Ultrathin electronic glass forming device and forming method

A kind of glass forming equipment and electronic technology, which is applied in the direction of glass production, etc., can solve the problems of ultra-thin electronic glass product performance, high energy consumption of heating metal tin, high processing cost, etc., to meet the requirements of subsequent processing and use, low cost, The effect of low modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

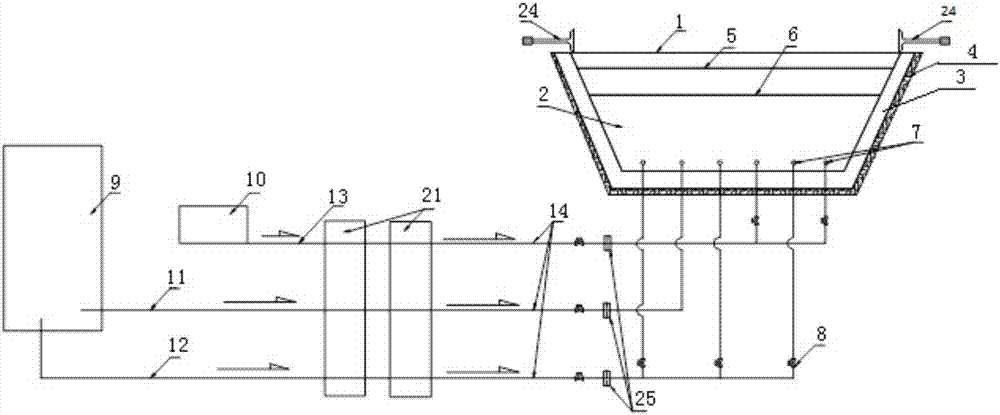

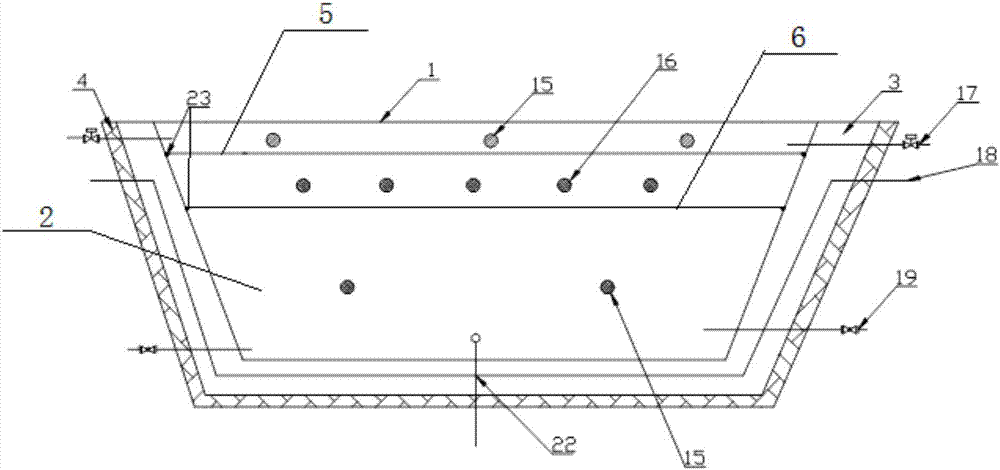

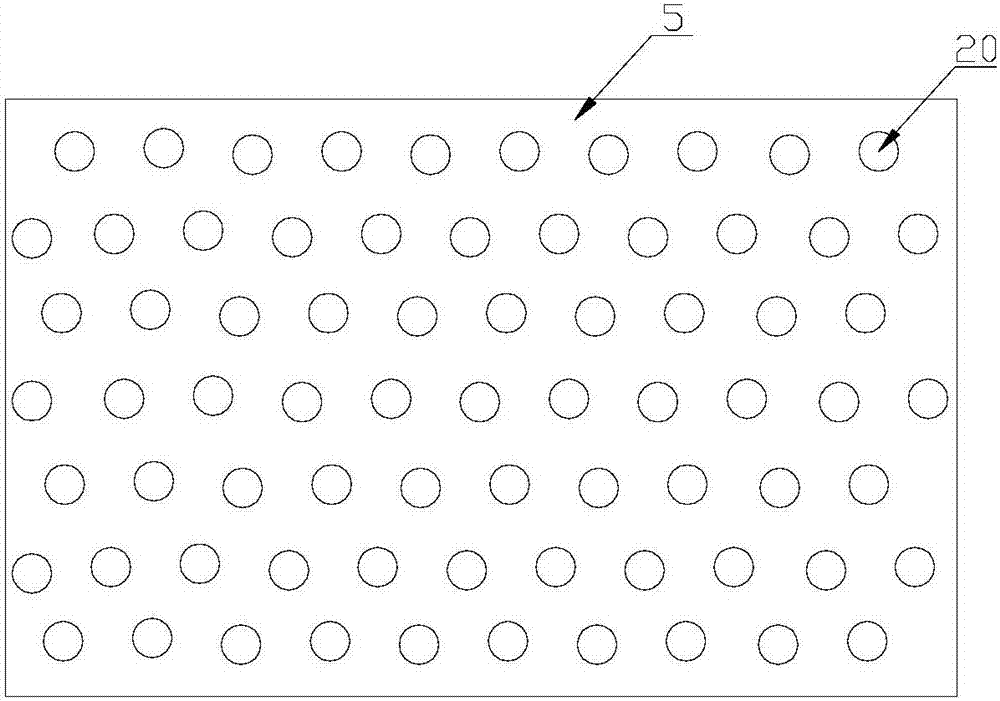

[0028] The forming equipment for ultra-thin electronic glass of the present invention includes a forming tank, a forming medium supply system, a detection control device, and a heating device.

[0029]Wherein, the forming tank is a device used to form the molten glass. The forming medium supply system is used to transport the forming medium—high-temperature nitrogen, argon and superheated saturated water vapor into the forming tank respectively through pipelines, and then mix them for glass forming. The detection and control device is used to detect and adjust the parameters in each pipeline and forming tank, and ensure the stability of the parameters. The heating device is set up to ensure the requirements of the molding temperature. It mainly uses silicon carbide rods to heat the casing of the molding tank, and the casing then conducts heat to the molding medium in the molding tank to ensure that the temperature of the molding tank meets the molding requirements.

[0030] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com