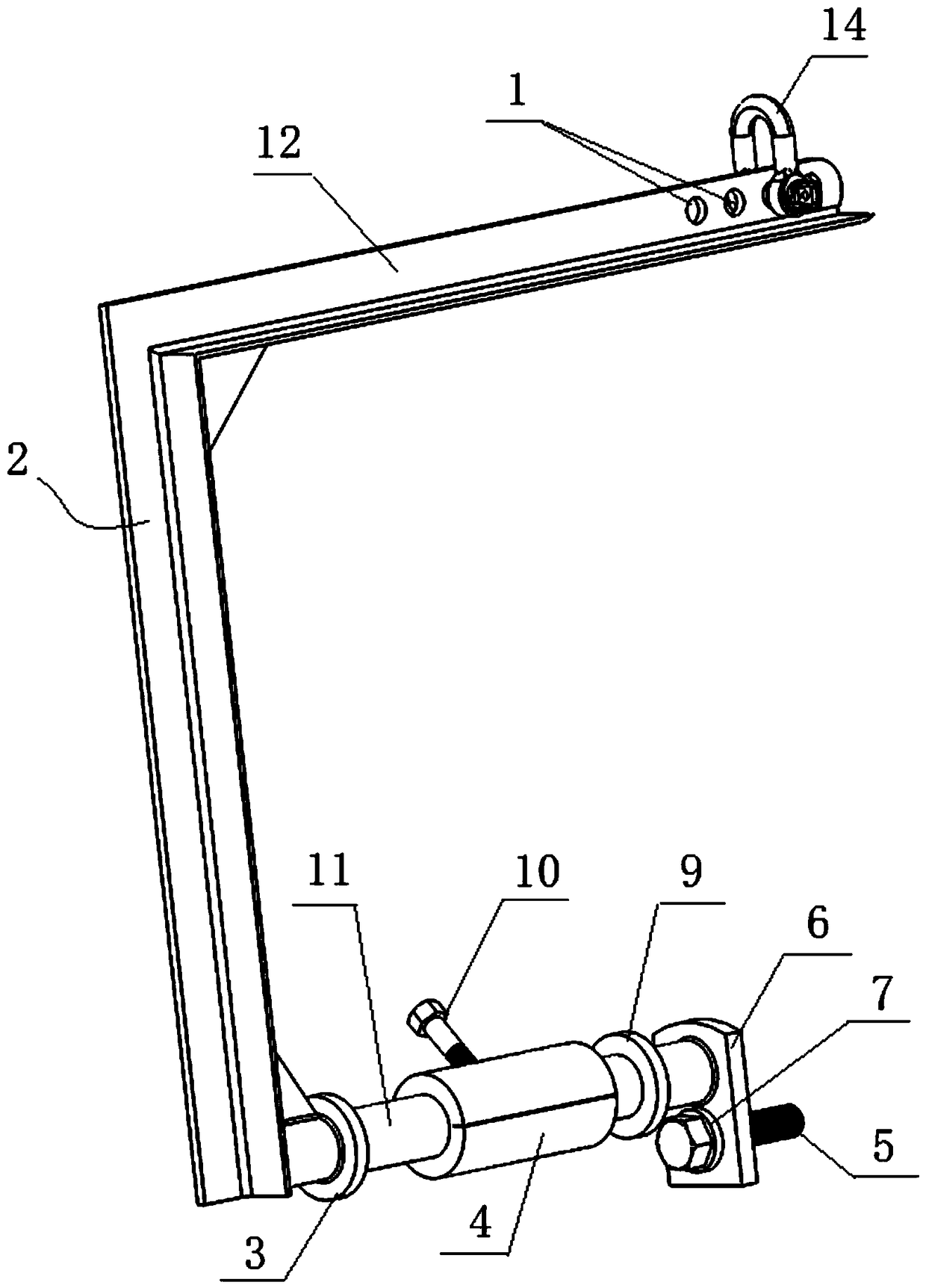

Method and device for testing geothermal floor

ActiveCN102495093AEasy to identifyEfficient screeningMaterial thermal analysisUnderfloor heatingEngineering

The invention discloses a method and a device for testing a geothermal floor. The method disclosed by the invention comprises the following steps of: placing the geothermal floor to be tested on an underfloor heating system in a sealed testing room; controlling a temperature of the underfloor heating system and a humidity in the testing room; treating for a certain time; and then, detecting the width dry shrinkage, the warpage and the width hygroscopic expansion rate of the floor, so that the testing of the geothermal floor is realized. According to the invention, the geothermal floor with poor quality performance, low stability and short service life can be effectively screened. The product which is qualified after being tested by the method and the device has the characteristics of stable performance and good consistency.

Owner:JIUSHENG WOOD

Optical cable preparation device

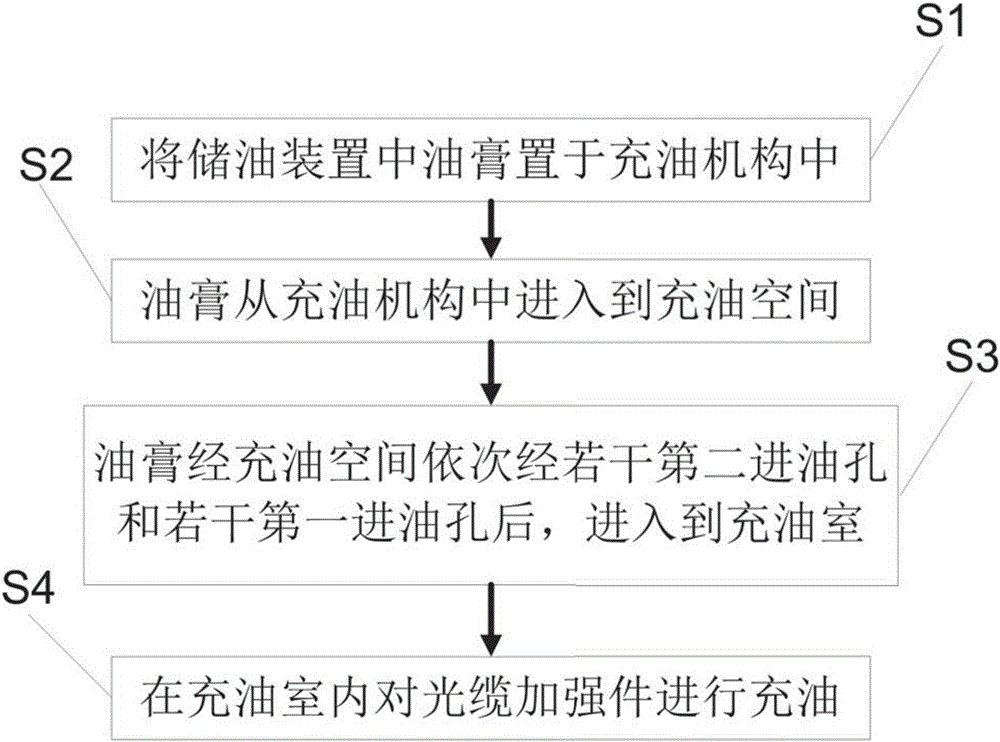

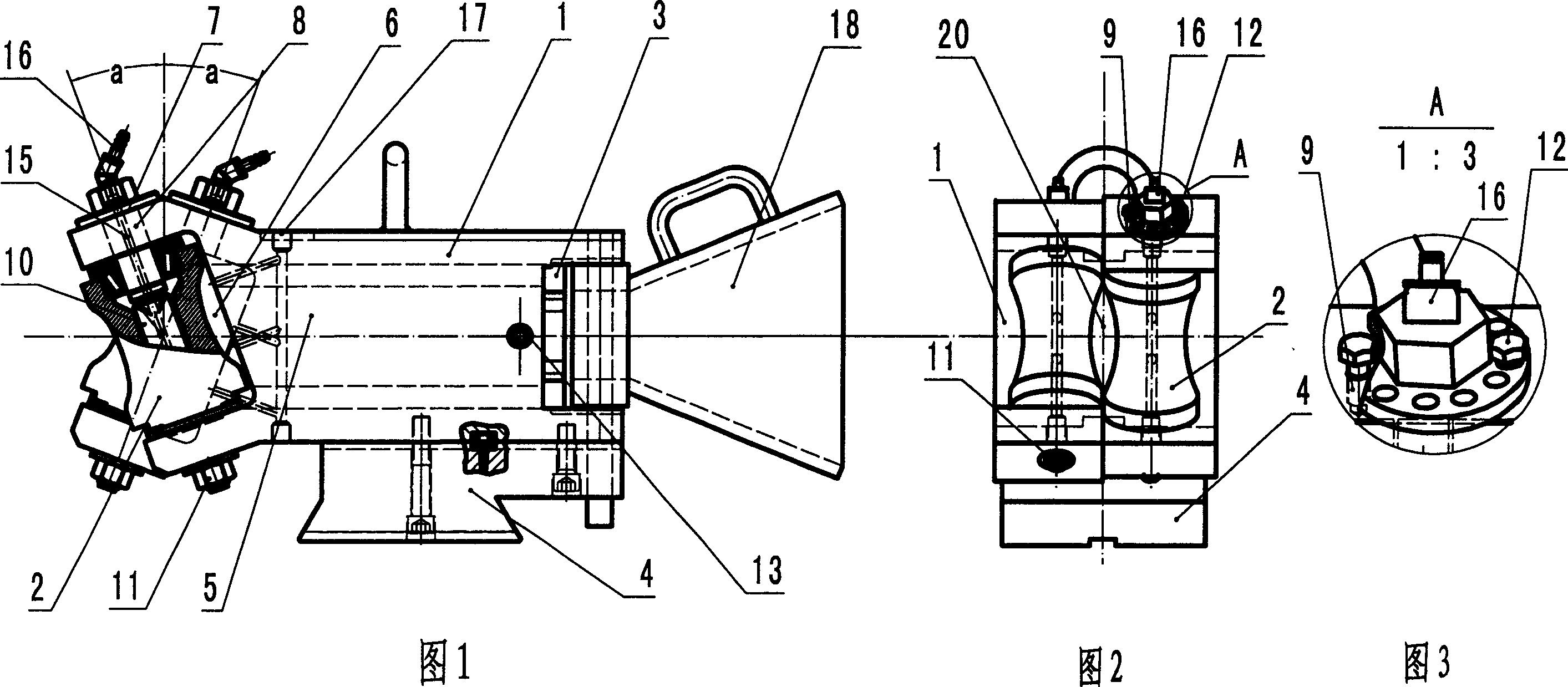

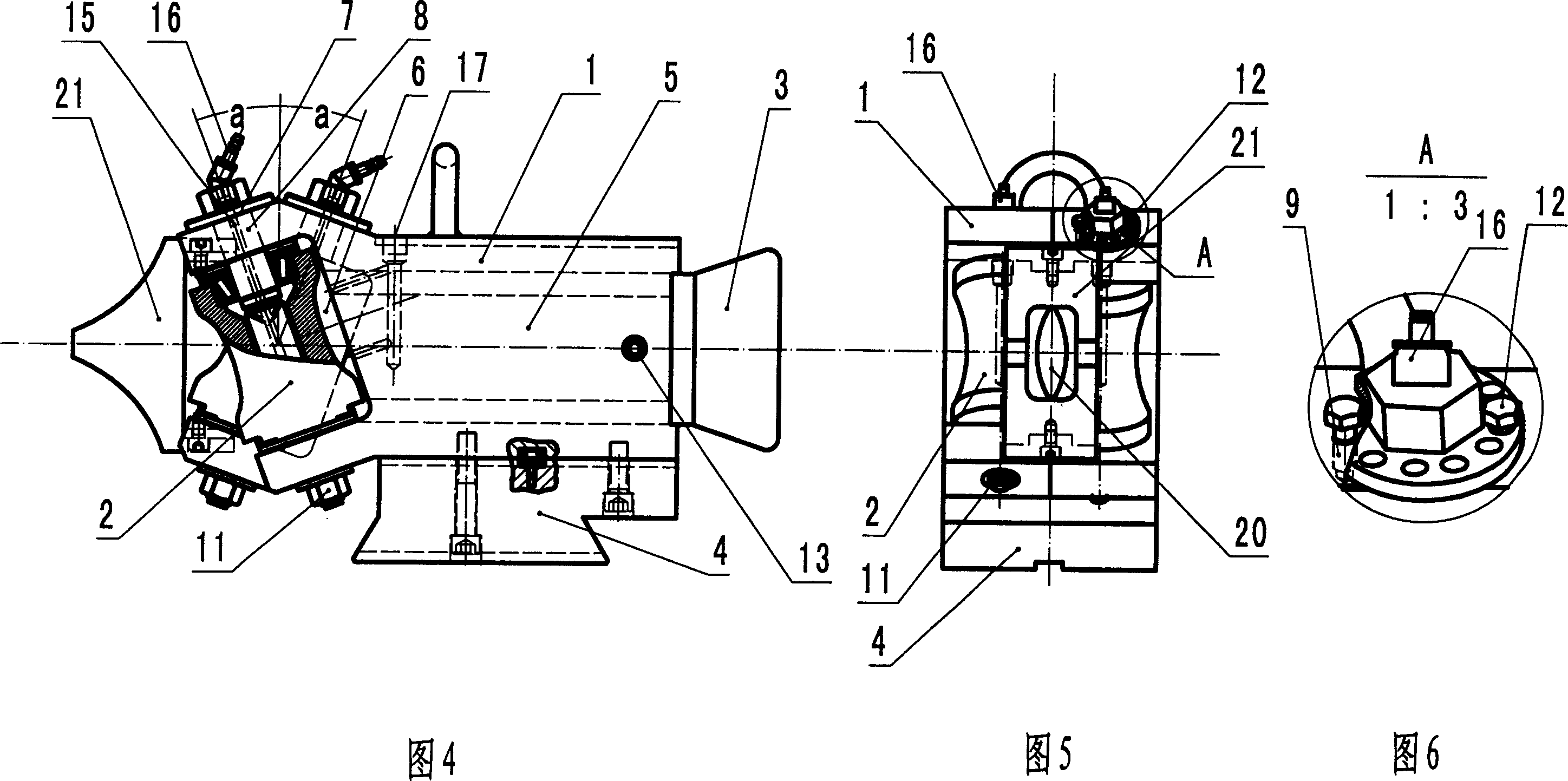

ActiveCN105044868AWill not blockWill not affect service lifeFibre mechanical structuresInjection devicePetroleum engineering

The invention provides an optical cable preparation device comprising an optical cable reinforcing member oil charge device and an optical fiber plastic coating guiding device. The optical cable reinforcing member oil charge device comprises an oil charge chamber of which the wall is hollow, the internal wall is provided with multiple first oil inlet holes, and the external wall is provided with multiple second oil inlet holes; an oil charge mechanism which is arranged at the external surface of the oil charge chamber; and an oil charge part which is arranged at the external surface of the oil charge mechanism. The optical fiber plastic coating guiding device comprises an injection device which is used for injection of protective layer material; a formation device which is used for enabling the protective layer material injected by the injection device to form a protective layer structure and is communicated with the injection device; and a transmission and oil charge device which is used for transmitting an optical fiber to the formation device and performing oil charge on the optical fiber in the transmission process and is communicated with the formation device. The oil charge mechanism is not blocked, and the service life of the oil charge mechanism is not influenced so that a product quality problem caused by scratching of a blocking object and the optical fiber can be completely solved.

