Dynamic subsection control method of tinned product annealing temperature

A technology of annealing temperature and subsection control, applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of long heating time, inability to apply feedforward control of the same coil of strip steel, and hot bending furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

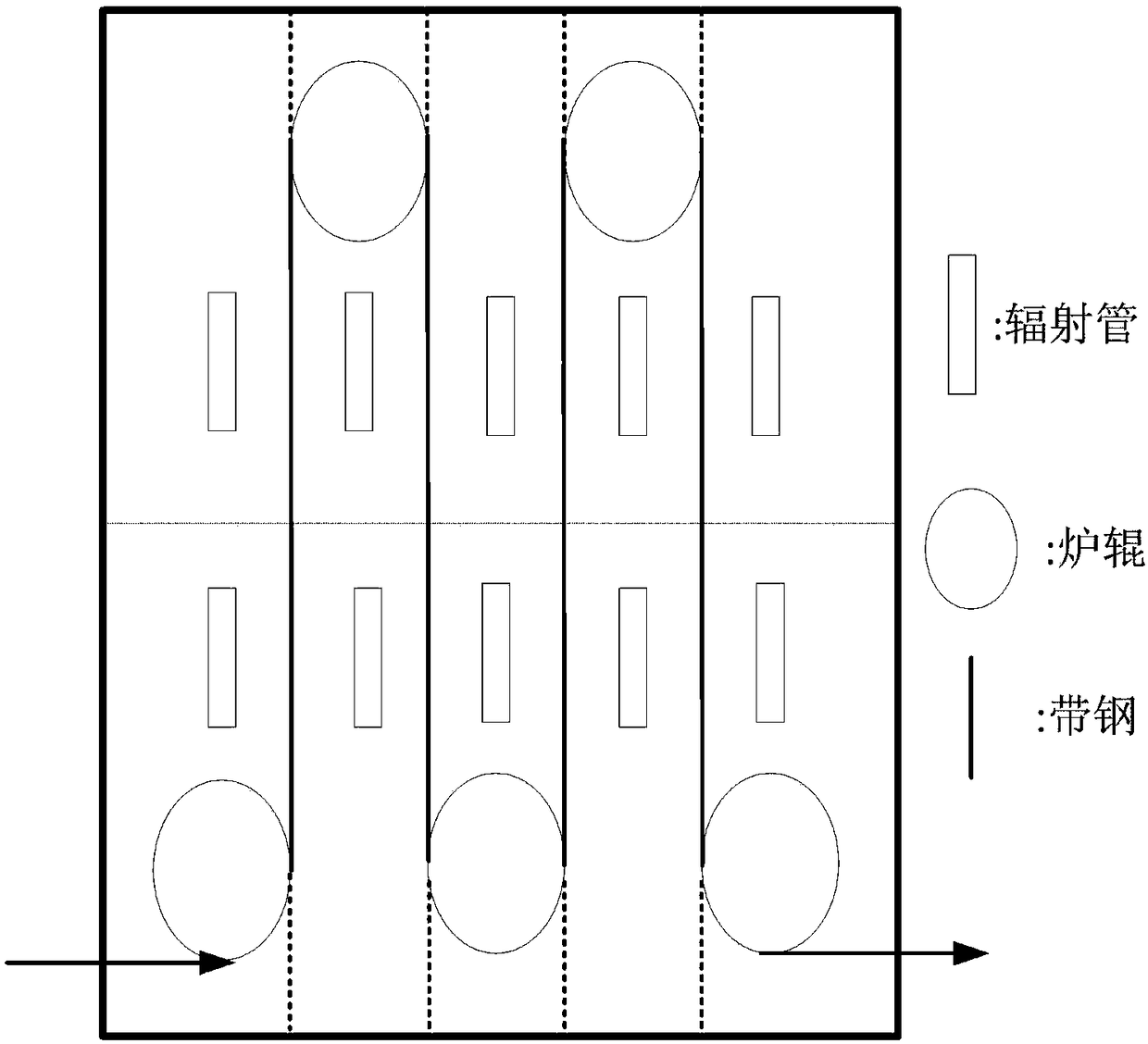

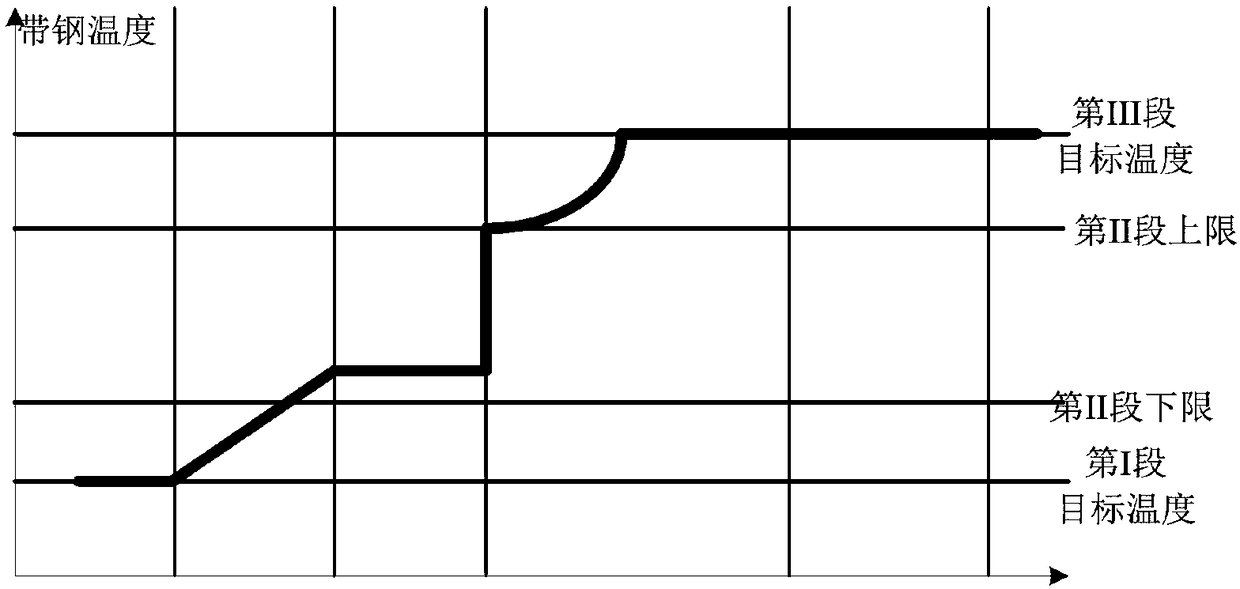

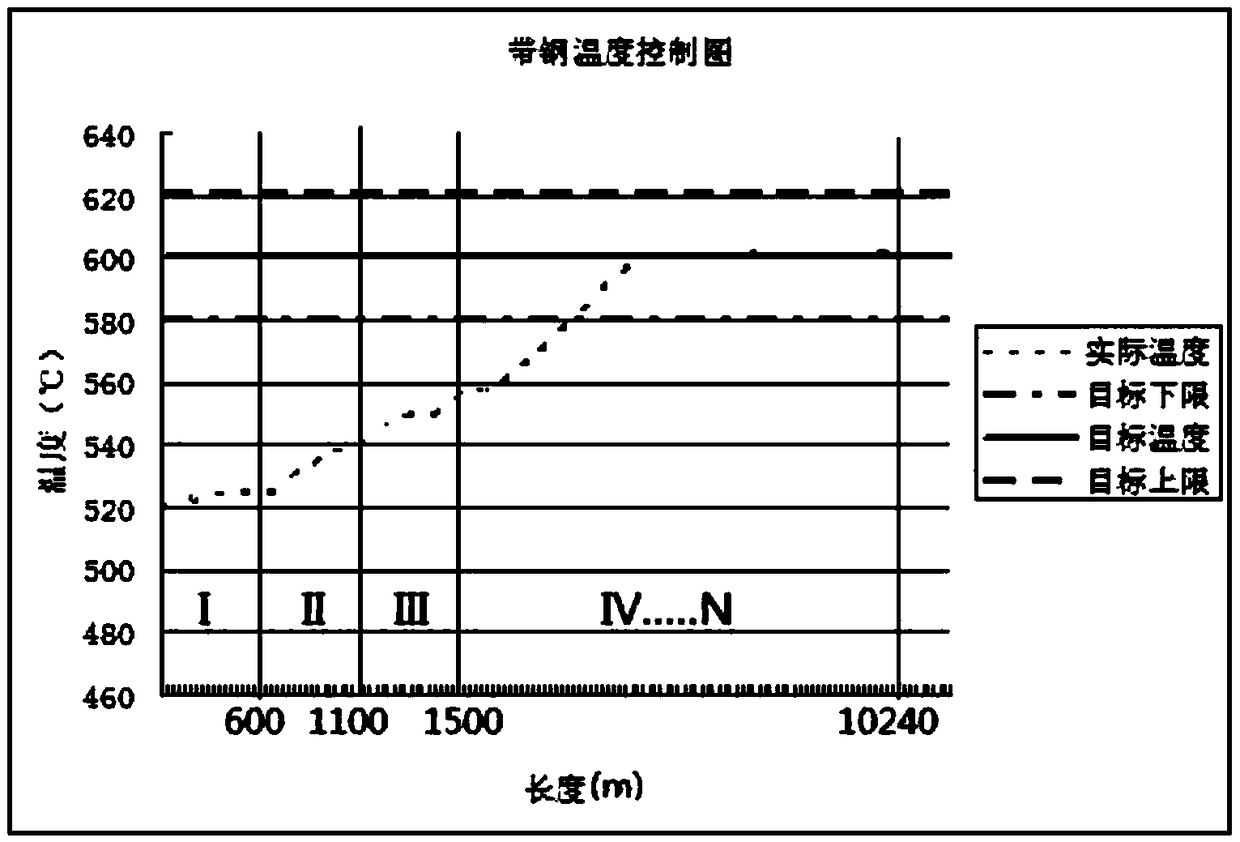

[0091] Embodiment 1: see figure 1 , figure 2 , a dynamic segmental control method for the annealing temperature of tin-plated products, see Figure 5 , Figure 5 For marking the dynamic segmentation of the strip. Generally, the length of Section I is the length of unstable rolling of strip steel. The setting of this length is generally obtained through a large number of field test data, and then the data is analyzed and screened; according to the test analysis of field collected data, the general strip The steel first undergoes fluctuating rolling of about 300 meters at the head, and then basically enters a relatively stable rolling process, and the reliability of various index values obtained after 600 meters is relatively high. Before heating the strip steel at high temperature, the temperature and "genetic factor" of the strip steel section I in the furnace are calculated according to the strip steel temperature in the preheating section and the temperature in the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com