Raw material treatment device for jujube wine preparation

A technology for raw material processing and jujube fruit, which is applied in the field of raw material processing equipment for winter jujube, can solve the problems of reduced processing efficiency, poor practicability, high labor intensity of staff, etc., and achieves the effects of accelerating denucleation speed, convenient operation, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

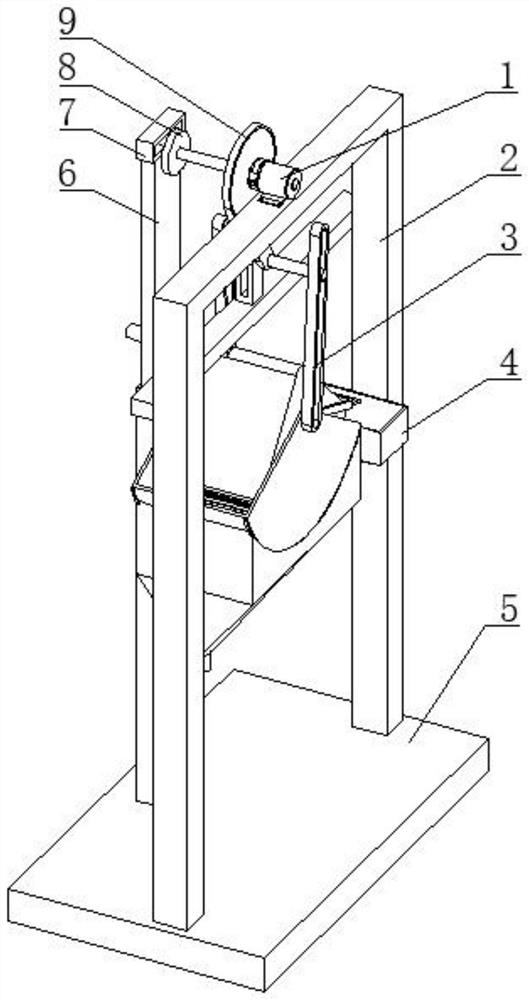

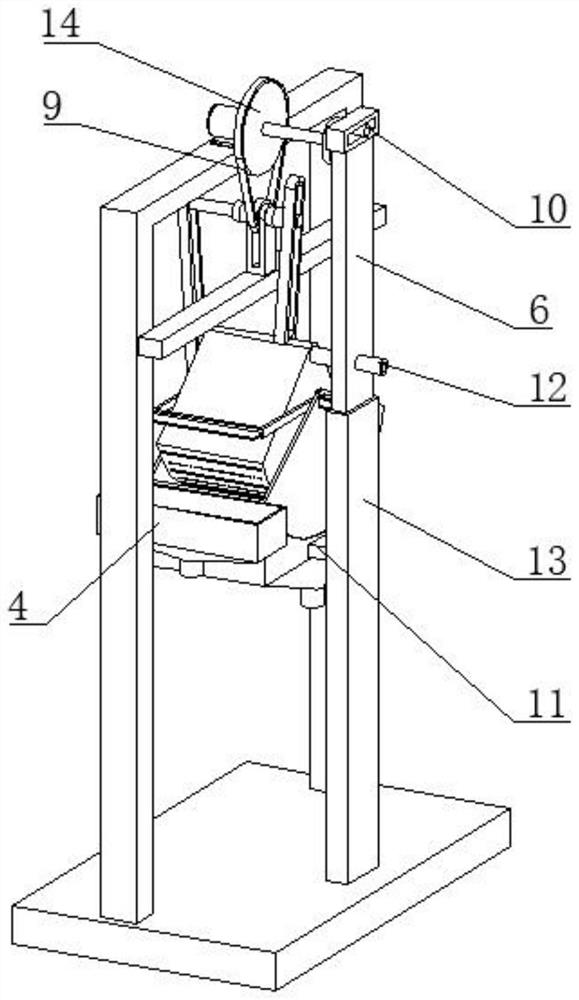

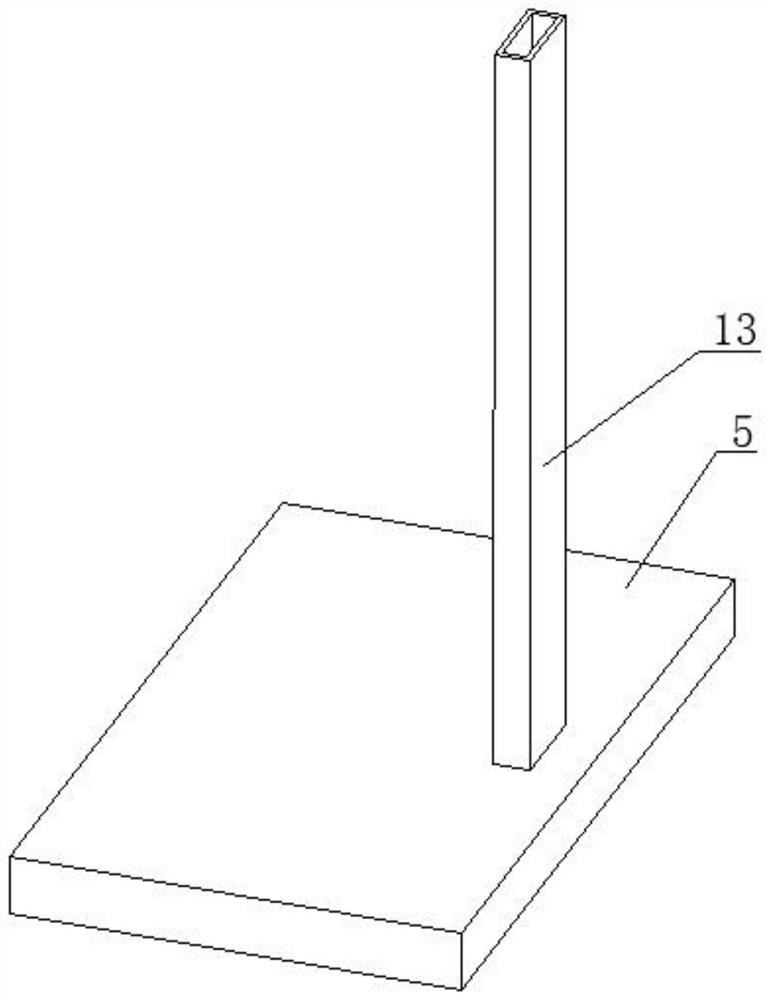

[0036] Such as Figure 1-Figure 13 As shown, the present invention includes a bottom plate 5,

[0037] The middle part of both ends of the upper side of the base plate 5 is respectively fixedly connected to the vertical plate lower end of the U-shaped support plate 2, and the upper middle part of the horizontal plate of the U-shaped support plate 2 is fixedly connected to the motor one 1, and the output shaft of the motor one 1 Fixedly connected to the center of pulley one 14, said pulley one 14 is connected with pulley two 18 by belt 9, and the center shafts at both ends of said pulley two 18 respectively pass through and are movably connected to the upper ends of both sides of U-shaped projection 26 In the middle part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com