Owner:SHENYANG HENGTONG OPTICAL COMM CO LTD +1

Hot-rolled elliptical rolled piece inlet rolling guide

ActiveCN1923393AReduce distortionReduce skewGuiding/positioning/aligning arrangementsMechanical engineeringHot rolled

The invention relates to a device used to align, position and guide metal rolling element. Wherein, it comprise bank with guide plate with rolling element channel; the bank has cooling water open; the guide roller axle has oil let connected to oil ejector; the bank has at least a couple of crossed guide roller at 2aphla angle; two guide rollers with arc holes are inserted into the rolling element channel inclined, to form trapezium hole; when the rolling element is through said trapezium hole, the roller will align, clamp and correct the rolling element to vertically feed long axle into round hole or square hole. The invention has simple structure while it can reduce the impact of rolling element on guide roller and bearing, to prolong its service life.

Owner:MAANSHAN IRON & STEEL CO LTD

Refrigerant leakage detection equipment and method

PendingCN113390564AImprove accuracyReduce security risksFluid-tightness measurement using fluid/vacuumMechanical conveyorsThermodynamicsEngineering

The invention relates to the technical field of refrigerant leakage detection, and discloses refrigerant leakage detection equipment and method. The refrigerant leakage detection equipment comprises a sealing element which can controllably seal a to-be-detected device so as to seal a refrigerant leaked from the to-be-detected device in the sealing element; and a detection element which is located in the next working procedure of the sealing element, and can controllably detect the concentration of the refrigerant in the sealing element. The to-be-detected device is sealed through the sealing element, and the concentration of the refrigerant in the sealing element is detected through the detection element in the next working procedure. In the process between the first working procedure and the second working procedure, if the problem of refrigerant leakage exists in the to-be-detected device, the leaked refrigerant is stored in the sealing element in a centralized mode. Compared with open detection in the prior art, the detection method is higher in accuracy.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

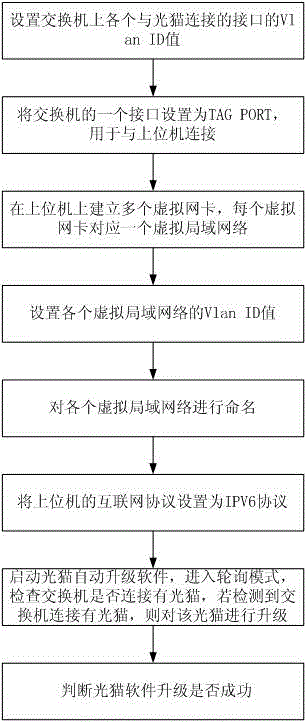

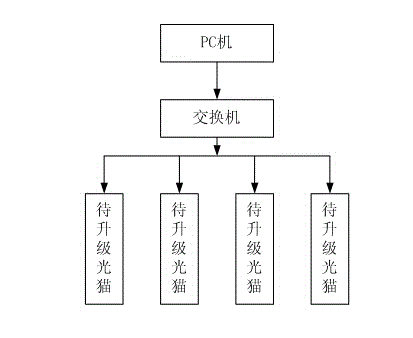

Method and system for simultaneously and automatically upgrading software of multiple optical modems

InactiveCN104639663AImprove upgrade efficiencyLow costNetworks interconnectionVirtual LANModem device

The invention discloses a method for simultaneously and automatically upgrading software of multiple optical modems. The method is characterized by comprising the following steps: setting a Vlan ID value of each interface connected with the optical modems on a switch; setting one interface of the switch to be TAG PORT for connection with an upper computer; establishing multiple virtual network cards on the upper computer, wherein each virtual network card corresponds to a virtual local area network; setting a Vlan ID value of each virtual local area network; naming each virtual local area network; setting an Internet protocol of the upper computer to be IPV6 (Internet Protocol Version 6); starting the optical modems to automatically upgrade the software, entering a polling mode, checking whether all the interfaces of the switch are connected with the optical modems or not, and if the interfaces of the switch are detected to be connected with the optical modems, upgrading the software of the optical modems; judging whether the software of the optical modems is successfully upgraded or not, and if the software of the optical modems is successfully upgraded, causing the optical modems to enter the next production flow. According to the method, multiple optical modems are simultaneously and automatically upgraded, so that the efficiency is improved, and upgrading errors are reduced.

