Battery aluminum foil non-landing clean producing and packaging line

A packaging line and aluminum foil technology, applied in the field of battery aluminum foil clean production packaging line, can solve the problems of increasing quality control costs, reducing product yield, affecting production efficiency, etc., to reduce the probability of contamination, increase production efficiency, The effect of avoiding quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in detail:

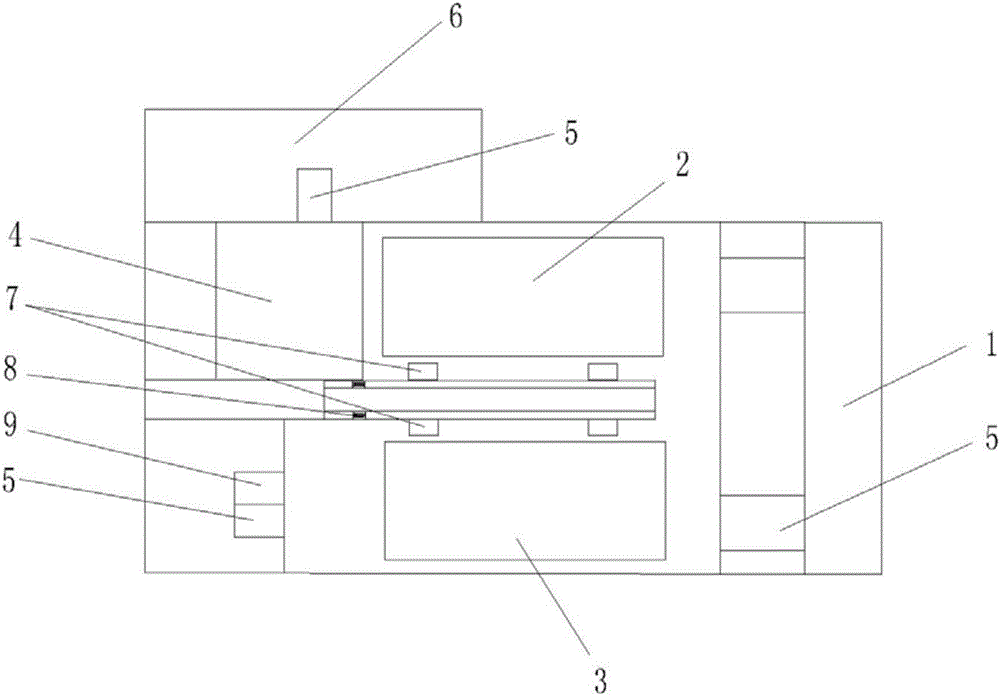

[0017] Such as figure 1 The battery aluminum foil non-floor clean production and packaging line shown includes blank warehouse 1, finished product warehouse 6, cutting area 2, production area 3 and packaging area 4, and cutting area 2 and production area 3 are set opposite to each other. A material transport trolley 8 and an unloading trolley 7 are set between the production area and the transport trolley and the unloading trolley are controlled by the master control room.

[0018] The transport trolley is set on the track, and the track extends to the packing area. Both the transport trolley and the unloading trolley include a traveling mechanism, which is arranged on the track, and the upper part of the traveling mechanism of the unloading trolley is provided with a rotating mechanism and a lifting mechanism in turn, and a telescopic mechanism capable of lateral telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com