Crosshead pin lifting device

A crosshead pin and hoisting device technology, which is applied in the direction of transportation, packaging, and load hanging components, can solve the problems of crosshead pin repair, unstable installation, and impact on the construction period, so as to reduce quality accidents, improve production efficiency, and install Easy and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

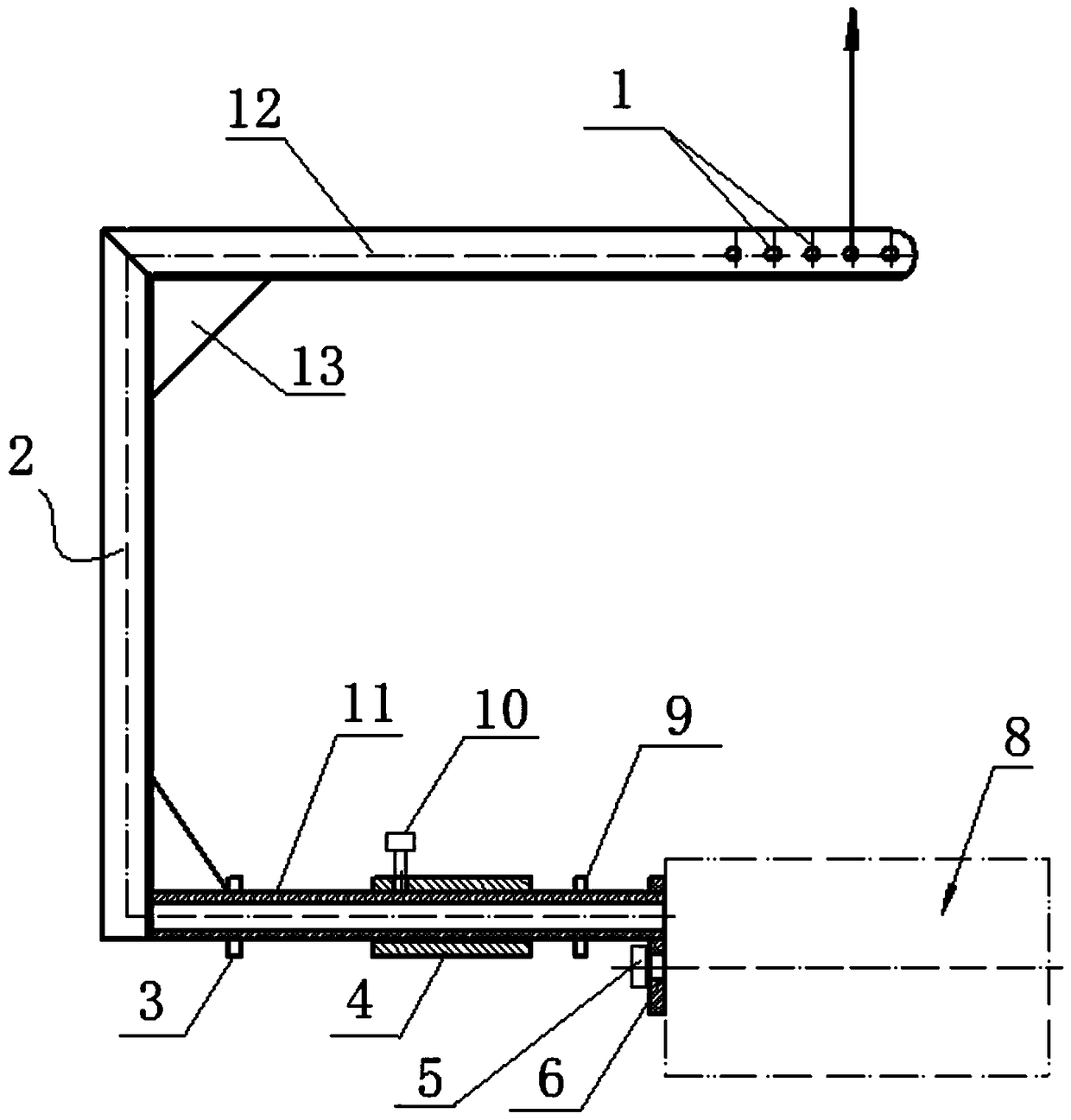

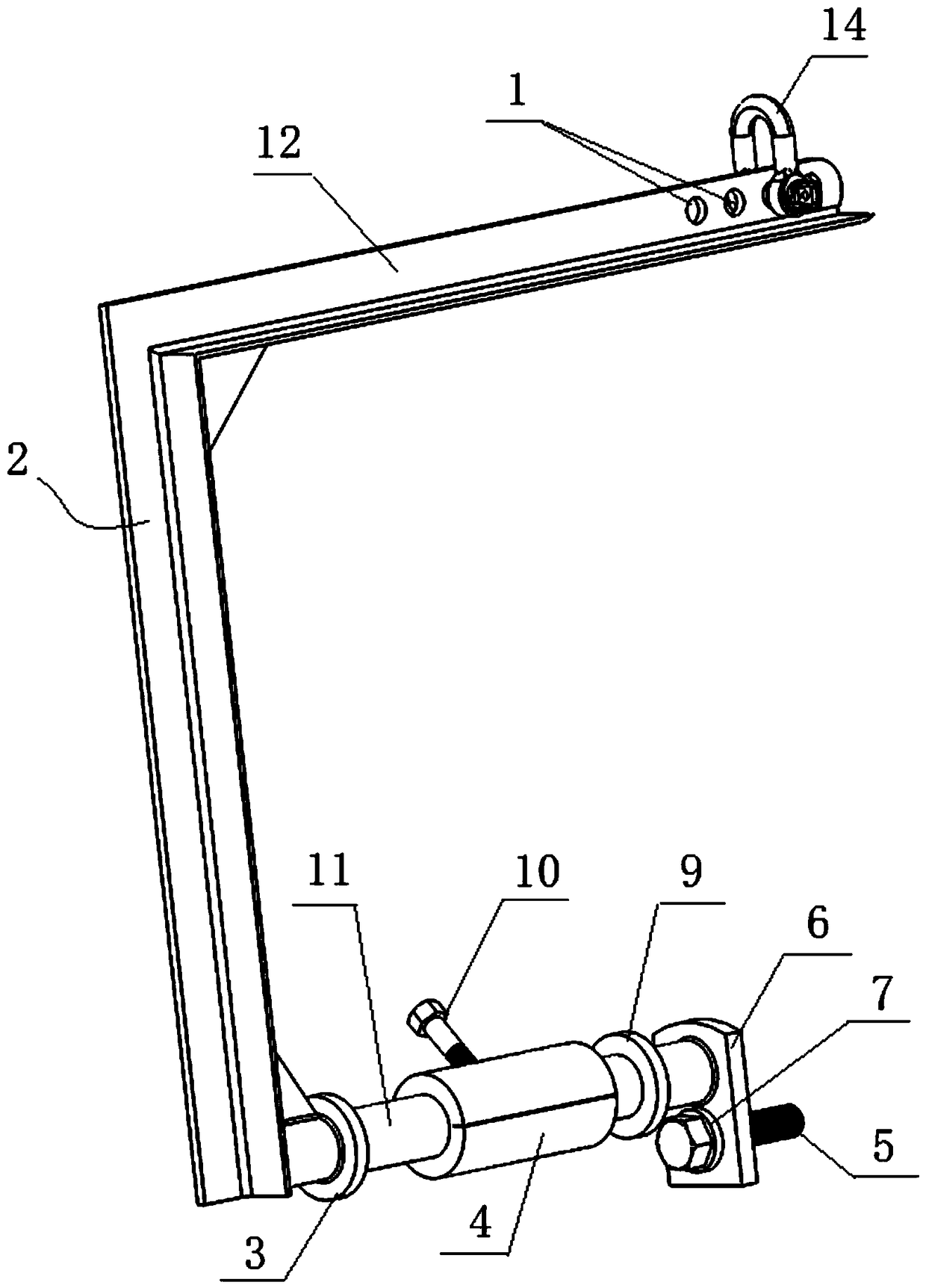

[0022] like Figure 1~2 As shown, the spreader body 2 of the present invention is concave, the sling of the hoisting device is connected to the end of the first side bar 12 of the spreader body 2, and the end of the second side bar 11 of the spreader body 2 is connected to the The crosshead pin 8 is connected, the second side bar 11 is sleeved with a movable bumper 4, and on the second side bar 11, a first The stop ring 9 and the second stop ring 3, the crosshead pin 8 is moved by hitting any stop ring through the collision block 4, and a triangular reinforcement plate 13 is arranged between the adjacent rods of the spreader body 2.

[0023] like Figure 1~2 As shown, a shackle 14 is provided at the end of the first side bar 12 of the spreader body 2, and a plurality of shackle holes 1 are equidistantly arranged at the end of the first side bar 12. The buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com