Owner:SICHUAN TIANYI COMHEART TELECOM

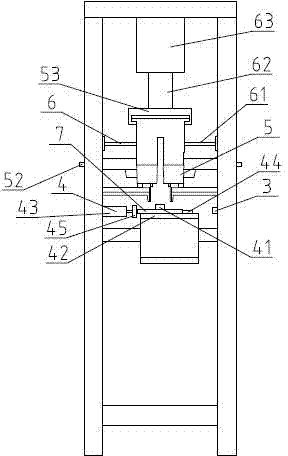

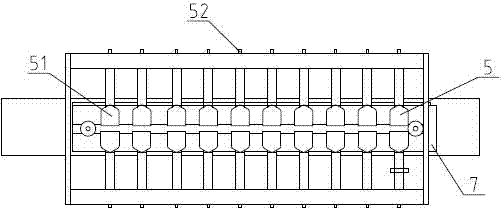

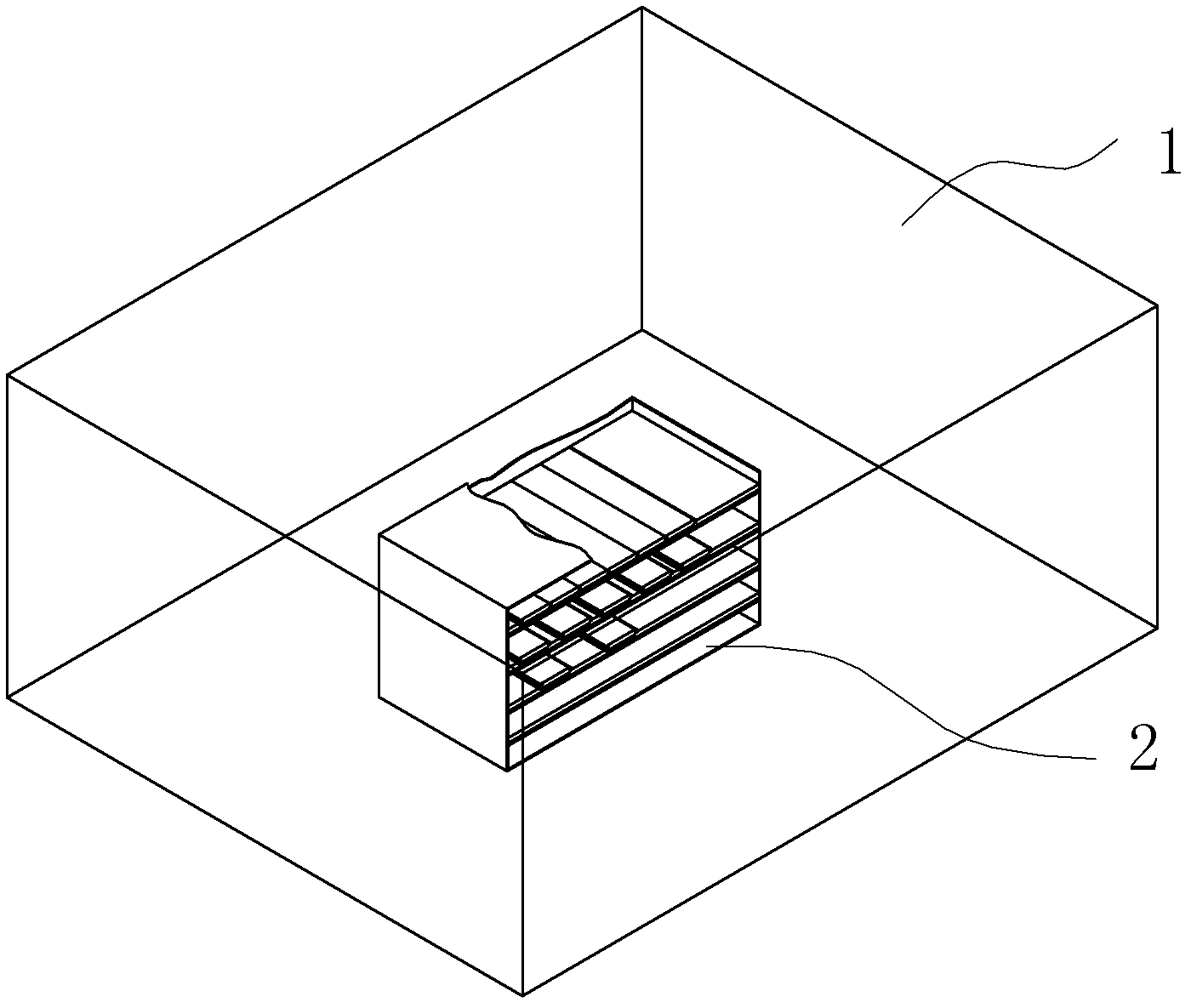

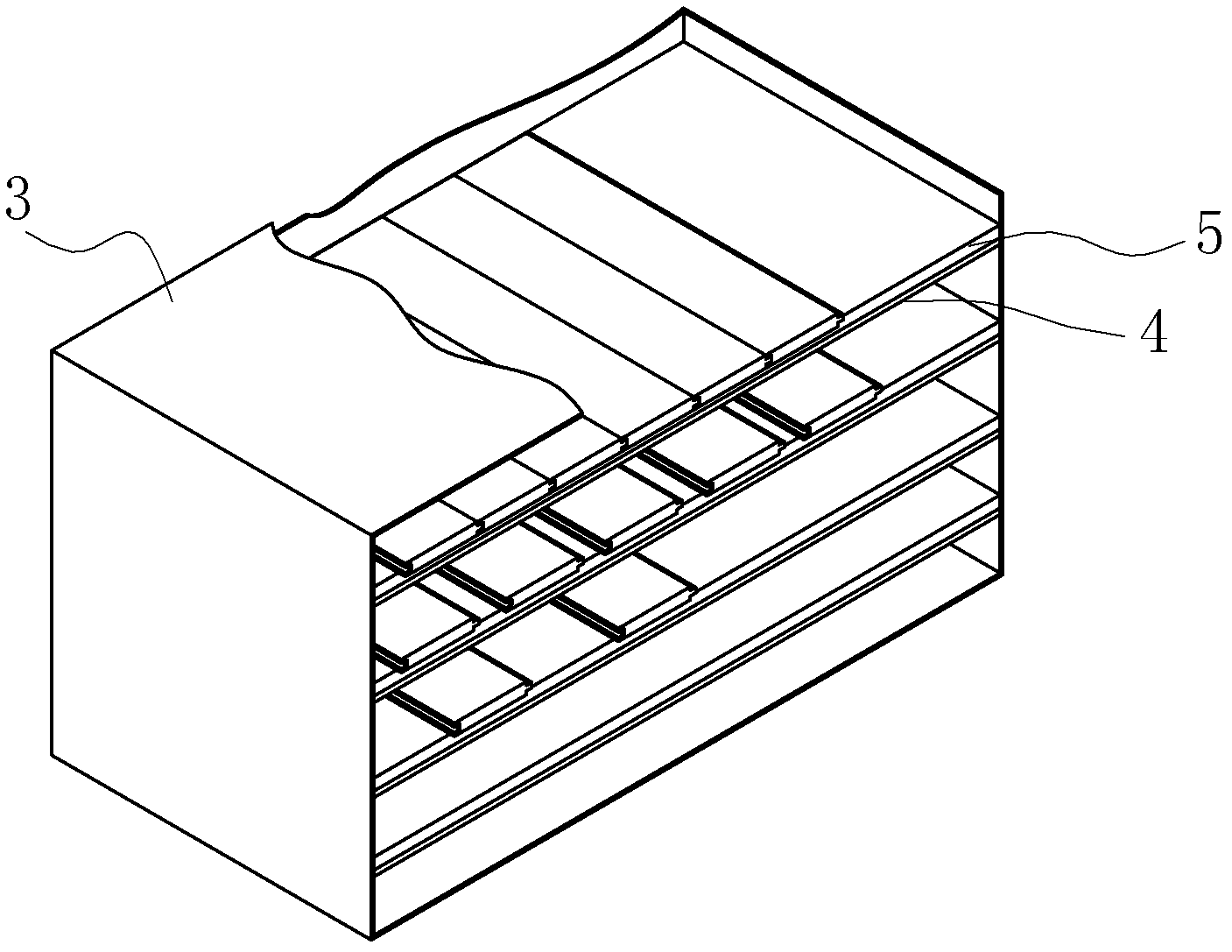

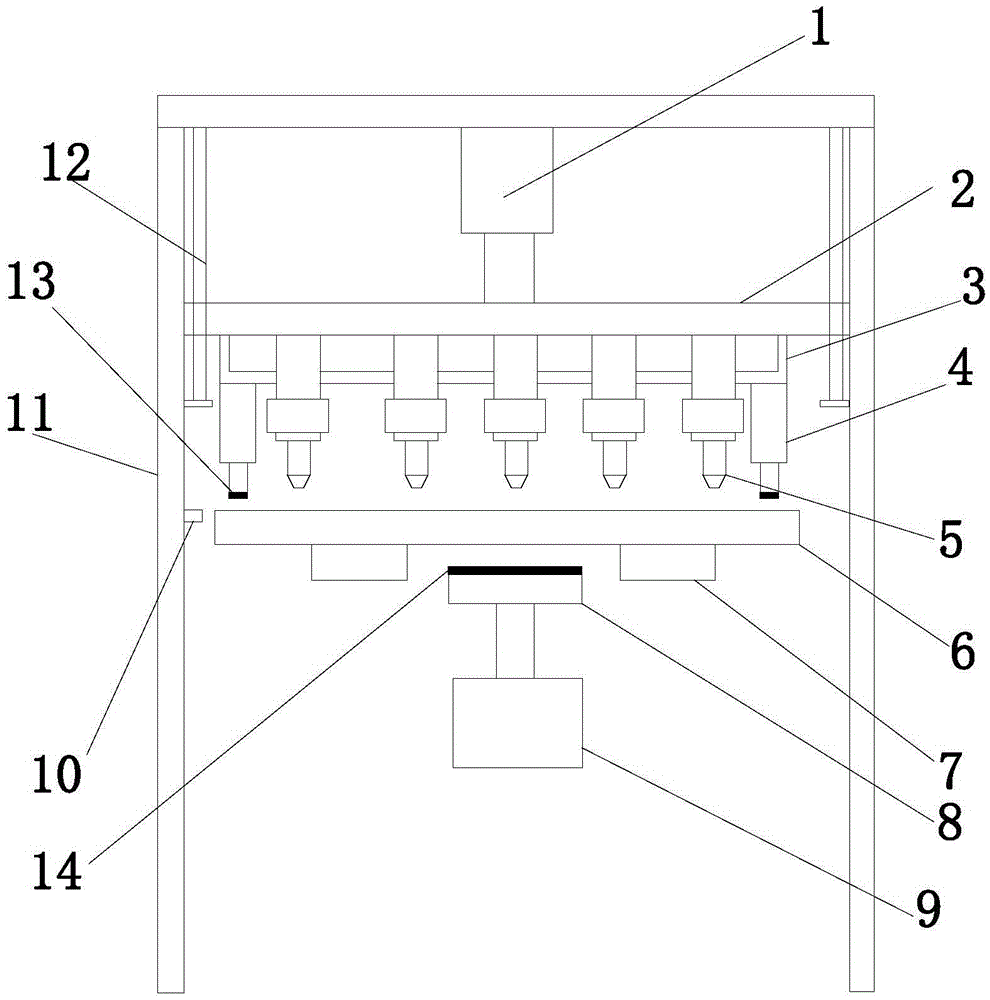

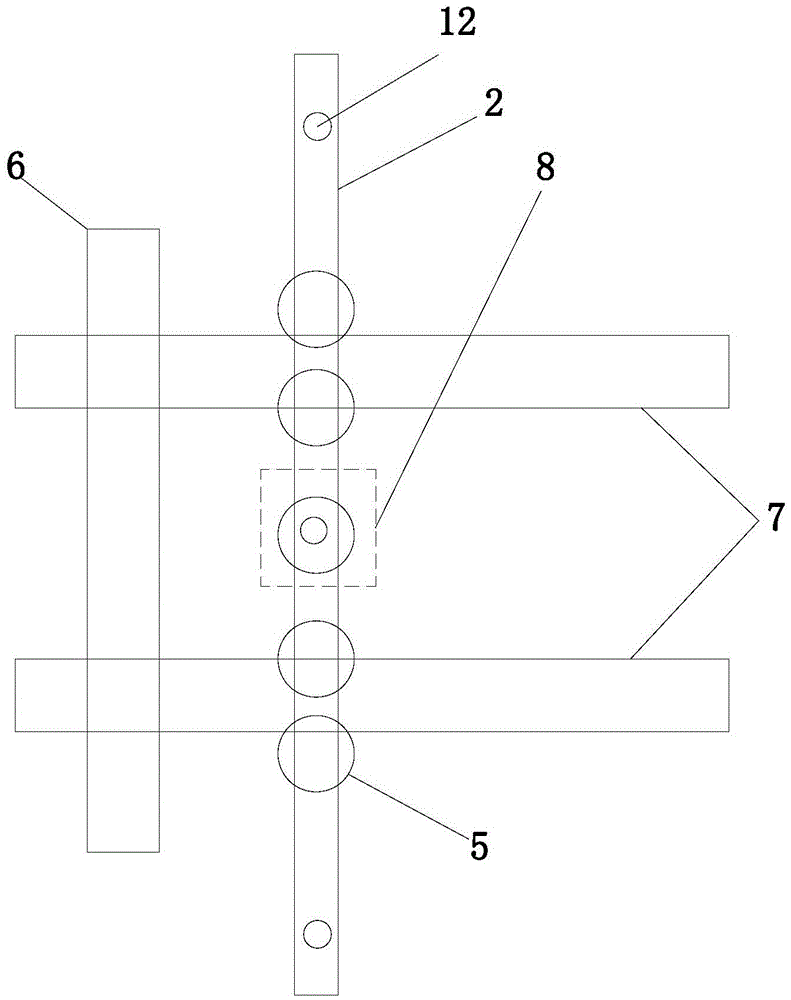

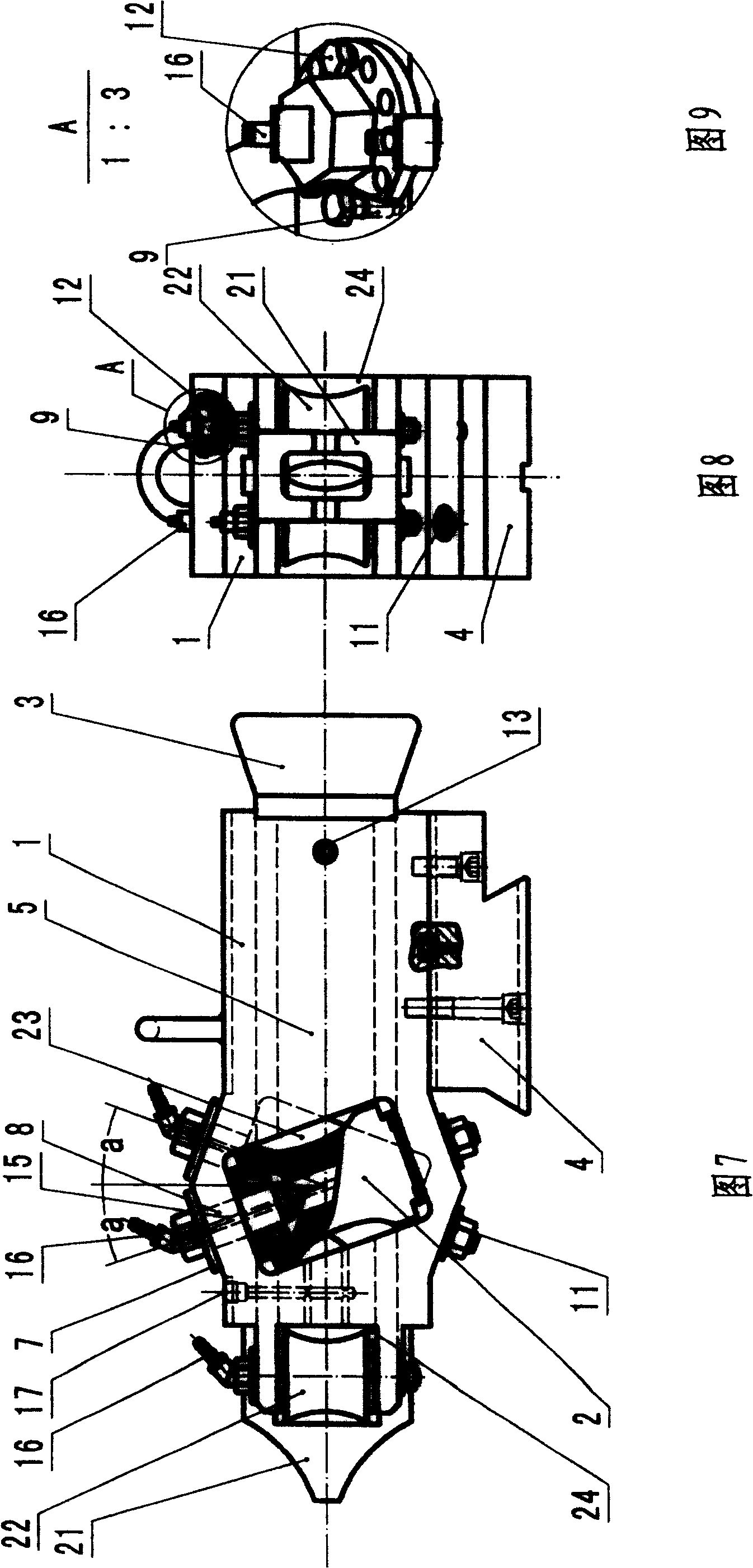

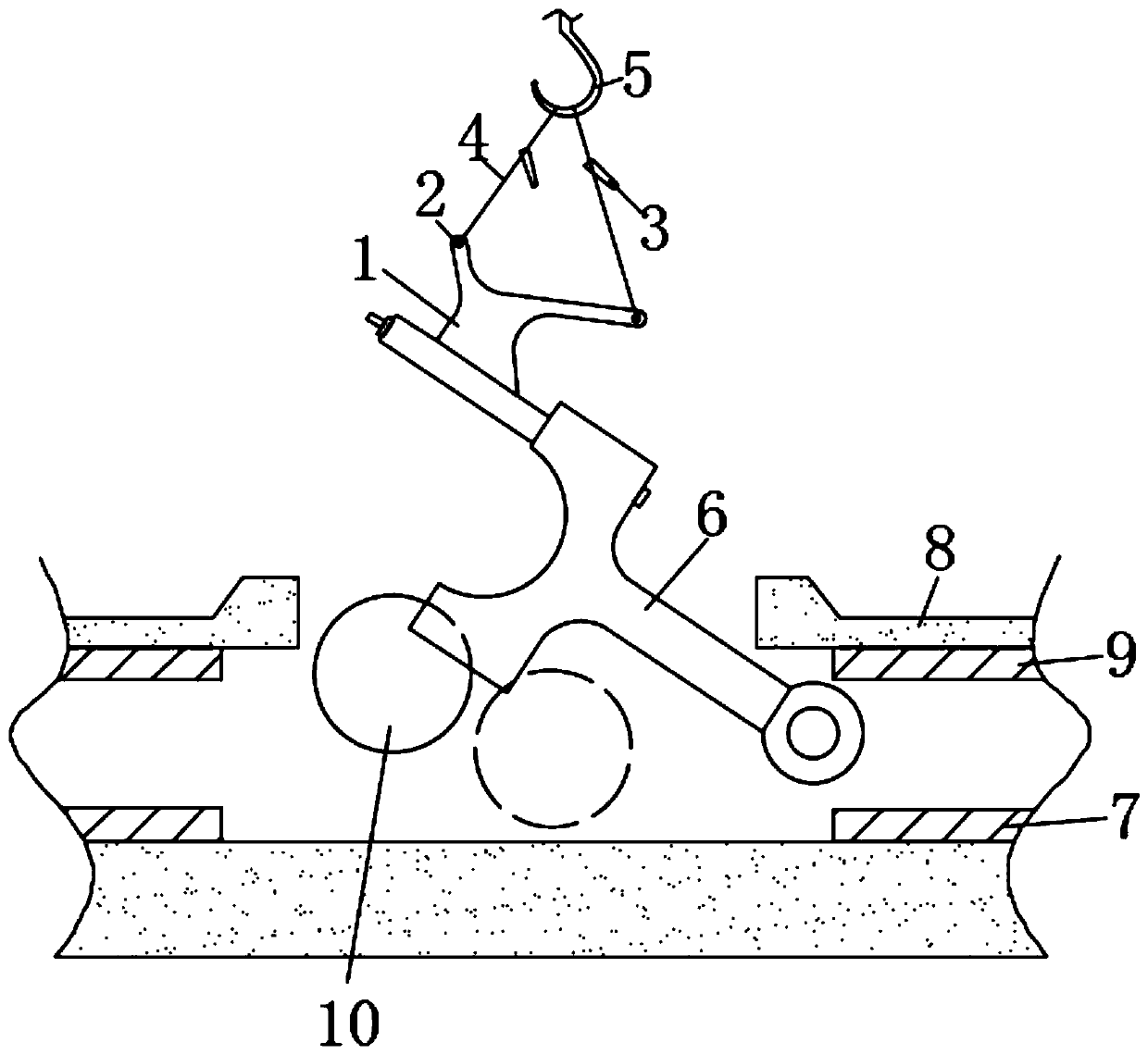

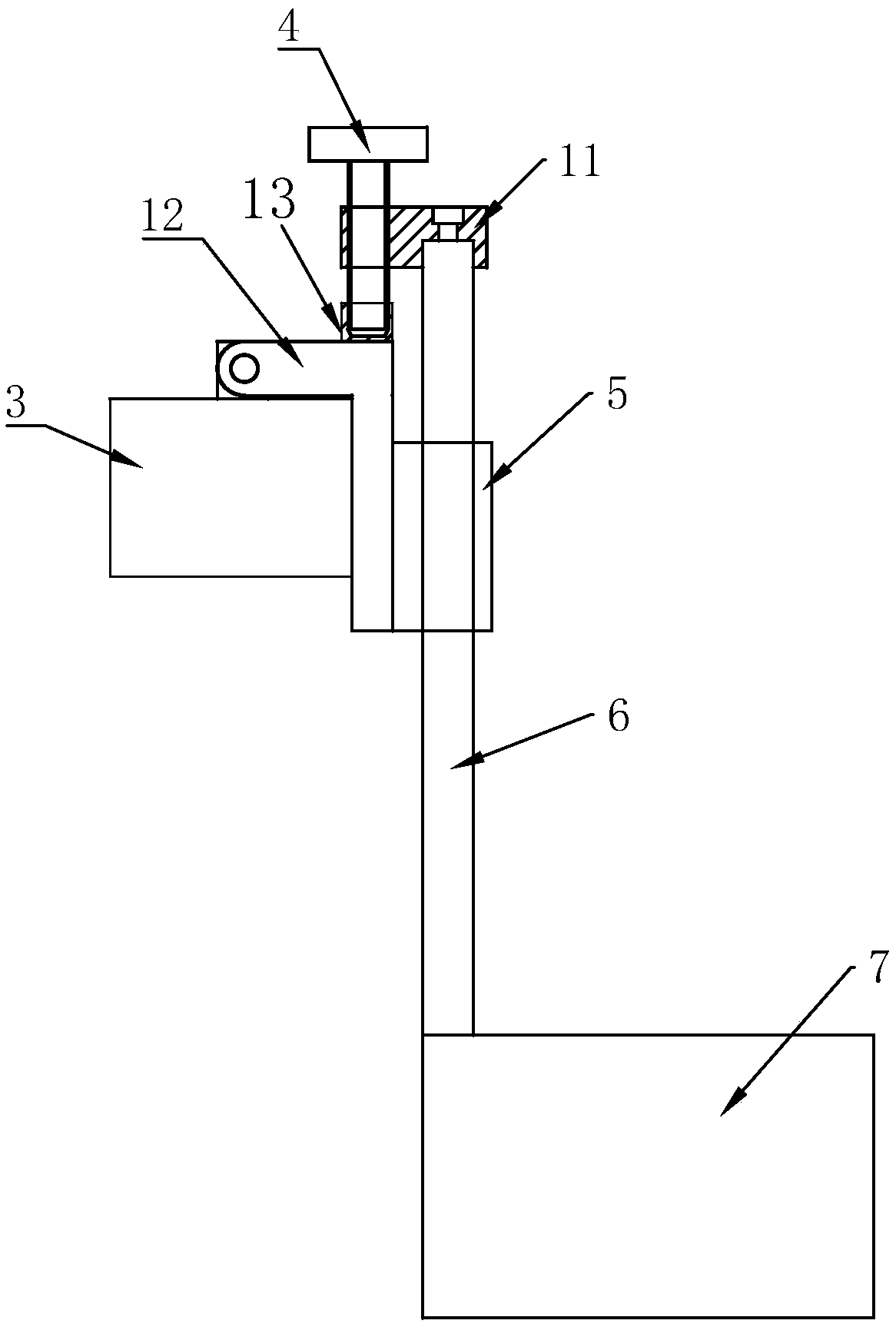

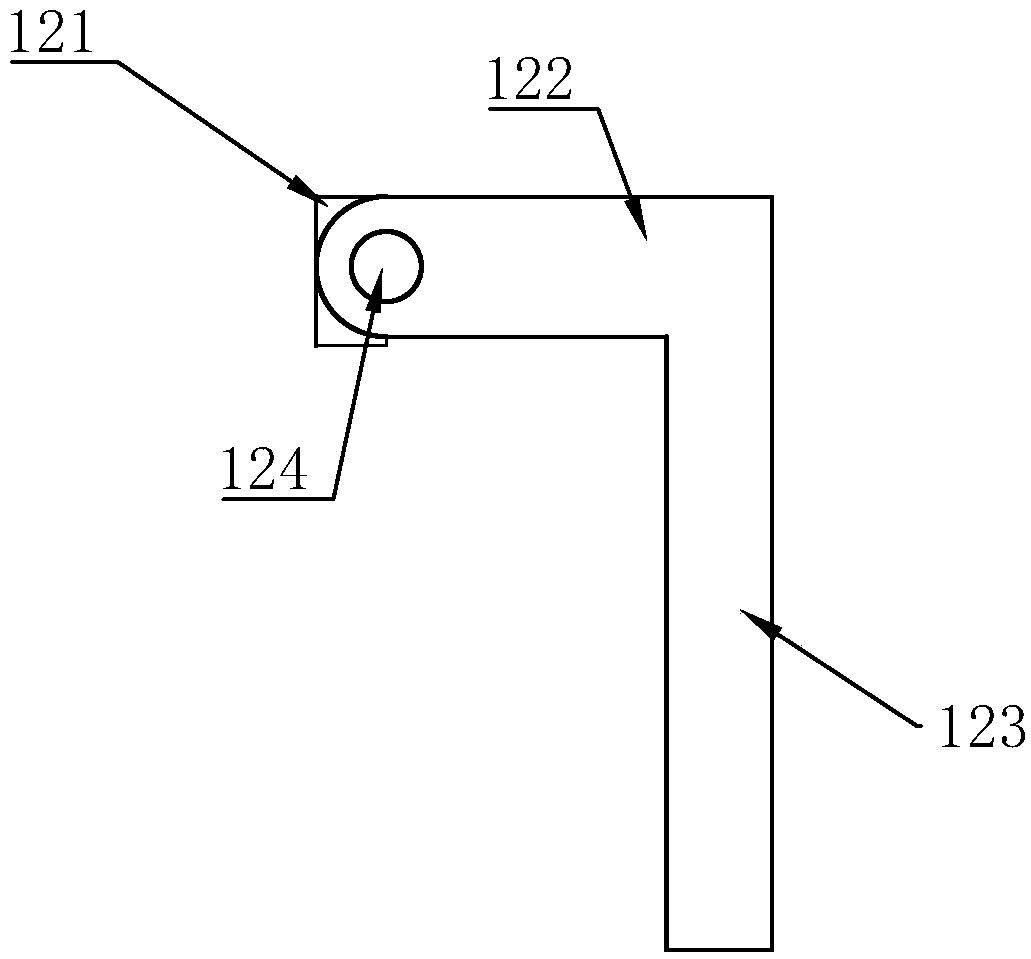

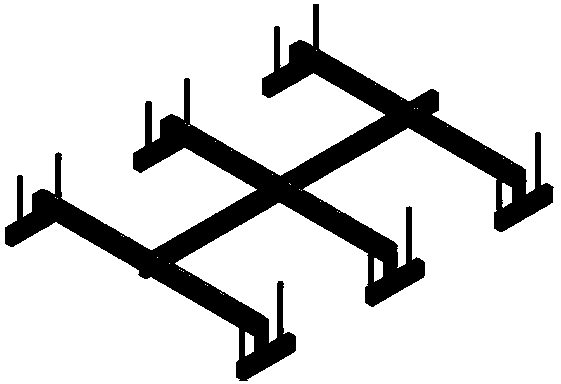

Nailing device for heated floor

InactiveCN105522621AReduce quality accidentsQuality improvementStapling toolsNailing toolsHydraulic cylinderEngineering

The invention discloses a nailing device for a heated floor. The nailing device comprises a rack, wherein a lifting mechanism is arranged on the rack; a plurality of air guns with downward muzzles are arranged on the lifting mechanism; two parallel conveyor belts are arranged below the air guns; a lifting platform is arranged below and between the two conveyor belts; the lifting mechanism is composed of a hydraulic cylinder fixed on the rack; a lifting rod is arranged on a telescopic rod of the hydraulic cylinder; the air guns with downward muzzles are arranged on the lifting rod through a U-shaped connector; guide rods are arranged at the two ends of the lifting rod respectively and fixed to the side parts of the rack respectively; lower air cylinders are arranged at the two ends of the U-shaped connector respectively; a rubber cushion is arranged at the end part of a telescopic rod of each lower air cylinder; and an infrared sensor is arranged at one end part of the rack. The nailing device can realize automatic nailing, effectively ensures the quality of a floor and simultaneously improves the production efficiency.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

