Automatic tire marking device

An automatic scribing and tire technology, applied to printing, typewriters, etc., can solve the problems of short service life, low production efficiency, waste, etc., and achieve the effect of reducing quality accidents, reducing labor intensity, and reducing cost expenditures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

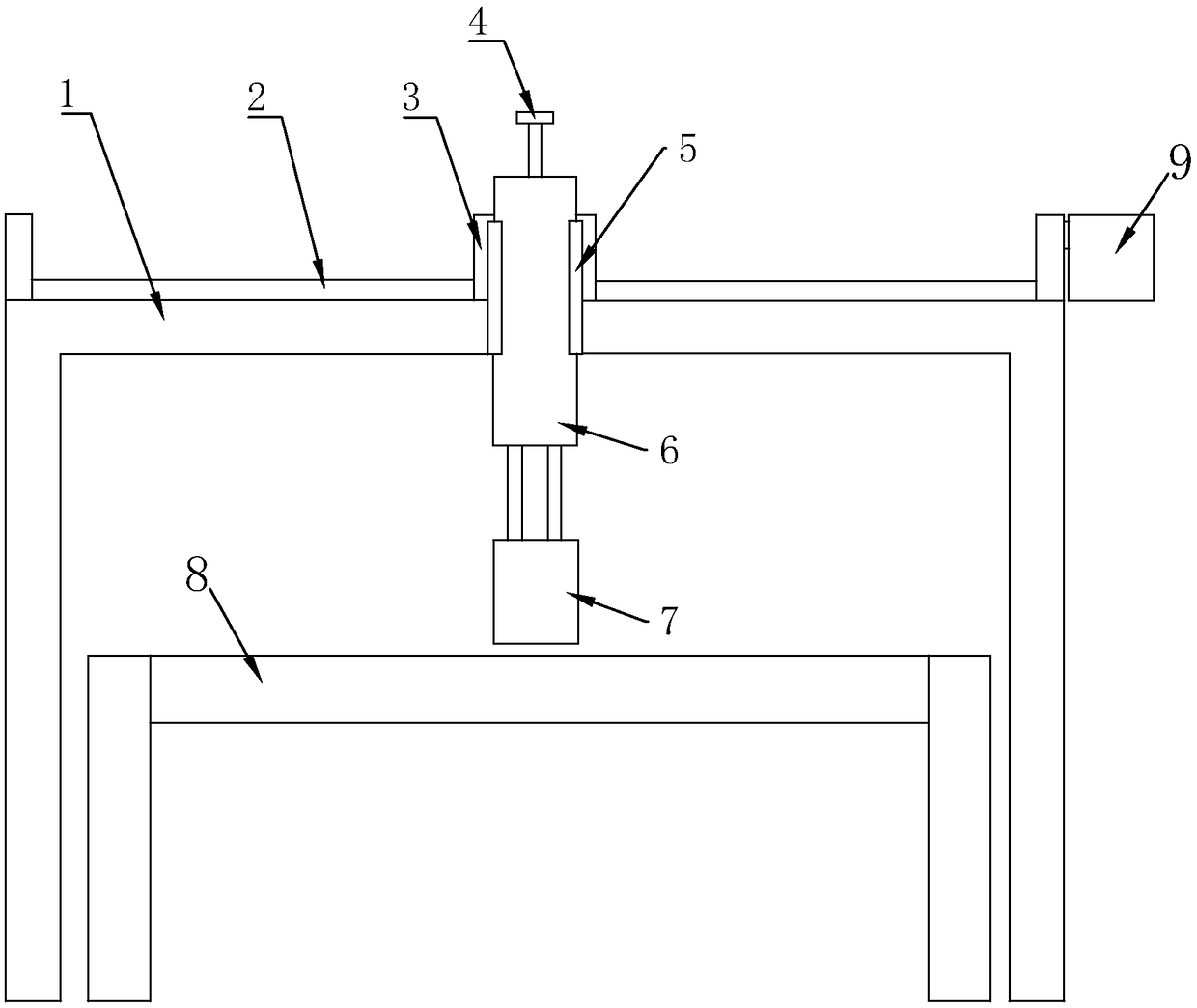

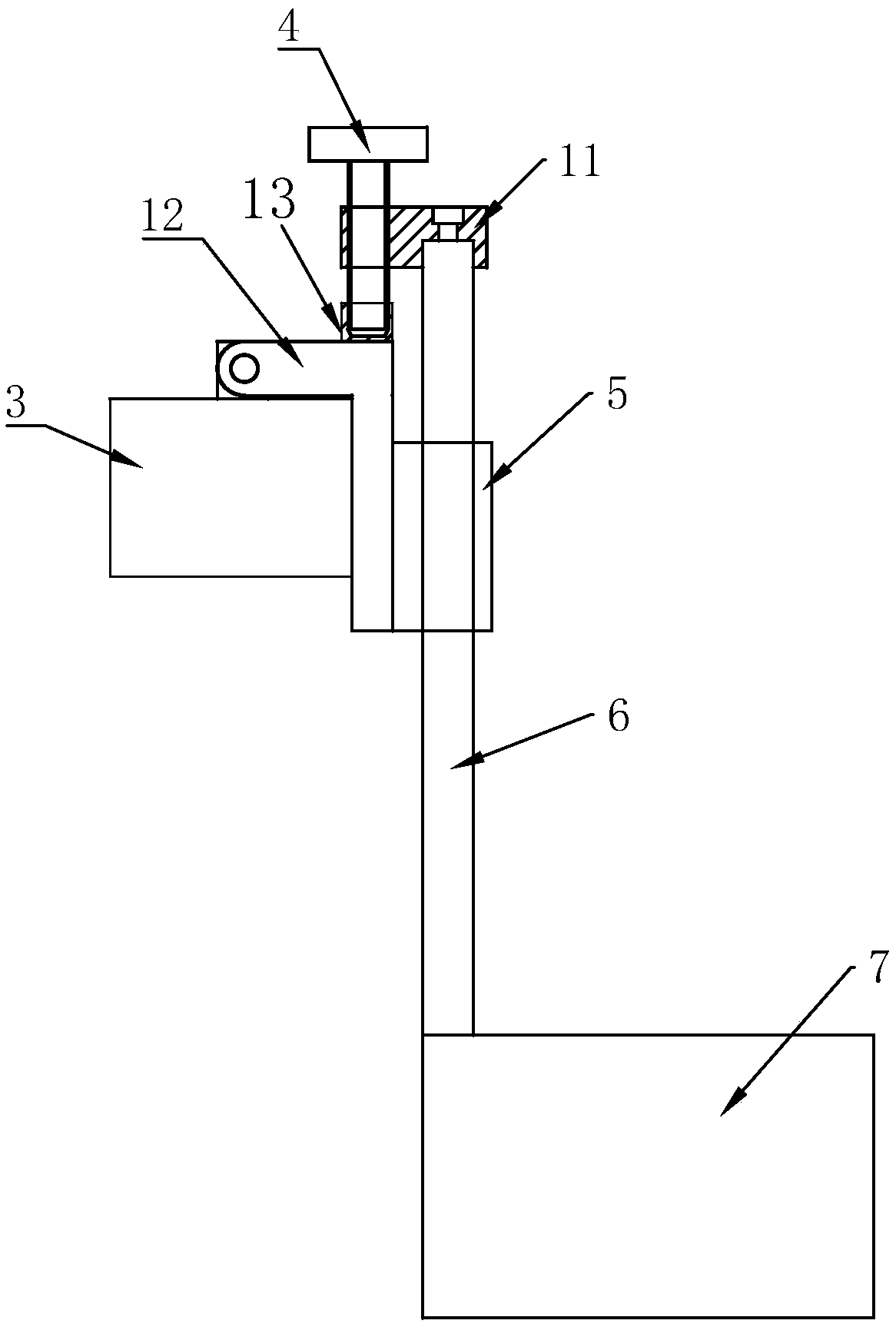

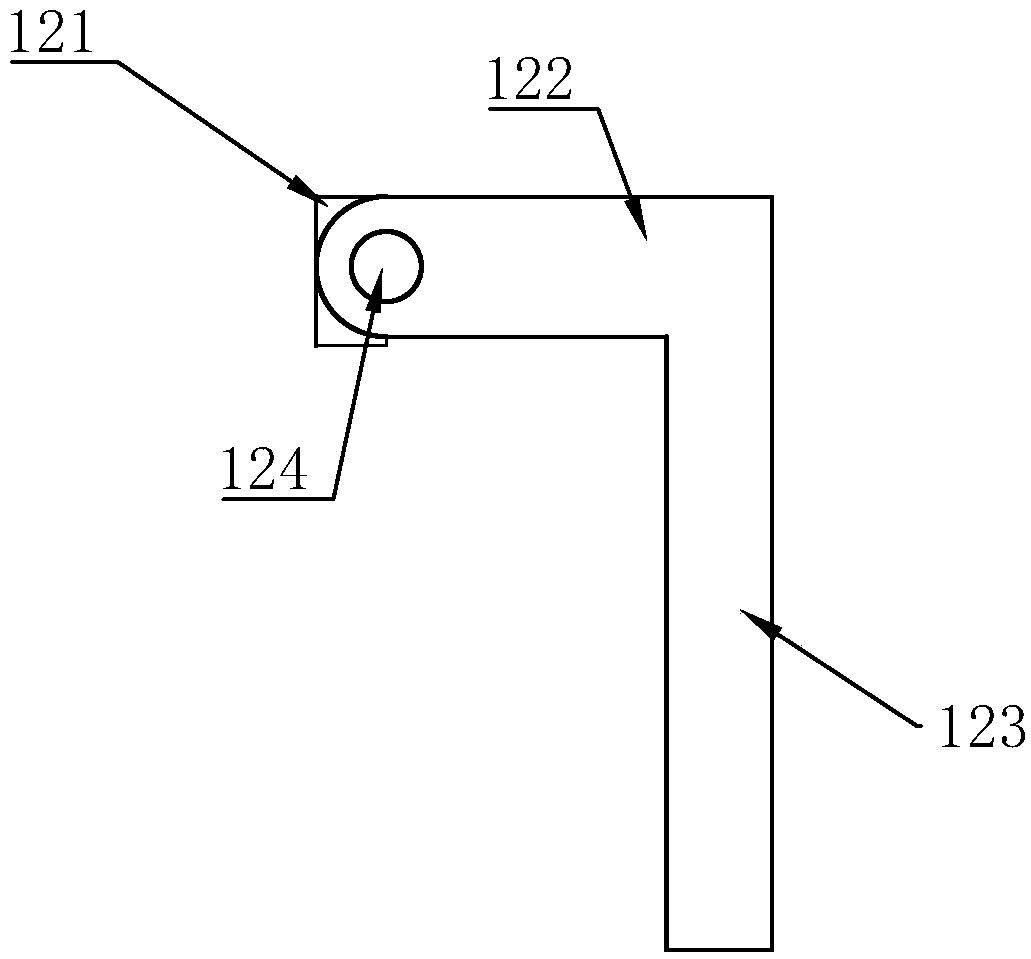

[0028] Such as Figure 1-Figure 4 As shown, an automatic tire scribing device of the present invention includes a transmission platform and multiple sets of scribing mechanisms equidistantly arranged on the transmission platform. There is a toothed belt assembly, the slider is connected with the stepper motor through the toothed belt assembly, one side of the anti-collision fixing assembly is connected to the slider for longitudinal rotation, and the other side of the anti-collision fixing assembly is provided with a vertical sliding relative to it. The large-character inkjet printer includes a large-character nozzle and an ink supply device. The large-character nozzle is connected to the ink supply device. The large-character nozzle is located above the transfer table and fixed to the output end of the cylinder.

[0029] Among them, each group of scribing mechanism only sprays the corresponding scribing color for the scribing position corresponding to one process. By setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com