Converter oxygen gun/charging/temperature institution comprehensive simplified model system and operation method

A converter oxygen lance and temperature system technology, applied in the direction of manufacturing converters, improving process efficiency, etc., can solve the problems of high accident risk, many abnormal furnace times, furnace condition loss, etc., and achieve a high degree of intelligent comprehensiveness and standardized operation. behavior, the effect of reducing quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

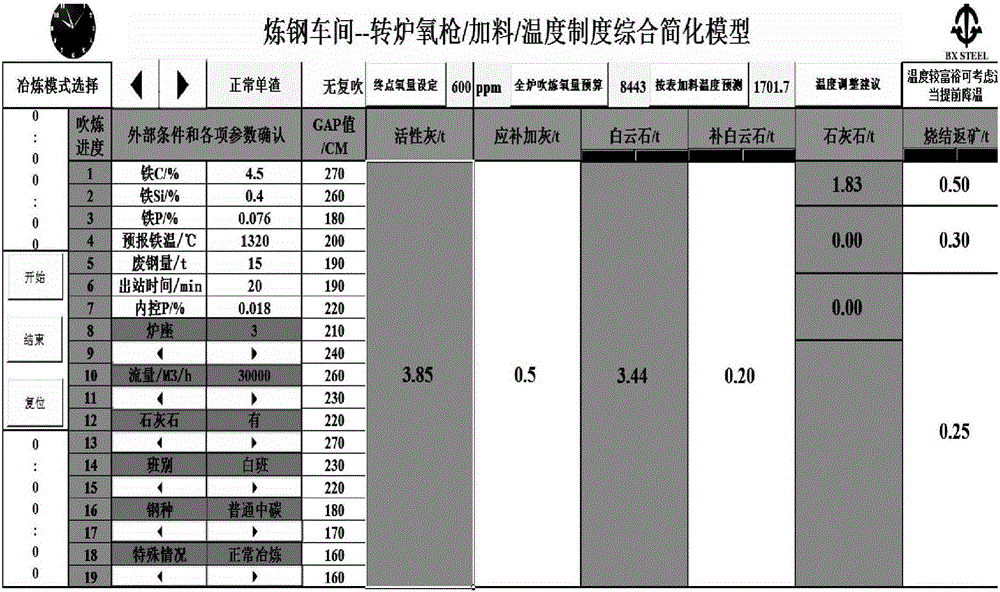

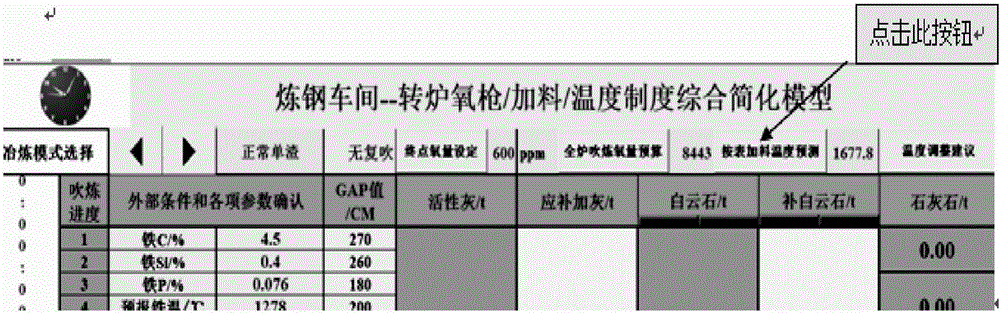

[0044] A comprehensive simplified model system of converter oxygen lance / feeding / temperature system of the present invention comprises the following steps:

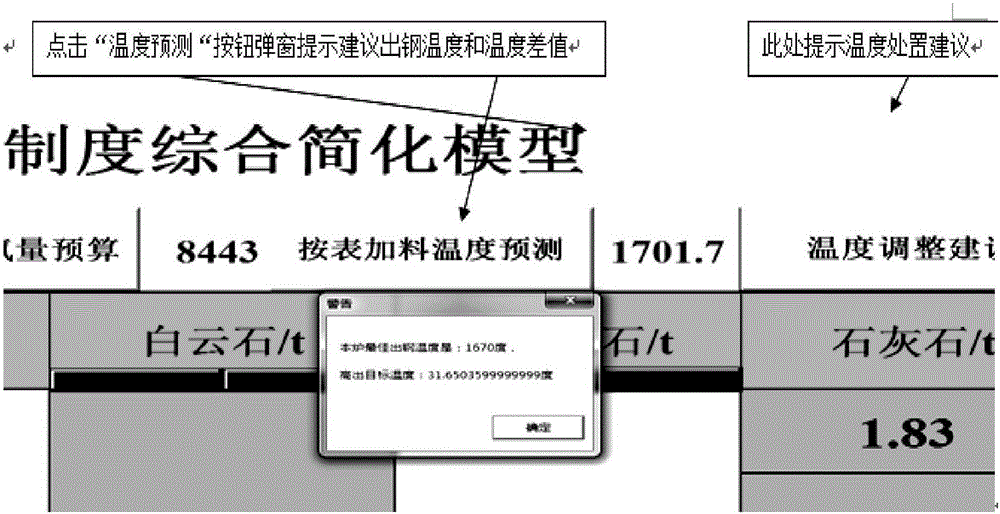

[0045] According to the chemical elements of molten iron conditions, temperature and amount of molten iron, the amount of scrap steel and the influence of various external conditions on temperature, the amount of various materials added is calculated according to the target oxygen and tapping temperature prediction at the end of the steel grade;

[0046] When the predicted temperature is seriously insufficient to affect the safety of tapping temperature, according to the gap between the predicted end point temperature and the theoretical tapping temperature, reduce the blowing flow rate and reduce scrap steel to make up for it;

[0047] The position of the oxygen lance is calculated separately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com