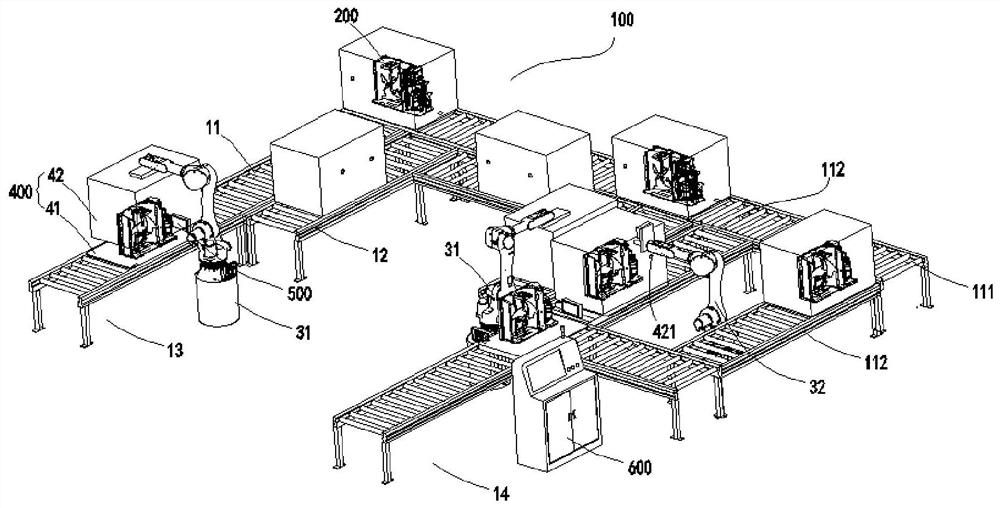

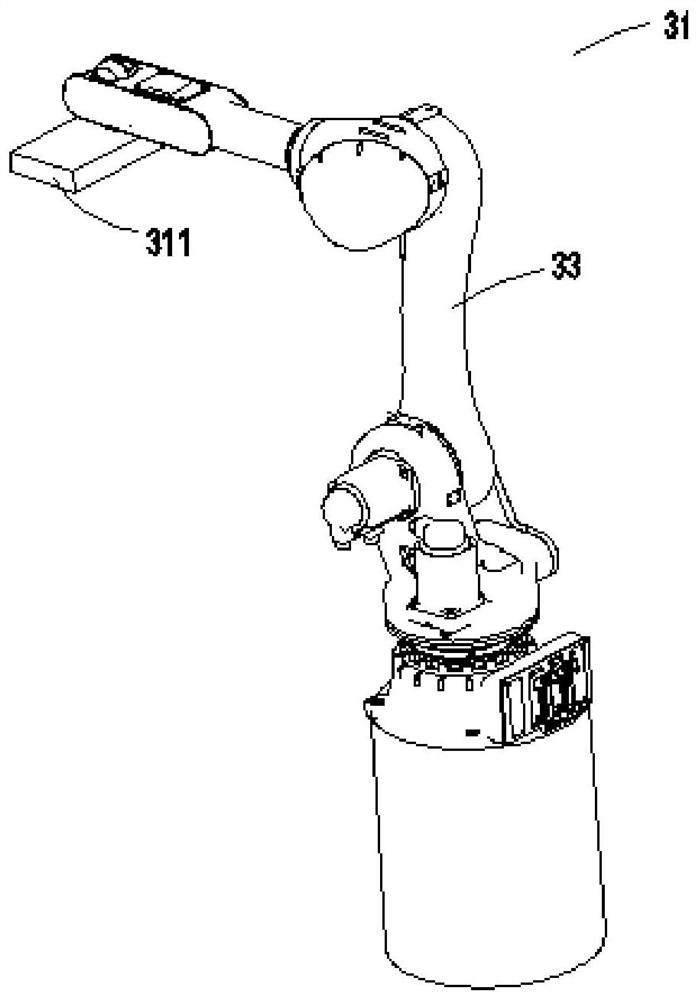

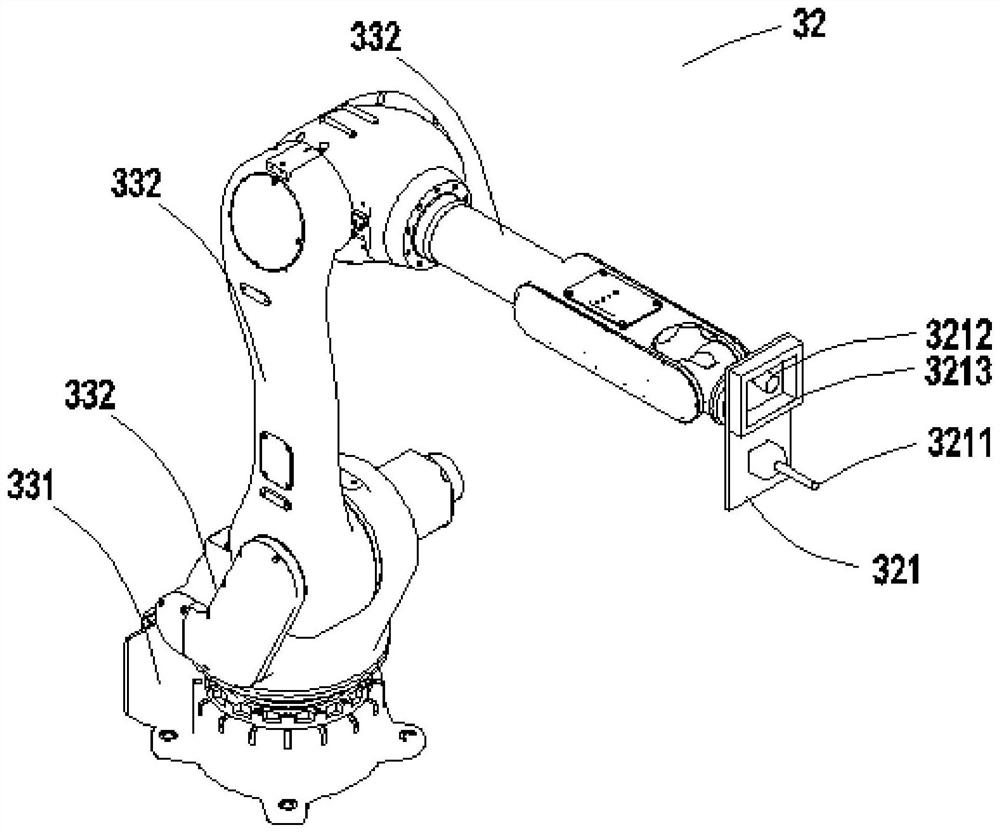

Continuous intelligent flexibility production method for woolen spinning

ActiveCN108803521AHigh sensitivityReduce stackingContinuous processingTotal factory controlProduction lineYarn

The invention provides a continuous intelligent flexibility production method for woolen spinning and relates to an automatic production method. The continuous intelligent flexibility production method comprises a control unit, an oil centralized blending and conveying unit, a plurality of production units and a cone yarn packaging and storing unit, wherein each production unit comprises a cardingsystem, a combined spinning and winding system and a combined winding and twisting system; subsystems in each production unit have no intersection with subsystems in other production units; the control unit controls the oil centralized blending and conveying unit, the production units and the cone yarn packaging and storing unit for production. With the adoption of the method, continuous single-piece lean production is realized, logistics in a workshop is rapid, efficient and punctual, and material inventory of the workshop is reduced greatly. Quality problems are easy to find by single cheese flow in the processing process of the product, anomaly of a production line can be reflected in real time through data monitoring of a production and execution system of the whole production line, and the product can be traced in the whole process. A digital management mode for the workshop is realized, and synchronization and integration of logistics and information flow in the workshop are realized.

