Hot-rolled elliptical rolled piece inlet rolling guide

A technology of ellipse and rolled pieces, applied in the direction of guiding/positioning/alignment devices, etc., can solve problems affecting the clamping and righting of rolled pieces, out-of-round section of rolled pieces, frequent replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

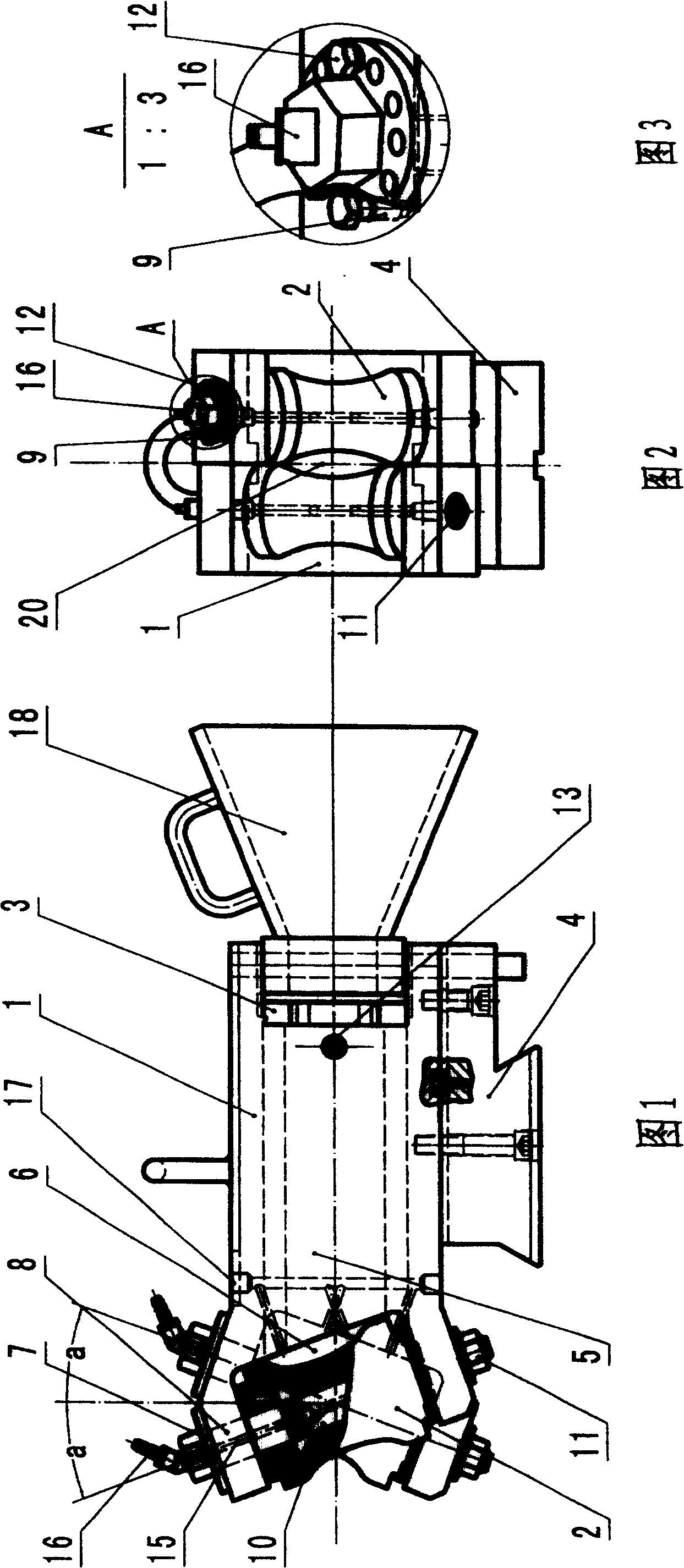

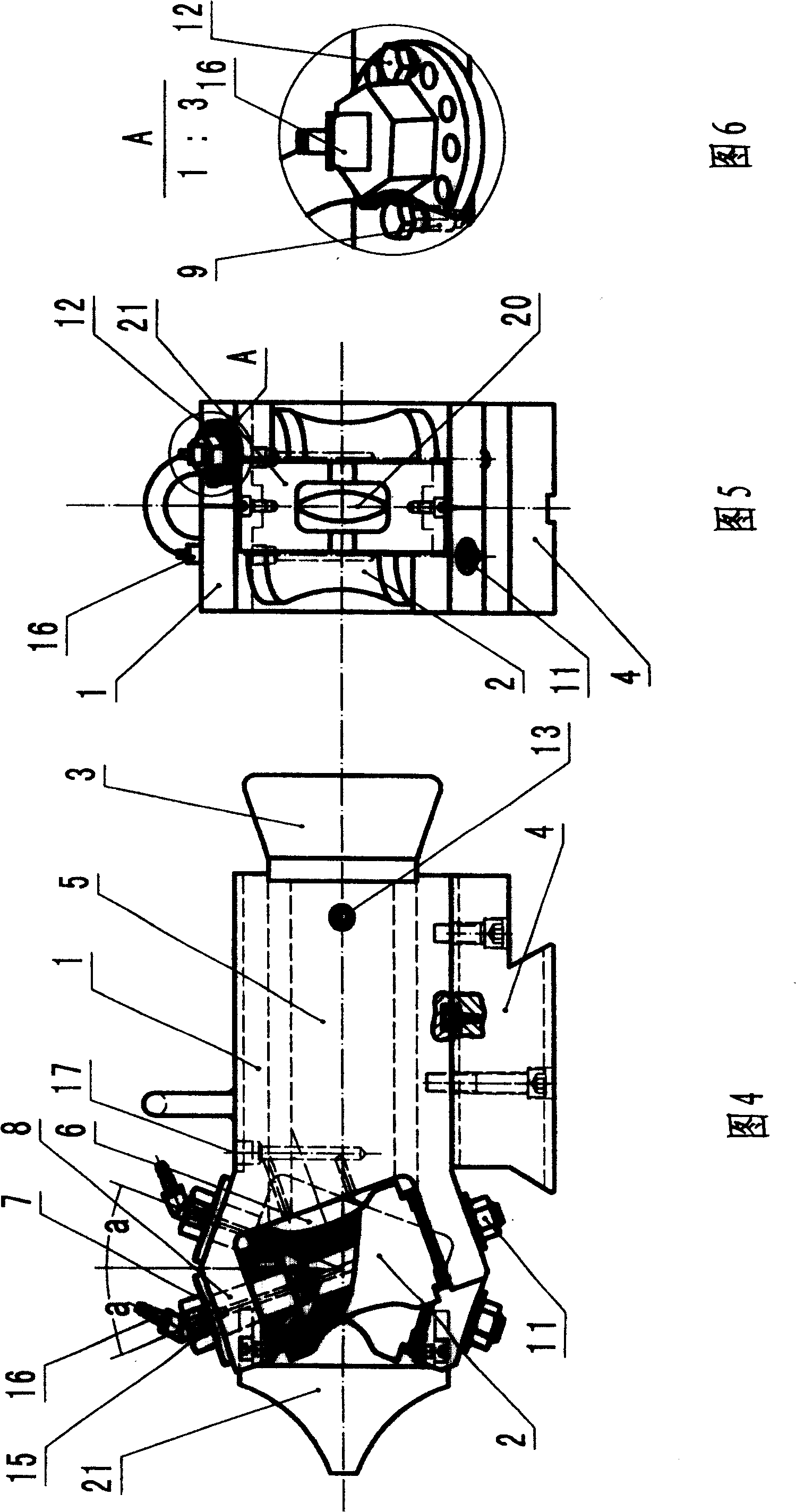

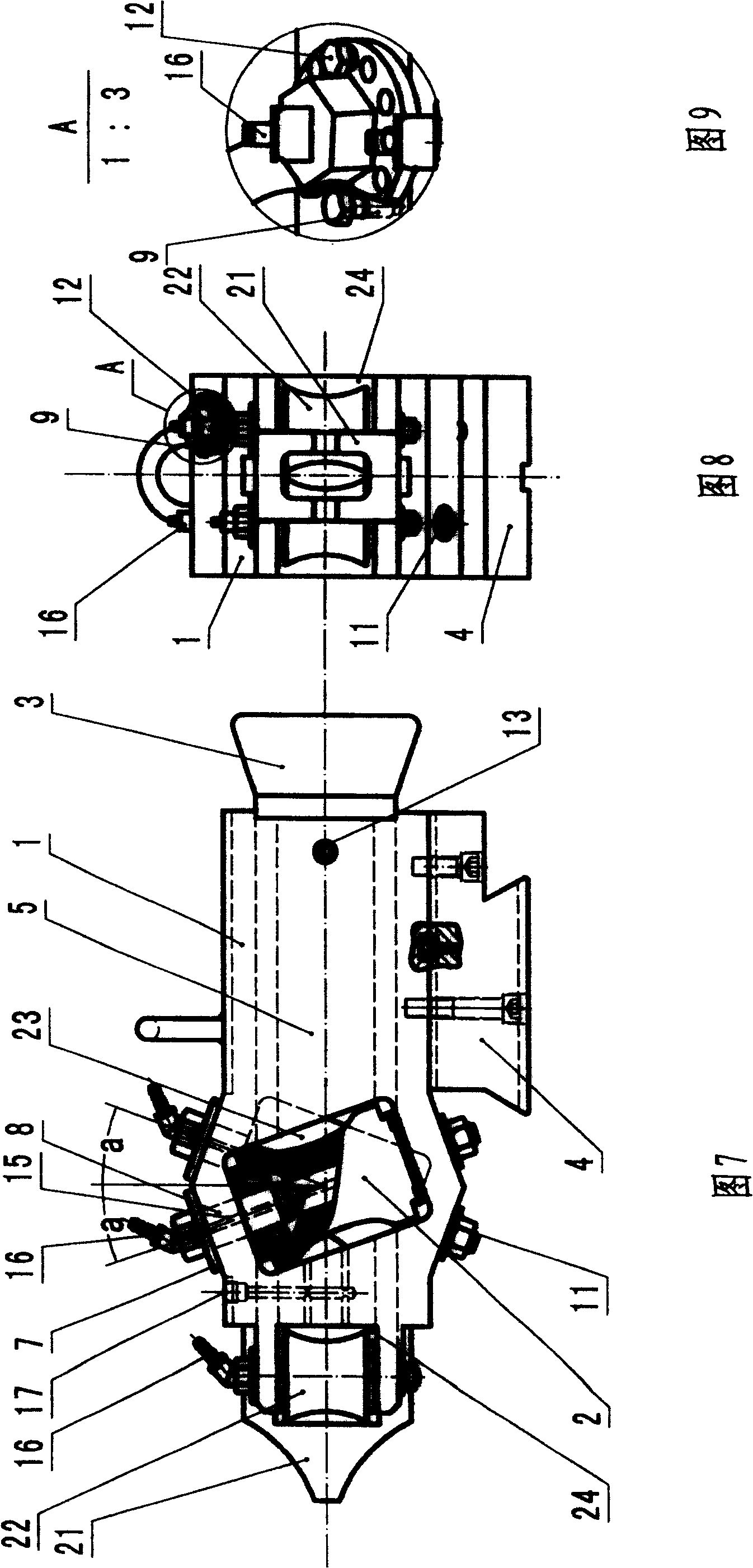

[0022] The inlet rolling guide for the hot-rolled elliptical rolling piece shown in Figure 1, Figure 2, and Figure 3 is composed of a box body 1, an inclined guide roller 2, a guide plate 3 and a dovetail seat 4 arranged on the box body 1. The box body 1 is provided with guide plates (3), the middle arc grooves of the left and right guide plates 3 constitute the rolling piece channel 5. The front parts of the two side walls of the box body 1 are provided with a gap 6 and an inclined platform 7 for the fixed guide roller 2, and the inclined platform 7 is provided with Axle hole 8, the inclined platform is also provided with a positioning hole 9, the guide roller shaft 10 passes through the axis hole 8 on the inclined platform 7, the bottom is fixed on the inclined platform 7 by a fastening nut 11, and the upper is fixed on the inclined platform 7 by a positioning bolt 12 The guide roller 2 of the arc-shaped hole is installed obliquely in the gap 6 and extends into the channel 5 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com