Hot-rolled elliptical rolled piece inlet rolling guide

An ellipse, rolling piece technology, applied in the direction of guide/positioning/alignment device, etc., can solve the problems of easy distortion, scratches, easy damage to guides, guide rollers, and bearings that are easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

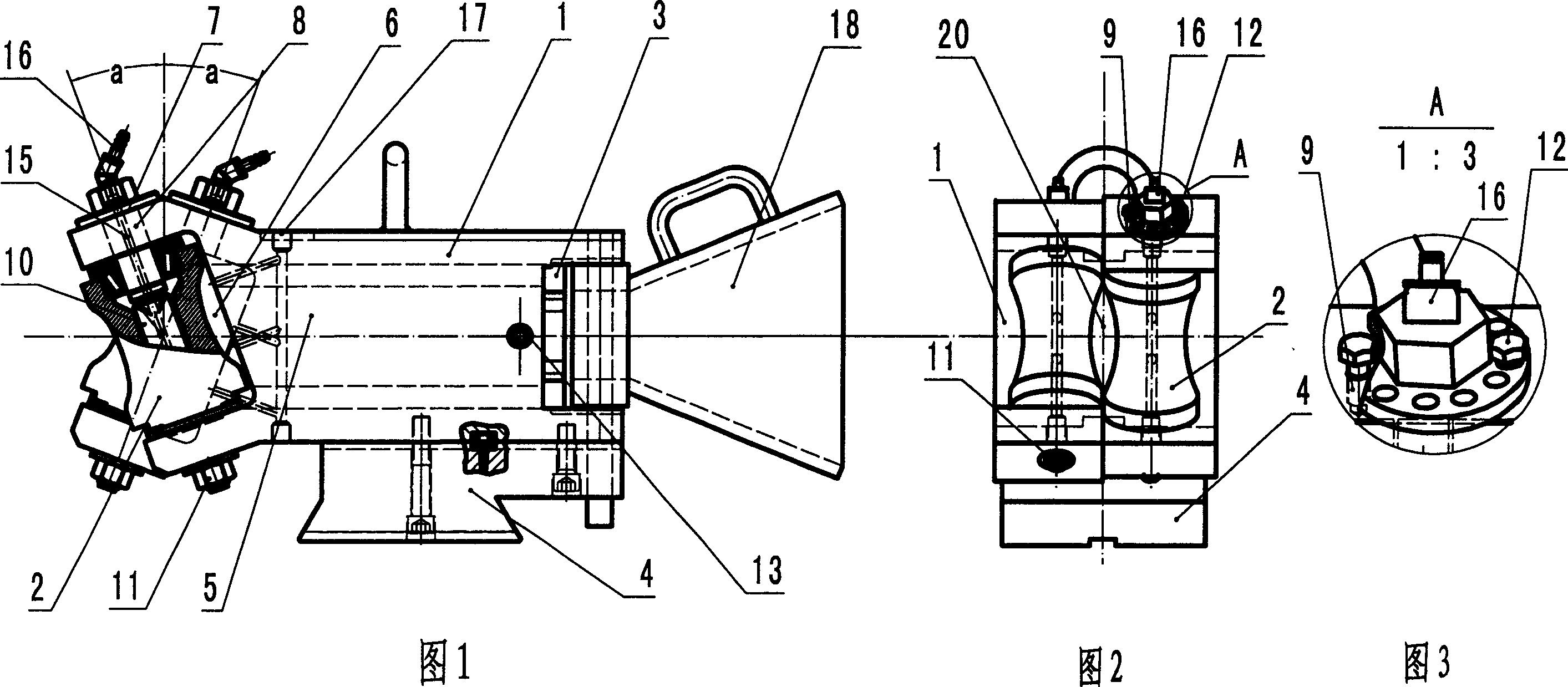

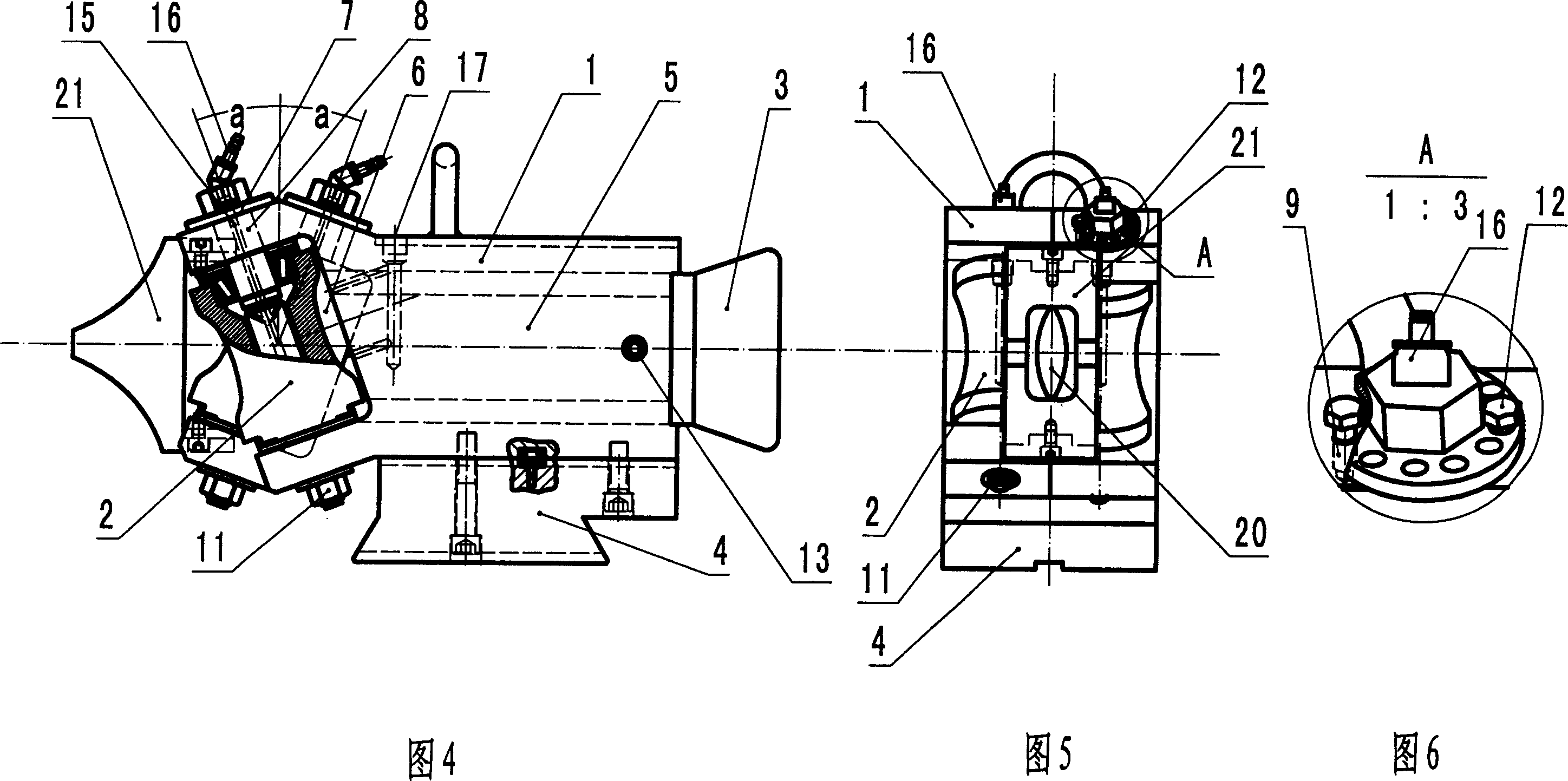

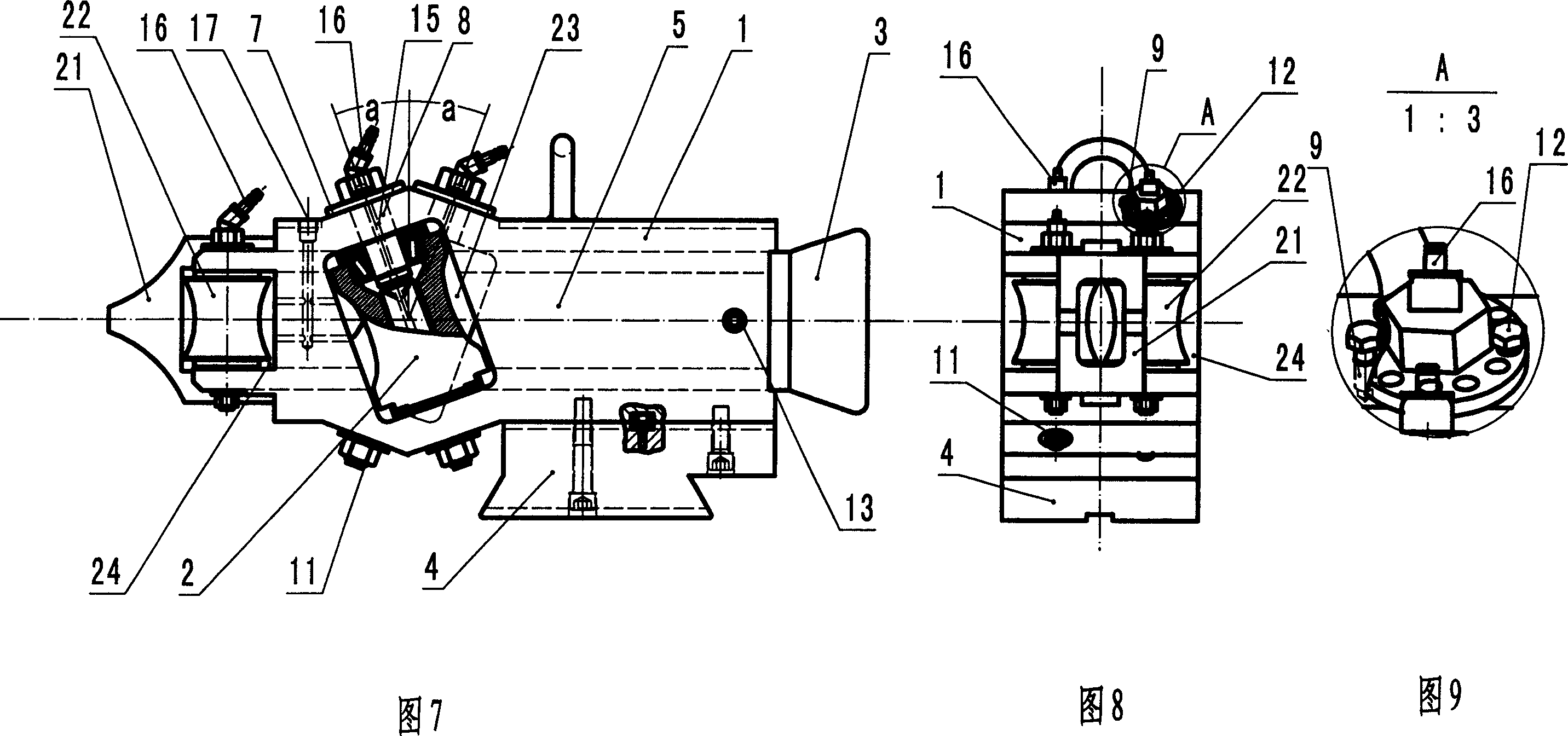

[0022] Shown in Fig. 1, Fig. 2 and Fig. 3, the rolling guide at the entrance of the hot-rolled elliptical rolling piece is composed of a box body 1, an inclined guide roller 2 arranged on the box body 1, a guide plate 3 and a dovetail seat 4. A guide plate (3) is arranged inside the box body 1, and the arc-shaped groove in the middle of the left and right guide plates 3 constitutes the rolled piece passage 5. The front part of the two side walls of the box body 1 is provided with a gap 6 for fixing the guide roller 2 and an inclined platform 7. The inclined platform 7 is provided with Shaft hole 8, the upper inclined platform is also provided with a positioning hole 9, the eccentric guide roller shaft 10 passes through the axis hole 8 on the inclined platform 7, the lower is fixed on the inclined platform 7 by the fastening nut 11, and the upper is fixed on the inclined platform 7 by the positioning bolt 12. The guide roller 2 with arc-shaped pass is obliquely installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com