Owner:CONSINEE GRP CO LTD

Production technology of waterproof and heat-insulated integrated board

ActiveCN102806745AHigh bonding strengthAvoid chemical reactionsLaminationLamination apparatusChemical reactionPlasticizer

The invention discloses a production technology of a waterproof and heat-insulated integrated board. The production technology comprises the following steps of: firstly, compositing an enhanced isolating material at one side of a waterproof roll; pre-heating the waterproof roll composited with the enhanced isolating material by a pre-heating device; compositing an heat-insulated material at one side of the waterproof roll composited with the enhanced isolating material after pre-heating; and finally, covering another pre-heated waterproof roll on the surface of the heat-insulated material. By providing the enhanced isolating material at one side of the waterproof roll, not only can the bonding strength between the enhanced isolating material and the waterproof roll be enhanced, but also the waterproof roll and the heat-insulated material can be effectively isolated; the condition that the waterproof roll is contacted with the heat-insulated material for a long time to cause chemical reaction can be avoided; a plasticizer inside the roll is prevented from migrating; the quality of the product is ensured; a procedure of pre-heating the waterproof roll is added before the waterproof roll and the heat-insulated material are composited; and the phenomenon that a waterproof layer and an insulating layer are stripped after the board is molded can be avoided, and the performance and quality of the board are further improved.

Owner:SHENZHEN ZHUOBAO TECH

A production process of waterproof and thermal insulation integrated board

ActiveCN102806745BHigh bonding strengthAvoid chemical reactionsLaminationLamination apparatusChemical reactionPlasticizer

Owner:SHENZHEN ZHUOBAO TECH

Battery aluminum foil non-landing clean producing and packaging line

InactiveCN106185143AReduced Chances of ContaminationSave human resourcesStorage devicesPackaging machinesElectrical batteryQuality control

The invention relates to a battery aluminum foil non-landing clean producing and packaging line. Original battery aluminum foil producing and packaging are completed through cooperation of multiple devices and multiple times of transportation over workshops, the production efficiency is affected, and the quality control cost is increased. The battery aluminum foil non-landing clean producing and packaging line is characterized by comprising a blank warehouse, a finished product warehouse, a slitting region, a producing region and a packaging region, wherein the slitting region and the producing region are oppositely arranged, and material transporting trolleys and unloading trolleys are arranged between the slitting region and the producing region and controlled by a master control room to move. The battery aluminum foil non-landing clean producing and packaging line has the beneficial effects that the manpower resource is reduced, and bumping damage, end face oil contamination and other quality accidents caused by human operation errors are also reduced; and the transportation time is shortened, the production benefits are increased, and meanwhile the quality accidents caused during transportation are avoided.

Owner:HANGZHOU FIVE STAR ALUMINUM

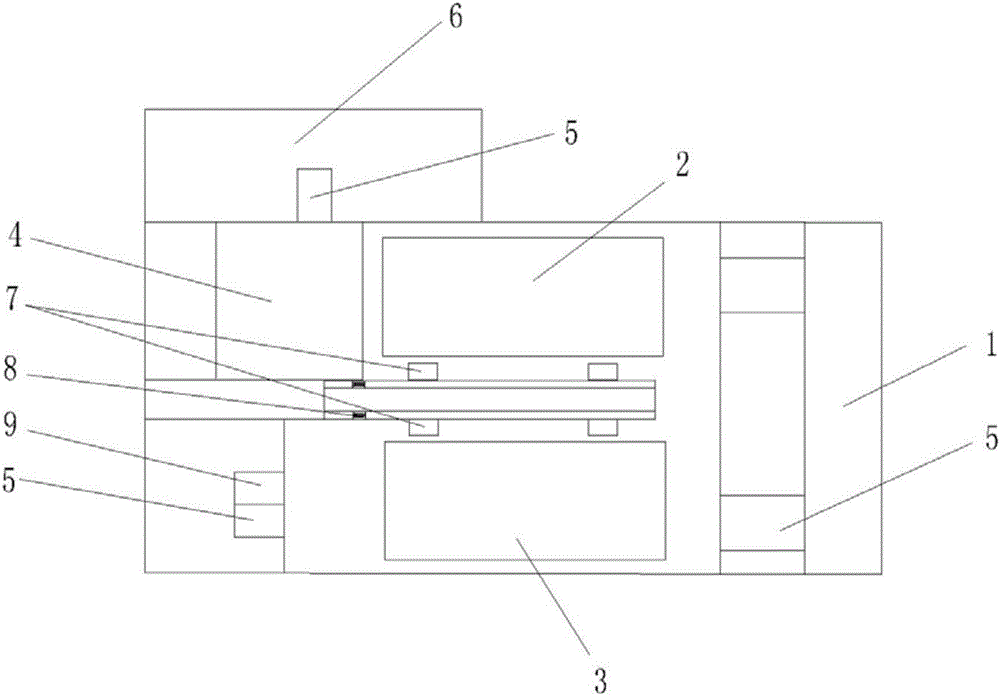

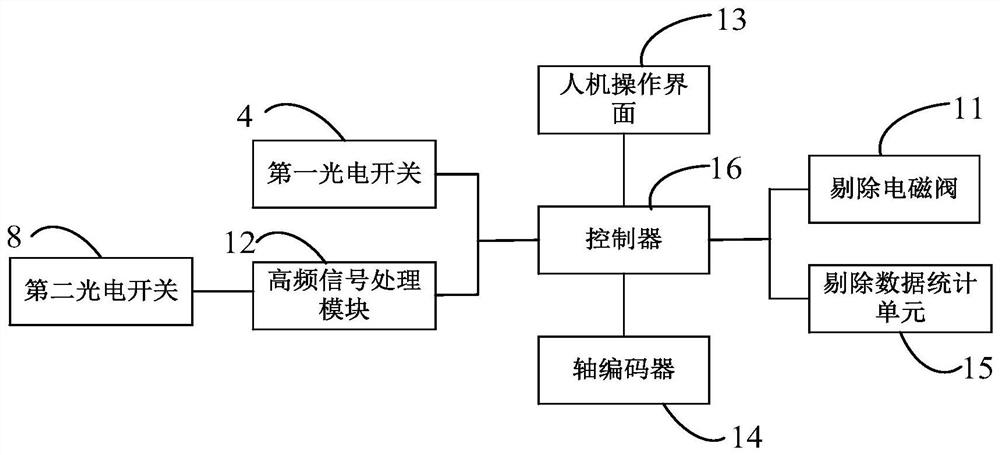

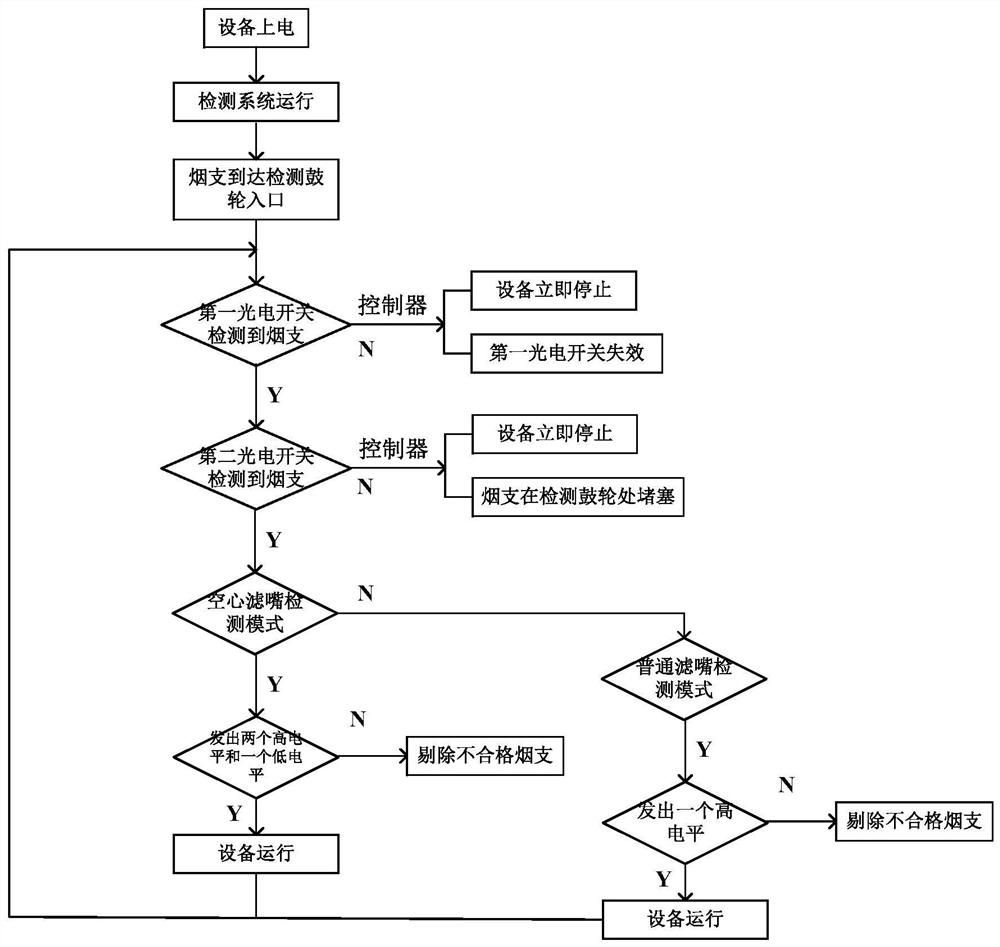

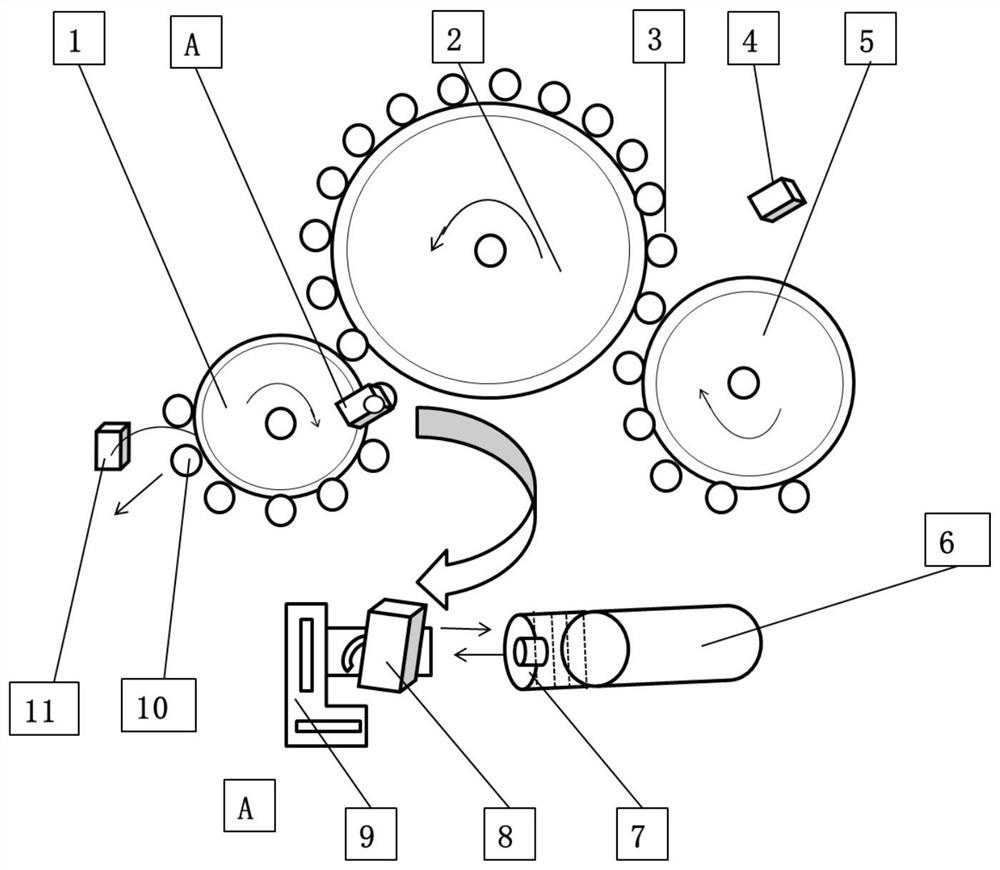

Cigarette making machine cigarette filter detection system

PendingCN112772967APrevent inflowReal-time effective real-time detection one by oneCigarette manufactureCigarette filterMechanical engineering

The invention discloses a cigarette making machine cigarette filter detection system which comprises a first optoelectronic switch, a second optoelectronic switch, a high-frequency signal processing module, a shaft encoder and a controller, the first optoelectronic switch is arranged at an inlet of a detection drum wheel and detects whether cigarettes exist or not, the second optoelectronic switch is a high-speed optoelectronic switch, is arranged in front of an inlet of a rejection drum wheel and is used for detecting the end face of a cigarette filter tip and generating a high-frequency electric signal, the high-frequency signal processing module is used for processing the high-frequency electric signal to obtain a level signal which can be identified by the controller, and the shaft encoder is coaxially connected with the detection drum wheel and is used for generating a phase signal according to the running position of the detection drum wheel; and the first photoelectric switch and the second photoelectric switch are positioned and detected. According to the cigarette filter tip detection system, the end faces of the cigarette filter tips are detected one by one in real time, cigarettes without filter tips and cigarettes inconsistent with a production mode are prevented from flowing into the next procedure, quality accidents are reduced, and consumption of raw and auxiliary materials is reduced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

