Floorboard nailing device

A floor and transmission device technology, applied in the direction of nailing tools, staple nailing tools, manufacturing tools, etc., to achieve the effect of reducing labor cost input, reducing quality accidents, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

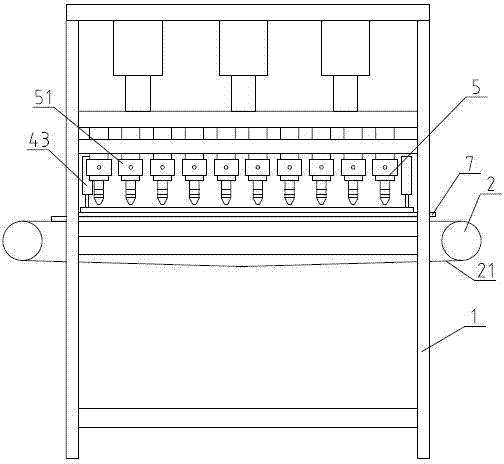

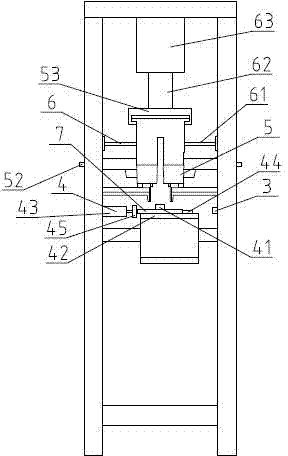

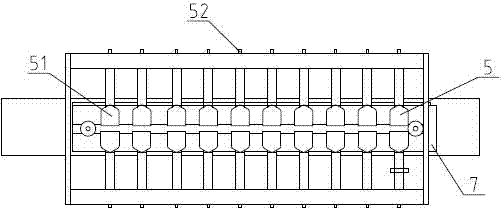

[0024] As shown in the figure: a floor nailing device, including a body 1, a transmission device 2, an induction device 3, a positioning device 4, a nailing device 5, a position adjustment device 6, the transmission device 2, the induction device 3 , the positioning device 4, the nailing device 5 and the position adjusting device 6 are all arranged on the fuselage 1, the transmission device 2 is used to transmit the floor 7, and the induction device 3 is used to control the The conveying device 2 , the positioning device 4 is used for positioning and clamping the floor 7 , and the position adjusting device 6 is used for adjusting the relative position of the nailing device 5 and the floor 7 .

[0025] The conveying device 2 includes a conveying belt 21 , the positioning device 4 includes a pressing plate 41 , a bottom plate 42 , a first cylinder 43 , a baffle 44 , and a fastening baffle 45 , and the bottom plate 42 is arranged below the conveying belt 21 , so The floor 7 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com