Full-automatic red date pitter

A fully automatic, jujube technology, applied in fruit pitting devices, food science, applications, etc., can solve problems such as low production efficiency, imperfect semi-automatic machines, and lifting, and achieve simple and effective mechanisms, saving manpower and production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

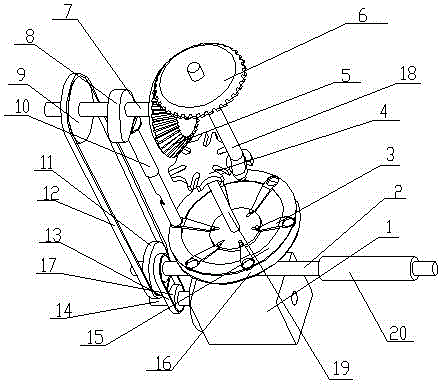

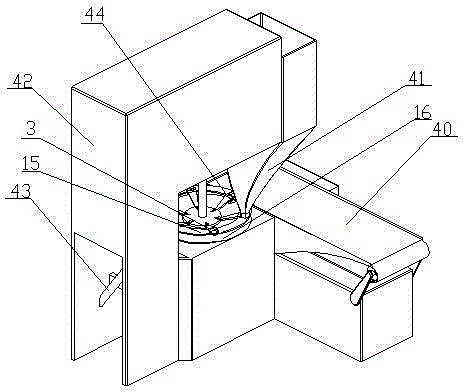

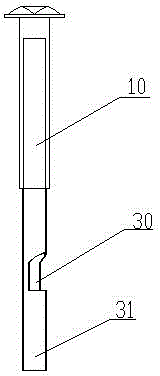

[0016] combine figure 1 , 2 , 3 to specifically illustrate the present invention, the lower end of the frame 42 inner cavity is provided with a motor 1, a pulley three 17 is installed on the drive shaft 14 of the motor 1, and a transmission shaft one 2 is arranged above the pulley three 17, and the Pulley three 17 drives power transmission shaft one 2 through belt two 11, and described power transmission shaft one 2 is provided with pulley two 13 and power transmission shaft five 20, and described pulley two 13 transmits power to pulley one 9 by belt one 12, and described Belt pulley one 9 drives transmission shaft two 7, and described transmission shaft two 7 is provided with belt pulley one 9, cam 8 and bevel gear one 5 successively from left to right, and described belt pulley one 9, cam 8 and bevel gear one 5 are coaxial , the underside of the cam 8 is provided with a nuclear tube 10, and the first bevel gear 5 drives the second bevel gear 6 by meshing with the second bev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com