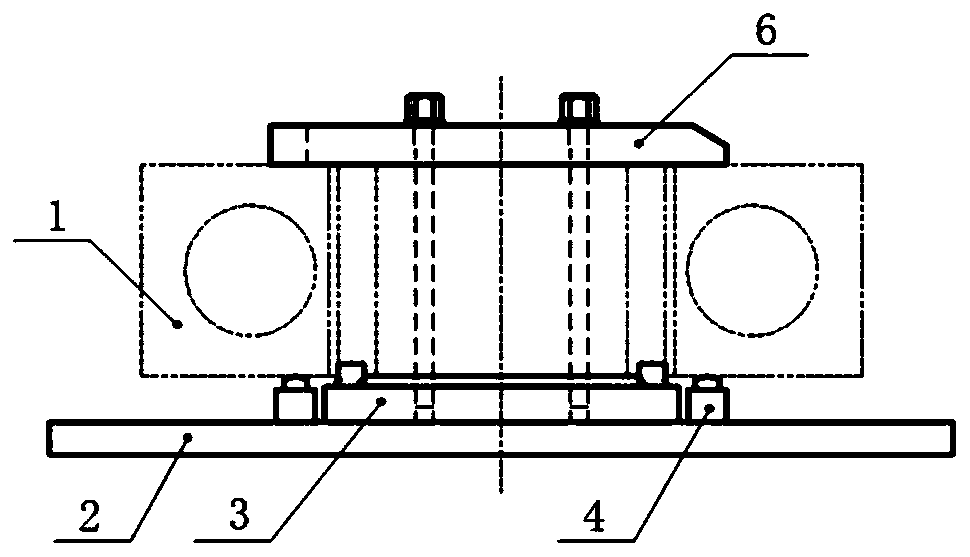

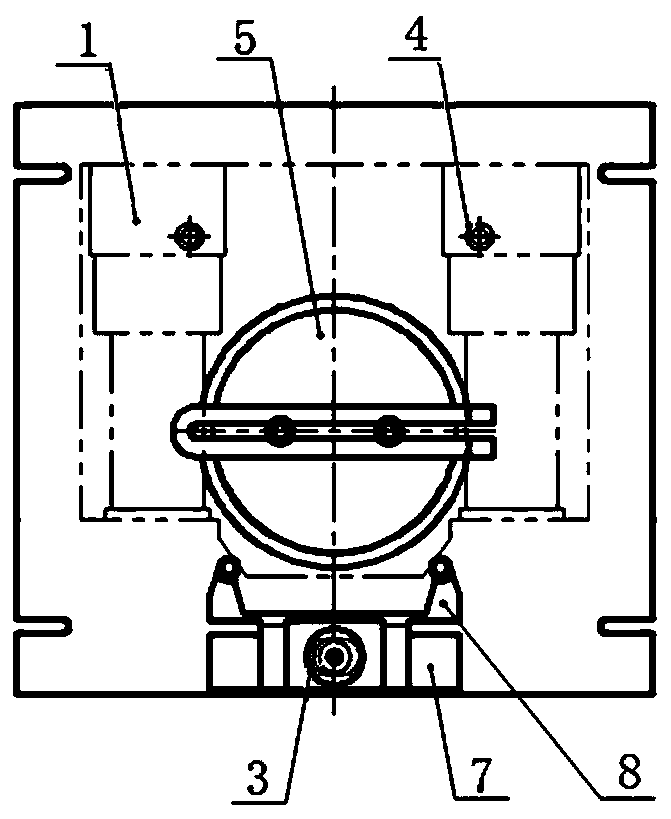

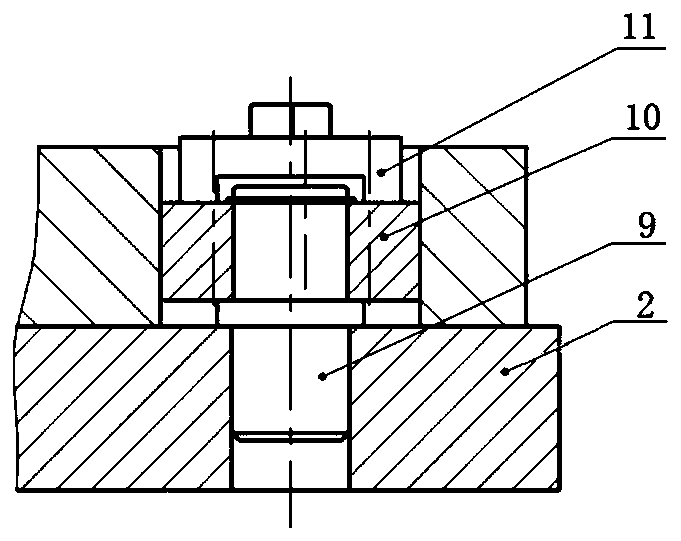

Rapid positioning clamp for bearing base machining

PendingCN110900253AImprove processing qualitySolve complexityPositioning apparatusMetal-working holdersFixed bearingEngineering

The invention discloses a rapid positioning clamp for bearing base machining and belongs to the technical field of machining. The clamp comprises a circumferential positioning mechanism, a floating supporting mechanism, a positioning boss and a pressing plate mechanism, wherein the circumferential positioning mechanism, the floating supporting mechanism and the positioning boss are arranged on a bottom plate at intervals, the circumferential positioning mechanism is arranged on one side of the positioning boss and matched with the positioning boss to circumferentially fix the bearing base, thefloating supporting mechanism assists in supporting the bearing base, the positioning boss is T-shaped, the shaft portion of the positioning boss is sleeved in an inner hole of the bearing base, thestep face supports an end face of the bearing base, and the pressing plate mechanism is located at the top of the positioning boss and matched with the positioning boss to axially fix the bearing base. The clamp is advantaged in that the bearing base can be quickly positioned and clamped before being machined on a machine tool, and the clamp is reasonable in structure, accurate in positioning, easy to operate, high in efficiency, free of energy consumption, capable of improving part machining quality and capable of reducing production cost.

Owner:CISDI HEAVY MACHINERY

Hot-rolled elliptical rolled piece inlet rolling guide

ActiveCN100415400CReduce distortionReduce skewGuiding/positioning/aligning arrangementsMechanical engineeringHot rolled

Owner:MAANSHAN IRON & STEEL CO LTD

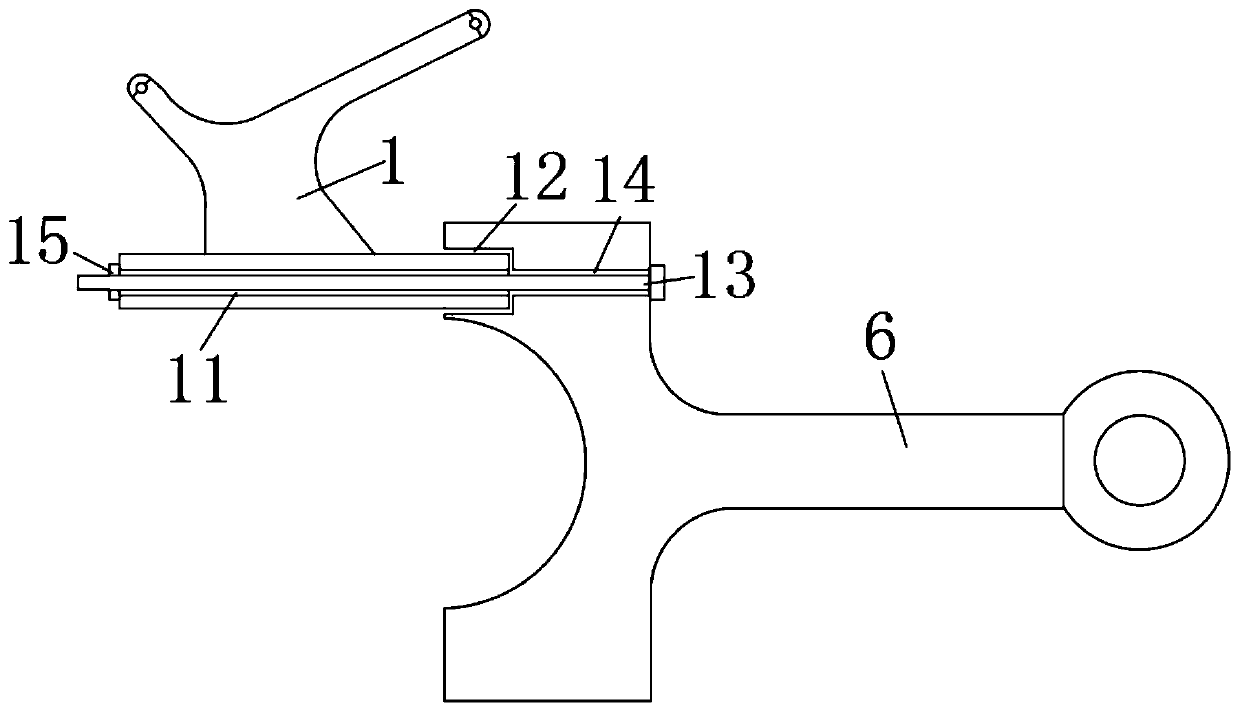

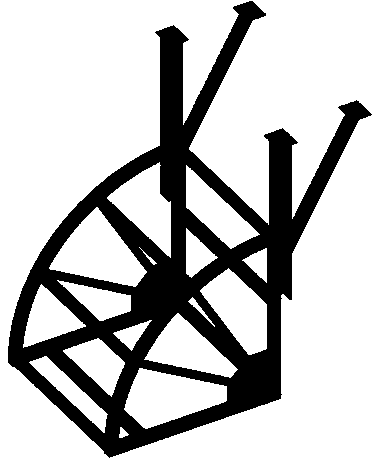

Crosshead pin lifting device

ActiveCN106744269BMeet the development requirements of large-scaleImprove securityLoad-engaging elementsCross pinIndustrial engineering

The invention relates to a lifting device, in particular to a cross head pin lifting device applied to a reciprocating compressor. A lifting device body of the lifting device is of a concave shape. A lifting rope of lifting equipment is connected with the end of a first side rod of the lifting device body, and the end of a second side rod of the lifting device body is connected with a cross head pin. The second side rod is sleeved with a movable collision block. A first stopping ring and a second stopping ring are fixedly arranged on the second side rod and located at the front side and the rear side of the collision block separately. The cross head pin can collide with any stopping ring to move through the collision block. By the adoption of the cross head pin lifting device, the labor intensity of workers is relieved, safety is improved, and meanwhile quality accidents caused by human factors are reduced.

Owner:沈阳鼓风机集团往复机有限公司

Drying equipment capable of removing moisture on wire rod surface

ActiveCN106382802AFully dryAvoid damageDrying machines with progressive movementsDrying solid materialsElectrical controlEngineering

The invention provides drying equipment capable of removing moisture on the wire rod surface. The drying equipment comprises a box body, a drying transmission unit and an electrical control system. The box body is internally provided with a partition plate, and the partition plate divides the box body into a first space and a second space. The second space is a closed body, and a wire passing groove is formed in the top of the second space. The electrical control system is arranged inside the second space. A wire rod dryer is fixed to the left wall of the second space. The drying transmission unit is arranged inside the first space and comprises a first wire passing wheel and a second wire passing wheel. The first wire passing wheel and the second wire passing wheel are arranged on a first fixed shaft and a second fixed shaft through bearings in a sleeving mode correspondingly, and the first fixed shaft and the second fixed shaft are parallel to each other. The first fixed shaft is located above the second fixed shaft, and the distances from the first fixed shaft and the second fixed shaft to the left wall of the box body are equal. According to the drying equipment capable of removing moisture on the wire rod surface, the functions of conducting damping and automatically adjusting the drying temperature are achieved, and the drying efficiency is high.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

