Automatic nailing device

An automatic and conveying device technology, which is applied in the direction of nailing tools, staple nailing tools, manufacturing tools, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

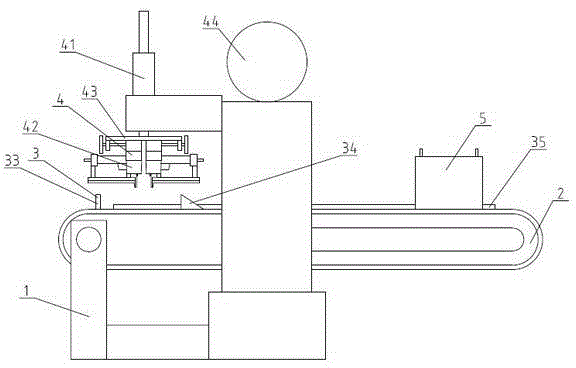

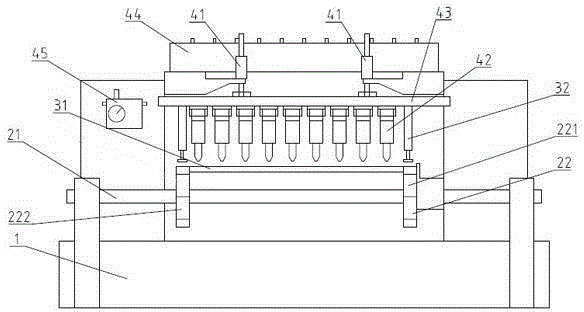

[0021] As shown in the figure: an automatic nailing device, including a fuselage 1, a transmission device 2, a positioning device 3 and a nailing device 4, the transmission device 2 includes a transmission shaft 21 and a transmission chain 22, and the transmission chain 22 is set On the transmission shaft 21, the transmission shaft 21 is arranged on the fuselage 1, the transmission shaft 21 is driven by a motor, and the positioning device 3 includes a support plate 31, a first cylinder 32, a fixed card 33, Movable card 34 and backing plate 35, described support plate 31 is perpendicular to the conveying direction of described transmission chain 22, and described support plate 31 is arranged on the described fuselage 1, and described first cylinder 32 is arranged on described support plate 31, the fixed card 33 is arranged on the body 1 on one side of the conveying device 2, and the movable card 34 is arranged on the other side of the conveying device 2 corresponding to the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com