Rapid installation device and method for hydraulic breaking hammer drill rod base assembly drill rod bushing

A technology of hydraulic breaker and installation device, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as shortening the service life of products, scratching of bushings and drill rod seats, and wear of drill rods and bushings, etc. Achieve the effect of improving assembly efficiency, reducing quality accidents and ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

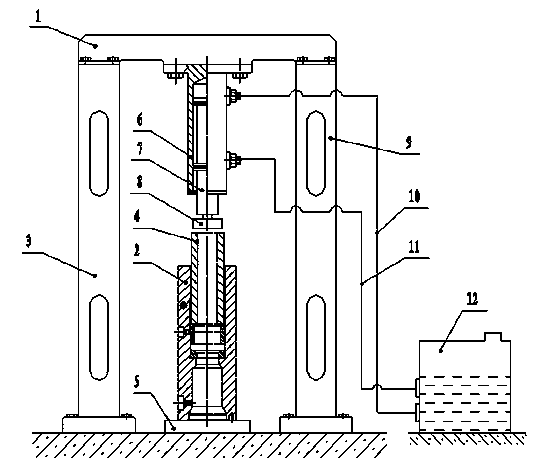

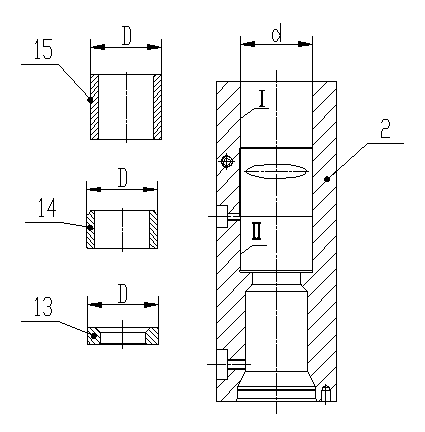

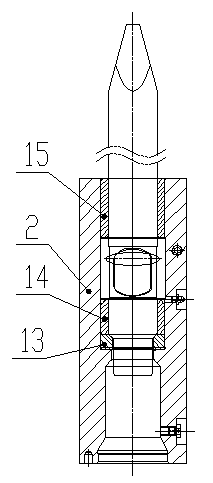

[0017] Such as figure 1 As shown, the rapid installation device for the drill rod bushing of the hydraulic breaker drill rod seat assembly of the present invention includes a beam 1, a left column 3, a pressure sleeve 4, a cylinder seat 6 of a high-pressure oil cylinder, a piston 7, a pressure rod 8, and a right column 9. The high-pressure oil inlet circuit 10, the low-pressure oil return circuit 11, the hydraulic station 12, the left and right columns 3, 9 and the hydraulic station 12 are fixed on the base surface, and the left and right columns 3, 9 and the beam 1 are connected by fasteners to form a The whole frame, the cylinder seat 6 of the high-pressure oil cylinder is fixedly arranged directly under the beam 1, and the head of the piston 7 inside is connected with the pressure rod 8, and the cylinder seat 6 of the high-pressure oil cylinder passes through the high-pressure oil inlet circuit 10 and the low-pressure oil return circuit 11 It communicates with the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com