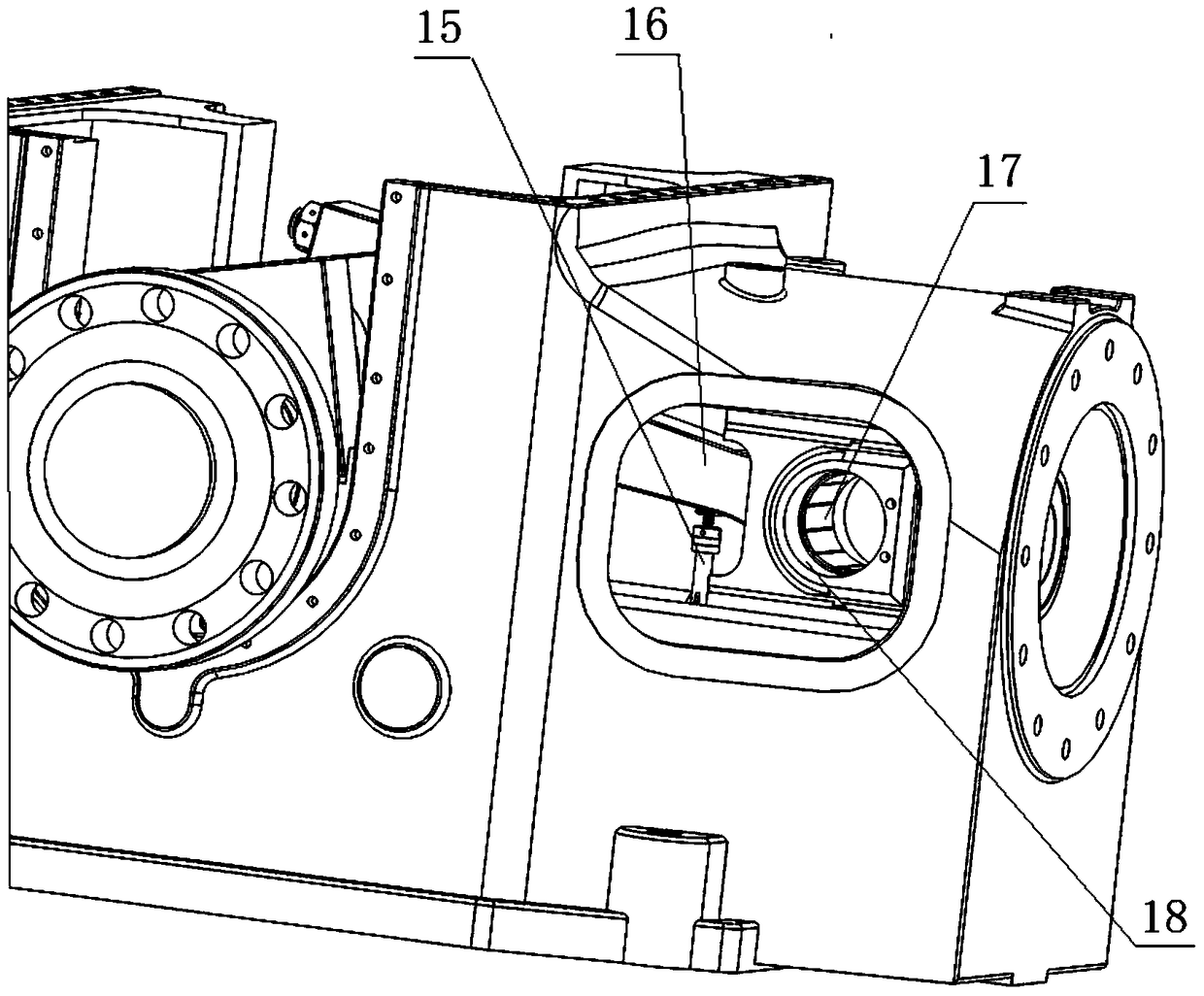

Component balance lifting device with irregular inner chamber of machine body

InactiveCN109761143AImprove securityReduce quality accidentsLoad-engaging elementsMaterial resourcesFuselage

The invention discloses a component balance lifting device with an irregular inner chamber of a machine body, and relates to the technical field of machinery installation. The component balance lifting device with the irregular inner chamber of the machine body comprises an I-shaped sling, a connecting rod and the machine body, wherein lifting lugs are arranged at the two ends of the top of the I-shaped sling, and the inner parts of the two lifting lugs are fixedly connected with lifting ropes; the tops of the two lifting ropes are movably connected with lifting hooks, and the middles parts ofthe two lifting ropes are fixedly connected with level blocks; and a through hole is formed in formed in one side of the bottom of the I-shaped sling. The component balance lifting device with the irregular inner chamber of the machine body can improve the safety of unit installation and maintenance, reduce quality accidents caused by human factors, steadily improve the quality of unit installation and maintenance, and thoroughly solve the problem of time consumption and labor consumption during installation. Meanwhile, the working intensity is reduced, the waste of manpower and material resources is saved, the working efficiency can also be improved, and the unit installation and maintenance cost can be reduced.

Owner:ANHUI JINMEI ZHONGNENG CHEM IND

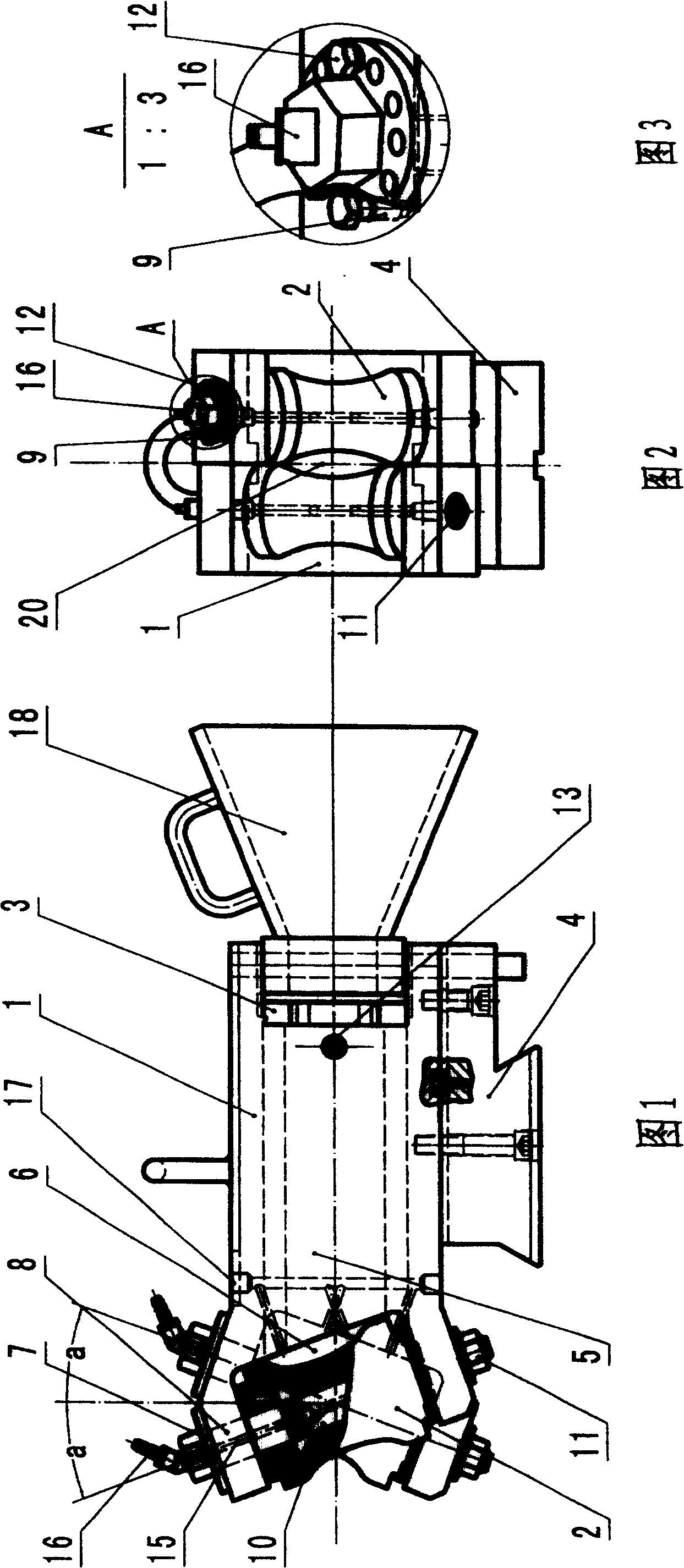

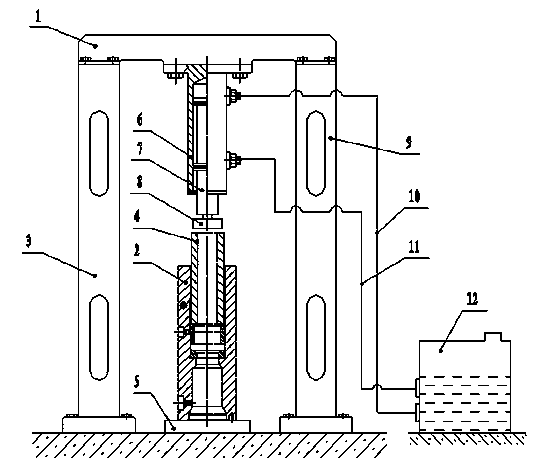

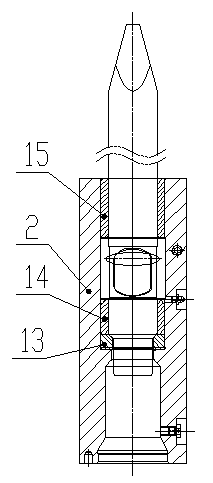

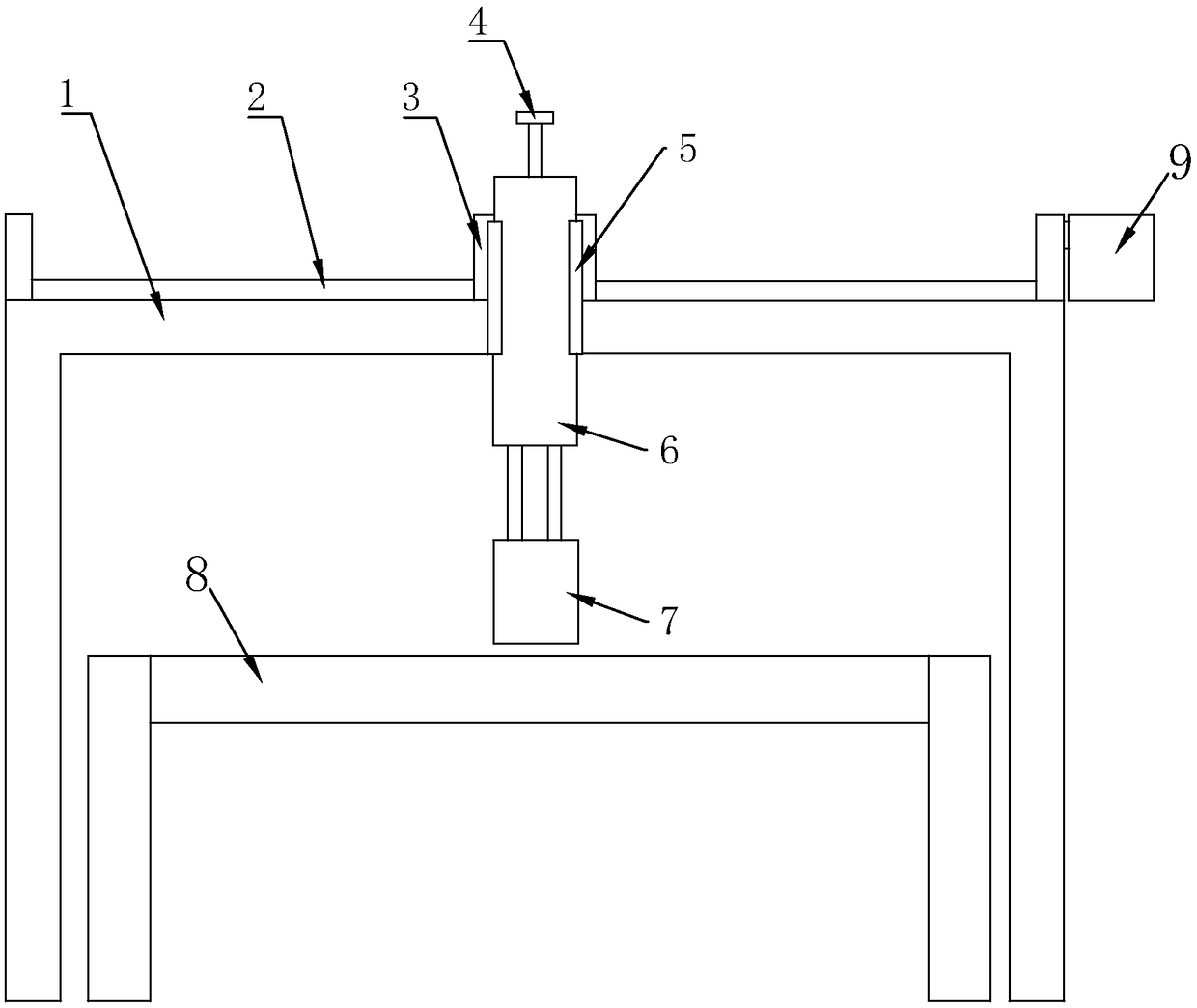

Rapid installation device and method for hydraulic breaking hammer drill rod base assembly drill rod bushing

The invention discloses a rapid installation device for a hydraulic breaking hammer drill rod base assembly drill rod bushing. The rapid installation device comprises a beam, a left stand column, a pressing sleeve, a high-pressure oil cylinder base, a piston, a pressing rod, a right stand column, a high-pressure oil inlet loop, a low-pressure oil return loop and a hydraulic station. The left stand column, the right stand column and the hydraulic station are fixedly arranged on a base face. The left stand column, the right stand column and the beam are connected through fasteners to form a whole rack body. The high-pressure oil cylinder base is fixedly arranged under the beam. The head of the piston inside a high-pressure oil cylinder is connected with the pressing rod. The high-pressure oil cylinder base is communicated with the hydraulic station through the high-pressure oil inlet loop and the low-pressure oil return loop. The invention further discloses an installation method for the hydraulic breaking hammer drill rod base assembly drill rod bushing. According to the rapid installation device and method for the hydraulic breaking hammer drill rod base assembly drill rod bushing, the drill rod bushing and a drill rod base can be rapidly installed, assembling efficiency is improved, and assembling quality is ensured.

Owner:MAANSHAN BOWEI MACHINERY MFG

Automatic tire marking device

The invention relates to an automatic tire marking device. The automatic tire marking device comprises a conveying table and a plurality of marking mechanisms arranged on the conveying table at equalintervals, each marking mechanism comprises a support, an anti-collision fixing assembly and a large-character ink-jet printer, a sliding rail is arranged on each support, a sliding block which horizontally slides along the corresponding sliding rail is arranged on each sliding rail, each sliding block is connected with a stepping motor through a tooth-shaped belt assembly, one side of each anti-collision fixing assembly is longitudinally and rotationally connected with the corresponding sliding block, the other side of each anti-collision fixing assembly is provided with an air cylinder whichslides vertically relative to the corresponding anti-collision fixing assembly, each large-character ink-jet printer comprises a large-character spray head and an ink supply device, the large-character spray heads are connected with the ink supply devices, the large-character spray heads are located above the conveying table and are fixed to the output ends of the air cylinders. According to theautomatic tire marking device, marking process intelligent manufacturing in the tire industry is realized, the marking beauty is improved, return rubber generated in the tire production pressing-out link is reduced, the energy consumption is reduced, the graded product rate is increased, the waste of the coating is reduced, the cost expenditure of easily damaged parts is reduced, the production efficiency is improved, the labor intensity is reduced, and the quality accidents are reduced.

