Loquat kernel removal through cylinder and loquat kernel removal process thereof

A technology of the through-tube and loquat, which is applied in the loquat-removing-nucleating-through-tube and its loquat-removing process, which can solve the problems of large opening, large opening of the small head 11', and irregular opening, so as to ensure consistent shape, Improve the speed of denucleation and the effect of tidy opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

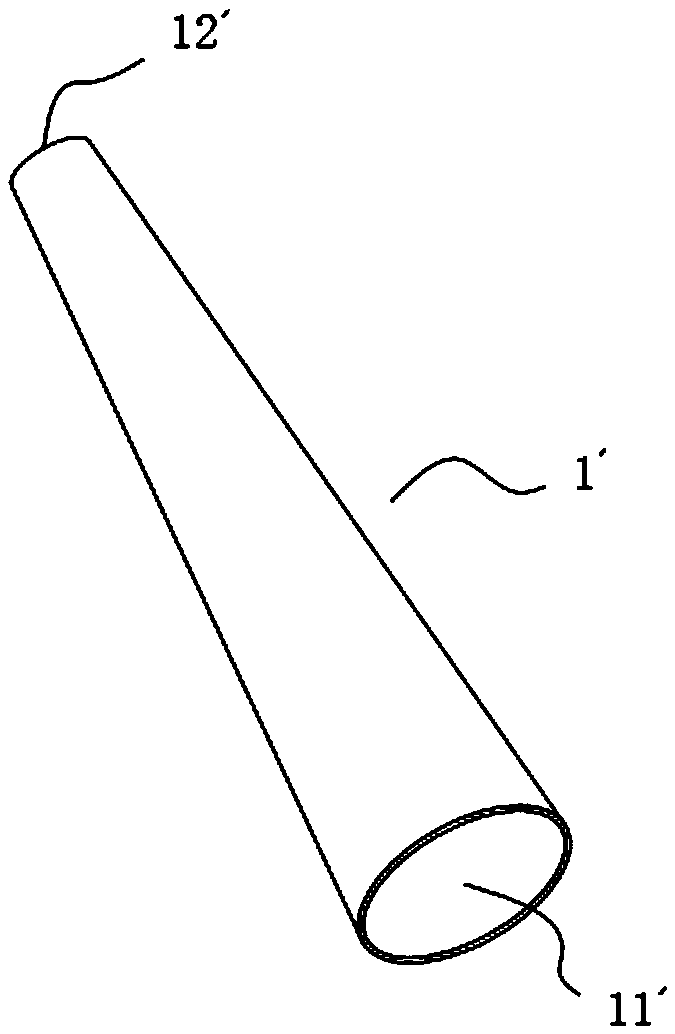

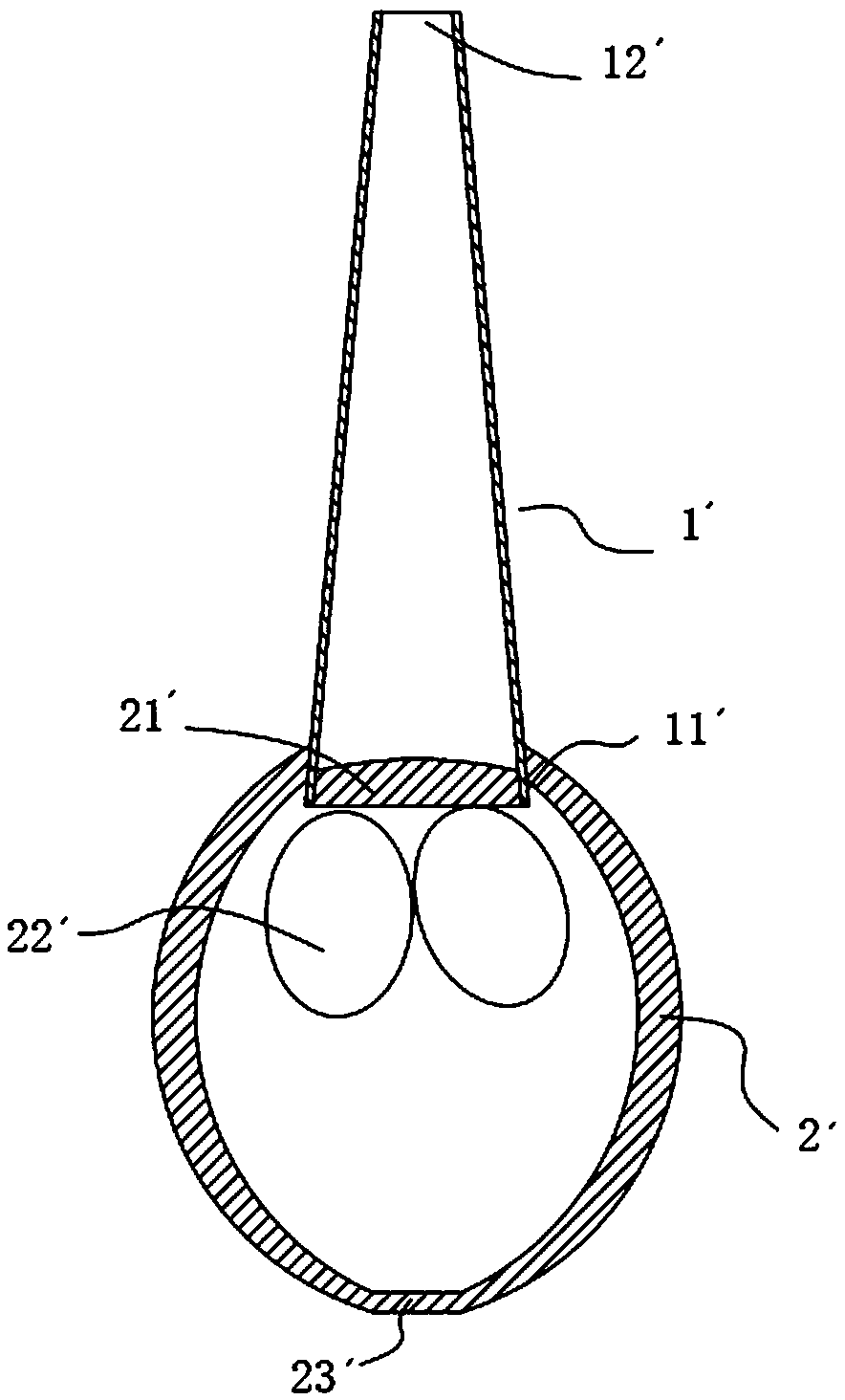

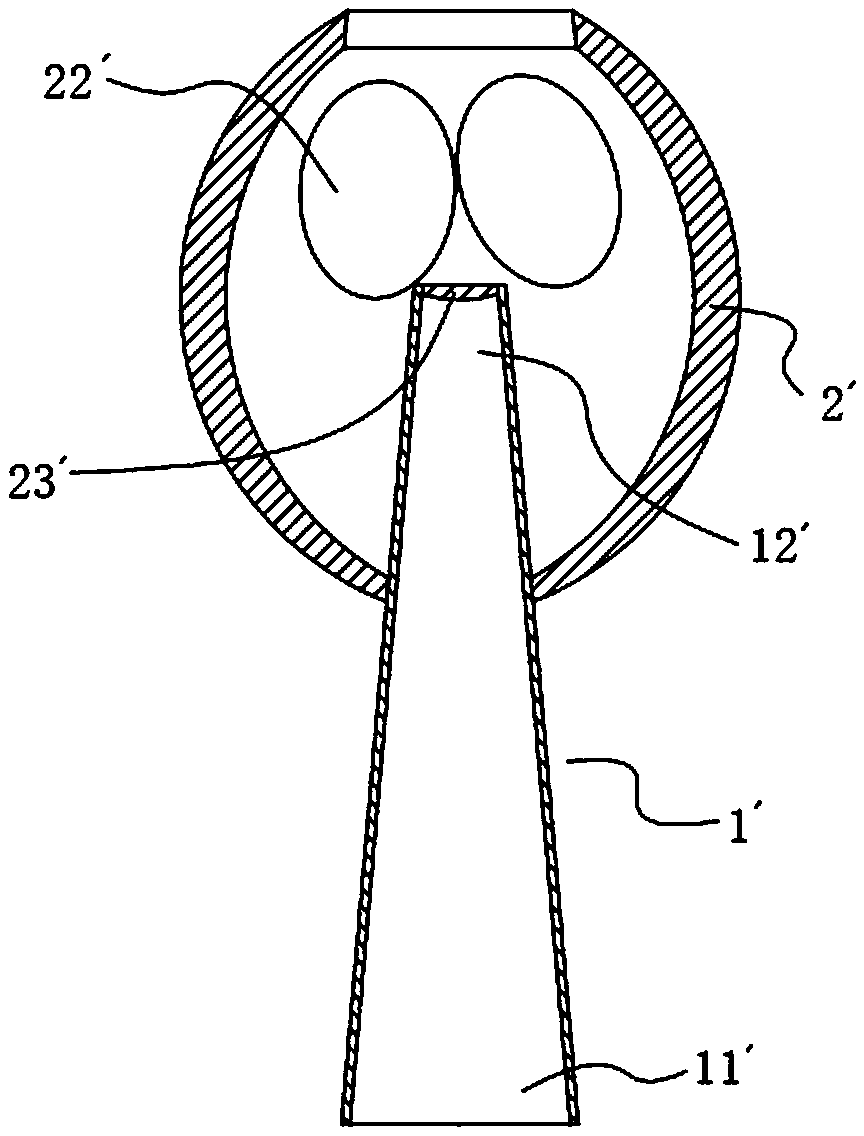

[0034] Such as Figure 4 Shown, a kind of loquat removes nuclear through tube, and whole tube 1 comprises the through tube big head 11 of large hole equal diameter and the through tube through bar 12 of small hole equal diameter, and the side wall of through tube big head 12 is provided with fruit obliquely behind. The pedicle outlet 13; the upper knife edge 111 is arranged on the top of the big head 11 of the through-tube; the lower knife-edge 121 is arranged on the top of the through-tube rod 12 .

[0035] For explaining in more detail the operation and use method of the tube of the present invention, a kind of loquat 2 denucleating process adopting the tube 1 is provided below, which comprises the following steps:

[0036] 1. Divide the loquat 2 raw materials into three grades: large, medium and small, and enter the workshop for production and processing respectively. The loquat 2 is blanched and peeled. No. through the tube.

[0037] 2. Hold the loquat 2 after removing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com