Owner:天津浩泰瑞森科技发展有限公司

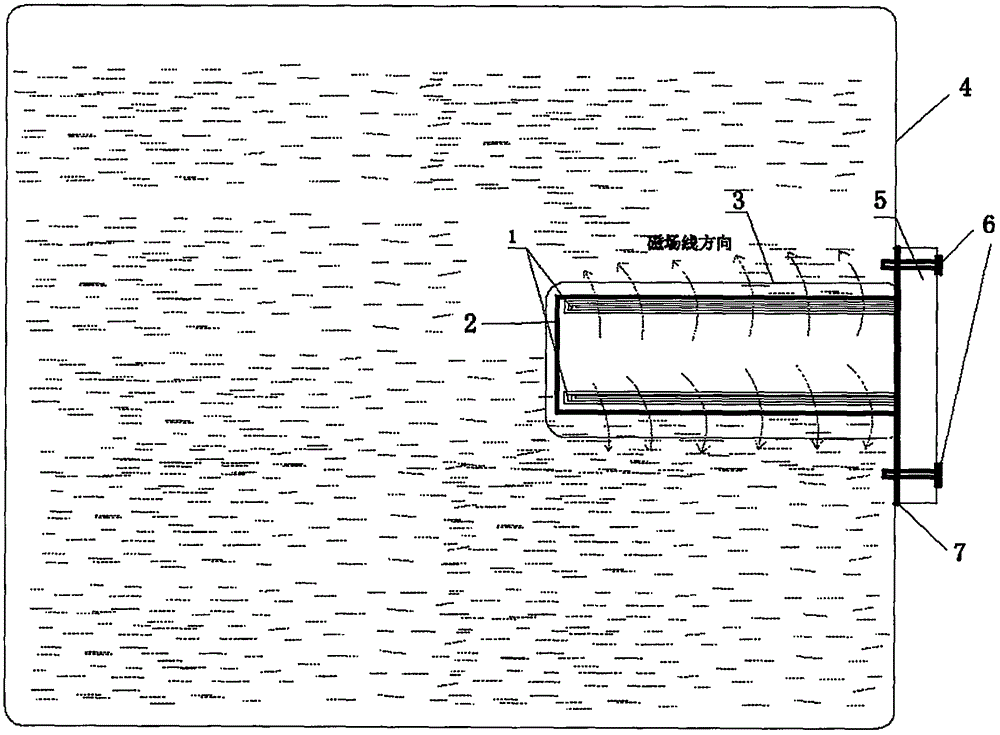

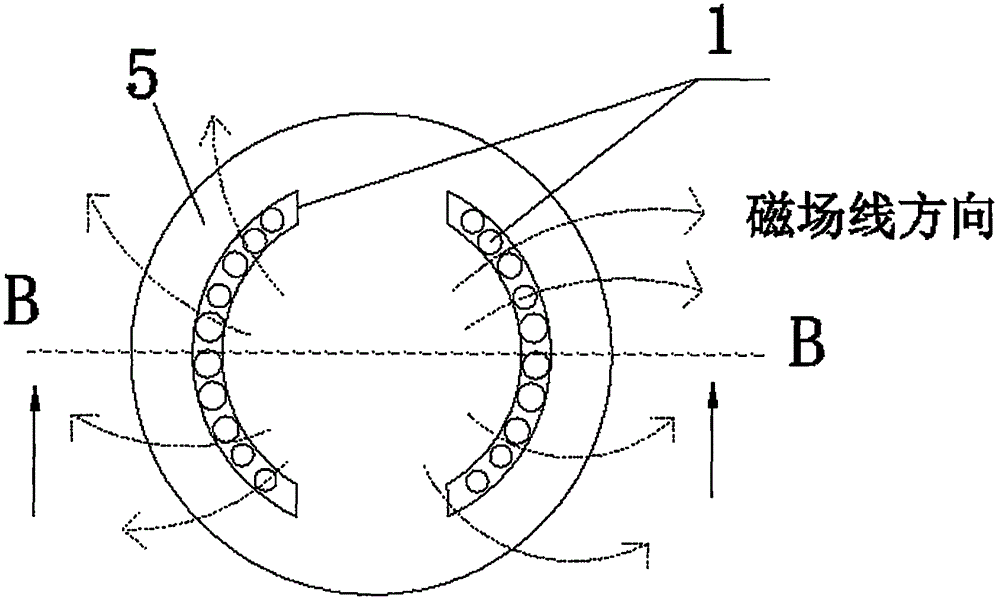

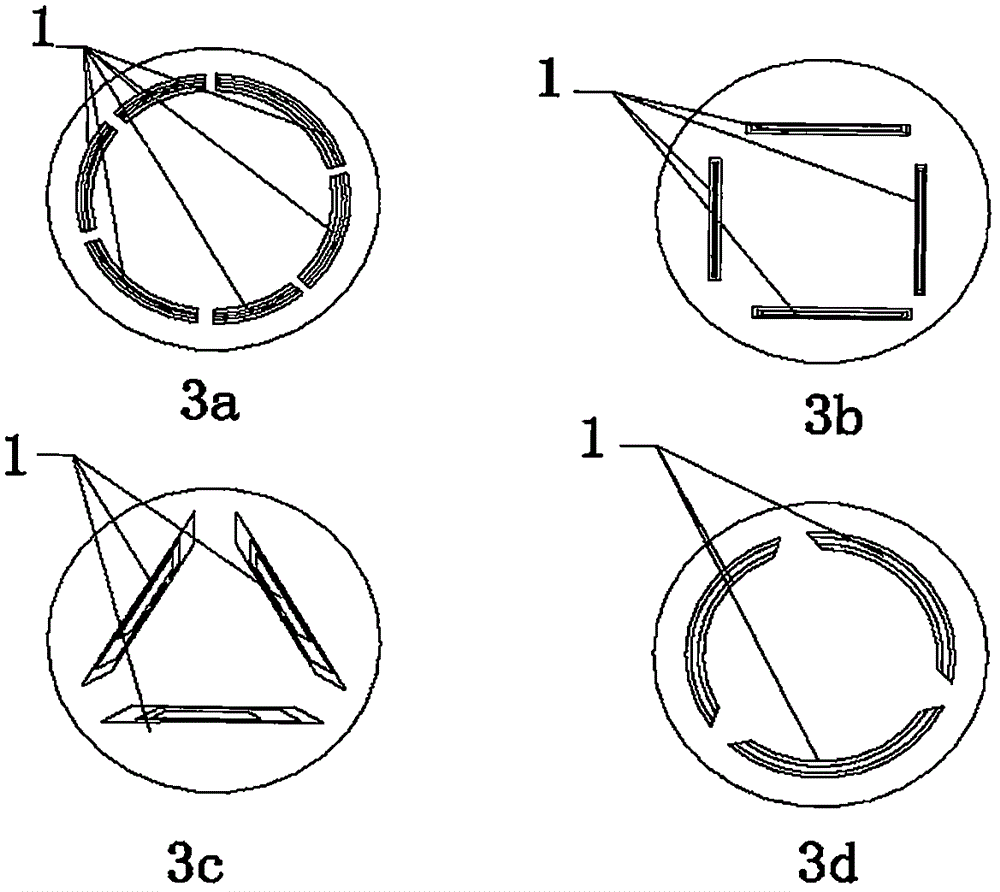

Electromagnetic type liquid heating device and electromagnetic water heater

InactiveCN106766129AReduce quality accidentsSimple structureCoil arrangementsOhmic-resistance heatingElectromagnetic heatingFluid warmer

The invention discloses an electromagnetic type liquid heating device, and relate to the technical field of heating equipment. The electromagnetic type liquid heating device comprises a liquid container, and an electromagnetic heating assembly; the electromagnetic heating assembly is at least partially inserted into the liquid container; and the electromagnetic heating assembly heats the liquid in the liquid container from inside to outside. Thereby, the designed water heater or liquid heater has the advantages that the structure is simple, the design is novel, heating is direct and uniform, and the heating efficiency is high; meanwhile, the installation is flexible, and the costs for manufacturing, mounting, and later maintaining are reduced; the electromagnetic type liquid heating device has a good effect and makes contribution for achieving social energy conservation and production efficiency improvement; and when applied to the water heater, a heating body independently heats the water in the water, the water is directly and uniformly heated, and the heating efficiency can reach above 80%.

Owner:胡小庆

Automobile hub coating line horizontal cableway rotation station

The invention provides an automobile hub coating line horizontal cableway rotation station. The automobile hub coating line horizontal cableway rotation station is composed of a rotation station motor (1), a cableway hanging fixture (2), a hanging fixture rotating speed measuring device (3), a layer board (4), a layer board boss (5), a rotation station chain driven gear (6), a driven gear shaft (7), a rotation station chain (8), a rotation station bottom plate (9), a cableway hanging fixture gear (10), a push air cylinder (11), a rotation station bottom plate slide way (12), a rotation station motor drive gear (13) and a rotation station motor drive gear shaft (14). The automobile hub coating line horizontal cableway rotation station is ingenious in design, simple in structure and capable of avoiding sagging and coating missing, and the occurrence of quality accidents is reduced.

Owner:CITIC DICASTAL

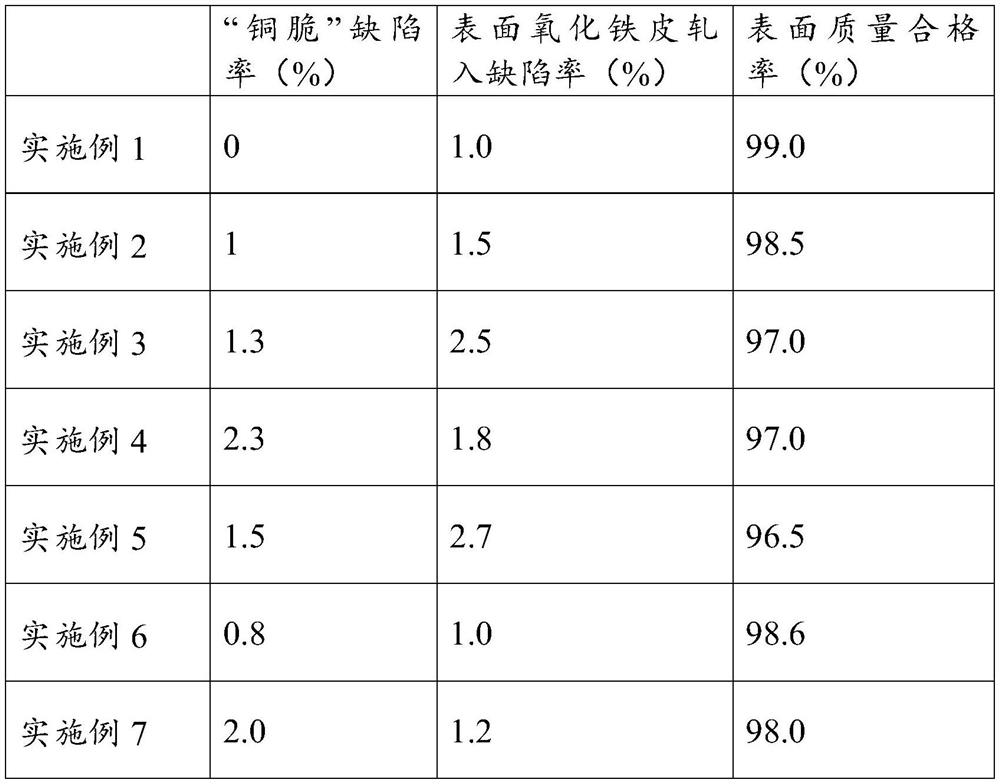

Method for reducing surface cracks of alloy steel, alloy steel and preparation method of alloy steel

ActiveCN114367645AReduce brittlenessAvoid brittlenessTemperature control deviceWork treatment devicesCopperSteel belt

The invention belongs to the technical field of continuous casting processes in the metallurgical industry, and particularly relates to a method for reducing surface cracks of alloy steel, the alloy steel and a preparation method of the alloy steel, and the method for reducing the surface cracks of the alloy steel comprises the steps of continuous casting and heating; in the continuous casting step, the upper surface temperature of a straightening section continuous casting billet is controlled to be larger than the lower surface temperature, delta T is larger than 0 and smaller than or equal to 60 DEG C, and the lower surface temperature T of the straightening section continuous casting billet is larger than or equal to 840 and smaller than or equal to 900 DEG C; the heating step at least comprises two heating stages, and the time of the first heating stage is 0 lt; t is less than or equal to 15 minutes, the temperature T is more than or equal to 1060 and less than or equal to 1100 DEG C, and the total heating time is 110-160 minutes. By controlling the straightening temperature of the continuous casting billet, the straightening temperature difference of the upper surface and the lower surface and the heating process, the copper brittleness phenomenon of the sulfuric acid dew point corrosion resistant steel belt is effectively reduced, the edge of a finished product is free of macroscopic edge cracks, the plate surface is free of V-shaped copper brittleness cracks, and the copper brittleness defect rate is reduced.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Integrally-mounted bridge cable laying method

PendingCN110518496AReduce time spent working at heightsReduce frequencyApparatus for laying cablesCable trayEngineering

The invention relates to an integrally-mounted bridge cable laying method. The method comprises the following steps: 1, hoisting and segmenting are carried out on a bridge by applying a pipeline comprehensive technology; 2, holes are formed in the corresponding positions of a top plate, and expansion bolts are installed; 3, connecting, segmenting and straightening of the bridge on the ground are carried out; 4, cable protection riding wheels are installed at the tail ends of the two sides of the head segment, a cable sliding supporting device is laid in the hoisting secondary segment bridge, and a cable horizontal laying restraining device is installed at the turning position; 5, cable laying is carried out, except formal cable fixing at the head segment of the hoisting, other segments alladopt cable temporary fixing devices; 6, the cable protection riding wheels, the sliding supporting device, a temporary restraining device, the temporary fixing devices and the like are disassembledand displacement installation work is completed; and 7, installation of the cable bridge of the vertical part at the tail end of the equipment is completed finally. The overall is enhanced after laying of the cable bridge and the cable on the ground, and the labor cost of cable laying and the aerial work risk are reduced.

Owner:SHANGHAI BAOYE GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com